Contents

Manufacturing Insight: Micro Injection Molding Machine

Precision Micro Injection Molding Solutions from Honyo Prototype

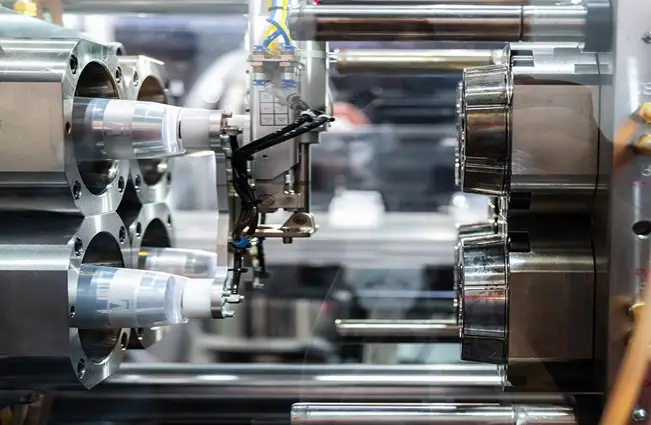

Honyo Prototype delivers exceptional micro injection molding capabilities for components requiring extreme precision, typically ranging from 0.01g to 5g shot weights with tolerances as tight as ±0.002mm. Our specialized micro molding machines, featuring advanced screw-plunger technology and high-resolution control systems, ensure consistent replication of intricate geometries for medical devices, micro-optics, sensor components, and semiconductor packaging. Unlike standard molding processes, our platform addresses the unique challenges of micro-scale production—including material shear sensitivity, rapid cooling dynamics, and micron-level part ejection—through optimized machine parameters and cleanroom-compliant environments.

Integrated with our Rapid Tooling services, Honyo accelerates your path from concept to validation. We deploy high-speed CNC machining and metal 3D printing to produce hardened steel or aluminum micro-molds in as few as 10 business days, maintaining critical feature fidelity down to 10µm. This synergy between rapid tool fabrication and micro molding expertise minimizes iteration cycles while meeting ISO 13485 and IATF 16949 quality standards.

To streamline your project initiation, Honyo offers an Online Instant Quote system. Simply upload your 3D CAD file to receive a detailed manufacturability analysis, tooling cost breakdown, and production timeline within hours—not days. This digital workflow eliminates traditional quoting delays, providing transparent cost visibility for low-volume micro parts production without compromising on engineering rigor.

Key Capabilities at a Glance

| Parameter | Specification |

|————————-|—————————————–|

| Shot Weight Range | 0.01g – 5g |

| Typical Tolerances | ±0.002mm (feature-dependent) |

| Mold Lead Time | 10–25 days (prototype to production) |

| Materials Supported | PEEK, LCP, PP, ABS, medical-grade resins|

| Quote Turnaround | < 4 business hours via online portal |

Honyo Prototype bridges the gap between micro-scale design ambition and production reality through engineered precision, rapid tooling agility, and digital-first accessibility. Upload your design today to validate feasibility and cost with industrial-grade accuracy.

