Introduction: Navigating the Global Market for metallic grey powder coat

In today’s competitive global market, sourcing high-quality metallic grey powder coat can be a daunting task for international B2B buyers. The challenge lies not only in finding suppliers who meet specific quality standards but also in navigating the complexities of pricing, application methods, and regional compliance regulations. This guide aims to demystify the procurement process for metallic grey powder coat, providing insights into various types, their applications across industries, and essential supplier vetting strategies.

We will delve into the nuances of different finishes, including semi-gloss and high-gloss options, that cater to diverse aesthetic and functional requirements, from automotive to architectural applications. Additionally, our comprehensive analysis includes a breakdown of cost factors, ensuring that businesses can make informed financial decisions while maximizing value.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Brazil—this guide equips you with the knowledge needed to confidently navigate the global supply chain. By the end of this resource, you will have the tools to identify reliable suppliers, understand pricing structures, and select the most suitable metallic grey powder coat for your business needs, empowering you to achieve both quality and cost-effectiveness in your projects.

Understanding metallic grey powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Metallic Grey | Dark silver/grey with a semi-gloss finish | Automotive, industrial equipment | Pros: Versatile, cost-effective. Cons: May require a top coat for durability. |

| Charcoal Grey Metallic | Heavy silver metallic flake with high gloss finish | Architectural applications, furniture | Pros: High aesthetic appeal, durable. Cons: Higher cost compared to standard variants. |

| Anthracite Grey Metallic | Deep, dark grey with a matte finish | Home appliances, consumer electronics | Pros: Modern look, excellent for high-tech products. Cons: Matte finish can show fingerprints. |

| Steel Grey | Sparkle effect under sunlight | Outdoor furniture, automotive parts | Pros: Unique visual appeal, good weather resistance. Cons: Limited color matching options. |

| Dark Grey Metallic | Rich grey tone with a smooth finish | Industrial tools, machinery | Pros: Professional appearance, easy to clean. Cons: May fade under prolonged UV exposure. |

What are the characteristics of Standard Metallic Grey Powder Coat?

Standard Metallic Grey is characterized by its dark silver hue and semi-gloss finish, making it a popular choice for a wide range of applications. This type of powder coat is versatile and cost-effective, often used in automotive and industrial equipment. When purchasing, consider the need for a top coat to enhance durability and weather resistance, especially in outdoor applications.

How does Charcoal Grey Metallic differ from other types?

Charcoal Grey Metallic features a heavy silver metallic flake and is known for its high gloss finish. It is often used in architectural applications and furniture, providing a sophisticated aesthetic. While it offers durability and a striking appearance, buyers should be aware of its higher cost compared to standard variants, which may affect budget considerations.

Why choose Anthracite Grey Metallic for high-tech products?

Anthracite Grey Metallic is distinguished by its deep, dark grey color and matte finish, making it an excellent choice for home appliances and consumer electronics. Its modern look appeals to contemporary designs, but buyers should note that matte finishes can show fingerprints more easily than glossy options. This factor is crucial for products where appearance is paramount.

What benefits does Steel Grey offer for outdoor applications?

Steel Grey powder coat is notable for its sparkle effect when exposed to sunlight, making it ideal for outdoor furniture and automotive parts. Its unique visual appeal is complemented by good weather resistance. However, buyers should consider the limited color matching options available, which may restrict design flexibility.

What are the advantages of using Dark Grey Metallic in industrial settings?

Dark Grey Metallic provides a rich grey tone with a smooth finish, suitable for industrial tools and machinery. Its professional appearance and ease of cleaning make it a practical choice for B2B applications. However, potential buyers should be aware that prolonged exposure to UV light can lead to fading, which may impact long-term aesthetics.

Key Industrial Applications of metallic grey powder coat

| Industry/Sector | Specific Application of metallic grey powder coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wheel rims and chassis components | Enhances aesthetic appeal while providing corrosion resistance | Ensure compliance with automotive industry standards and specifications. |

| Architectural & Design | Exterior metal fixtures and furniture | Offers a modern, sleek finish that is durable and weather-resistant | Look for suppliers with a variety of finishes and custom color options. |

| Industrial Equipment | Machinery and equipment housings | Protects against wear and tear, extending equipment lifespan | Consider the powder’s heat resistance and chemical compatibility. |

| Consumer Electronics | Enclosures for electronics and appliances | Improves product durability while allowing for stylish designs | Prioritize sourcing from manufacturers with high-quality control standards. |

| Powersports | Parts for motorcycles and ATVs | Provides a visually appealing finish that withstands harsh conditions | Check for UV resistance and flexibility in color matching. |

How is Metallic Grey Powder Coat Used in the Automotive Sector?

In the automotive industry, metallic grey powder coat is primarily utilized for wheel rims and chassis components. This application not only enhances the visual appeal of vehicles but also provides significant corrosion resistance, essential for prolonging the lifespan of automotive parts exposed to harsh environmental conditions. For international buyers, particularly in regions like Africa and South America, sourcing high-quality powder coatings that comply with automotive industry standards is crucial to ensure durability and performance.

What are the Architectural and Design Applications of Metallic Grey Powder Coat?

Metallic grey powder coat is popular in architectural and design sectors, used for exterior metal fixtures and furniture. Its modern, sleek finish complements various architectural styles while offering durability against weather conditions. Buyers from Europe and the Middle East should consider suppliers that provide a range of finishes, ensuring the coating meets aesthetic requirements and functional durability for outdoor applications.

