Contents

Manufacturing Insight: Micro Machining Cnc

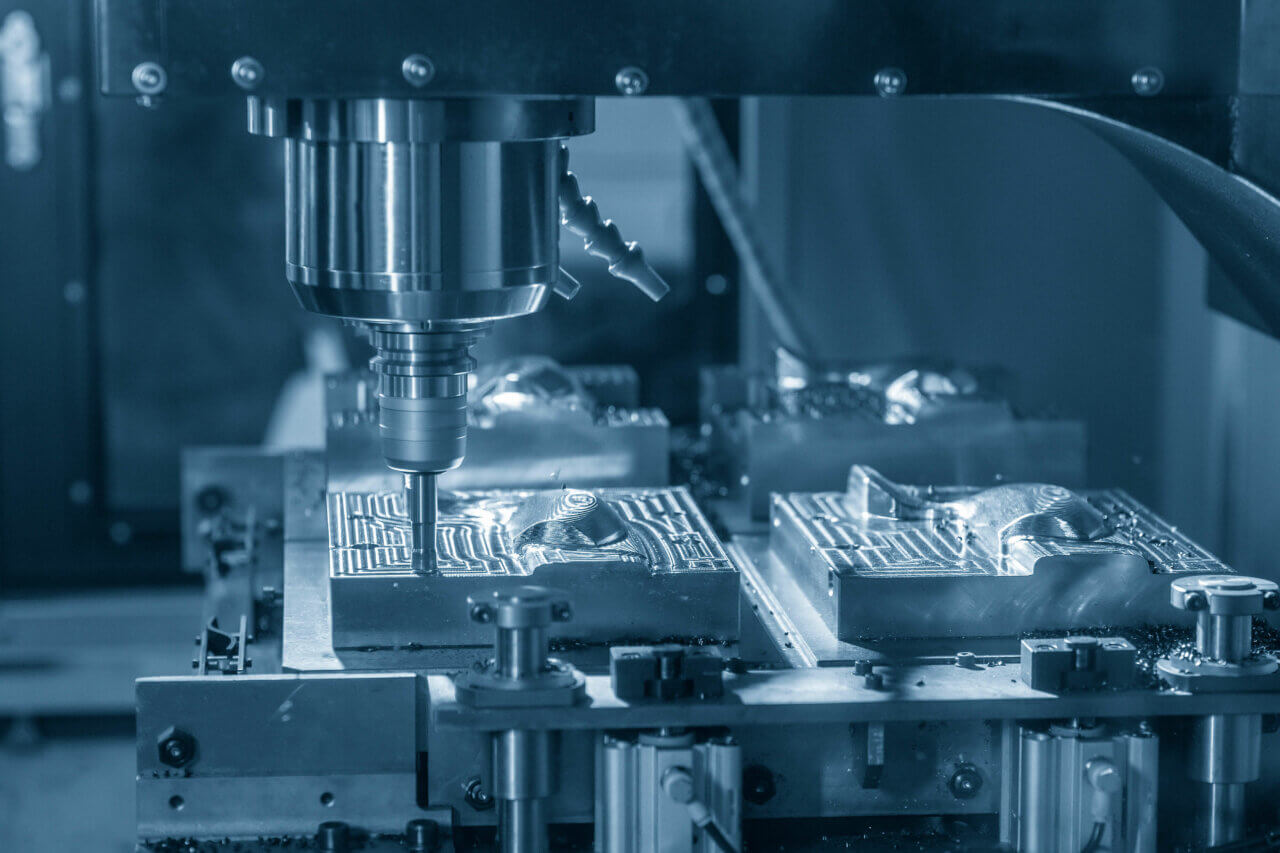

Precision Micro Machining CNC Services

Honyo Prototype delivers advanced micro machining CNC solutions engineered for extreme precision and complex geometries in high-value components. Our specialized capabilities achieve tolerances down to ±0.0001 inches across challenging materials including titanium, Inconel, medical-grade polymers, and hardened steels. Utilizing state-of-the-art 5-axis CNC systems with sub-micron resolution, we consistently produce intricate features for aerospace fuel systems, medical implants, semiconductor tooling, and optical assemblies where conventional machining falls short.

Engineers specify Honyo for rapid iteration of mission-critical micro parts without sacrificing repeatability or surface integrity. Our integrated quality protocol combines in-process metrology with post-machining verification using coordinate measuring machines and optical comparators to ensure every component meets stringent industry standards. Accelerate your development cycle with Honyo’s Online Instant Quote platform, providing detailed manufacturability feedback and turnaround estimates in under 60 seconds for prototype and low-volume production orders. This seamless digital workflow eliminates quotation delays while maintaining the technical rigor expected from a precision manufacturing partner.

Technical Capabilities

Micro machining CNC refers to high-precision computer numerical control machining processes designed for producing small, complex components with tight tolerances, typically in the range of ±0.0001″ (±2.5 µm) to ±0.0005″ (±12.7 µm). These systems are commonly used in aerospace, medical devices, optics, and electronics industries where precision and surface finish are critical.

The primary configurations include 3-axis, 4-axis, and 5-axis CNC milling machines, along with micro turning centers. Multi-axis capabilities enable complex geometries to be machined in a single setup, reducing cumulative error and improving accuracy. High spindle speeds (up to 100,000 RPM), sub-micron resolution feedback systems, thermally stable machine structures, and advanced vibration damping are typical features.

Micro CNC machines can process a variety of materials including metals such as aluminum and steel, and engineering plastics like ABS and nylon. Each material presents unique challenges in micro machining due to differences in thermal expansion, ductility, and chip evacuation.