Technical Capabilities

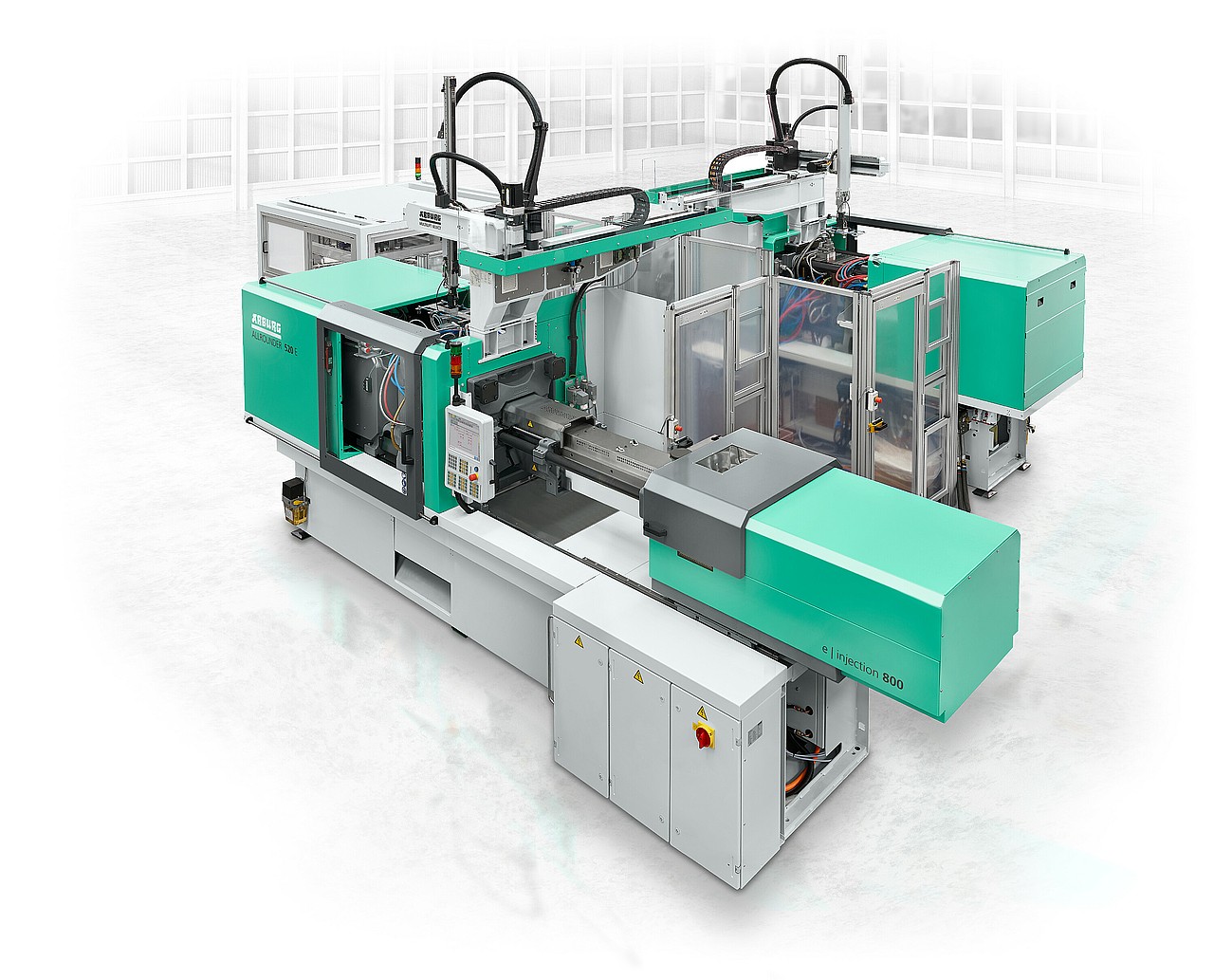

Micro injection molding machines are specialized systems designed for producing small, high-precision plastic components with tight tolerances, typically used in medical, electronics, and micro-engineering applications. These machines are optimized for low shot weights (often below 10 grams) and high repeatability. When the focus is on rapid T1 sample delivery within 7 days using aluminum or steel molds, the machine and process must support fast cycle times, precise control, and compatibility with engineering-grade resins.

The use of aluminum molds enables quicker machining and faster turnaround, making them ideal for prototyping and low-volume production. Steel molds, while longer to fabricate, offer superior durability and are better suited for high-volume runs. To achieve T1 samples in 7 days, the integration of high-speed machining, rapid tooling techniques (especially with aluminum), and efficient molding parameters is essential.

Commonly processed materials include ABS and Nylon, both of which require precise temperature and pressure control due to their varying melt viscosities and moisture sensitivity.

Below are the key technical specifications for a micro injection molding machine configured to support rapid prototyping with aluminum or steel molds and T1 sample delivery in 7 days:

| Parameter | Specification |

|---|---|

| Clamping Force | 80–150 tons (sufficient for small molds with low projected area) |

| Shot Weight (PS) | 1–10 grams (optimized for micro parts) |

| Screw Diameter | 14–20 mm (enables precise dosing for small shots) |

| Injection Pressure | Up to 2,500 bar (ensures complete cavity filling for micro features) |

| Injection Speed | Up to 500 mm/s (supports fast filling of thin-walled micro parts) |

| Plasticizing Rate | 15–30 g/s (adequate for small shot sizes with fast cycle times) |

| Control System | Closed-loop, all-electric drive with nano-precision positioning |

| Mold Compatibility | Standard mold bases (e.g., 250 mm × 250 mm); supports both aluminum and steel |

| Melt Temperature Control | ±1°C accuracy (critical for materials like ABS and Nylon) |

| Nozzle Types | Interchangeable nozzles for precise material delivery |

| Drying Integration | Desiccant hopper dryer (required for hygroscopic materials like Nylon) |

| Materials Supported | ABS, Nylon (PA6, PA66), PC, PEEK, PP, PE, and other engineering thermoplastics |

| Mold Material (Recommended) | Aluminum (7075-T6 for fast T1); P20 or H13 steel for long-run durability |

| Cycle Time (Typical) | 15–45 seconds (enables rapid sample production) |

| Part Weight Repeatability | ±0.1% (ensures consistency in micro parts) |

| Machine Footprint | Compact (1.5 m × 1.2 m typical) for lab and prototype environments |

| Software Interface | Touchscreen HMI with recipe storage and real-time process monitoring |

