Guide Contents

Project Insight: Metal Sintering 3D Printing

Metal Sintering 3D Printing: Accelerating Innovation with Precision

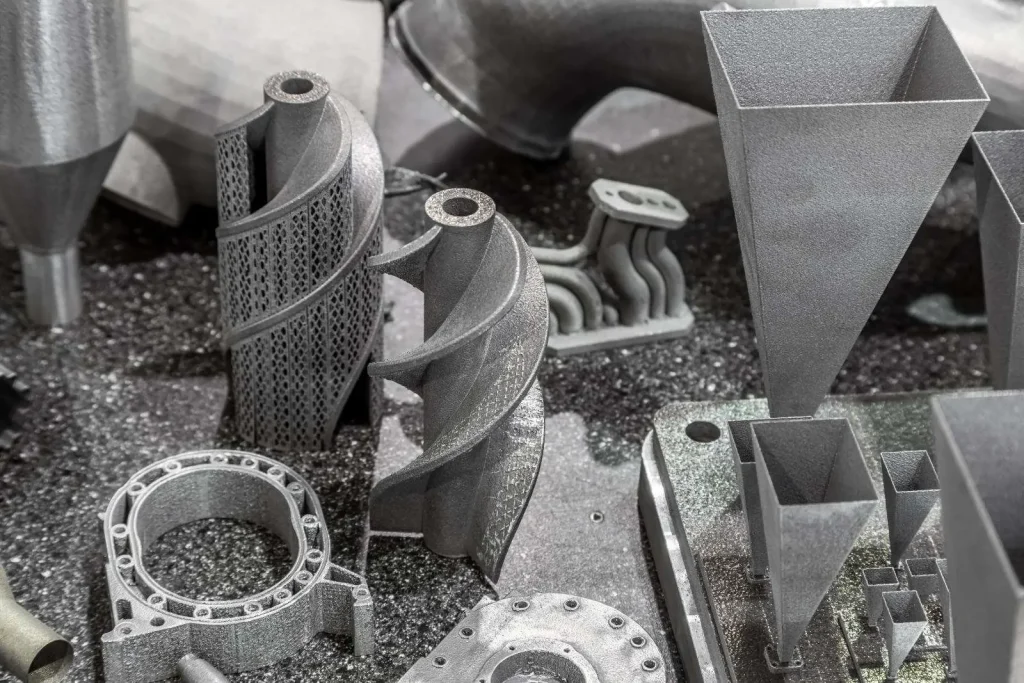

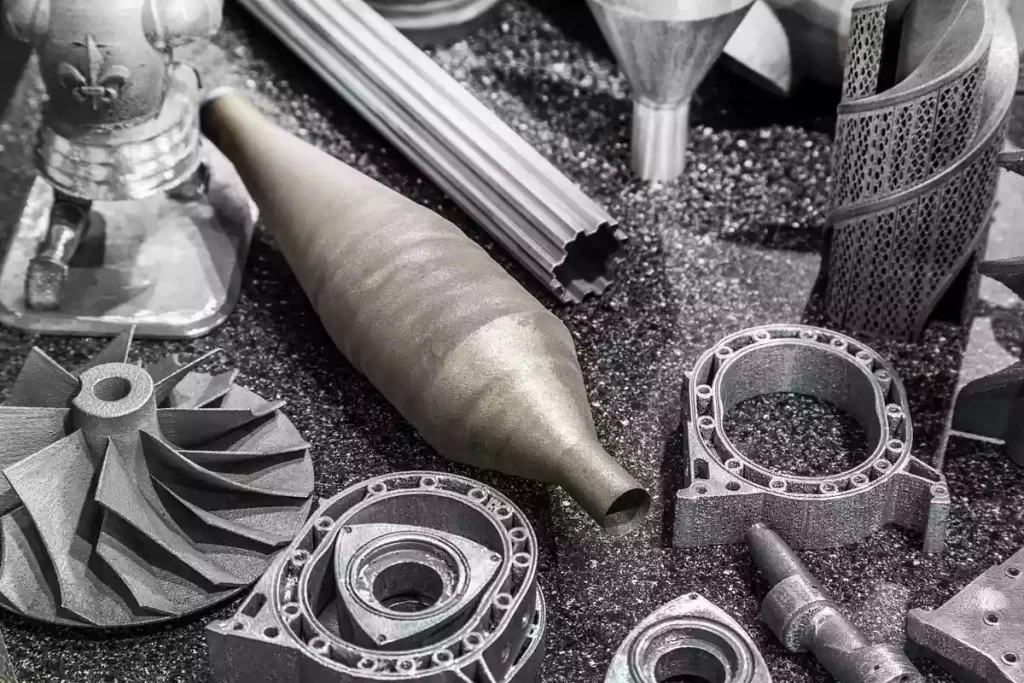

Metal sintering 3D printing (DMLS) is revolutionizing product development by enabling the creation of complex, high-strength metal parts with unmatched precision and speed. For hardware startups and engineers, this technology eliminates traditional manufacturing bottlenecks—allowing rapid iteration, reduced time-to-market, and innovative designs that were previously impossible.