Below is a summary of technical specifications relevant to micro machining CNC systems:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Micro Turning |

|---|---|---|---|---|

| Positioning Accuracy | ±0.00004″ (±1 µm) | ±0.00004″ (±1 µm) | ±0.00004″ (±1 µm) | ±0.00008″ (±2 µm) |

| Repeatability | ±0.00002″ (±0.5 µm) | ±0.00002″ (±0.5 µm) | ±0.00002″ (±0.5 µm) | ±0.00004″ (±1 µm) |

| Typical Tolerance Range | ±0.0001″ – ±0.0005″ | ±0.0001″ – ±0.0005″ | ±0.0001″ – ±0.0003″ | ±0.0001″ – ±0.0004″ |

| Spindle Speed | 20,000 – 60,000 RPM | 20,000 – 60,000 RPM | 30,000 – 100,000 RPM | 10,000 – 30,000 RPM |

| Tool Diameter Range | 0.002″ – 0.25″ (50–6350 µm) | 0.002″ – 0.25″ (50–6350 µm) | 0.001″ – 0.125″ (25–3175 µm) | 0.003″ – 0.125″ (75–3175 µm) |

| Axis Resolution | 0.000001″ (0.025 µm) | 0.000001″ (0.025 µm) | 0.0000008″ (0.02 µm) | 0.000001″ (0.025 µm) |

| Common Work Envelope | 4″ × 4″ × 3″ | 6″ × 6″ × 4″ | 6″ × 6″ × 4″ | Ø1″ × 2″ max workpiece |

| Materials – Aluminum | Yes (e.g., 6061, 7075) | Yes | Yes | Yes |

| Materials – Steel | Yes (e.g., 4140, 17-4PH) | Yes | Yes | Yes |

| Materials – ABS | Yes | Yes | Yes | Yes |

| Materials – Nylon | Yes (challenging due to gummy chips) | Yes (with cooling) | Yes (with chip control) | Yes (low feed rates) |

| Surface Finish (typical) | 8–16 µin Ra | 8–16 µin Ra | 4–12 µin Ra | 8–16 µin Ra |

| Control System | Fanuc, Siemens, Heidenhain, or proprietary high-resolution CNC | |||

| Coolant/Lubrication | Mist, air, or minimum quantity lubrication (MQL) preferred for chip control and thermal stability |

Note: Performance varies by machine manufacturer (e.g., Kern, Microlution, DMG MORI, MAZAK) and application-specific configurations. Material selection impacts tool life, cutting parameters, and achievable tolerances—especially in plastics like ABS and nylon, where thermal management and tool geometry are critical to avoid deformation.

From CAD to Part: The Process

Honyo Prototype Micro Machining CNC Process Flow

Our end-to-end micro machining process integrates precision engineering with digital efficiency, specifically designed for components requiring tolerances down to ±0.001mm and feature sizes below 0.1mm. The workflow begins when a client uploads a native CAD file (STEP, IGES, or Parasolid preferred) to our secure customer portal. Our system validates geometric integrity, material compatibility, and critical micro-features such as thin walls, micro-channels, or intricate contours. File encryption and access controls ensure IP protection throughout the process.

The AI-powered quoting engine then analyzes the CAD geometry against our micro machining capabilities, including Swiss-type lathes, ultra-precision mills, and wire EDM systems. It dynamically calculates machine time, tooling requirements (e.g., 0.02mm micro-end mills), and secondary operations while factoring in material-specific challenges like work hardening in Nitinol or thermal sensitivity in polymers. The quote includes tolerance feasibility assessment, surface roughness predictions (Ra 0.1–0.8µm), and lead time estimates—typically 72 hours for complex micro parts.

During Design for Manufacturability (DFM) review, our senior engineers conduct a granular analysis beyond standard CNC protocols. We simulate micro-scale phenomena such as tool deflection, chip evacuation in deep cavities, and thermal drift using specialized software (e.g., Mastercam Simulator, Ansys Mechanical). Key focus areas include:

| Parameter | Micro Machining Threshold | Standard CNC Threshold |

|---|---|---|

| Minimum Feature | ≤ 0.1mm | > 0.5mm |

| Tolerance (±) | 0.001mm | 0.01mm |

| Surface Roughness | Ra 0.1µm | Ra 1.6µm |

| Wall Thickness | ≤ 0.2mm | > 1.0mm |

We provide actionable feedback on geometry modifications—such as chamfering sharp corners to prevent tool breakage or adding draft angles for micro-molding compatibility—along with material substitution recommendations to enhance yield. All DFM suggestions are justified with process physics data, not generic guidelines.

Production occurs in our ISO 14644 Class 7 cleanroom environment with temperature stability maintained at 20±0.5°C. Micro machining employs air-bearing spindles (up to 100,000 RPM), laser tool measurement, and in-process probing for real-time compensation. Each operation undergoes first-article inspection via coordinate measuring machines (CMM) with 0.5µm resolution and optical comparators. For features below 50µm, we utilize scanning electron microscopy (SEM) validation.

Final delivery includes traceable documentation: calibrated CMM reports with GD&T callouts, material certificates, and a process validation summary. Parts are packaged in ESD-safe containers with humidity control, and shipping includes real-time logistics tracking. Typical lead time for micro machining projects is 10–15 business days from CAD approval, with expedited options for prototyping. This integrated approach ensures >95% first-pass yield for geometries at the limits of machinability.

Start Your Project

For precision micro machining CNC services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-accuracy components for demanding industries including medical, aerospace, and electronics. With state-of-the-art CNC equipment and strict quality control, Honyo Prototype ensures tight tolerances down to ±0.0001″ and exceptional repeatability.

We specialize in micro milling, micro turning, and complex geometry machining for prototypes and low-to-mid volume production. All processes are supported by in-house engineering and metrology to guarantee part accuracy and fast turnaround.

Reach out today to discuss your micro machining requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.