How Does Metallic Grey Powder Coat Benefit Industrial Equipment?

For industrial equipment, metallic grey powder coat is applied to machinery and equipment housings. This protective layer guards against wear and tear, significantly extending the lifespan of equipment in demanding environments. B2B buyers must assess the powder’s heat resistance and chemical compatibility to ensure it meets the specific operational requirements of their machinery, particularly in regions with varying climate conditions.

Why is Metallic Grey Powder Coat Ideal for Consumer Electronics?

In the consumer electronics sector, metallic grey powder coat is used for enclosures of devices and appliances. This application not only enhances durability but also allows for stylish designs that appeal to modern consumers. International buyers should prioritize sourcing from manufacturers with stringent quality control standards to ensure that the coatings can withstand the rigors of daily use and provide a long-lasting finish.

What Role Does Metallic Grey Powder Coat Play in Powersports?

Metallic grey powder coat is extensively used in powersports for parts of motorcycles and ATVs. This coating provides a visually appealing finish while ensuring that the components can withstand the harsh conditions typical in outdoor sports. Buyers should verify the UV resistance and flexibility in color matching when sourcing these coatings, particularly in markets like Brazil and Vietnam, where outdoor activities are prevalent.

3 Common User Pain Points for ‘metallic grey powder coat’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Color Match

The Problem: One of the significant challenges B2B buyers face when sourcing metallic grey powder coat is ensuring a consistent color match across different batches. This inconsistency can lead to discrepancies in the final product appearance, especially when parts are painted at different times or locations. Such variations can affect brand integrity and client satisfaction, particularly for businesses in industries like automotive or high-end consumer goods where aesthetics are critical.

The Solution: To overcome color matching issues, buyers should establish a robust communication process with suppliers. It is advisable to request sample swatches or color chips before placing large orders. Utilizing a standardized color matching system, such as the RAL color chart, can also help ensure consistency. Additionally, buyers should consider using the same supplier for subsequent orders to minimize variations. Implementing a quality control process that includes visual inspections of the powder coat application can further ensure that the final product meets color specifications.

Scenario 2: Performance Limitations in Harsh Environments

The Problem: Metallic grey powder coats may not always provide the necessary durability in harsh environmental conditions, such as extreme temperatures, UV exposure, or chemical exposure. For industries operating in challenging environments, like construction or manufacturing, this can lead to premature wear, fading, or corrosion, affecting product longevity and increasing maintenance costs.

The Solution: To ensure the metallic grey powder coat meets the required performance standards, buyers should specify the appropriate powder formulation tailored for their specific environmental conditions. Researching and selecting a high-quality polyester or epoxy-based powder coat designed for durability can make a significant difference. Additionally, buyers should work closely with suppliers to understand the product’s specifications, such as the gloss level and UV resistance. Conducting field tests on coated samples before full-scale application can also help assess the powder coat’s performance under real-world conditions.

Scenario 3: Limited Application Options and Techniques

The Problem: Many B2B buyers encounter limitations regarding the application methods for metallic grey powder coats. Different application techniques, such as electrostatic spray or fluidized bed coating, can yield varying results. Inadequate knowledge of these techniques can lead to poor adhesion, uneven coverage, or undesirable texture, ultimately affecting the final product’s quality.

The Solution: To address application challenges, buyers should invest in training for their applicators on the specific techniques suited for metallic grey powder coats. Engaging with suppliers who offer training sessions or resources can enhance applicator skills and knowledge. Buyers should also consider investing in high-quality application equipment that can handle metallic powders effectively. Regular maintenance of spray guns and booths can ensure optimal performance. Additionally, establishing a standardized application process and conducting periodic reviews can help maintain quality control throughout the coating process.

Strategic Material Selection Guide for metallic grey powder coat

What Are the Key Materials Used for Metallic Grey Powder Coating?

When selecting a metallic grey powder coat for various applications, it is essential to consider the materials used in the powder formulation. Each material offers unique properties that can significantly influence the performance, cost, and suitability of the final product. Here, we analyze four common materials used in metallic grey powder coatings: polyester, epoxy, polyurethane, and acrylic.

How Does Polyester Affect Metallic Grey Powder Coat Performance?

Polyester is one of the most widely used materials for metallic powder coatings due to its excellent durability and aesthetic appeal. It provides good resistance to UV light, making it suitable for outdoor applications. Polyester coatings typically have a temperature rating of up to 200°C and can withstand moderate chemical exposure.

Pros: Polyester coatings are known for their vibrant colors and gloss retention, which are crucial for aesthetic applications. They are also relatively cost-effective and easy to apply, making them suitable for high-volume production.

Cons: While polyester offers good weather resistance, it may not be as effective against harsh chemicals compared to other materials. Additionally, it can be more prone to chipping and scratching.

International Considerations: Buyers in regions such as Africa and the Middle East should ensure compliance with local environmental regulations regarding VOC emissions, as polyester formulations can vary in this regard.

What Role Does Epoxy Play in Metallic Grey Powder Coating?

Epoxy powder coatings are known for their excellent adhesion and chemical resistance. They are often used in industrial applications where durability is paramount. Epoxy coatings can withstand temperatures of up to 250°C and provide a robust barrier against corrosion.

Pros: The superior chemical resistance makes epoxy ideal for manufacturing environments and outdoor equipment. It also offers exceptional hardness and toughness, which enhances the longevity of the coated products.

