Introduction: Navigating the Global Market for metallic purple powder coat

In the ever-evolving landscape of industrial coatings, sourcing high-quality metallic purple powder coat can present unique challenges for international B2B buyers. With diverse applications ranging from automotive finishes to architectural elements, the demand for vibrant and durable coatings is on the rise. This comprehensive guide addresses critical aspects of the metallic purple powder coat market, including various types, applications, and essential supplier vetting processes. Buyers will also gain insights into cost considerations, ensuring they make informed purchasing decisions that align with their business needs.

Navigating the global market can be particularly daunting for businesses in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil. This guide empowers buyers by providing actionable insights into selecting the right powder coatings that not only meet aesthetic requirements but also adhere to regulatory standards. By understanding the nuances of different finishes—such as high gloss, satin, or wrinkle effects—buyers can enhance their product offerings and stand out in competitive markets.

Ultimately, this resource aims to equip international B2B buyers with the knowledge necessary to confidently source metallic purple powder coat, ensuring they achieve both quality and cost-effectiveness while fostering long-term supplier relationships.

Understanding metallic purple powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Gloss Metallic | Reflective finish with vibrant color depth | Automotive parts, decorative items | Pros: Eye-catching appearance; Cons: May show scratches easily. |

| Candy Purple | Transparent layer over a metallic base for depth | Custom automotive finishes | Pros: Unique color variations; Cons: Requires a careful application process. |

| Wrinkle Finish | Textured surface that hides imperfections | Industrial equipment, furniture | Pros: Durable; Cons: Limited color vibrancy compared to smooth finishes. |

| Illusion Purple | Holographic effect that changes appearance with light | High-end automotive, art pieces | Pros: Striking visual appeal; Cons: Higher cost due to complexity. |

| Semi-Gloss Plum | Rich plum color with a balanced sheen | Home decor, architectural elements | Pros: Versatile aesthetic; Cons: May require additional top coats for durability. |

What are the Characteristics of High Gloss Metallic Purple Powder Coat?

High Gloss Metallic Purple powder coat features a highly reflective finish that enhances the vibrancy of the purple hue. This type is particularly suitable for automotive parts and decorative items where a striking appearance is paramount. Buyers should consider the potential for scratches and the need for careful handling to maintain the finish. Its aesthetic appeal is a significant draw for businesses looking to create standout products.

How Does Candy Purple Differ from Other Variations?

Candy Purple is distinguished by its transparent layer applied over a metallic base, creating a rich depth of color that shifts under different lighting conditions. This type is commonly used in custom automotive finishes and specialty projects. While it offers unique color variations, buyers must be aware of the careful application process required to achieve the desired effect, which can add to labor costs.

Why Choose Wrinkle Finish for Industrial Applications?

Wrinkle Finish powder coat presents a textured surface that effectively hides imperfections, making it a practical choice for industrial equipment and furniture. Its durability is a key benefit, providing long-lasting protection against wear and tear. However, the limited vibrancy in color compared to smooth finishes may deter some buyers seeking a more polished look.

What Makes Illusion Purple a Premium Choice?

Illusion Purple powder coat features a holographic effect that creates a dynamic appearance, changing with light angles. This type is often used in high-end automotive applications and artistic pieces where visual impact is crucial. While it offers an eye-catching aesthetic, the higher cost associated with this complexity can be a consideration for budget-conscious buyers.

How Does Semi-Gloss Plum Fit into Various Applications?

Semi-Gloss Plum provides a rich plum color with a balanced sheen, making it versatile for home decor and architectural elements. This finish is appealing for its aesthetic versatility but may require additional top coats for enhanced durability. Buyers should evaluate the specific application needs to ensure that the chosen finish meets their long-term performance expectations.

Key Industrial Applications of metallic purple powder coat

| Industry/Sector | Specific Application of metallic purple powder coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom vehicle parts and accessories | Enhances aesthetics and brand differentiation | Ensure UV resistance and compatibility with local climate |

| Architectural & Design | Decorative architectural elements | Provides a unique visual appeal and durability | Verify color consistency and finish quality |

| Consumer Electronics | Housing for electronic devices | Offers scratch resistance and a premium look | Check for thermal stability and compliance with safety standards |

| Furniture | Outdoor and indoor furniture finishes | Increases lifespan and maintenance ease | Assess chemical resistance and weather durability |

| Powersports | Motorcycle and ATV components | Improves corrosion resistance and custom styling | Confirm availability of specific shades and finishes |

How is metallic purple powder coat used in the automotive industry?

In the automotive sector, metallic purple powder coat is often utilized for custom vehicle parts and accessories, including wheels, grilles, and trim. This coating enhances the aesthetic appeal of vehicles, allowing manufacturers and aftermarket providers to offer distinctive designs that stand out in a competitive market. Buyers should prioritize sourcing coatings with excellent UV resistance to withstand harsh weather conditions, particularly in regions like Africa and South America where exposure to sunlight is significant.

