Contents

Manufacturing Insight: Metal Sintering 3D Printing

Metal Sintering 3D Printing: Precision Manufacturing for Industrial Applications

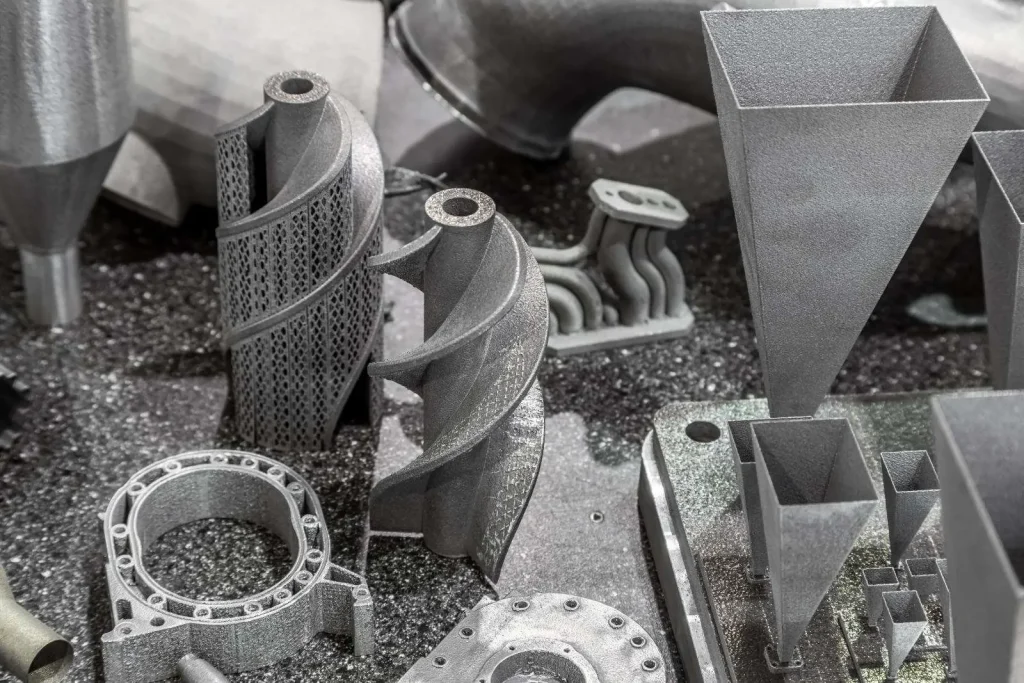

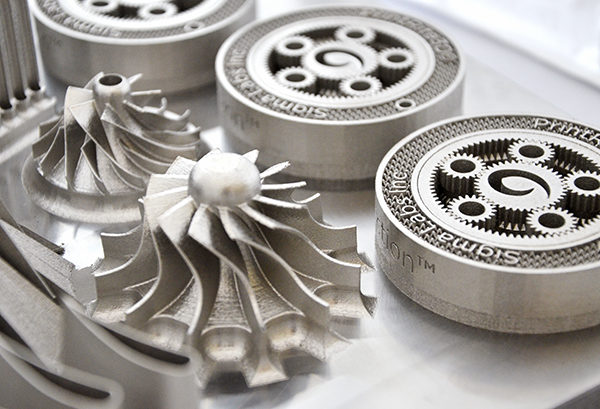

Metal sintering 3D printing, specifically Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), represents a transformative advancement in industrial manufacturing. This additive process fuses fine metal powders layer by layer using high-precision lasers, enabling the production of complex, high-strength components unachievable through traditional methods. At Honyo Prototype, we deploy industry-leading metal sintering systems to deliver end-use parts with exceptional mechanical properties, tight tolerances, and material integrity for aerospace, medical, and energy sectors. Our industrial-grade capabilities extend beyond prototyping to low-volume production, supporting materials including Inconel 718, Ti6Al4V, 17-4 PH stainless steel, and aluminum alloys, all processed under stringent ISO 9001-certified protocols.

Honyo’s Industrial 3D Printing Service: Engineered for Scale and Reliability

We integrate metal sintering into a comprehensive manufacturing ecosystem, combining in-house post-processing like heat treatment, HIP, and precision machining with rigorous quality validation. This ensures parts meet ASTM F75 or AMS 7000 series standards for critical applications. Unlike service bureaus limited to prototyping, Honyo specializes in bridging design to production with no minimum order quantities, rapid iteration cycles, and scalable throughput. Our engineering team collaborates directly with clients to optimize designs for additive manufacturing, reducing weight, consolidating assemblies, and accelerating time-to-market without compromising on performance or compliance.