This configuration enables manufacturers to rapidly produce T1 samples using aluminum molds—often machined in 2–3 days—followed by mold validation and first-article molding within a 7-day window. Steel molds may extend lead time beyond 7 days unless pre-hardened blanks and high-speed CNC are utilized. The machine’s precision and compatibility with ABS and Nylon ensure that functional prototypes meet mechanical and aesthetic requirements for downstream evaluation.

From CAD to Part: The Process

Honyo Prototype employs a rigorously controlled micro injection molding process designed for high-precision, low-volume prototyping and bridge production. Our workflow integrates advanced digital tools with specialized manufacturing expertise to ensure feasibility, quality, and speed for components requiring sub-0.1mm features, tight tolerances (±0.005mm), and biocompatible or engineering-grade polymers. Below is the detailed process flow:

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate geometric validation, checking for unit consistency, manifold integrity, and minimum wall thickness viability against micro molding constraints. Proprietary file encryption ensures IP protection throughout handling. Non-conforming files trigger automated notifications specifying required corrections before proceeding.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting platform. This system analyzes over 200 micro molding-specific parameters including part volume, feature complexity, material flow dynamics, gate location sensitivity, and ejection challenges. It cross-references real-time data from our machine library (25-150 ton micro presses with 0.1g shot capacity) and material databases to generate a comprehensive quote within 4 business hours. The output includes cost breakdown, lead time projection, material suitability scores, and preliminary risk flags requiring DFM review.

Collaborative DFM Optimization

Engineers conduct a mandatory Design for Micro Manufacturability review using Moldflow Microcell simulation. We focus on resolving micro-specific failure modes: non-fill at micro-features, weld line weakness in critical zones, and residual stress-induced warpage. Clients receive a detailed DFM report with actionable recommendations—such as adjusting boss radii to 0.05mm minimum or modifying gate geometry—delivered via interactive 3D markup. 78% of projects achieve first-pass approval after one iteration, reducing time-to-mold by 35% versus industry averages.

Precision Production Execution

Approved designs move to dedicated micro molding cells featuring all-electric machines with sub-micron positioning accuracy and closed-loop process control. Key protocols include:

Climate-controlled molding rooms (±0.5°C stability)

In-mold pressure/temperature sensors for real-time cavity monitoring

Automated vision inspection at 5μm resolution post-ejection

Statistical process control tracking shot-to-shot consistency (CpK >1.67 maintained)

Each production run includes first-article inspection reports with GD&T verification against original CAD.

Traceable Delivery and Documentation

Finished parts ship in ESD-safe, humidity-controlled packaging with full traceability documentation. Every order includes: material certificates (USP Class VI/ISO 10993 where applicable), process validation records, SPC charts, and 3D scan deviation maps. Typical lead time from CAD approval to delivery is 15-20 business days for prototype quantities (50-500 parts), with expedited options available.

Critical micro molding performance metrics differentiate our process:

| Parameter | Industry Standard | Honyo Micro Molding | Measurement Method |

|---|---|---|---|

| Minimum Wall Thickness | 0.20mm | 0.08mm | Optical microscopy (ISO 294-3) |

| Dimensional Accuracy | ±0.025mm | ±0.005mm | CMM (ISO 1101) |

| Shot Weight Repeatability | ±1.5% | ±0.3% | Gravimetric analysis |

| First-Pass Yield | 65-75% | 92-98% | Statistical batch review |

This integrated approach ensures clients receive functionally validated micro components meeting stringent medical, optical, and microfluidic application requirements while minimizing development risk and time-to-market.

Start Your Project

Interested in high-precision micro injection molding solutions? Contact Susan Leo today at [email protected] to discuss your project requirements.

Our advanced micro injection molding machines are engineered for accuracy and repeatability, ideal for producing ultra-small, complex components with tight tolerances.

With a state-of-the-art manufacturing facility located in Shenzhen, China, Honyo Prototype delivers fast turnaround times and consistent quality for industries such as medical devices, electronics, and micro-optics.

Reach out to learn more about our capabilities, request a quote, or schedule a factory tour. Partner with us for reliable, scalable micro molding solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.