What are the architectural applications of metallic purple powder coat?

Metallic purple powder coat serves as a decorative finish for various architectural elements, such as railings, facades, and outdoor furniture. Its unique visual appeal not only enhances the design but also provides durability against environmental factors. For international buyers, ensuring color consistency and high-quality finish is crucial, as these elements directly impact the overall aesthetic and longevity of the installations.

In what ways is metallic purple powder coat applied in consumer electronics?

In the consumer electronics industry, metallic purple powder coat is applied to housings and casings for devices such as smartphones, laptops, and gaming consoles. This coating offers not only a premium look but also scratch resistance, which is vital for maintaining product aesthetics over time. Buyers should consider thermal stability and compliance with safety standards to ensure that the coating does not compromise the functionality or safety of the devices.

How does metallic purple powder coat benefit the furniture industry?

Metallic purple powder coat is increasingly used in the furniture industry for both indoor and outdoor finishes. This application enhances the lifespan of furniture by providing a protective layer against scratches and weather elements, making maintenance easier for consumers. Buyers should assess the chemical resistance and weather durability of the powder coat to ensure it meets the specific needs of their target markets, particularly in regions with diverse climates.

Why is metallic purple powder coat popular in powersports?

In the powersports industry, metallic purple powder coat is commonly applied to motorcycle and ATV components, enhancing both performance and style. The coating improves corrosion resistance, which is essential for parts exposed to the elements. When sourcing, it is important for buyers to confirm the availability of specific shades and finishes to meet customer preferences, as personalization is a key trend in this sector.

3 Common User Pain Points for ‘metallic purple powder coat’ & Their Solutions

Scenario 1: Difficulty Achieving Color Consistency

The Problem: B2B buyers often face challenges in achieving consistent color across batches of metallic purple powder coat. Variations in the manufacturing process or differences in application techniques can lead to noticeable discrepancies in hue and finish. This inconsistency can be particularly problematic for businesses in industries like automotive or consumer goods, where brand image is tied to color accuracy.

The Solution: To ensure color consistency, buyers should establish a robust color matching process. This includes obtaining color swatches from suppliers and performing test applications before committing to large orders. It’s advisable to work closely with a trusted powder coating manufacturer that offers color matching services. Additionally, maintaining a controlled environment during application—such as consistent temperature and humidity—can further enhance color uniformity. Documenting the specific powder mix and application conditions will also help replicate the desired finish in future batches.

Scenario 2: Challenges with Surface Preparation

The Problem: Effective surface preparation is critical for the adhesion and longevity of metallic purple powder coat. However, many B2B buyers struggle with this aspect, often leading to poor finish quality, peeling, or bubbling. This issue can stem from inadequate cleaning, improper substrate selection, or insufficient pre-treatment, causing frustration and financial loss.

The Solution: Buyers should prioritize thorough surface preparation by implementing a multi-step cleaning and pre-treatment process. Start with a complete removal of any old coatings, oils, or contaminants using appropriate solvents or abrasive methods. Following this, a chemical or mechanical pre-treatment—like phosphating or sandblasting—should be applied to enhance adhesion. Testing the substrate’s compatibility with the chosen powder coat can also prevent future issues. Regular training sessions for staff on surface preparation techniques will ensure that best practices are consistently followed, improving the overall quality of finished products.

Scenario 3: Navigating Stock Availability and Custom Orders

The Problem: Another common pain point for B2B buyers is the availability of specific shades of metallic purple powder coat. Many suppliers may not stock every variant, and custom orders can lead to extended lead times and increased costs. This can disrupt production schedules and impact project timelines, especially when quick turnaround is essential.

The Solution: To mitigate stock availability issues, buyers should establish strong relationships with multiple suppliers. This allows for a broader range of options and the ability to source materials quickly. Additionally, buyers should consider investing in a small inventory of popular shades to avoid delays. When ordering custom colors, it’s beneficial to communicate clearly with suppliers about lead times and potential costs upfront. Implementing a forecasting system based on project timelines can also help in planning purchases effectively, ensuring that materials are on hand when needed and minimizing the risk of production disruptions.

Strategic Material Selection Guide for metallic purple powder coat

When selecting materials for metallic purple powder coating, it’s essential to consider various factors that influence performance, durability, and suitability for specific applications. Here, we analyze four common materials used in metallic purple powder coatings, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Polyester Powder Coatings?

Polyester powder coatings are among the most widely used materials for metallic purple finishes. They exhibit excellent weather resistance, UV stability, and a smooth finish, making them ideal for both indoor and outdoor applications. Polyester coatings are also known for their good chemical resistance and durability against corrosion.

Pros: Polyester coatings offer a balance of cost-effectiveness and performance, making them suitable for a wide range of applications, including automotive and architectural finishes. They can be formulated to achieve various gloss levels and textures.