Why Speed & Precision Are Non-Negotiable in Modern Product Development

Rapid Iteration Cycles: Test and refine designs in days, not weeks—critical for startups competing in fast-moving markets where speed equals market advantage.

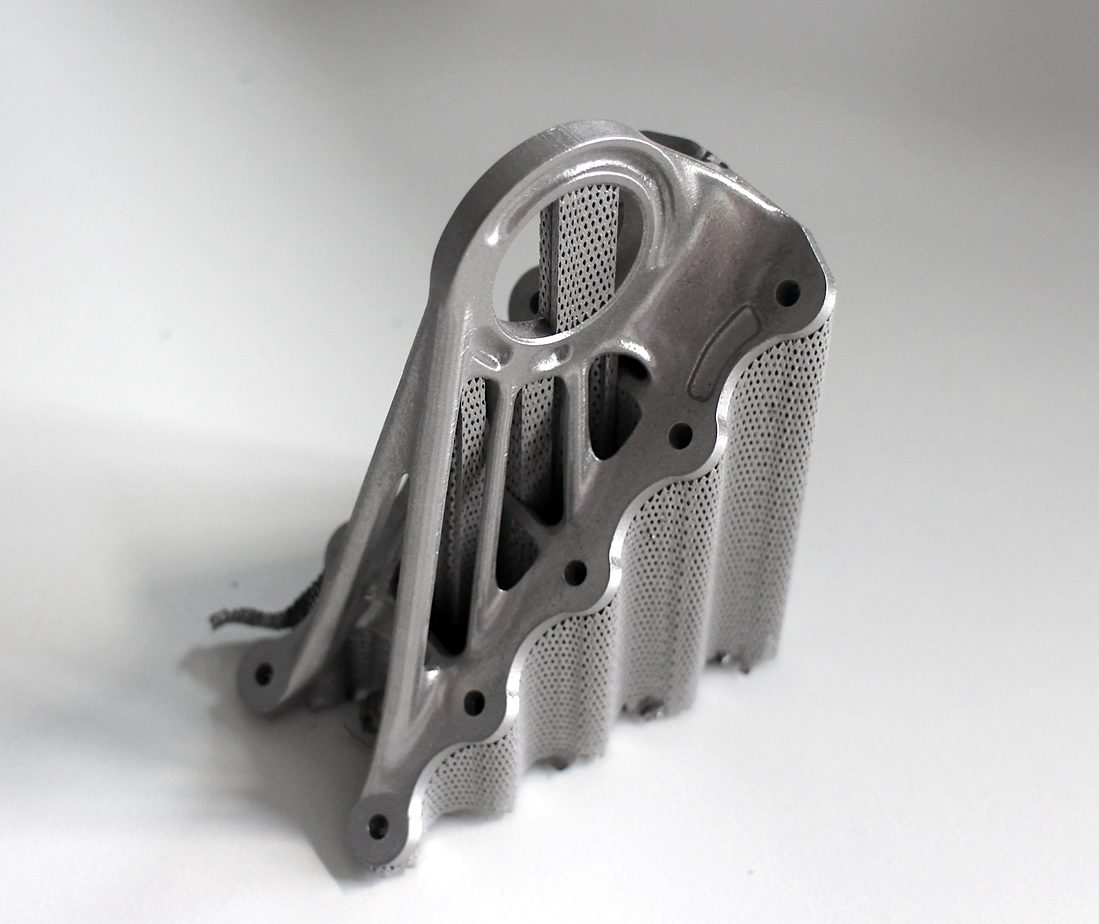

Complex Geometries Unlocked: Create lightweight, intricate structures impossible with CNC machining or casting, enhancing performance without added weight or material waste.

Precision Engineering: Achieve tight tolerances (±0.05mm) and surface finishes suitable for functional prototypes and end-use parts in aerospace, medical, and automotive applications.

Honyo Prototype: Your Digital Manufacturing Partner for Metal Sintering Excellence

Online Instant Quote: Get real-time pricing and lead times in seconds—no manual quotes, no delays. Our AI-driven platform instantly analyzes your design for manufacturability.

AI-Powered Design Optimization: Automatically detect potential issues, optimize part orientation, and suggest material choices to reduce costs and improve print success rates.

Fast Turnaround Guarantee: Metal parts delivered in 3–5 business days, enabling rapid prototyping and quick market validation—no minimum order quantities required.

