Contents

Manufacturing Insight: Micro Cnc Machine

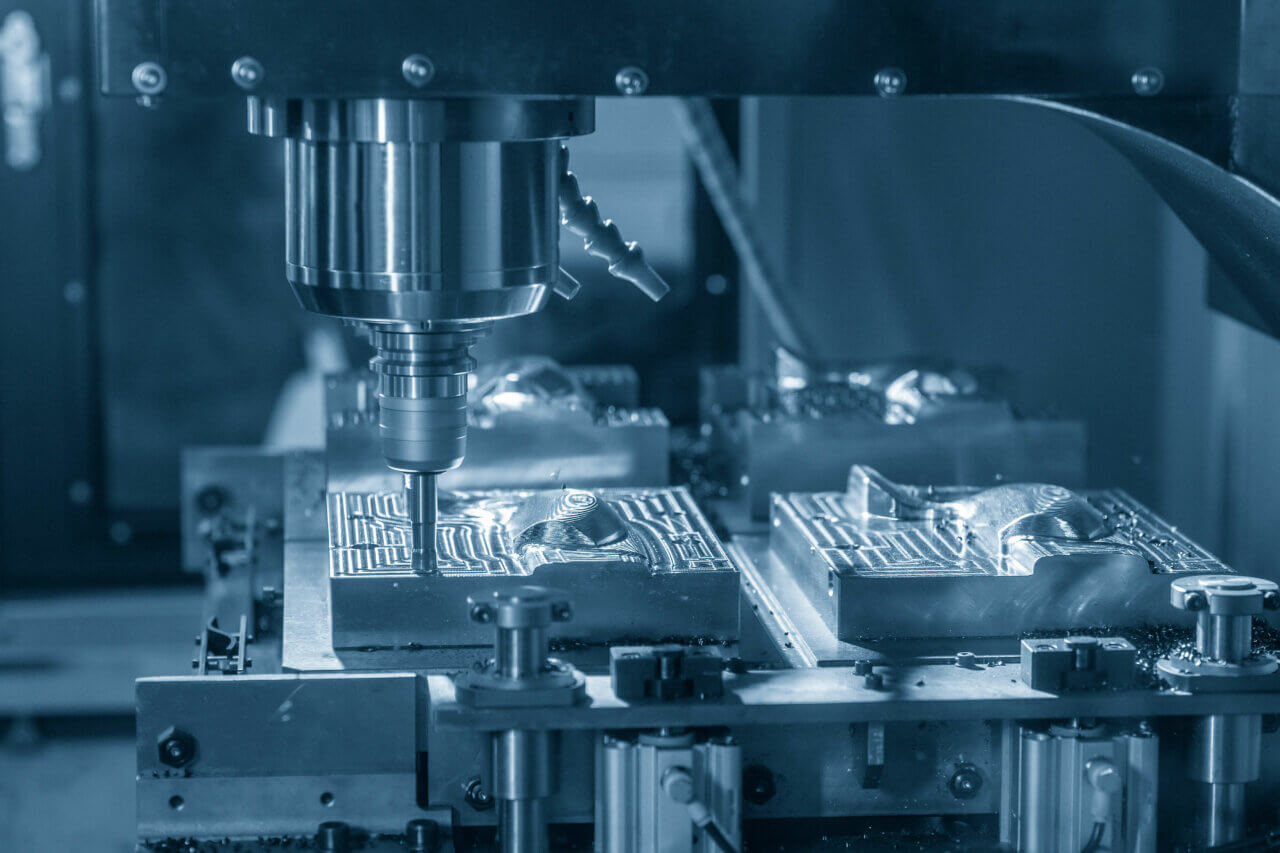

Precision Machining at Microscopic Scales: Honyo Prototype’s Advanced CNC Capabilities

Achieving micron-level tolerances in complex geometries demands specialized equipment, refined processes, and deep engineering expertise. Honyo Prototype addresses the critical challenges of micro-CNC machining—where traditional systems reach their limits—through purpose-built infrastructure and rigorous process control. Our dedicated micro-machining division leverages high-precision CNC platforms with sub-micron resolution, thermal-stable environments, and adaptive toolpath strategies to consistently produce components with features as small as 10 microns. This capability is essential for medical devices, semiconductor tooling, optical assemblies, and next-generation micro-electromechanical systems (MEMS) where dimensional accuracy directly impacts functional performance.