Cons: Epoxy coatings can be less UV resistant than polyester, leading to potential fading when exposed to sunlight. They are also generally more expensive and may require more complex application processes.

International Considerations: Compliance with ASTM standards is crucial for epoxy coatings, especially in regions like Europe where regulatory scrutiny is high. Buyers should also consider the availability of skilled applicators familiar with epoxy systems.

How Does Polyurethane Enhance Metallic Grey Powder Coating Applications?

Polyurethane powder coatings are recognized for their outstanding flexibility and resistance to abrasion. They can handle temperatures up to 200°C and provide excellent protection against UV light and chemicals.

Pros: The flexibility of polyurethane makes it suitable for applications requiring impact resistance, such as automotive parts and outdoor furniture. Its gloss retention and color stability are also noteworthy.

Cons: Polyurethane coatings can be more expensive than polyester or epoxy options. They may also require specific curing conditions to achieve optimal performance, adding complexity to the manufacturing process.

International Considerations: Buyers from South America and Europe should be aware of the specific environmental regulations surrounding the use of polyurethane, particularly in relation to its chemical composition and emissions during application.

What Are the Benefits of Using Acrylic in Metallic Grey Powder Coating?

Acrylic powder coatings are known for their brilliant color and gloss, making them a popular choice for decorative applications. They can withstand temperatures of up to 180°C and provide good weather resistance.

Pros: Acrylic coatings offer excellent aesthetic qualities and are easy to apply. They are also less prone to yellowing over time compared to other materials, maintaining their appearance longer.

Cons: While they are visually appealing, acrylic coatings may not provide the same level of durability and chemical resistance as epoxy or polyurethane options. They can also be more susceptible to scratching.

International Considerations: Buyers in regions with stringent safety regulations, such as the Middle East, should ensure that acrylic coatings meet local compliance standards, particularly regarding chemical safety.

Summary Table of Material Selection for Metallic Grey Powder Coating

| Material | Typical Use Case for metallic grey powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor furniture, automotive parts | Excellent UV resistance and color retention | Prone to chipping and scratching | Medium |

| Epoxy | Industrial equipment, outdoor structures | Superior chemical resistance and durability | Less UV resistant, higher cost | High |

| Polyurethane | Automotive parts, outdoor furniture | Outstanding flexibility and abrasion resistance | More expensive, complex application | High |

| Acrylic | Decorative items, consumer goods | Brilliant color and gloss retention | Less durable, susceptible to scratching | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions regarding metallic grey powder coatings, considering both performance and compliance factors across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for metallic grey powder coat

What Are the Main Stages of Manufacturing Metallic Grey Powder Coat?

The manufacturing process for metallic grey powder coat involves several critical stages, each contributing to the final product’s quality and performance. Here’s a breakdown of these stages:

-

Material Preparation: The process begins with the selection of high-quality raw materials, including resins, pigments, and additives. The choice of polyester or epoxy resin is crucial, as these materials influence the coating’s durability and finish. In this phase, raw materials are blended according to specific formulations to achieve the desired metallic grey color.

-

Forming: Once the raw materials are prepared, they undergo a process called extrusion. This involves heating the mixture until it becomes pliable, then forcing it through a die to form a continuous sheet. This sheet is then cooled and broken into small particles. The particle size is essential for ensuring even application and optimal coverage.

-

Assembly: In the context of powder coating, assembly refers to the blending of the powder with metallic flakes. This step enhances the metallic finish, giving the powder coat its characteristic appearance. The metallic flakes must be uniformly distributed to avoid clumping and ensure a consistent color throughout the batch.

-

Finishing: The final stage involves the application of the powder coat to the metal substrate. This is typically done using electrostatic spray guns, which charge the powder particles to ensure they adhere evenly to the surface. After application, the coated items are cured in an oven, allowing the powder to melt and form a durable, hard finish. The curing process is critical, as it directly affects the coating’s hardness, gloss, and resistance to environmental factors.

Which Key Techniques Are Employed in Manufacturing Metallic Grey Powder Coat?

Several techniques are vital in the production of metallic grey powder coat:

-

Electrostatic Spraying: This technique ensures an even and efficient application of powder to metal surfaces. The electrostatic charge causes the powder to adhere to the substrate, minimizing waste and ensuring a smooth finish.

-

Fluidized Bed Coating: This method involves suspending powder particles in a stream of air, allowing for an even coating on parts that may be difficult to reach with traditional spraying. It’s particularly useful for complex shapes.

-

Curing Technology: Advanced curing methods, such as infrared curing or convection ovens, are employed to ensure that the powder melts and adheres properly to the substrate. These technologies can significantly reduce curing times and improve energy efficiency.

How Is Quality Assurance Implemented in Metallic Grey Powder Coat Production?

Quality assurance (QA) is integral to the manufacturing process of metallic grey powder coat, ensuring that the final product meets international standards and customer expectations. Key elements of QA include:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, a widely recognized standard for quality management systems. Compliance with ISO 9001 assures buyers that the manufacturer has established processes for consistent quality and continual improvement.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be relevant. For example, products used in construction may need CE marking, while those for oil and gas industries could require API certifications.

-

Quality Control Checkpoints: The manufacturing process typically includes several quality control checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Monitoring occurs throughout the production process to catch any deviations from quality standards.

– Final Quality Control (FQC): The finished product undergoes rigorous testing to confirm it meets all quality specifications before shipment.

What Common Testing Methods Are Used in Quality Assurance?