Cons: While polyester coatings are durable, they may not withstand extreme temperatures as well as some other materials. Additionally, they can be more susceptible to scratching and chipping compared to tougher alternatives.

Impact on Application: Polyester coatings are compatible with a variety of substrates, but it’s crucial to ensure proper surface preparation for optimal adhesion.

Considerations for International Buyers: Compliance with local standards such as ASTM and DIN is vital. Buyers in regions like Africa and South America should consider the availability of polyester materials and local suppliers for consistent quality.

How Do Epoxy Powder Coatings Compare?

Epoxy powder coatings are known for their exceptional adhesion and chemical resistance, making them suitable for industrial applications. They provide a robust barrier against corrosion, especially in harsh environments.

Pros: Epoxy coatings are highly durable and can withstand high levels of wear and tear. They are particularly effective in protecting metal substrates from corrosive elements.

Cons: The primary limitation of epoxy coatings is their UV resistance; they can yellow or degrade when exposed to sunlight. This makes them less suitable for outdoor applications unless a topcoat is applied.

Impact on Application: Epoxy coatings are ideal for environments where chemical exposure is a concern, such as in manufacturing or processing facilities.

Considerations for International Buyers: Buyers must ensure that epoxy coatings meet local environmental regulations, especially regarding VOC emissions. Understanding the specific requirements in regions like the Middle East can help in compliance.

What Are the Advantages of Polyurethane Powder Coatings?

Polyurethane powder coatings offer superior flexibility and abrasion resistance, making them ideal for high-performance applications. They are often used in automotive and industrial sectors where durability is paramount.

Pros: Polyurethane coatings provide excellent gloss retention and color stability, even under harsh conditions. They are also available in a variety of finishes, enhancing aesthetic appeal.

Cons: The complexity of the application process can increase manufacturing costs. Additionally, polyurethane coatings may require a primer for optimal adhesion, adding another layer to the application process.

Impact on Application: These coatings are suitable for a variety of substrates and can be tailored for specific performance needs, such as enhanced scratch resistance.

Considerations for International Buyers: Buyers should be aware of the specific application techniques required for polyurethane coatings and ensure that local applicators are trained in these methods to maintain quality.

How Do Thermoplastic Powder Coatings Perform?

Thermoplastic powder coatings are known for their flexibility and can be reprocessed, making them unique among powder coatings. They are often used in applications requiring impact resistance and repairability.

Pros: The ability to reprocess thermoplastic coatings makes them highly versatile. They are also resistant to chemicals and can withstand high temperatures.

Cons: Thermoplastic coatings may not provide the same level of finish or aesthetic appeal as other powder coatings. Additionally, their application can be more complex and may require specialized equipment.

Impact on Application: These coatings are particularly effective in environments where parts may be subject to impact or abrasion, such as in the automotive or aerospace industries.

Considerations for International Buyers: Buyers should consider the availability of specialized application equipment and trained personnel in their regions, particularly in emerging markets.

Summary Table of Material Selection for Metallic Purple Powder Coat

| Material | Typical Use Case for metallic purple powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Automotive and architectural finishes | Excellent weather resistance and UV stability | Less durable against extreme temperatures | Medium |

| Epoxy | Industrial applications | Exceptional adhesion and corrosion resistance | Poor UV resistance; may yellow outdoors | Medium |

| Polyurethane | High-performance automotive and industrial | Superior flexibility and gloss retention | Higher application complexity and cost | High |

| Thermoplastic | Impact-resistant applications | Reprocessability and flexibility | Less aesthetic appeal and complex application | Medium |

This guide provides a comprehensive overview of material options for metallic purple powder coatings, enabling international B2B buyers to make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metallic purple powder coat

What Are the Key Stages in the Manufacturing Process of Metallic Purple Powder Coat?

The manufacturing of metallic purple powder coat involves several critical stages, each essential to ensuring a high-quality finish.

Material Preparation

The process begins with the selection of raw materials, which typically include resin, pigments, and additives. For metallic purple powder coats, specific metallic flakes are also integrated to achieve the desired visual effect. The raw materials are weighed and mixed in precise proportions to create a homogenous blend. This mixture is then extruded through a process that involves heating and forcing the materials through a die, creating a continuous strand of powder.

Forming and Size Reduction

Once extruded, the strands are cooled and broken into smaller particles. The size of these particles is crucial as it affects the powder’s flow characteristics and application efficiency. The powder is then classified using air classification techniques to ensure uniformity in particle size, which is vital for achieving a smooth finish during application.

Finishing Techniques

After classification, the powder may undergo surface treatments or be blended with additional materials to enhance its properties, such as UV resistance or chemical durability. This stage may also include the application of a base coat or top coat to enhance the metallic effect and improve adhesion to the substrate.

How Is Quality Control Implemented in the Powder Coating Manufacturing Process?

Quality assurance in the manufacturing of metallic purple powder coat is paramount, particularly given the diverse markets served by B2B buyers. Several international standards and industry-specific certifications guide these processes.

