Contents

Manufacturing Insight: Micro Machining Company

Precision Micro Machining for Demanding Applications

Honyo Prototype delivers advanced CNC machining services engineered specifically for micro-scale components requiring micron-level precision and exceptional repeatability. Our specialized capabilities address the critical challenges of manufacturing intricate parts across aerospace, medical device, semiconductor, and optical industries where tolerances consistently reach ±0.0001″ (2.5µm) and feature sizes descend below 100µm. Utilizing state-of-the-art multi-axis CNC Swiss lathes, high-speed milling centers, and wire EDM systems with sub-micron resolution, we achieve uncompromising accuracy in materials ranging from titanium and nitinol to engineering plastics and exotic alloys.

Our integrated manufacturing ecosystem combines proprietary fixturing methodologies with in-process metrology to ensure dimensional stability and surface integrity at microscopic scales, eliminating common pitfalls like tool deflection and material deformation. This technical rigor enables reliable production of complex geometries—including micro-fluidic channels, implant threads, sensor housings, and optical mounts—that demand zero-defect performance in mission-critical applications.

Accelerate your prototyping and low-volume production cycles with Honyo Prototype’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and competitive pricing within minutes—no manual RFQ delays. This seamless digital workflow provides immediate cost transparency while our engineering team proactively identifies potential micro-machining optimizations before order placement. Partner with Honyo Prototype for precision you can measure and responsiveness you can count on.

Technical Capabilities

Honyo Prototype – Micro Machining Technical Capabilities

Honyo Prototype specializes in high-precision micro machining for industries requiring tight tolerance components, including medical devices, aerospace, and precision instrumentation. Our advanced CNC equipment supports complex geometries and small feature machining with consistent repeatability and surface finish control.

| Parameter | Specification |

|---|---|

| Primary Processes | 3-Axis, 4-Axis, and 5-Axis CNC Micro Milling, CNC Turning (Swiss & Standard) |

| Tolerance Capability | ±0.0001″ (2.5 µm) for critical dimensions; typical tolerances ±0.0002″ (5 µm) |

| Minimum Feature Size | 0.004″ (0.1 mm) achievable with specialized tooling and microscopy support |

| Max Work Envelope (Milling) | 10″ x 6″ x 6″ (254 x 152 x 152 mm) – standard; larger for non-micro parts |

| Max Work Envelope (Turning) | Diameter up to 1.25″ (32 mm), length up to 6″ (152 mm) |

| Spindle Speed (Milling) | Up to 60,000 RPM with high-frequency spindles for micro tool engagement |

| Tool Diameter Range | 0.002″ (0.05 mm) to 0.25″ (6.35 mm) |

| Positioning Accuracy | ±0.00005″ (1.27 µm) |

| Repeatability | ±0.00004″ (1 µm) |

| Surface Finish (Typical) | 8–16 µin Ra; down to 4 µin Ra with polishing or specialized tool paths |

Supported Materials

We routinely machine a wide range of metals and engineering plastics suitable for micro components:

Aluminum Alloys: 6061, 7075, 2024 – ideal for lightweight, high-strength micro parts with excellent machinability.

Steels: 4140, 4340, 17-4 PH Stainless, 303/304/316 Stainless – used for wear resistance and structural integrity.

Engineering Plastics: ABS and Nylon (PA6, PA66) – selected for insulation, low friction, and chemical resistance in non-metal applications.

All materials are verified for lot traceability and suitability in precision environments. Secondary operations such as deburring, passivation, and precision cleaning are performed in-house to maintain component integrity.

From CAD to Part: The Process

Honyo Prototype Micro Machining Workflow: Precision Execution from Concept to Component

Honyo Prototype delivers exceptional micro machining services through a rigorously defined, technology-driven workflow designed for accuracy, speed, and manufacturability. Our process eliminates traditional bottlenecks while ensuring micron-level precision for components typically under 25mm in size with features down to 10μm. The sequence begins when a client uploads their CAD model via our secure customer portal, accepting industry-standard formats including STEP, IGES, and native SOLIDWORKS files. This initial upload triggers immediate geometric validation to confirm file integrity and suitability for micro-scale production, rejecting non-conforming files with specific error diagnostics to prevent downstream delays.

The validated CAD model then enters our proprietary AI-powered quoting engine. Unlike conventional manual quoting, our system analyzes over 200 geometric and material parameters—including feature density, aspect ratios, wall thicknesses below 0.1mm, and surface roughness requirements—against a database of 50,000+ historical micro machining projects. This generates a technically validated quote within 2 hours, complete with cost drivers broken down by material utilization, machine time estimates for Swiss-type lathes or 5-axis micro mills, and secondary operation requirements. Crucially, the AI identifies potential manufacturability risks early, such as tool access limitations for sub-0.5mm cavities or thermal distortion concerns in thin-walled structures.