To ensure the performance and durability of metallic grey powder coat, several testing methods are commonly employed:

-

Adhesion Testing: This assesses the bond strength between the powder coat and the substrate, ensuring it can withstand mechanical stresses without peeling or chipping.

-

Gloss Measurement: This determines the sheen of the finish, which is crucial for aesthetic applications.

-

Weathering Tests: These simulate environmental conditions to assess the coating’s resistance to UV light, humidity, and temperature fluctuations, ensuring long-term performance.

-

Thickness Measurement: This ensures that the coating is applied at the correct thickness to meet durability and aesthetic standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their quality control practices. This includes evaluating their manufacturing processes, equipment, and adherence to standards.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control measures, testing results, and certifications. These reports can help buyers assess the reliability of the product.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of a supplier’s quality control practices. This is particularly important for buyers in regions with varying standards of quality assurance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. Considerations include:

-

Understanding Regional Standards: Different regions may have varying standards and regulations governing powder coatings. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Logistical Considerations: Shipping times and costs can affect the supply chain, making it essential to work with suppliers who have efficient quality control processes to prevent delays.

-

Cultural Differences in Quality Expectations: Quality perceptions may vary across cultures. Establishing clear communication and expectations with suppliers can help mitigate misunderstandings and ensure that product quality meets international standards.

In conclusion, understanding the manufacturing processes and quality assurance practices for metallic grey powder coat is crucial for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring they partner with suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metallic grey powder coat’

Introduction

This sourcing guide serves as a practical checklist for international B2B buyers looking to procure metallic grey powder coat. With applications spanning various industries, understanding the nuances of sourcing this specific coating is essential for ensuring product quality, compliance, and cost-effectiveness. Follow this structured approach to streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to your sourcing strategy. Identify the exact shade of metallic grey you require, such as semi-gloss or high-gloss finishes, and any specific performance characteristics like durability, weather resistance, or application methods.

- Considerations: Look for detailed product descriptions and datasheets from manufacturers to understand the properties of the powder coat.

- Standards: Ensure your specifications align with industry standards and regulations relevant to your market.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for manufacturers and distributors with a solid reputation in the powder coating industry, especially those with experience in your target markets like Africa, South America, and Europe.

- Sources: Utilize online directories, trade shows, and industry publications to compile a list of potential suppliers.

- Reviews: Check customer reviews and testimonials to gauge the quality of products and services offered.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your potential suppliers possess the necessary certifications. This includes ISO certifications and compliance with environmental regulations, which can vary by region.

- Importance: Certifications indicate a supplier’s commitment to quality and sustainability, which can enhance your brand’s reputation.

- Documentation: Request copies of certifications and ensure they are current and relevant to your requirements.

Step 4: Request Samples and Test Performance

Always request samples of the metallic grey powder coat before placing a large order. Testing the samples for adhesion, finish quality, and resistance to elements will help you ascertain whether the product meets your expectations.

- Testing: Conduct a variety of tests, including gloss measurement, durability assessments, and compatibility with your application process.

- Feedback: Gather feedback from your production team on the application process and the final appearance of the coated product.

Step 5: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing structures and payment terms. Ensure that the prices align with your budget while also considering the overall value, including quality and service.

- Negotiation: Don’t hesitate to negotiate for better pricing, especially for bulk orders, as many suppliers offer discounts.

- Payment Options: Evaluate the payment options available and their implications on your cash flow and purchasing strategy.

Step 6: Review Logistics and Delivery Times

Consider the logistics involved in the procurement process, including shipping times and costs. Understanding the lead times for delivery is crucial, especially if you operate in regions with longer shipping durations.

- Supply Chain: Assess the supplier’s ability to meet your delivery timelines and their logistics capabilities, including international shipping if necessary.

- Contingencies: Discuss contingency plans in case of delays or stock shortages to minimize disruptions to your operations.

Step 7: Establish a Long-term Partnership

Once you have successfully procured the metallic grey powder coat, focus on establishing a long-term relationship with your supplier. Regular communication and feedback can lead to better service and future collaborations.

- Monitoring: Continuously monitor the performance of the powder coat in your applications and provide feedback to the supplier.

- Collaboration: Explore opportunities for joint product development or special color matching to enhance your offerings.

By following these steps, you can streamline the procurement process for metallic grey powder coat, ensuring that you make informed decisions that contribute to your business’s success.

Comprehensive Cost and Pricing Analysis for metallic grey powder coat Sourcing

Analyzing the cost structure and pricing for metallic grey powder coat sourcing is essential for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the various cost components and pricing influencers can help businesses make informed purchasing decisions and optimize their procurement strategies.

What Are the Key Cost Components for Metallic Grey Powder Coating?

The cost structure for metallic grey powder coating comprises several components:

-

Materials: The primary raw materials include polyester resins, metallic pigments, and additives. Prices can vary based on quality, with high-grade materials often yielding better finishes and durability.

-

Labor: Labor costs encompass the wages of skilled workers involved in the production process. In regions with higher labor costs, such as Europe, this can significantly impact the overall price.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance of equipment, and factory operations. Efficient production processes can help minimize these costs.

-

Tooling: Customization may require specific tooling, which adds to the initial investment. Buyers should consider whether the supplier can accommodate their specific requirements without excessive tooling costs.

-

Quality Control (QC): Ensuring that the powder coating meets industry standards necessitates quality control measures. This involves testing batches for consistency and performance, contributing to the overall cost.