What International Standards Guide Quality Assurance in Powder Coating?

Manufacturers often adhere to ISO 9001, which sets the criteria for a quality management system. This standard helps ensure that products meet customer and regulatory requirements consistently. Additionally, certifications like CE mark for European markets and API standards for certain industrial applications may be applicable, depending on the specific use case of the powder coat.

What Are the Critical Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process. Key stages include:

-

Incoming Quality Control (IQC): This initial checkpoint involves testing raw materials for compliance with specifications before they are used in production.

-

In-Process Quality Control (IPQC): During production, samples of the powder are periodically tested for particle size distribution, color consistency, and other critical properties. This ensures that any deviations from the standard can be identified and corrected in real time.

-

Final Quality Control (FQC): After production, the finished powder coat undergoes comprehensive testing, which may include assessing the coating’s adhesion, durability, and visual appearance. This final inspection is crucial to ensure that the product meets all required standards before it reaches the customer.

What Common Testing Methods Are Used for Metallic Purple Powder Coat?

Several testing methods are employed to ensure the quality and performance of metallic purple powder coats:

-

Adhesion Testing: This evaluates how well the powder adheres to the substrate, which is critical for ensuring durability during use.

-

Corrosion Resistance Testing: Commonly conducted via salt spray tests (ASTM B117), this assesses the powder coat’s ability to withstand corrosive environments.

-

UV Resistance Testing: This measures how well the powder maintains its color and structural integrity when exposed to ultraviolet light over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to ensure product consistency and reliability.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed reports on quality control processes, including results from IQC, IPQC, and FQC stages. Regular audits by third-party organizations can provide additional assurance that the supplier is adhering to industry standards. Buyers should also look for any certifications that validate the supplier’s commitment to quality, such as ISO certifications.

How Do Quality Control Nuances Differ for International Buyers?

International buyers may face unique challenges, such as differing regulatory standards or market expectations. It is crucial for buyers to understand the specific requirements for their region, especially if the powder coat will be used in products that must comply with local regulations. Establishing clear communication with suppliers about these requirements can help mitigate risks.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for metallic purple powder coat is essential for B2B buyers aiming to ensure product quality and compliance. By familiarizing themselves with the key stages of production, relevant international standards, and effective quality control measures, buyers can make informed decisions that align with their specific needs and market requirements. This knowledge not only helps in choosing the right supplier but also in fostering long-term partnerships that emphasize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metallic purple powder coat’

In today’s competitive marketplace, sourcing metallic purple powder coat requires careful consideration to ensure quality and suitability for your specific applications. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the metallic purple powder coat. This includes aspects such as gloss level, finish type (e.g., high gloss, satin), and any specific durability or chemical resistance standards. Defining these specifications upfront will streamline your search and help you identify suppliers that can meet your needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in powder coating materials. Look for suppliers with a proven track record, positive customer reviews, and a portfolio showcasing their products. Utilize online marketplaces, industry-specific directories, and trade shows to gather a list of potential suppliers.

Step 3: Evaluate Product Quality and Compliance

Once you have a list of potential suppliers, request product samples to assess the quality of their metallic purple powder coat. Check for adherence to international standards and certifications, such as ISO 9001, which indicate a commitment to quality management. Additionally, inquire about the raw materials used and any testing protocols they follow to ensure consistency and performance.

Step 4: Assess Supplier Capabilities and Capacity

Understanding the supplier’s production capabilities is crucial for ensuring they can meet your demand. Inquire about their manufacturing processes, lead times, and whether they can accommodate custom orders or larger quantities. This will help you gauge their reliability and whether they can deliver on time.

Step 5: Verify Supplier Certifications

Confirm that potential suppliers hold relevant certifications that align with your industry standards. Certifications such as RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) are essential, especially if your products will be used in regulated markets. Verification of these certifications can mitigate risks associated with compliance and product safety.

Step 6: Request Detailed Quotations

When you narrow down your list of suppliers, request detailed quotations that include pricing, minimum order quantities, and shipping costs. Compare these quotes not only on price but also on the value offered, such as customer service, warranty terms, and after-sales support. This comprehensive approach will help you make an informed decision.

Step 7: Establish Clear Communication Channels

Once you select a supplier, establish clear communication channels for ongoing discussions. Effective communication is vital for addressing any issues that may arise during the procurement process. Ensure that both parties understand expectations regarding delivery schedules, product specifications, and any potential changes to orders.

By following this checklist, B2B buyers can navigate the complexities of sourcing metallic purple powder coat with confidence, ensuring they partner with suppliers that meet their quality and operational needs.

Comprehensive Cost and Pricing Analysis for metallic purple powder coat Sourcing

What Are the Key Cost Components in Sourcing Metallic Purple Powder Coat?

When sourcing metallic purple powder coat, several cost components come into play that impact the overall pricing structure. These include:

-

Materials: The cost of raw materials is significant, as the quality of the pigments and additives used can vary widely. High-quality metallic pigments, for instance, can increase costs but enhance the aesthetic and durability of the final product.