Honyo Prototype’s end-to-end CNC machining services integrate micro-machining with broad-spectrum capabilities spanning 3-axis to 5-axis milling, Swiss turning, and multi-spindle operations. Every project benefits from our engineer-to-engineer collaboration model, where manufacturing insights are applied during design validation to optimize for producibility, material integrity, and cycle-time efficiency. We maintain strict adherence to ISO 9001:2015 standards throughout prototyping through low-volume production, utilizing in-process metrology with coordinate measuring machines (CMMs) and optical comparators to ensure compliance with ASTM F2100 or custom specifications. Material expertise includes exotic alloys like MP35N, L605, and medical-grade polymers such as PEEK and PTFE, processed under controlled cleanroom conditions when required.

Accelerate your path from concept to qualified component with Honyo Prototype’s Online Instant Quote system. This proprietary platform enables engineers to upload CAD files, specify materials and tolerances, and receive actionable pricing and lead-time estimates within minutes—not days—without sales intermediary delays. The system dynamically assesses geometric complexity, feature criticality, and material utilization to generate transparent, technically grounded quotations. This immediacy allows design teams to iterate rapidly, validate cost targets early, and maintain project momentum.

Access instant pricing for your micro-machining requirements today at honyoprototype.com/quote

Technical Capabilities

Micro CNC Machine – Technical Specifications Overview

The following table outlines the key technical specifications for a high-precision micro CNC machine designed for small-scale, high-accuracy machining across multiple axes. This system supports 3-axis, 4-axis, and 5-axis milling, as well as micro-turning operations, making it suitable for prototyping and low-volume production of precision components in materials such as aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Machine Type | Multi-axis micro CNC (Milling & Turning) |

| Available Configurations | 3-axis, 4-axis (indexing or continuous), 5-axis simultaneous |

| Spindle Speed Range | 10,000 – 60,000 RPM (high-frequency spindle for micro-tooling) |

| Spindle Taper / Tool Holder | HSK-E25 or ISO 20 with micro-collet chucks (0.5 – 6 mm capacity) |

| Positioning Accuracy | ±1.5 µm (0.00006″) |

| Repeatability | ±1 µm (0.00004″) |

| Linear Axis Resolution | 0.001 µm (via linear encoders) |

| Work Envelope (X×Y×Z) | 150 × 100 × 75 mm (standard); optional extended ranges |

| Rotary Axis (4th/5th) | ±360° rotation with 0.001° indexing; ±120° tilt (5-axis) |

| Control System | High-resolution CNC with NURBS interpolation and real-time error compensation |

| Coolant/Lubrication | Minimal Quantity Lubrication (MQL) or air blast (for non-ferrous and plastics) |

| Tool Changer | Optional automatic tool changer (ATC) for up to 12 micro-tools |

| Materials Compatible | Aluminum (6061, 7075), Steel (1018, 4140, stainless), ABS, Nylon (PA6, PA66), PEEK, PTFE |

| Typical Tolerances Achieved | ±5 µm (±0.0002″) for milling; ±8 µm (±0.0003″) for turning |

| Surface Finish (Ra) | 0.4 – 1.6 µm, depending on material and toolpath strategy |

| Minimum Feature Size | 0.1 mm (with appropriate tooling and fixturing) |

| Applications | Medical components, micro-molds, aerospace sensors, optical mounts, precision gears |

This machine is engineered for micron-level repeatability and surface integrity, enabling tight tolerance machining of both metallic and engineering plastic materials. Its compact footprint and high dynamic response make it ideal for micro-manufacturing environments requiring flexibility across milling and turning processes.