-

Logistics: Shipping and handling fees can vary significantly based on distance and shipping methods. International buyers must factor in customs duties and potential delays.

-

Margin: Suppliers will typically add a profit margin, which can vary based on market competition and the perceived value of the product.

How Do Price Influencers Impact Metallic Grey Powder Coating Costs?

Several factors influence the pricing of metallic grey powder coatings:

-

Volume/MOQ: Higher order volumes often lead to discounted pricing. Suppliers may offer tiered pricing structures, incentivizing bulk purchases.

-

Specifications and Customization: Custom colors, finishes, or formulations may incur additional costs. Buyers should clarify their needs upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Products with specific certifications (e.g., ISO, RoHS) typically command higher prices due to the assurance of quality and compliance with environmental standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: The choice of Incoterms can significantly affect total costs. For instance, ‘Delivered Duty Paid’ (DDP) includes shipping and customs, while ‘Ex Works’ (EXW) places the onus of logistics on the buyer, potentially increasing costs.

What Tips Can Help Buyers Optimize Their Costs?

For international buyers, especially from regions like Africa and South America, navigating the complexities of sourcing metallic grey powder coatings requires strategic insights:

-

Negotiation: Engage in negotiations to secure better pricing. Suppliers may have flexibility, particularly for larger orders or long-term contracts.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and the long-term performance of the coating.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have higher labor costs, impacting pricing, whereas suppliers in Southeast Asia might offer lower costs but potentially different quality standards.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority during shortages, and access to exclusive products or services.

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and compare multiple suppliers. Benchmarking against industry standards can help identify competitive pricing.

Conclusion

Understanding the comprehensive cost and pricing analysis for metallic grey powder coat sourcing empowers B2B buyers to make informed decisions. By considering the various cost components, price influencers, and strategic procurement tips, businesses can optimize their purchasing strategies and enhance their competitive edge in the market.

Alternatives Analysis: Comparing metallic grey powder coat With Other Solutions

Exploring Alternatives to Metallic Grey Powder Coat

In the competitive landscape of coatings, selecting the right finish is crucial for enhancing aesthetics and durability. While metallic grey powder coat is a popular choice, buyers should consider viable alternatives that may better meet their specific requirements. This analysis compares metallic grey powder coat with two alternative solutions: liquid paint and anodizing. Each option presents unique benefits and drawbacks that can influence decision-making.

| Comparison Aspect | Metallic Grey Powder Coat | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | Excellent durability and resistance to corrosion and UV damage | Good initial appearance but less durable | High corrosion resistance and scratch resistance |

| Cost | Moderate; bulk pricing available | Generally lower upfront costs | Higher initial cost due to processing |

| Ease of Implementation | Requires specialized equipment and skilled applicators | Easier to apply; can be done with standard tools | Requires specialized anodizing equipment |

| Maintenance | Low; resistant to fading and peeling | Moderate; may require regular touch-ups | Low; very durable finish |

| Best Use Case | Suitable for automotive, furniture, and architectural applications | Ideal for quick jobs and less demanding environments | Best for items needing high durability and aesthetic appeal, such as aerospace and marine applications |

What Are the Pros and Cons of Liquid Paint as an Alternative?

Liquid paint is often viewed as a more accessible option for many businesses. One of its main advantages is the ease of application; it can be applied using standard spray equipment, which reduces the need for specialized training or equipment. Additionally, liquid paint generally has a lower upfront cost, making it a budget-friendly option for smaller projects. However, the durability of liquid paint is often inferior to that of powder coating. It is more susceptible to chipping, fading, and peeling, requiring more frequent maintenance and touch-ups, especially in harsh environments.

How Does Anodizing Compare to Metallic Grey Powder Coat?

Anodizing is a surface treatment that provides a high level of corrosion resistance, making it ideal for metal components that face harsh environmental conditions. Anodized finishes are also visually appealing, with a unique metallic look that can be customized through dyeing. However, the cost of anodizing is typically higher than both metallic grey powder coat and liquid paint, which may deter some buyers. Moreover, the process requires specialized equipment and expertise, making it less accessible for smaller operations. Despite these drawbacks, anodized finishes offer superior durability and longevity, making them a preferred choice for high-performance applications such as aerospace and marine industries.

How Should B2B Buyers Choose the Right Coating Solution?

When selecting the appropriate coating solution, B2B buyers should consider several key factors, including the intended application, environmental conditions, and budget constraints. Metallic grey powder coat is an excellent choice for those seeking a durable, visually striking finish that withstands the test of time. However, for projects with budget limitations or less demanding environments, liquid paint may provide a more practical solution. Conversely, for applications that require exceptional durability and resistance, anodizing could be the best option, despite its higher costs. Ultimately, understanding the specific needs and operational capabilities will guide buyers to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for metallic grey powder coat

What Are the Key Technical Properties of Metallic Grey Powder Coat?

Metallic grey powder coat is valued for its aesthetic appeal and protective qualities in various industrial applications. Understanding its key technical properties is essential for B2B buyers to make informed decisions.