-

Labor: Labor costs encompass the workforce required for manufacturing, application, and quality control. Regions with higher labor costs will influence overall pricing, making it essential to consider the location of the supplier.

-

Manufacturing Overhead: This includes expenses related to the operation of the manufacturing facility, such as utilities, equipment depreciation, and administrative costs. Efficient production processes can help mitigate these costs.

-

Tooling: Custom tooling for specific applications or designs can add to the upfront costs. Buyers should factor in these expenses if they require unique finishes or specifications.

-

Quality Control (QC): Rigorous QC processes ensure that the powder coat meets industry standards and customer specifications. These processes can add to the cost but are critical for maintaining product integrity.

-

Logistics: Shipping and handling costs are influenced by the distance from the supplier, weight of the shipment, and chosen shipping method. International buyers must be particularly aware of these costs, as they can significantly affect the total expenditure.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Metallic Purple Powder Coat?

Several factors can influence the price of metallic purple powder coat, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in reduced per-unit costs due to economies of scale. Buyers should assess their needs carefully to leverage potential volume discounts.

-

Specifications and Customization: Custom colors or finishes can lead to higher prices. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials Quality and Certifications: Higher quality materials and relevant certifications (e.g., ISO, ASTM) can increase costs. However, investing in quality can lead to better performance and longevity, reducing total ownership costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly impact costs. Buyers should clearly understand their responsibilities regarding shipping, insurance, and tariffs.

What Buyer Tips Can Help in Negotiating Costs for Metallic Purple Powder Coat?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

-

Negotiate Prices and Terms: Engage suppliers in discussions about pricing, especially for larger orders. Negotiating payment terms can also help manage cash flow.

-

Assess Total Cost of Ownership (TCO): Beyond initial purchase price, consider long-term costs, including maintenance, application, and potential rework. A lower upfront cost may not always lead to the best TCO.

-

Be Aware of Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should consider currency fluctuations, import duties, and local market conditions when evaluating costs.

-

Research Local Suppliers: Local sourcing may reduce shipping costs and lead times. Explore regional suppliers who can meet your specifications without the added costs of international shipping.

Conclusion

While sourcing metallic purple powder coat involves various cost components and price influencers, strategic negotiation and thorough understanding of the market can lead to more favorable terms for international B2B buyers. By focusing on total cost considerations and leveraging volume discounts, businesses can optimize their purchasing strategy, ensuring quality and affordability in their powder coating needs.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier quotes.

Alternatives Analysis: Comparing metallic purple powder coat With Other Solutions

Exploring Alternatives to Metallic Purple Powder Coat

In the competitive landscape of industrial coatings, businesses often seek alternatives to metallic purple powder coat to meet specific application needs. Understanding the nuances of different coating technologies can help B2B buyers make informed decisions based on performance, cost, and application requirements. Below, we provide a comparative analysis of metallic purple powder coat against two viable alternatives: liquid paint and anodizing.

| Comparison Aspect | Metallic Purple Powder Coat | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | High durability; excellent resistance to UV and corrosion. | Moderate durability; prone to chipping and fading. | Superior corrosion resistance; enhances surface hardness. |

| Cost | Generally lower per unit for large applications; setup costs can be higher. | Variable costs; generally lower upfront but can add up with touch-ups. | Higher initial costs; requires specialized equipment. |

| Ease of Implementation | Requires specific equipment and skilled applicators; longer curing time. | Easier to apply; can be done with standard spray equipment. | Requires specialized processes; typically not DIY-friendly. |

| Maintenance | Minimal maintenance; resists chemicals and wear well. | Higher maintenance; may require regular touch-ups. | Low maintenance; however, surface can be scratched. |

| Best Use Case | Ideal for automotive, industrial, and decorative applications requiring durability. | Best for quick jobs, home applications, and where cost is a concern. | Perfect for aerospace, automotive, and applications requiring enhanced strength. |

What Are the Pros and Cons of Liquid Paint as an Alternative?

Liquid paint is a traditional coating method that provides a wide range of colors and finishes. One of its significant advantages is the ease of application; it can be sprayed on using standard equipment, making it accessible for many businesses. However, its durability does not match that of powder coatings, and it is prone to chipping and fading, particularly in harsh environments. For B2B buyers looking for a cost-effective solution for less demanding applications, liquid paint may be a suitable choice, but it may require more frequent maintenance and touch-ups.

How Does Anodizing Compare to Metallic Purple Powder Coat?

Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces. This method offers excellent corrosion resistance and increases surface hardness, making it ideal for high-performance applications in industries like aerospace and automotive. However, anodizing typically comes with a higher upfront cost and requires specialized equipment, which may not be feasible for all businesses. While it provides a durable finish, the range of colors is often limited compared to powder coating. For companies that prioritize performance and can invest in the necessary technology, anodizing presents a compelling alternative.

