Contents

Manufacturing Insight: Micro Machining Inc

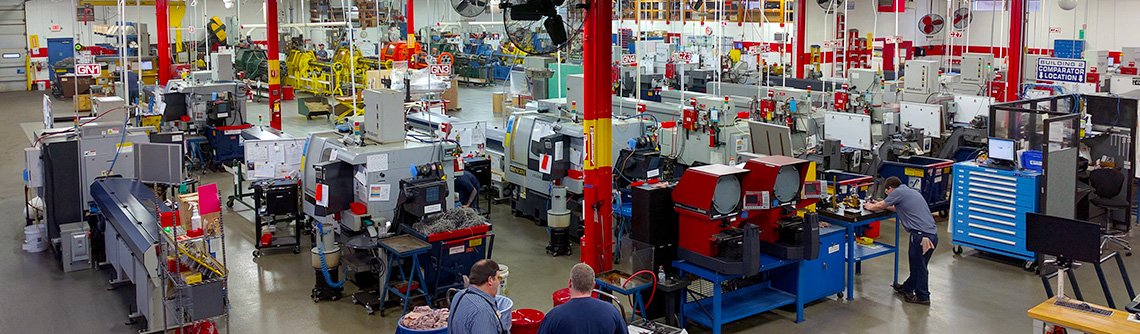

Precision Micro Machining Solutions for Demanding Applications

Honyo Prototype delivers advanced CNC machining services engineered specifically for the exacting requirements of Micro Machining Inc and similar high-precision industries. Our specialized capabilities bridge the gap between intricate design intent and flawless physical realization, focusing on components where tolerances measured in microns directly impact performance. We understand that micro-scale parts demand more than scaled-down processes; they require dedicated expertise, metrology-grade equipment, and an uncompromising commitment to dimensional stability.

Our manufacturing ecosystem centers on state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling and turning centers, all maintained within tightly controlled environmental conditions to ensure thermal stability. We routinely achieve tolerances down to ±0.0002 inches (±0.005 mm) across challenging materials including titanium alloys, medical-grade stainless steels, engineered plastics, and specialty ceramics. This precision is validated through integrated CMM, optical comparators, and surface profilometry, ensuring every component meets or exceeds Micro Machining Inc’s stringent specifications from prototype through low-volume production.

A critical differentiator for accelerating your development cycle is our Online Instant Quote platform. Unlike traditional RFQ processes that introduce delays, our system provides actionable pricing and lead time estimates within minutes for CNC machining projects. Simply upload your STEP or IGES file, specify material and quantity, and receive a detailed technical assessment alongside the quote—no manual intervention required. This transparency eliminates procurement bottlenecks, allowing Micro Machining Inc to iterate designs rapidly and move from concept to functional prototype with unprecedented speed.

| Feature | Industry Standard Process | Honyo Prototype Instant Quote |

|---|---|---|

| Quote Turnaround | 24-72 hours | Under 10 minutes |

| Technical Feasibility | Post-submission review | Automated DFM analysis |

| Revision Handling | New RFQ required | Real-time parameter update |

| Minimum Order Complexity | Often restricted | No complexity penalty |

Partner with Honyo Prototype to transform your most challenging micro-machining concepts into reality. Leverage our technical depth, precision infrastructure, and the efficiency of our Online Instant Quote system to reduce time-to-market while maintaining uncompromised quality. Visit our portal today to experience seamless quoting for your next precision component project.

Technical Capabilities

Technical specifications for Micro Machining Inc. are outlined below, focusing on their core capabilities in precision 3, 4, and 5-axis CNC milling, CNC turning, and tight-tolerance manufacturing. The company specializes in high-accuracy components for industries such as aerospace, medical, and industrial automation. Below is a summary of their key technical capabilities and material expertise.

| Capability | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Chucker types); Multi-Task Machining |

| Tolerance Range | ±0.0002″ (±0.005 mm) typical; tight-tolerance work maintained consistently across complex geometries |

| Positioning Accuracy (Milling) | ±0.0001″ (±0.0025 mm) |

| Repeatability (Milling) | ±0.0001″ (±0.0025 mm) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed spindles available for micromachining) |

| Turning Diameter Range | 0.04″ to 2.0″ (1 mm to 50 mm); capable of long-bar and short-run Swiss turning |

| Minimum Feature Size (Milling) | 0.005″ (0.127 mm) using micro-end mills |

| Surface Finish (Typical) | 8–32 μin Ra; polishable to <8 μin Ra with post-processing |

| Work Envelope (5-Axis Milling) | 14″ × 10″ × 10″ (355 mm × 254 mm × 254 mm) |

| CMM & Metrology | On-site coordinate measuring machines (CMM), optical comparators, laser micrometers, and vision systems for GD&T validation |

| Lead Time (Prototype) | 5–10 business days, expedited options available |

Material Compatibility

Micro Machining Inc. supports a wide range of engineering-grade materials suitable for precision components:

Aluminum: 6061, 7075, 2024, and 5052 alloys; ideal for lightweight, high-strength applications with excellent machinability

Steel: 4140, 4340, 1018, and tool steels (e.g., A2, D2); used in high-wear and structural components

Stainless Steel: 303, 304, 316, 17-4 PH; corrosion-resistant options for medical and food-grade applications

Plastics: ABS and Nylon (including Nylon 6 and Nylon 6/6); selected for electrical insulation, low friction, and chemical resistance

Other Materials: Titanium (Grade 2, 5), brass, and PEEK upon request

All processes are supported by full CAD/CAM integration, first-article inspection (FAI) reporting, and process validation to ensure repeatable, high-precision output. Micro Machining Inc. maintains ISO 9001:2015 certification and adheres to AS9100 standards for aerospace-grade quality control.