-

Material Composition

Metallic grey powder coats are typically made from a blend of polyester resins and metallic pigments. The polyester provides durability, while metallic pigments enhance visual appeal. For B2B buyers, knowing the composition is crucial for assessing suitability for specific applications, such as automotive, architectural, or industrial uses. -

Gloss Level

Gloss levels in metallic grey powder coats can range from matte to high gloss, with semi-gloss options commonly available (37-70 gloss units). The gloss level not only affects aesthetics but also impacts maintenance and cleaning requirements. For instance, higher gloss finishes tend to show fewer fingerprints and smudges, making them more suitable for high-traffic areas. -

Durability and Weather Resistance

These powder coatings are engineered to withstand environmental factors, including UV exposure, moisture, and temperature fluctuations. This resilience is particularly important for outdoor applications, where coatings face harsh conditions. B2B buyers should consider the product’s durability ratings to ensure longevity and minimize the need for frequent reapplication. -

Application Method

Metallic grey powder coatings are typically applied using electrostatic spray technology, which promotes even coverage and reduces waste. Understanding the application process is vital for buyers to ensure compatibility with their existing equipment and achieve optimal results. -

Thickness and Coverage

The thickness of the powder coat can significantly influence its performance. A typical application may range from 2 to 4 mils (0.002 to 0.004 inches). Coverage rates vary, but a general rule of thumb is that one pound of powder coat can cover approximately 15-20 square feet. Buyers should factor in these specifications to estimate material requirements accurately.

What Are Common Trade Terms Related to Metallic Grey Powder Coat?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM requirements is critical for buyers seeking custom powder coating solutions that align with specific design and performance criteria. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest order size a supplier is willing to accept. For metallic grey powder coats, MOQs can vary based on production capabilities and inventory levels. Buyers must consider MOQs to avoid overstocking or incurring higher costs. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers issue to suppliers to solicit price quotes for specific products or services. This is a vital tool for B2B transactions, enabling buyers to compare prices and terms effectively. -

Incoterms (International Commercial Terms)

These standardized terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, ensuring all parties understand their obligations and minimizing disputes. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. It’s a critical factor for buyers, particularly in just-in-time manufacturing environments, as it affects overall project timelines and inventory management. -

Color Matching

This term refers to the process of ensuring that the powder coat applied matches the specified color precisely. For B2B buyers, color matching is essential for maintaining brand consistency and meeting aesthetic requirements in various applications.

Understanding these technical properties and trade terms empowers B2B buyers to navigate the complexities of sourcing metallic grey powder coats effectively, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the metallic grey powder coat Sector

What Are the Current Market Dynamics and Key Trends in the Metallic Grey Powder Coat Sector?

The metallic grey powder coat sector is experiencing significant growth, driven by increased demand across various industries, including automotive, architectural, and industrial applications. As global markets continue to expand, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers are increasingly seeking high-quality finishes that offer both aesthetic appeal and durability. Notably, the rise of e-commerce platforms and digital sourcing tools has transformed how businesses procure powder coatings. Buyers now have access to a broader range of suppliers and can easily compare products, prices, and reviews online.

Emerging trends include a growing preference for custom colors and finishes, as businesses aim to differentiate their products in competitive markets. Additionally, the adoption of advanced technologies such as automated powder coating systems is enhancing efficiency and precision in application processes. This shift is particularly relevant for international buyers looking to streamline operations and reduce waste.

Furthermore, the demand for high-performance coatings that can withstand harsh environmental conditions is on the rise. This trend is particularly pronounced in the automotive sector, where metallic finishes are not just about aesthetics but also about longevity and resistance to corrosion. As such, suppliers are innovating to develop coatings that not only meet these performance criteria but are also cost-effective for manufacturers.

How Is Sustainability Influencing Sourcing Trends in the Metallic Grey Powder Coat Market?

Sustainability has become a critical factor in the sourcing decisions of B2B buyers. The environmental impact of manufacturing processes and materials used in metallic grey powder coatings is under scrutiny. Buyers are increasingly prioritizing suppliers that adopt sustainable practices, including the use of eco-friendly materials and processes that minimize waste and emissions.

Ethical sourcing is also gaining traction, with businesses seeking to ensure that their suppliers adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials are becoming essential for suppliers aiming to attract conscientious buyers. These certifications not only enhance the credibility of suppliers but also help buyers align with their corporate social responsibility (CSR) goals.

Moreover, the concept of circular economy is influencing sourcing trends. Businesses are exploring options to recycle powder coatings and other materials, reducing their overall environmental footprint. This trend is particularly relevant for industries where sustainability is a competitive differentiator, such as construction and automotive. By choosing suppliers who prioritize sustainability, buyers can contribute to a more responsible supply chain while also meeting consumer demand for environmentally friendly products.

How Has the Metallic Grey Powder Coat Sector Evolved Over Time?

The metallic grey powder coat sector has evolved significantly since the introduction of powder coating technology in the mid-20th century. Initially, powder coatings were primarily used for their durability and resistance to chipping and fading, making them an attractive option for various industrial applications. Over the years, advancements in formulation and application techniques have expanded the range of finishes available, including the popular metallic grey options that provide aesthetic appeal alongside functional benefits.

As industries became more design-oriented, the demand for diverse color palettes and finishes surged. Manufacturers began to innovate, creating powders that offer unique visual effects, such as sparkle and gloss, which have become staples in automotive and architectural designs. Today, the market is characterized by a blend of aesthetic and performance-oriented products, catering to a wide array of applications and customer preferences.