Making the Right Choice: Which Coating Solution Suits Your Needs?

When deciding between metallic purple powder coat and its alternatives, B2B buyers should consider their specific application requirements, budget constraints, and desired performance characteristics. For applications where durability and resistance to environmental factors are paramount, metallic purple powder coat is often the best choice. Conversely, if cost is a critical factor and the application does not face extreme conditions, liquid paint may suffice. For industries that require high strength and corrosion resistance, anodizing could be the optimal solution. Ultimately, the right choice will depend on the unique needs of the project and the operational capabilities of the business.

Essential Technical Properties and Trade Terminology for metallic purple powder coat

What Are the Key Technical Properties of Metallic Purple Powder Coat?

When sourcing metallic purple powder coat for industrial applications, understanding its technical properties is crucial for ensuring product quality and compatibility with specific projects. Here are several essential specifications:

-

Material Composition

Metallic purple powder coats are typically made from polyester or polyurethane resins, which contribute to their durability and aesthetic appeal. Polyester powders are known for their excellent weather resistance, making them suitable for outdoor applications. Polyurethane powders offer superior hardness and chemical resistance, ideal for automotive or industrial uses. Understanding the resin type helps buyers match the powder coat to their specific environmental conditions and performance needs. -

Gloss Level

The gloss level of a powder coat significantly affects its appearance and can range from matte to high gloss. For metallic purple finishes, gloss levels typically fall between 70% to 90% at 60 degrees, which is essential for aesthetic applications like automotive or decorative items. Higher gloss levels enhance the metallic effect but may require more maintenance to keep surfaces looking pristine. -

Chemical Resistance

The ability of a powder coat to resist chemicals is vital for applications in environments exposed to oils, solvents, or acids. Metallic purple powders often pass stringent chemical resistance tests, ensuring they maintain their integrity and appearance over time. For businesses, this means reduced maintenance costs and longer-lasting finishes. -

Application Method

Most metallic purple powder coats are applied using electrostatic spray techniques, requiring specific equipment and expertise. The recommended bake cycle (typically around 15 minutes at 390°F) is also critical to achieving the desired finish. Understanding the application method can help buyers assess their existing capabilities and determine if additional equipment or training is necessary. -

Coverage Rate

The coverage rate of a powder coat indicates how much area can be covered per pound of powder. This metric is essential for budgeting and material estimation, especially for large-scale projects. Buyers should inquire about the coverage rate to ensure they purchase sufficient quantities for their applications.

What Are Common Trade Terms Related to Metallic Purple Powder Coat?

Familiarity with industry jargon can streamline communication and negotiation processes for B2B buyers. Here are some key terms related to powder coating:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of powder coating, OEMs often specify unique colors and finishes, such as metallic purple, to meet their branding requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. For metallic powder coats, MOQs can vary significantly based on the manufacturer and the specific color or finish. Understanding MOQ is crucial for buyers to plan their orders and manage inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for a specific quantity of goods or services. When dealing with metallic purple powder coats, an RFQ helps buyers compare prices and terms from multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping, risk, and cost responsibilities effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For customized metallic purple powder coats, lead times can vary based on stock availability and manufacturing processes. Knowing lead times helps businesses plan their production schedules and avoid delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing metallic purple powder coats, ensuring that their selections meet both aesthetic and functional requirements.

Navigating Market Dynamics and Sourcing Trends in the metallic purple powder coat Sector

What Are the Key Market Dynamics and Trends in the Metallic Purple Powder Coat Sector?

The metallic purple powder coat sector is currently experiencing significant growth driven by various global trends. One of the primary factors is the rising demand for customized finishes across multiple industries, including automotive, architectural design, and consumer goods. As companies increasingly seek to differentiate their products, the unique aesthetic appeal of metallic purple coatings is becoming a popular choice. Additionally, advancements in powder coating technology are enabling manufacturers to produce more vibrant, durable, and environmentally friendly products.

B2B tech trends, such as the adoption of e-commerce platforms for sourcing materials, are reshaping how buyers interact with suppliers. International buyers from regions like Africa, South America, the Middle East, and Europe can now easily access a broader range of products and suppliers online. This shift is facilitating competitive pricing and faster delivery times, making it easier for businesses to find the right metallic purple powder coat solutions to meet their needs.

Moreover, sustainability is influencing purchasing decisions. Companies are increasingly prioritizing suppliers who demonstrate a commitment to eco-friendly practices, which is prompting manufacturers to innovate in their product offerings. In this dynamic market, buyers must stay informed about emerging trends, technological advancements, and shifting consumer preferences to make strategic sourcing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Metallic Purple Powder Coat Market?

Sustainability is becoming a cornerstone of the metallic purple powder coat sector, driven by both regulatory pressures and consumer expectations. The environmental impact of powder coating processes, including VOC emissions and waste generation, is prompting manufacturers to adopt greener practices. This includes using low-VOC or VOC-free formulations and implementing recycling programs for powder overspray, significantly reducing waste.