Following client approval of the quote, the design undergoes a mandatory Design for Micro Manufacturability (DFM) review conducted by our specialized micro machining engineering team. This phase focuses exclusively on the unique physics of micro-scale production, where conventional machining rules no longer apply. Engineers scrutinize factors like tool deflection compensation for end mills under 0.2mm diameter, minimum chip thickness requirements relative to material grain structure, and fixturing strategies to prevent part movement under minimal clamping forces. Clients receive a detailed DFM report with actionable recommendations—such as adjusting radii to prevent tool chipping or modifying draft angles to facilitate ejection—delivered via collaborative markup tools within 24 hours. Implementation of these suggestions is free of charge and typically reduces production iterations by 70%.

Approved designs advance to our climate-controlled micro machining cell, featuring sub-micron precision equipment including CNC Swiss lathes with live tooling, 5-axis wire EDM for intricate geometries, and laser micromachining centers. All processes operate under strict environmental controls (±0.5°C temperature stability, HEPA filtration) to mitigate thermal drift and particulate contamination. Real-time in-process metrology using non-contact vision systems and tactile probes verifies critical dimensions after each operation, with automated SPC data logging ensuring statistical process control. Material handling employs custom vacuum chucks and anti-static protocols to prevent damage to delicate features.

Final inspection adheres to AS9102 aerospace standards, utilizing high-magnification metrology (up to 1000x optical comparison, 3D laser scanning) to certify tolerances as tight as ±2μm. Components undergo rigorous cleaning in ultrasonic baths with IPA-grade solvents followed by controlled drying to eliminate residue. Delivery includes full traceability documentation—material certs, first-article inspection reports, and process validation data—packaged in ESD-safe containers with foam inserts designed for micro part geometry. Typical lead times from CAD upload to shipment range from 5-12 business days depending on complexity, with global express logistics partners ensuring secure, temperature-monitored transit.

Critical Process Parameters: Standard vs. Micro Machining

| Parameter | Standard Machining | Honyo Micro Machining |

|————————|————————–|————————–|

| Typical Tolerance | ±25μm | ±2μm to ±5μm |

| Minimum Feature Size | 0.5mm | 10μm to 50μm |

| Tool Diameter Range | 0.5mm – 20mm | 0.02mm – 0.5mm |

| Surface Roughness (Ra) | 0.8μm – 3.2μm | 0.05μm – 0.2μm |

| Material Removal Rate | High (mm³/min) | Ultra-Low (mm³/sec) |

| Primary Error Source | Machine vibration | Tool deflection/thermal |

This integrated workflow ensures clients receive not just parts, but validated solutions where every micron matters. Our closed-loop system—from AI-driven quoting to post-delivery metrology data analysis—provides unparalleled confidence for medical implants, semiconductor components, and optical assemblies where failure is not an option.

Start Your Project

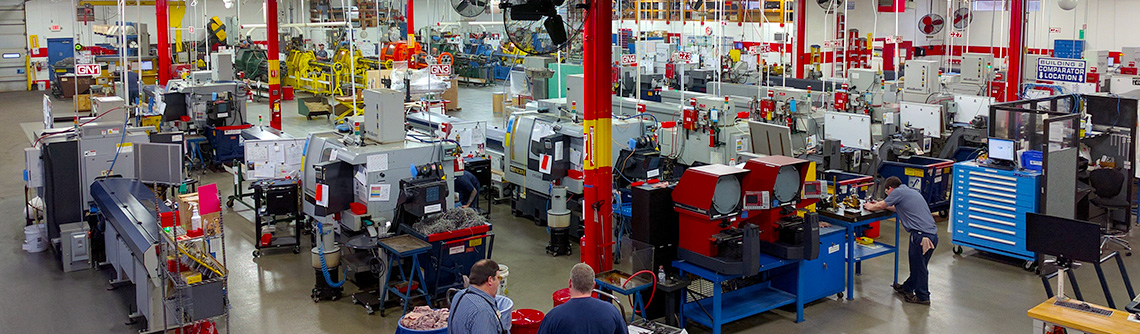

Discover precision-engineered micro machining solutions from Honyo Prototype. With advanced capabilities in micro-scale manufacturing, we deliver high-accuracy components for medical, electronics, and aerospace applications. Our state-of-the-art facility in Shenzhen ensures tight tolerances, rapid turnaround, and consistent quality for your most demanding projects.

Contact Susan Leo today to discuss your micro machining requirements.

Email: [email protected]

Let us support your innovation with precision you can trust.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.