The rise of digital technologies has further transformed the sector, enabling suppliers to reach global markets and allowing buyers to access a wealth of information about products, suppliers, and trends. This evolution reflects a broader shift towards customization and sustainability in manufacturing, ensuring that the metallic grey powder coat sector remains relevant and competitive in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of metallic grey powder coat

-

1. How do I choose the right metallic grey powder coat for my project?

Choosing the right metallic grey powder coat involves considering several factors. First, assess the specific requirements of your application, such as the environment (interior vs. exterior), desired finish (matte, semi-gloss, high gloss), and compatibility with materials. It’s also crucial to evaluate the powder coat’s durability, resistance to chemicals, UV stability, and aesthetic appeal. Request samples to test on your actual materials, and consult with suppliers who can provide technical data sheets for a better understanding of each product’s performance characteristics. -

2. What are the typical minimum order quantities (MOQs) for metallic grey powder coat?

Minimum order quantities for metallic grey powder coat can vary significantly by supplier and region. Generally, MOQs can range from as low as 5 lbs to over 100 lbs, depending on the manufacturer’s policies and the specific product line. When sourcing internationally, it’s essential to confirm MOQs upfront and consider the logistics involved in shipping smaller quantities. Some suppliers may offer flexibility on MOQs for new customers or larger orders, so it’s advisable to negotiate and establish a good relationship with your supplier. -

3. What payment terms are commonly offered by suppliers of metallic grey powder coat?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or cash in advance. Some suppliers might also accept letters of credit for larger orders, especially in international transactions. It’s critical to clarify payment terms before placing an order to avoid any misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers, to mitigate risks associated with international trade. -

4. How can I ensure the quality of metallic grey powder coat products?

To ensure quality, start by vetting potential suppliers through reviews, certifications, and samples of their products. Request detailed technical data sheets and safety data sheets to understand the powder coat’s properties and compliance with international standards. Implement a quality assurance process that includes inspections upon receipt of goods and performance testing on your applications. Establishing a good communication channel with your supplier can also help address any quality concerns proactively. -

5. What should I know about the logistics of importing metallic grey powder coat?

When importing metallic grey powder coat, it’s essential to understand the regulations and customs requirements specific to your country. This includes ensuring that the products comply with local safety and environmental standards. Work with a reliable freight forwarder who can assist with the shipping process, handle customs clearance, and provide insights on potential duties or taxes. Also, consider shipping times and choose suppliers who can meet your delivery timelines to avoid disruptions in your production schedule. -

6. Can I customize the metallic grey powder coat to match a specific color?

Yes, many suppliers offer customization options for metallic grey powder coat, including the ability to match specific colors. This process often involves providing a color sample or a Pantone reference to the supplier. Keep in mind that custom colors may have longer lead times and could require larger minimum order quantities. Discuss your requirements with suppliers upfront to understand their capabilities and any additional costs associated with custom formulations. -

7. What are the environmental considerations when using metallic grey powder coat?

Metallic grey powder coat is generally more environmentally friendly than traditional liquid paints, as it produces minimal volatile organic compounds (VOCs). However, it’s still important to check for compliance with environmental regulations in your region. Suppliers may provide information on the sustainability of their products, including any certifications such as Green Seal or ISO compliance. Additionally, consider the disposal methods for any waste generated during application, as recycling powder coat overspray can minimize environmental impact. -

8. How do I handle potential disputes with my metallic grey powder coat supplier?

Handling disputes effectively starts with clear communication and documentation. Ensure that all agreements regarding product specifications, payment terms, and delivery schedules are documented. If a dispute arises, attempt to resolve it directly with the supplier through open dialogue. If necessary, escalate the issue to a formal dispute resolution process, such as mediation or arbitration, especially for international transactions. Understanding local laws and regulations regarding business disputes can also aid in resolving issues amicably and professionally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Metallic Grey Powder Coat Manufacturers & Suppliers List