Ethical sourcing is also gaining traction, with buyers increasingly scrutinizing their supply chains. The importance of transparency in sourcing materials cannot be overstated, as businesses aim to align with suppliers who share their values regarding social responsibility and environmental stewardship. Buyers should look for suppliers that possess relevant certifications, such as ISO 14001 for environmental management or other green certifications that demonstrate a commitment to sustainability.

Investing in products made from sustainably sourced materials not only enhances a company’s brand reputation but also meets the growing demand for environmentally responsible products. By prioritizing ethical sourcing, businesses can contribute to a more sustainable future while ensuring they meet regulatory requirements and consumer expectations.

What Is the Historical Context of the Metallic Purple Powder Coat Industry?

The metallic powder coating industry has evolved significantly since its inception in the 1960s. Initially, powder coatings were primarily used for industrial applications due to their durability and efficiency. Over the decades, advancements in formulation technology allowed for a broader range of colors and finishes, including the vibrant metallic purples that are now popular in consumer products and specialty applications.

The 1990s marked a pivotal point as manufacturers began to recognize the aesthetic potential of powder coatings, leading to their adoption in automotive finishes and architectural designs. The introduction of sophisticated application techniques and equipment further enhanced the appeal of metallic finishes. As the industry continues to evolve, the demand for metallic purple powder coatings is expected to grow, driven by innovation, customization, and sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of metallic purple powder coat

-

How do I choose the right metallic purple powder coat for my project?

Selecting the appropriate metallic purple powder coat involves considering the desired finish, application method, and substrate. Evaluate the gloss level (high gloss, satin, or matte) and whether you need a transparent or opaque coating. Some finishes may require a base coat to achieve the desired color depth. It’s advisable to request samples or swatches to compare colors directly and see how they appear on your specific materials. -

What is the best application method for metallic purple powder coat?

The best application method depends on your equipment and the specific powder coat. Electrostatic spray application is commonly used, providing an even coat and reducing waste. Ensure your oven can reach the required curing temperature, typically around 350-400°F (177-204°C) for 10-20 minutes. Always consult the manufacturer’s guidelines for specific application instructions to achieve optimal results. -

What are the typical minimum order quantities (MOQs) for metallic purple powder coats?

Minimum order quantities for metallic purple powder coats vary by supplier and can range from as low as 5 kg to several hundred kilograms. It’s essential to clarify MOQs when sourcing to ensure they align with your production needs. Some suppliers may offer flexibility based on order frequency or long-term contracts, so it’s beneficial to discuss your requirements directly with them. -

How can I verify the quality of metallic purple powder coat before purchasing?

To ensure quality, request certification for compliance with industry standards, such as ASTM or ISO. Additionally, ask for samples to conduct adhesion, hardness, and corrosion resistance tests. Reviews and testimonials from previous clients can provide insights into the supplier’s reliability and product performance. Engaging in a trial order can also be a prudent approach before committing to larger quantities. -

What payment terms are typically offered by suppliers of metallic purple powder coats?

Payment terms vary widely among suppliers. Common arrangements include upfront payments, net 30 or net 60 days, and letters of credit for larger international transactions. Always negotiate terms that align with your cash flow and risk tolerance. Establishing a good relationship with suppliers can often lead to more favorable terms over time. -

What logistics considerations should I keep in mind when importing metallic purple powder coat?

When importing, consider shipping methods, lead times, and customs regulations in your country. Ensure that the supplier provides documentation for customs clearance, including invoices, certificates of origin, and safety data sheets. Shipping costs can vary significantly based on weight, volume, and destination, so obtaining quotes from multiple logistics providers can help in budgeting. -

Can I customize the color or finish of metallic purple powder coat?

Yes, many suppliers offer customization options for color matching and finish types. You can provide a Pantone color or a physical sample for accurate matching. Be aware that custom colors may have longer lead times and higher costs. It’s advisable to discuss your specific requirements with the supplier early in the process to ensure they can accommodate your needs. -

What factors influence the price of metallic purple powder coat?

Pricing for metallic purple powder coat is influenced by several factors including the quality of the materials, finish complexity, and order volume. Specialty powders with unique effects or higher durability typically cost more. Additionally, international shipping costs, tariffs, and local market conditions can affect overall pricing. Always request detailed quotes and compare them across suppliers to ensure competitive pricing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Metallic Purple Powder Coat Manufacturers & Suppliers List

1. The Powder Coat Store – Purple Powder Coating Paints

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: Purple powder coating paints including flat, satin, high gloss, candy and wrinkle finishes. Products available: 1. Transparent Candy Purple Powder Coating Paint – 1 LB – From $11.49 – Rating: 5.0 (11 reviews) 2. High Gloss Purple Powder Coating Paint – 1 LB – From $7.99 – Rating: 5.0 (9 reviews) 3. Dormant Purple Powder Coating Paint – 1 LB – From $15.99 – Rating: 5.0 (3 reviews) – Sold out 4. Can…

