Contents

Manufacturing Insight: Micro Injection Molding Machines

Precision Micro Injection Molding: Accelerating Your Miniaturized Component Development

Micro injection molding presents unique engineering challenges requiring exceptional precision, material control, and process stability for components often weighing less than one gram and demanding micron-level tolerances. Traditional approaches frequently suffer from extended lead times and prohibitive costs during prototyping and low-volume production, hindering innovation in critical sectors like medical devices, microfluidics, and advanced electronics.

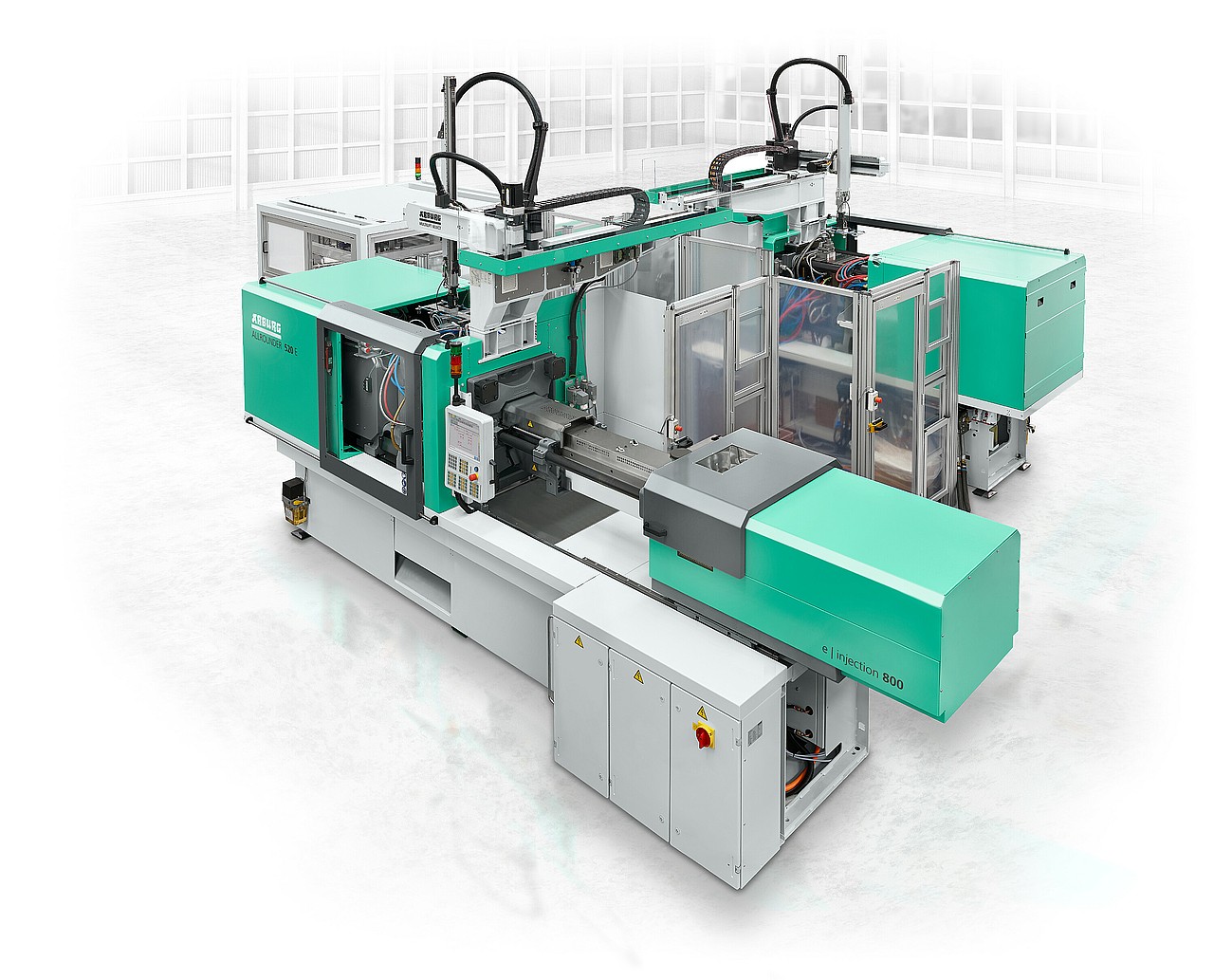

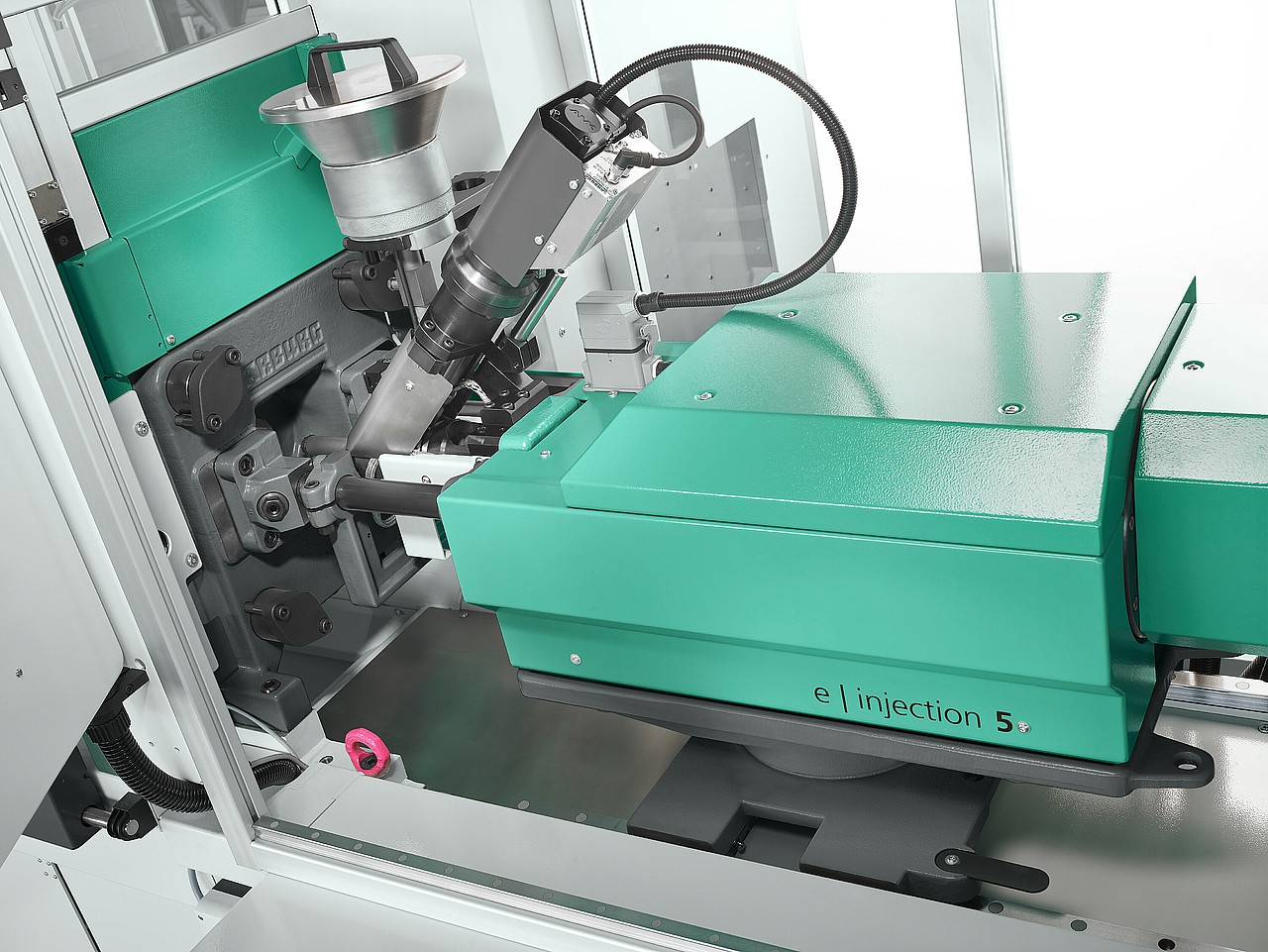

Honyo Prototype directly addresses these constraints through integrated Rapid Tooling and Micro Injection Molding services. Our specialized micro molding machines feature advanced screw-plunger systems, high-resolution dosing control, and real-time cavity pressure monitoring to ensure repeatable production of complex geometries down to 0.01 grams. Crucially, we pair this capability with proprietary rapid steel tooling processes, enabling functional prototype validation and pilot production within days—not weeks—using production-intent materials and processes. This eliminates the typical compromise between speed and manufacturability, ensuring your design transitions seamlessly to full-scale production.