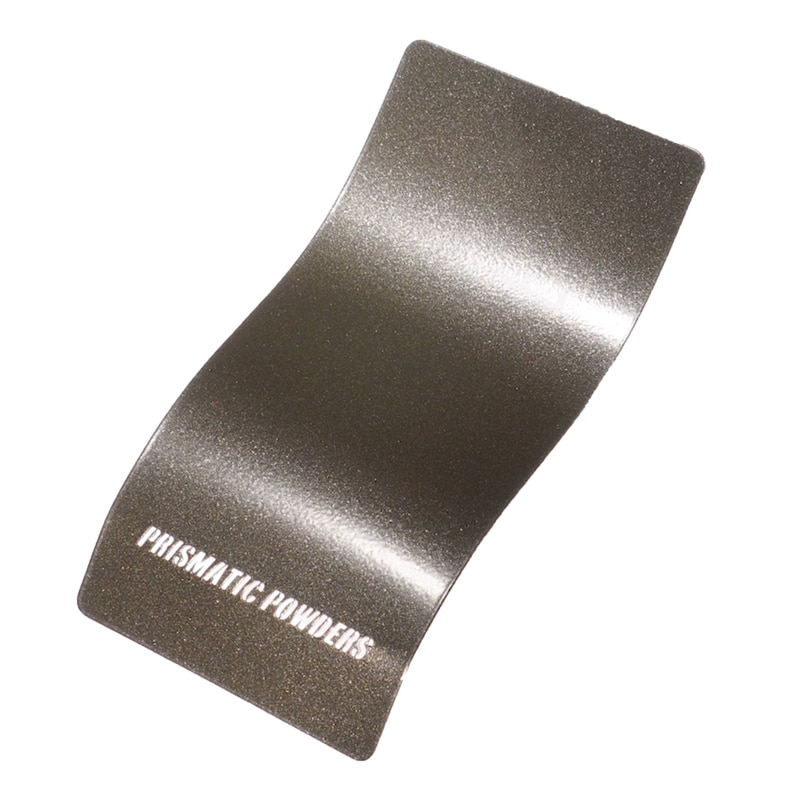

1. Columbia Coatings – Kilo Grey Metallic

Domain: columbiacoatings.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Kilo Grey Metallic”, “description”: “A nice ‘gun metal’ grey color with heavy metallic flakes. This powder is suitable for interior and exterior applications.”, “price_per_pound”: {“1-9”: “$18.27”, “10-24”: “$13.11”, “25-43”: “$10.93”, “44-87”: “$9.43”, “88+”: “$8.21”}, “availability”: “FORMULATED”, “shipping_time”: “Usually ships In 1-4 Business Days”, “item_number”: “M562259”, …

2. The Powder Coat Store – Ultimate Chrome Powder Coating Paint

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: Gray powder coating paints including flat, satin, high gloss, candy and wrinkle finishes. Products available: 1. Ultimate Chrome Powder Coating Paint – 1 LB – From $80.00 – Rating: 5.0/5.0 (1 review) 2. Sterling Charcoal Gunmetal Powder Coating Paint – 1 LB – From $80.00 – Rating: 5.0/5.0 (5 reviews) 3. Outgas Forgiving Epoxy Primer Powder Coat Paint – 1 LB – From $64.00 – Rating: 5.0/5.0 (6 revie…

3. PPG – Metallic Powder Coating

Domain: powdercoatings.ppg.com

Registered: 1990 (35 years)

Introduction: Metallic Powder Coating from PPG offers beautiful UL approved colors in various finishes including durable hammertone, smooth, texture, and wrinkle metallic finishes. The product is available with free standard shipping.

4. Kingsport – Grey Powder Coat

Domain: landwfab.com

Registered: 2006 (19 years)

Introduction: {‘name’: ‘Kingsport Grey Powder Coat’, ‘sku’: ”, ‘price’: ‘$16.00’, ‘description’: ‘Kingsport Grey is a charcoal grey with a heavy silver metallic flake. This color is a polyester metallic powder coat with a high gloss finish.’, ‘minimum_order’: ‘5lb minimum’, ‘warranty’: ‘Lifetime Warranty’, ‘made_in’: ‘100% in the USA’}

5. Tiger Coatings – Anthracite Grey Metallic

Domain: tiger-coatings.com

Registered: 2000 (25 years)

Introduction: 29/71334 – anthracite grey metallic

6. Moz Designs – Dark Grey Metallic Powder Coat

Domain: mozdesigns.com

Registered: 1998 (27 years)

Introduction: Dark Grey Metallic Powder Coat suitable for both interior and exterior applications. Available on solid-core .040″ – .250″ Aluminum in 4′ x 8′ and 4′ x 10′ sheets, as well as custom sizes. Options include perforated, laser cut, engraving, and corrugated metals. Comes with a 5-year warranty. Additional colors with extended exterior warranties available upon request.

7. Smith Powder Coating – Steel Grey Powder Coating

Domain: smithpowdercoating.com

Registered: 2016 (9 years)

Introduction: Steel Grey Powder Coating provides a sparkle effect when exposed to sunlight, featuring a lustrous finish. It is resistant to rust, corrosion, chips, and sun fade. Similar to Mindful Gray, it highlights the ‘steel’ aspect in its color.

8. UAPainter – HiGloss GUNMETAL GREY Metallic Powder Coat Paint

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “HiGloss GUNMETAL GREY metallic powder coat paint”, “Weight”: “1Lb/0.45kg”, “Brand”: “UAPainter”, “Condition”: “New”, “Quantity Available”: “10”, “Price”: “US $22.00”, “Shipping Cost”: “US $18.00”, “Location”: “Khmelnitskyi, Khmelnitskaya, Ukraine”, “Delivery Estimate”: “Between Fri, Aug 8 and Thu, Aug 21”, “Returns”: “14 days returns, buyer pays for return shipping”, “Features”: …

9. All Powder Paints – Single Stage Metallics

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: Single Stage Metallics are a category of powder coating colors offered by All Powder Paints. They include various finishes such as standard metallics, heavy metallics, holographic, and flip flop options. These coatings are suitable for a range of applications, including automotive, furniture, and OEM products. The product line features vibrant colors and is designed to provide a durable and aesthe…

Strategic Sourcing Conclusion and Outlook for metallic grey powder coat

As international B2B buyers increasingly seek durable and aesthetically pleasing finishes, metallic grey powder coat emerges as a versatile solution across multiple industries, including automotive, architectural, and industrial applications. Its semi-gloss finish not only enhances the visual appeal of products but also offers superior protection against corrosion and wear, making it a smart investment.

Strategic sourcing in this domain is essential for optimizing supply chains and ensuring product quality. By partnering with reliable suppliers, buyers can leverage bulk pricing, access a diverse range of shades, and benefit from the latest advancements in powder coating technology. This approach not only reduces costs but also improves lead times, crucial for meeting market demands.

Looking ahead, the demand for metallic grey powder coat is set to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Companies are encouraged to stay informed about innovations in coating technologies and sustainability practices to enhance their competitive edge. By prioritizing strategic sourcing now, businesses can position themselves advantageously in a dynamic market. Engage with trusted suppliers today to explore the full potential of metallic grey powder coat for your projects.