From CAD to Part: The Process

Honyo Prototype employs a rigorously optimized workflow for micro machining projects, designed to ensure precision, reduce lead times, and mitigate risks inherent in sub-millimeter feature manufacturing. Our process integrates advanced digital tools with hands-on engineering expertise specifically calibrated for micro-scale tolerances (typically ±2μm to ±10μm) and delicate material handling. Below is a detailed technical breakdown of each phase.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native CAD files (preferred formats: STEP, IGES, Parasolid) via our secure client portal. For micro machining, we strongly recommend native formats over mesh-based formats (e.g., STL) to preserve geometric fidelity of critical micro-features such as thin walls (<0.1mm), micro-channels, or intricate lattices. Our system performs an immediate automated geometry validation check, flagging potential issues like non-manifold edges or unit inconsistencies that could compromise micro-scale accuracy. File encryption and audit trails are maintained per ISO 27001 standards throughout transmission.

AI-Powered Quoting Engine

Uploaded CAD data feeds into our proprietary AI quoting engine, trained on 12,000+ historical micro machining jobs. The engine analyzes geometric complexity, material properties (e.g., 17-4PH stainless steel, titanium alloys, or engineered plastics), and tolerance stack-ups to generate a preliminary cost and lead time estimate within 90 minutes. Key factors evaluated include:

Feature density per mm³

Minimum tool access diameter requirements

Surface roughness (Ra) specifications

Risk of deflection in sub-0.5mm features

This phase reduces quoting time by 70% compared to manual methods while providing data-driven feasibility insights before engineering review.

Engineering-Led DFM Analysis

All quotes undergo mandatory DFM verification by our micro machining specialists. This human-in-the-loop stage focuses on manufacturability risks unique to micro-scale production:

Verification of minimum wall thickness against material ductility

Assessment of burr formation risks in intersecting micro-features

Optimization of toolpath sequencing to prevent micro-vibration

Material-specific thermal expansion compensation planning

We provide actionable DFM reports with annotated CAD markups, typically resolving 85% of potential production issues before work begins. Clients receive clear options for design modifications if necessary, with impact analysis on cost/timeline.

Precision Micro Machining Production

Approved jobs move to our dedicated micro machining cell featuring:

Swiss-type lathes with 0.5μm resolution encoders

5-axis micro-mills with 10,000 RPM spindles and coolant-through-tooling

In-process metrology via integrated vision systems (2.5μm repeatability)

Class 10,000 cleanroom environment for contamination-sensitive parts

Each operation follows a documented process plan with mandatory in-process inspections at critical stages. For features below 50μm, we implement statistical process control (SPC) with real-time tool wear compensation. Material traceability is maintained via laser-etched part IDs linked to batch certificates.

Traceable Delivery and Documentation

Completed parts undergo final CMM inspection (using Zeiss CONTURA with 0.8μm MPEE) with full GD&T reporting. All micro machining projects include:

First-article inspection report (FAIR) with 3D deviation maps

Process validation documentation per AS9100/ISO 13485

Material test reports with lot traceability

Packaging in ESD-safe, humidity-controlled containers

Standard lead time from CAD upload to delivery is 7–12 business days for prototype quantities, with expedited options available. Critical parameters like surface roughness and dimensional conformance are validated against client specifications prior to shipment.

Process Efficiency Metrics

Our integrated workflow consistently achieves the following performance benchmarks for micro machining projects:

| Process Stage | Average Duration | Key Improvement vs. Traditional Methods |

|---|---|---|

| AI Quote Generation | 1.5 hours | 70% faster than manual quoting |

| DFM Resolution | 24–48 hours | 50% reduction in design iterations |

| Production Cycle Time | 5–10 days | 30% shorter due to pre-validated processes |

| First-Pass Yield | 92% | 22% higher than industry average for micro parts |

This closed-loop methodology ensures that geometric complexity at microscopic scales translates directly into reliable, high-yield production without compromising on the stringent quality requirements of aerospace, medical device, and semiconductor clients. All process data feeds into our continuous improvement database to refine AI models and machining protocols for future micro-scale projects.

Start Your Project

For all inquiries related to micro machining services at Micro Machining Inc., please contact Susan Leo directly via email at [email protected]. Our precision manufacturing facility is located in Shenzhen, China, and supports high-accuracy component production for demanding industries including medical, aerospace, and electronics. Reach out to discuss your project requirements, request a quote, or schedule a factory tour.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.