Accelerate your project timeline immediately with Honyo’s Online Instant Quote system. Submit your 3D CAD file and requirements to receive a detailed manufacturability analysis and competitive pricing for micro molding tooling and parts within hours, providing the clarity needed for rapid decision-making in your development cycle.

Technical Capabilities

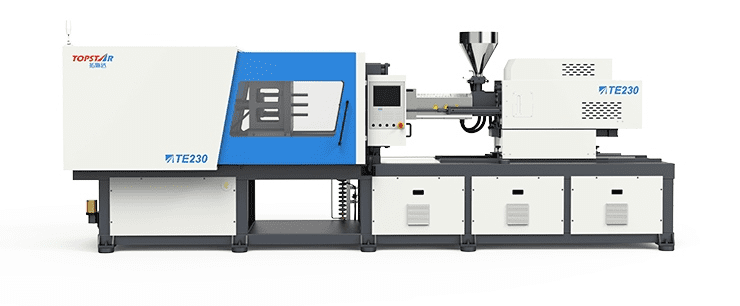

Micro injection molding machines are engineered for precision molding of small, intricate components typically used in medical, electronics, and micro-optics industries. These machines deliver high accuracy, repeatable dosing, and controlled injection speeds suitable for shot weights ranging from 0.01g to 10g. When utilizing aluminum or steel molds, the choice impacts lead time, durability, and surface finish. Aluminum molds enable faster machining and are ideal for prototyping, supporting T1 sample delivery within 7 days. Steel molds (e.g., P20, H13, 420 SS) offer extended lifespan and are better suited for high-volume production but may extend initial lead time.

The process supports engineering thermoplastics such as ABS and Nylon (e.g., PA6, PA66), which require precise temperature and moisture control. ABS offers good impact resistance and processability, while Nylon provides high strength, thermal resistance, and chemical stability—critical for functional prototypes and end-use micro parts.