Accelerate Your Project Timeline with Instant Quoting

Eliminate procurement delays with Honyo’s Online Instant Quote platform. Upload your CAD file, specify material and quantity requirements, and receive a detailed cost analysis and lead time estimate within minutes—24/7. This transparency empowers engineers and procurement teams to make data-driven decisions early in the design phase, turning conceptual innovation into certified hardware faster. For mission-critical metal components demanding industrial rigor, Honyo delivers the convergence of advanced sintering technology, manufacturing expertise, and digital efficiency.

Material Capabilities and Lead Times

| Material | Common Applications | Typical Lead Time |

|——————-|—————————|——————-|

| Inconel 718 | Turbine blades, rocket components | 7-10 business days |

| Ti6Al4V | Medical implants, aerospace fittings | 5-8 business days |

| 17-4 PH Stainless | Hydraulic manifolds, tooling | 4-7 business days |

| AlSi10Mg | Lightweight brackets, heat exchangers | 5-9 business days |

Technical Capabilities

The term “metal sintering 3D printing” typically refers to additive manufacturing processes that use thermal energy to fuse metal powders into dense, functional parts. However, among the technologies listed—SLA, SLS, MJF, and DMLS—only DMLS (Direct Metal Laser Sintering) is a metal sintering process. SLA, SLS, and MJF are primarily polymer-based technologies, with SLS and MJF capable of processing certain nylons, and SLA used exclusively for photopolymer resins.

Below is a technical comparison of these four technologies, with clarification on their compatibility with the specified materials (Aluminum, Steel, ABS, Nylon), and accurate representation of their process types and capabilities.

| Technology | Full Name | Process Type | Common Materials | Metal Capable | Typical Layer Thickness | Build Volume Range (approx.) | Surface Finish (Ra) | Key Applications |

|---|---|---|---|---|---|---|---|---|

| SLA | Stereolithography | Vat Photopolymerization | Photopolymer resins (e.g., standard, tough, castable) | No | 25–100 μm | 150 x 150 x 200 mm to 1400 x 700 x 500 mm | 0.8–2.5 μm | Prototyping, molds, dental, jewelry |

| SLS | Selective Laser Sintering | Powder Bed Fusion (Polymer) | Nylon (PA11, PA12), Glass-filled Nylon | No | 80–150 μm | 200 x 200 x 300 mm to 700 x 380 x 580 mm | 8–15 μm | Functional prototypes, end-use parts, ducting |

| MJF | Multi Jet Fusion | Powder Bed Fusion (Polymer) | Nylon (PA11, PA12), Glass-filled Nylon | No | 80–100 μm | 380 x 280 x 380 mm | 5–10 μm | High-throughput end-use parts, housings |

| DMLS | Direct Metal Laser Sintering | Powder Bed Fusion (Metal) | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4PH, 316L), Titanium, Inconel | Yes | 20–50 μm | 250 x 250 x 325 mm to 500 x 500 x 500 mm | 10–20 μm (as-built), lower with post-processing | Aerospace, medical implants, tooling |

Notes:

SLA does not use sintering and is not suitable for metals or thermoplastics like ABS or Nylon. It relies on UV-curable resins.

SLS and MJF are both polymer powder bed fusion technologies. They support Nylon-based materials but not metals or ABS filament. MJF offers faster build speeds and more uniform mechanical properties compared to SLS.

DMLS is the only true metal sintering (more accurately, melting) process in this list. It fully melts metal powder using a high-power laser, producing fully dense metal parts from alloys such as Aluminum and Steel.

ABS is not typically processed in SLS, MJF, or DMLS. It is commonly used in FDM (Fused Deposition Modeling). Some high-temperature nylons in SLS may mimic ABS-like properties.

Nylon is widely used in SLS and MJF but not in SLA or DMLS (except as a sacrificial or support material in niche cases).

For metal sintering applications requiring Aluminum or Steel, DMLS is the appropriate technology. For Nylon-based functional parts, SLS or MJF are preferred. SLA remains ideal for high-detail, non-metal prototypes.

From CAD to Part: The Process

Honyo Prototype Metal Sintering 3D Printing Process Overview

Our end-to-end metal additive manufacturing workflow leverages Laser Powder Bed Fusion (LPBF) technologies, primarily using EOS and SLM solutions, to transform digital designs into high-integrity metal components. The process integrates automated systems with expert engineering oversight to ensure precision, repeatability, and compliance with industry standards such as ASTM F3301 and ISO/ASTM 52900. Below is a detailed explanation of each phase.