2. Eastwood – Hotcoat Powder Metallic Purple

Domain: eastwood.com

Registered: 1995 (30 years)

Introduction: Hotcoat Powder Metallic Purple is a high-quality powder coating designed for a durable and attractive finish. It features a vibrant metallic purple color, suitable for various applications including automotive, home, and industrial uses. The powder is easy to apply and provides excellent coverage, ensuring a smooth and even finish. It is resistant to chipping, scratching, and fading, making it ide…

3. PPG – Purple Powder Coatings

Domain: powdercoatings.ppg.com

Registered: 1990 (35 years)

Introduction: This company, PPG – Purple Powder Coatings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

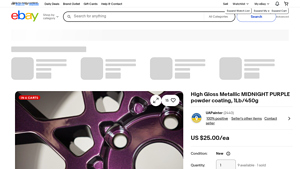

4. High Gloss Metallic MIDNIGHT PURPLE Powder Coating – 1Lb

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “High Gloss Metallic MIDNIGHT PURPLE powder coating”, “weight”: “1Lb/450g”, “condition”: “New”, “price”: “$25.00/ea”, “shipping_cost”: “$18.00”, “estimated_delivery”: “Wed, Aug 6 – Tue, Aug 19”, “bulk_savings”: [{“quantity”: 1, “price”: “$25.00/ea”}, {“quantity”: 2, “price”: “$22.50/ea”}, {“quantity”: 3, “price”: “$22.00/ea”}, {“quantity”: 4, “price”: “$21.25/ea”}, {“quantity”: 5,…

5. Columbia Coatings – Dormant Purple TGIC

Domain: columbiacoatings.com

Registered: 2001 (24 years)

Introduction: {“name”: “Dormant Purple TGIC”, “price_per_pound”: {“1-9”: “$31.46”, “10-24”: “$30.61”, “25-43”: “$27.78”, “44+”: “$25.87”}, “description”: “A rich candy purple with no sparkles”, “application_instructions”: “Partial Cure: 15 min. total time in oven preheated to 400ºF. Then apply our Super Mirror Clear and fully cure.”, “availability”: “In Stock”, “shipping_time”: “Usually ships In 1-2 Business Da…

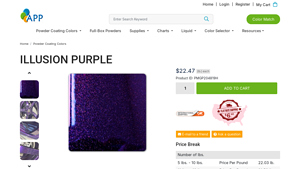

6. All Powder Paints – Illusion Purple

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: {“name”: “Illusion Purple”, “price”: “$22.47 (lb.)”, “product_id”: “PMGP204819H”, “price_breaks”: [{“weight_range”: “5 lbs. – 10 lbs.”, “price_per_pound”: “$22.03”}, {“weight_range”: “11 lbs. – 19 lbs.”, “price_per_pound”: “$21.52”}, {“weight_range”: “20 lbs. – 29 lbs.”, “price_per_pound”: “$20.98”}, {“weight_range”: “30 lbs. – 39 lbs.”, “price_per_pound”: “$20.18”}, {“weight_range”: “40 lbs. – 20…

7. Prismatic Powders – Purple Powder Coated Auto Parts

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Purple Powder Coat for auto parts and rims, featuring various shades of purple. Includes products like Prismatic Powders – Powder Coated Purple Metallic Toyota Wheels, Lift Kits in Clear Vision and Illusion Violet, Scion Tc Wheels in Lazer Purple, and 22″ Aluminum Rims in Illusion Purple. Offers customization options for any color and quantity. Provides tips on preparing rims for powder coating, m…

8. PPG – Purple Starlight Powder Coating

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Purple Starlight Powder Coating from PPG

Strategic Sourcing Conclusion and Outlook for metallic purple powder coat

As the demand for metallic purple powder coat continues to rise across various industries, strategic sourcing becomes crucial for international B2B buyers. The ability to identify reliable suppliers offering diverse finishes—from high gloss to candy and wrinkle effects—ensures that businesses can meet the aesthetic and functional needs of their projects. Furthermore, understanding regional preferences and the availability of specific shades can significantly influence sourcing decisions, especially in markets like Africa, South America, the Middle East, and Europe.

Investing in high-quality metallic purple powder coatings not only enhances product appeal but also contributes to durability and performance. Buyers should prioritize partnerships with manufacturers who offer transparent pricing, detailed product specifications, and responsive customer service. This approach not only mitigates risks but also fosters long-term collaborations that can adapt to changing market dynamics.

Looking ahead, the metallic purple powder coat sector is poised for innovation, with advancements in color technology and application techniques. International B2B buyers are encouraged to stay informed about emerging trends and to leverage strategic sourcing to gain a competitive edge. Engage with suppliers today to explore how metallic finishes can elevate your products and meet evolving customer demands.