Below are key technical specifications relevant to micro injection molding machines optimized for rapid T1 sampling with aluminum or steel molds:

| Parameter | Specification / Detail |

|---|---|

| Clamping Force | 30 to 150 tons (sufficient for small mold footprints and low projected area) |

| Screw Diameter | 12 to 20 mm (enables precise control over small shot volumes) |

| Shot Weight (Typical Range) | 0.01 to 10 grams (optimized for micro parts) |

| Injection Pressure | Up to 2,500 bar (high pressure for filling thin walls and micro-features) |

| Position Repeatability | ±0.001 mm (critical for dimensional accuracy in micro-scale features) |

| Mold Materials Supported | Aluminum (7075, 6061), Steel (P20, H13, 420 Stainless) |

| Mold Lead Time (T1 Sample) | 7 days (achievable with aluminum; steel molds may require 10–14 days) |

| Compatible Materials | ABS, Nylon (PA6, PA66), PEEK, PC, PP, PE, PSU |

| Melt Temperature Range | 230–300°C (adjustable based on material, e.g., ABS: 230–260°C, Nylon: 260–290°C) |

| Drying Requirements | ABS: 80°C for 2–4 hrs; Nylon: 80–90°C for 4–6 hrs (mandatory pre-processing) |

| Machine Control System | Closed-loop servo with real-time monitoring for pressure, speed, and position |

| Nozzle Types | Standard, valve gate, or hot runner nozzles for precise material delivery |

| Typical Applications | Micro connectors, medical cannulas, sensor housings, micro gears |

