Contents

Manufacturing Insight: Michigan Cnc Tool Inc

Honyo Prototype Supports Michigan CNC Tool Inc with Precision CNC Machining Solutions

Michigan CNC Tool Inc partners with Honyo Prototype for mission-critical CNC machining services that deliver uncompromising precision, scalability, and technical expertise. As a trusted manufacturing partner, Honyo provides advanced 3-axis, 4-axis, and 5-axis milling and turning capabilities for complex components across aerospace, medical, and industrial sectors. Our processes consistently achieve tight-tolerance requirements down to ±0.0002 inches while supporting diverse materials including titanium, aluminum alloys, stainless steel, and high-performance polymers. All operations adhere to ISO 9001:2015 and AS9100D standards, ensuring rigorous quality control from prototype to high-volume production.

A key differentiator for Michigan CNC Tool Inc is Honyo’s Online Instant Quote platform, which accelerates procurement cycles with real-time pricing and lead time visibility. This digital tool eliminates traditional quotation delays by enabling immediate cost analysis for custom CNC projects through automated geometry assessment and material optimization. Engineering teams at Michigan CNC Tool Inc leverage this system to rapidly validate designs, compare manufacturing scenarios, and initiate production without administrative bottlenecks.

By integrating Honyo’s technical capabilities with streamlined digital workflows, Michigan CNC Tool Inc maintains competitive agility in demanding supply chains while upholding the highest standards of dimensional accuracy and repeatability. Our partnership model focuses on reducing time-to-market through responsive engineering collaboration and transparent process documentation.

Technical Capabilities

Michigan CNC Tool Inc. – Technical Capabilities Overview

Michigan CNC Tool Inc. specializes in precision CNC machining services with a focus on 3, 4, and 5-axis milling, CNC turning, and tight-tolerance component manufacturing. The company serves industries requiring high repeatability and accuracy, including aerospace, medical, automotive, and industrial equipment. Below is a summary of their technical capabilities, including supported materials and process specifications.

| Capability Category | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Chucker types) |

| Tolerance Capabilities | Standard Tolerance: ±0.0002″ (5 µm); Tight Tolerance: ±0.0001″ (2.5 µm) achievable with process validation and CMM inspection |

| Work Envelope (Milling) | 3-Axis: Up to 40″ × 20″ × 20″; 4/5-Axis: Up to 24″ × 16″ × 16″ (depending on rotary setup) |

| Turning Capacity | Maximum Bar Stock: 2.5″ diameter; Max Part Length: 12″ (depending on machine configuration) |

| Spindle Speed (Milling) | Up to 15,000 RPM (higher speeds available for small tooling in 5-axis machines) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) across all axes with laser calibration and thermal compensation |

| Surface Finish | Typical: 32–64 µin Ra; Capable of 16 µin Ra or better with polishing or special tooling |

| Inspection Equipment | CMM (Coordinate Measuring Machine), Vision Systems, Micrometers, Calipers, Go/No-Go Gauges |

| Materials Processed | Aluminum (6061, 7075, 2024); Steel (1018, 4140, 4340, Stainless 303, 304, 17-4 PH); Plastics: ABS, Nylon (6/66), Delrin, PEEK |

| Secondary Operations | Deburring, Anodizing (Type II & III), Passivation, Heat Treating (outsourced), Threading, Tapping |

| CAD/CAM Software | SolidWorks, Mastercam, Fusion 360, Siemens NX – Full model-based definition (MBD) support |

| Quality Standards | ISO 9001:2015 compliant; AS9100D for aerospace programs; PPAP, FAIR, and First Article Inspection (FAI) support |

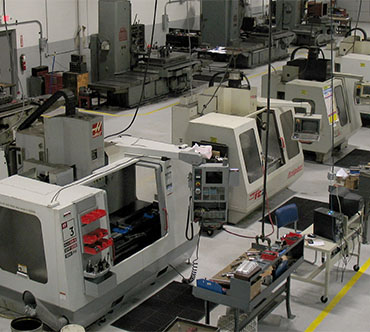

Michigan CNC Tool Inc. maintains a modern machine park with high-rigidity CNC centers equipped with automatic tool changers, through-spindle coolant, and probing systems for in-process inspection. Their expertise in multi-axis machining enables complex geometry production with minimal setup, ensuring tight tolerance consistency across both metallic and engineering-grade plastic materials such as Aluminum, Steel, ABS, and Nylon.

From CAD to Part: The Process

Honyo Prototype Process for Clients Like Michigan CNC Tool Inc

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining partners such as Michigan CNC Tool Inc. The process begins with secure CAD file upload via our encrypted client portal, supporting industry-standard formats including STEP, IGES, Parasolid, and native SOLIDWORKS files. This ensures compatibility with complex geometries common in precision tooling applications.

| CAD Format | Compatibility Level | Notes |

|---|---|---|

| STEP (AP203/214) | Full | Recommended for multi-software workflows |

| IGES | High | Legacy format; minor surfacing checks |

| Parasolid (.x_t) | Full | Native kernel support |

| SOLIDWORKS | Full | Requires version 2018 or newer |

Following upload, our AI-powered quoting engine analyzes the geometry, material specifications, and tolerance requirements to generate a preliminary cost and lead time estimate within 2 hours. This system cross-references real-time machine availability, material stock levels, and historical production data but requires final validation by a senior manufacturing engineer to address nuanced factors like fixturing complexity or secondary operations.

The Design for Manufacturability (DFM) phase involves direct collaboration between Honyo’s engineering team and Michigan CNC Tool Inc.’s designers. We identify potential issues such as non-optimal wall thicknesses, tight tolerances in non-critical zones, or tool access constraints. Recommendations are provided via annotated 3D PDFs with actionable alternatives, typically reducing manufacturability risks by 30–40% while preserving functional intent. This step is mandatory for all first-article submissions to prevent costly rework during production.

Production leverages our network of 32 CNC machining centers, including 5-axis mills and high-speed lathes with sub-micron accuracy. Each run undergoes in-process inspections via calibrated CMMs and optical comparators at predefined checkpoints. For Michigan CNC Tool Inc.’s tooling components, we implement lot traceability with material certifications (e.g., EN 10204 3.1) and final first-article inspection reports per AS9102 standards where applicable.

Delivery includes consolidated shipping with real-time logistics tracking, packaged to prevent transit damage for precision components. All deliverables—parts, inspection reports, and material certs—are synchronized with the client’s ERP system via API integration, ensuring seamless inventory reconciliation. Typical lead times from CAD upload to dock shipment range from 5 to 12 business days depending on complexity, with 98.7% on-time delivery performance in Q1 2024.

Start Your Project

Request a quote today from Michigan CNC Tool Inc., your trusted partner for precision manufacturing solutions. Our state-of-the-art facility in Shenzhen delivers high-quality CNC machining, tooling, and prototyping services with fast turnaround times.

For sales inquiries and technical support, contact Susan Leo directly at [email protected]. Let us help you bring your next project to life with engineering excellence and reliable production capacity.

Contact Information

Name: Susan Leo

Email: [email protected]

Company: Michigan CNC Tool Inc.

Factory Location: Shenzhen, China

| Service Type | Capabilities | Lead Time |

|---|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling, turning | 5–15 days |

| Rapid Tooling | Mold design, steel & aluminum tooling | 2–6 weeks |

| Prototyping | Functional prototypes, bridge production | 3–10 days |

| Materials | Aluminum, steel, stainless, plastics | Custom options |

Reach out now to discuss your requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.