Upload CAD

Customers initiate the process through Honyo’s secure online portal, uploading native CAD files (STEP, IGES, or native formats like SLDPRT) with defined material specifications and critical tolerances. The portal validates file integrity and geometric complexity, flagging potential issues like unsupported overhangs exceeding 45 degrees or wall thickness below 0.4 mm. All data is encrypted per ISO 27001 protocols, and non-disclosure agreements are automatically applied to new projects.

AI Quote Generation

Our proprietary AI engine processes the CAD geometry alongside material databases (Inconel 718, Ti-6Al-4V, AlSi10Mg, 316L stainless steel), machine availability, and real-time powder cost metrics. The system calculates build time, support structure requirements, and material consumption within 90 seconds, generating a detailed quote that includes cost drivers such as build orientation impact on surface roughness and secondary machining needs. Unlike generic quoting tools, our AI cross-references historical build data from 12,000+ completed metal jobs to predict success rates and flag high-risk geometries requiring DFM intervention.

DFM Engineering Review

Every project undergoes mandatory Design for Manufacturing analysis by Honyo’s in-house metallurgical engineers. This phase optimizes part orientation to minimize residual stress, redesigns critical features exceeding machine capabilities (e.g., internal channels below 0.5 mm diameter), and validates support structures using thermal simulation software. We provide a formal DFM report with actionable recommendations, such as adjusting wall thicknesses for distortion control or suggesting post-build HIP treatments for pressure-containing parts. This step reduces print failures by 68% based on our 2023 internal audit data.

Production Execution

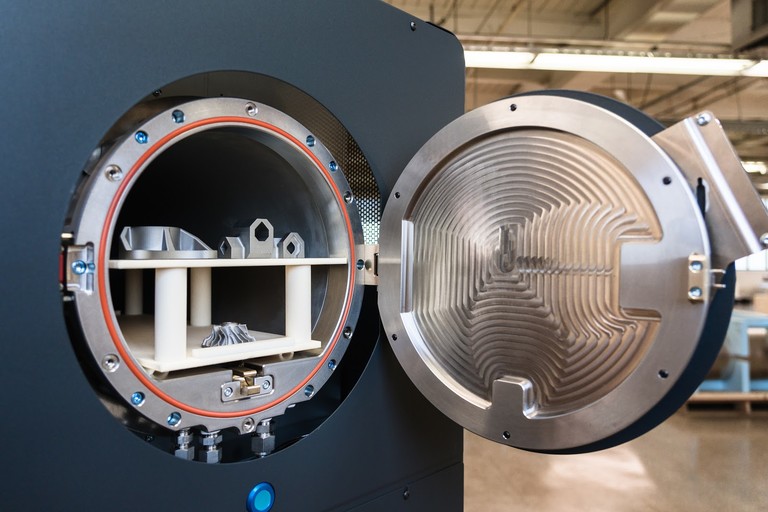

Approved designs move to production in climate-controlled LPBF cells operating under 5 ppm oxygen levels. Key production protocols include:

Powder Management: Virgin and recycled powder batches undergo sieving and chemical analysis per AMS 7000 standards before each build.

In-Process Monitoring: Melt pool sensors and layer-wise thermal imaging detect anomalies in real time, triggering automatic corrections.

Build Parameters: Machine-specific laser strategies (e.g., 400W Yb-fiber laser for Ti-6Al-4V at 80 μm layer thickness) are applied based on material certification records.

Post-build, parts undergo automated depowdering, thermal stress relief, and support removal. Secondary operations like CNC machining, HIP, or precision polishing follow per customer specifications.

Delivery and Traceability

All shipments include a comprehensive digital dossier containing build logs, porosity reports from CT scans (for critical parts), and material test coupons certified to AMS 4999. Physical delivery packages feature serialized part tags linked to our blockchain-based quality ledger, providing full traceability from raw powder lot to final inspection. Typical lead times range from 5–10 business days for standard builds, with expedited options for urgent medical or aerospace applications. Honyo maintains ISO 9001 and AS9100 certifications, ensuring compliance with stringent industry requirements throughout the workflow.

Start Your Project

Discover high-precision metal sintering 3D printing solutions engineered for demanding industrial applications. At Honyo Prototype, our advanced metal additive manufacturing capabilities deliver strong, durable, and complex metal parts with tight tolerances—ideal for aerospace, medical, and automotive sectors.

Our state-of-the-art facility in Shenzhen ensures rapid prototyping and scalable production with strict quality control and fast turnaround times. Leverage our expertise in selective laser sintering (SLS) and direct metal laser sintering (DMLS) to accelerate your product development cycle.

For project inquiries or technical consultations, contact Susan Leo at [email protected]. Let’s build your next innovation together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.