This configuration enables Honyo Prototype to deliver high-precision T1 samples within 7 days using aluminum molds, while offering a seamless transition to steel molds for volume production. Process stability, material expertise, and rapid tooling cycles ensure reliable outcomes for both ABS and Nylon micro components.

From CAD to Part: The Process

Honyo Prototype executes micro injection molding with a rigorously defined workflow designed for precision components typically under 1 gram and with critical features measured in microns. Our process ensures dimensional stability, material integrity, and repeatability for high-value applications in medical devices, micro-optics, and semiconductor packaging.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure portal. Our system performs immediate geometric validation specifically for micro-scale constraints, checking for minimum wall thicknesses below 0.1 mm, undercuts under 0.05 mm, and draft angles below 0.5 degrees. Files failing validation trigger automated feedback on non-compliant features before proceeding, preventing downstream delays.

AI Quote Generation

Honyo’s proprietary AI engine analyzes the validated CAD geometry against our database of 12,000+ micro-molding projects. It calculates machine-specific parameters including shot weight (as low as 0.001g), clamp force requirements (5–30 tons), and cycle time projections based on material thermal properties. The AI cross-references real-time resin pricing, cavity count feasibility, and secondary operations to generate a detailed quote within 4 business hours. Critical outputs include predicted warpage tolerance (±0.005 mm typical), gate vestige height estimates, and recommended venting strategies for micro-cavities.

DFM Analysis and Refinement

Engineers conduct a dual-phase Design for Manufacturability review. Phase 1 uses simulation software to model flow behavior at micro-scale, identifying risks like jetting in channels under 0.2 mm or air traps in features under 0.1 mm³. Phase 2 involves direct collaboration with the client to resolve conflicts between design intent and micro-molding physics—for instance, modifying radii on micro-threads to prevent shear-induced degradation or adjusting ejection pin placement to avoid part deformation. All DFM recommendations include tolerance stack-up analysis specific to the material’s coefficient of thermal expansion.

Precision Production

Micro molding occurs on dedicated all-electric machines with sub-micron positioning accuracy, operating in ISO Class 7 cleanrooms. Key production parameters are tightly controlled:

| Parameter | Typical Range for Micro Parts | Control Method |

|---|---|---|

| Shot Weight | 0.001g – 1.0g | Laser-weighed shot monitoring |

| Melt Temperature | ±1°C stability | Closed-loop PID control |

| Injection Speed | 5–500 mm/s | Servo-driven screw profiling |

| Cavity Pressure | Real-time monitoring | Piezoelectric sensors |

Each run undergoes 100% inline metrology via vision systems with 2-micron resolution, rejecting parts outside tolerance bands before secondary operations like laser marking or plasma treatment.

Traceable Delivery

Finished parts ship with full traceability documentation including lot-specific material certificates, cavity-by-cavity SPC data, and first-article inspection reports per AS9102. For medical clients, we provide FDA-compliant device history records. All micro parts are packaged in ESD-safe, particulate-controlled containers with humidity indicators, with standard lead times of 15–20 days from approved DFM. This closed-loop process ensures zero defects for components where a 10-micron deviation can render a part nonfunctional.

Start Your Project

Explore high-precision micro injection molding solutions engineered for complex, miniaturized components. Our advanced machines deliver exceptional accuracy, repeatability, and efficiency—ideal for medical, optical, and electronics applications.

Contact Susan Leo to request technical specifications, pricing, or machine demonstrations.

Email: [email protected]

Manufactured with precision at our Shenzhen factory, Honyo Prototype ensures quality control and on-time delivery for global clients. Let’s discuss how our micro injection molding technology can support your production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.