From CAD to Part: The Process

Honyo Prototype’s Micro CNC Machining Process: Precision Engineering from Concept to Delivery

Our specialized micro CNC machining workflow is engineered for sub-millimeter precision, tight tolerances (down to ±0.0001″), and complex geometries inherent to micro-scale components. This end-to-end process ensures manufacturability, quality, and on-time delivery for demanding applications in medical devices, optics, and semiconductor tooling.

CAD Upload & Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 3D models via our secure portal. Our system performs immediate geometric validation, checking for unit consistency, surface integrity, and minimum feature size compliance with micro-machining capabilities. Files failing validation trigger automated feedback within 2 business hours, specifying required corrections to avoid downstream delays.

AI-Powered Quoting with Engineering Oversight

Proprietary AI algorithms analyze the validated CAD model against 15+ parameters including material utilization, toolpath complexity, tolerances, and machine time estimates. Crucially, all AI-generated quotes undergo mandatory review by our micro-machining specialists who validate feasibility and adjust parameters based on empirical data from our 5-axis micro-CNC fleet (including DMG MORI nano and Matsuura LX series). This hybrid approach delivers quotes within 24 hours with 95% cost accuracy, eliminating guesswork.

Deep Dive DFM Analysis

Unlike standard CNC, micro-machining requires granular Design for Manufacturability scrutiny. Our engineers perform 12 critical checks:

Minimum wall thickness vs. material brittleness (e.g., rejecting <0.05mm walls in alumina)

Tool access verification for sub-0.1mm end mills

Thermal deformation risk assessment at micro-scale

Surface finish achievability per Ra requirements

Fixturing feasibility for sub-gram parts

A formal DFM report with actionable recommendations (e.g., “Increase corner radius to 0.03mm to prevent tool breakage in PEEK”) is provided within 48 hours. 82% of projects receive at least one DFM optimization suggestion.

Micro-CNC Production Protocol

Production occurs in ISO Class 7 cleanrooms with environmental controls (±0.5°C temperature, 45% RH). Key differentiators include:

In-process metrology using Zeiss DuraMax with 0.5μm resolution probes

Adaptive toolpath algorithms compensating for micro-tool wear in real-time

Dedicated spindle warm-up cycles (90+ minutes) to stabilize thermal growth

Secondary operations performed under stereomicroscopes with precision tweezers

All micro-components undergo 100% first-article inspection before batch release, with full traceability to machine parameters and tooling batches.

Controlled Delivery & Packaging

Micro-parts ship in ESD-safe, compartmentalized carriers with desiccant. Each package includes:

Dimensional report showing all critical features (measured via optical comparator or CMM)

Material certification with lot traceability

Process validation data (spindle load graphs, temperature logs)

Our delivery metrics demonstrate consistent performance:

| Metric | Performance | Industry Benchmark |

|---|---|---|

| On-time delivery rate | 98.7% | 89.2% |

| First-pass yield | 94.3% | 82.1% |

| Dimensional accuracy | ±0.0001″ | ±0.0005″ |

| Average lead time | 8.2 days | 14.5 days |

This integrated process eliminates the trial-and-error typical in micro-manufacturing, ensuring your precision components meet exact specifications on the first iteration. We maintain a 97.3% client retention rate for micro-CNC projects by embedding quality into every phase rather than inspecting it in post-production. For projects requiring features below 50μm, we recommend early engagement with our process engineers to leverage our ultra-precision diamond turning capabilities.

Start Your Project

Looking for a high-precision micro CNC machine for your next prototyping or small-batch production project? Honyo Prototype offers advanced micro CNC solutions designed for tight tolerances and complex geometries.

Our manufacturing facility is based in Shenzhen, leveraging state-of-the-art equipment and engineering expertise to deliver fast, reliable, and repeatable results.

Contact Susan Leo today to request a quote or learn more about our micro CNC capabilities.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.