End-to-End Expertise: From material selection (Ti64, 17-4PH, AlSi10Mg) to post-processing, our engineers ensure your parts meet exact specifications for demanding applications.

Global Supply Chain Advantage: Leveraging Shenzhen’s manufacturing ecosystem for cost-effective, scalable production with seamless international shipping.

At Honyo Prototype, we don’t just print parts—we accelerate innovation. With Susan Leo’s vision driving our commitment to cutting-edge digital manufacturing, your designs become reality faster, smarter, and more efficiently than ever before.

Honyo Capabilities & Technology

Honyo’s Metal Sintering 3D Printing Capabilities

Industrial-Grade DMLS Technology

Zero capital expenditure: Access industrial-grade Direct Metal Laser Sintering (DMLS) without $150k–$575k machine investments—pay only for parts produced.

Aerospace-grade materials: Support for Titanium Ti64, Stainless Steel 316L, Aluminum AlSi10Mg, Inconel 718, and more—certified for high-stress applications.

Precision engineering: Achieve ±0.05mm tolerances and surface finishes as fine as Ra 3.2μm—ideal for complex geometries impossible with traditional machining.

AI-Powered Instant Quote & Streamlined Workflow

<60-second quotes: Upload your CAD file to our AI platform for real-time pricing, material recommendations, and design-for-manufacturability (DFM) feedback.

Automated optimization: AI-driven algorithms minimize support structures, reduce material waste, and accelerate print times—cutting costs by up to 30%.

Real-time tracking: Monitor progress from quote to delivery with automated updates and predictive delivery timelines—no more guesswork.

Scalable Production from 1 to 10,000+ Units

Seamless scaling: Start with a single prototype, then scale to high-volume production—no minimum order requirements or setup fees.

Consistent quality at scale: Dedicated production lines ensure identical precision across all batches, even for 10,000+ units.

Urgent turnaround: Expedited options available for critical projects—prototypes in 3–5 business days, production runs in 7–10 days.

ISO-Certified Quality Assurance

End-to-end compliance: ISO 9001-certified facility with full material traceability and third-party certifications (ASTM, ISO 13485 for medical).

Rigorous inspection: 100% part verification via CMM, X-ray, and metallurgical testing—guaranteeing performance for aerospace, automotive, and medical applications.

Post-processing excellence: Precision polishing, heat treatment, anodizing, and surface finishing to meet exact functional requirements.

💡 Why choose Honyo?

We eliminate the complexity and cost of owning metal 3D printers—delivering industrial-grade metal parts with the agility of a startup. From your first prototype to full-scale production, our AI-driven platform ensures speed, precision, and cost efficiency at every step.

Materials & Surface Finishes

Material Options & Finishes for Metal Sintering 3D Printing

At Honyo Prototype, we eliminate the barriers to industrial metal 3D printing—no million-dollar equipment investments, no engineering delays. Our DMLS (Direct Metal Laser Sintering) service delivers precision-engineered metal parts with unmatched design freedom, optimized for performance-critical applications. Get an instant quote in seconds via our AI-powered platform, with real-time material recommendations and lead times tailored to your project.

Precision Metal Alloys for DMLS

Stainless Steel 316L: Corrosion-resistant, biocompatible, and ideal for medical implants, marine hardware, and chemical processing equipment.

Titanium Ti6Al4V: Lightweight yet ultra-strong; perfect for aerospace components, orthopedic implants, and high-performance automotive parts.

Inconel 718: Exceptional high-temperature stability and oxidation resistance; used in jet engines, gas turbines, and oil/gas drilling tools.

Aluminum AlSi10Mg: Excellent thermal conductivity and lightweight properties; ideal for heat exchangers, automotive brackets, and rapid prototyping.

Tool Steel M300: High hardness and wear resistance; optimized for molds, dies, and tooling requiring sub-micron tolerances.

Surface Finishing Options

Mechanical Polishing: Achieve mirror-like finishes (Ra < 0.1 µm) for optical or medical components; compatible with stainless steel, titanium, and aluminum.

Bead Blasting: Uniform matte texture to remove support structures and enhance aesthetics; ideal for functional parts requiring consistent surface quality.

Passivation (Stainless Steel): Removes surface contaminants to maximize corrosion resistance; critical for food-grade and medical applications.

Electroplating: Add nickel, chrome, or gold layers for enhanced wear resistance or electrical conductivity; suitable for stainless steel and titanium.

Anodizing (Aluminum Only): Creates a durable, colored oxide layer for improved corrosion resistance and visual appeal.

Powder Coating: Durable, scratch-resistant color application for structural parts requiring aesthetic customization.

Painting: Custom color application for non-critical components where visual appeal is prioritized (requires surface priming for adhesion).

How to Choose the Right Material for Your Project

Selecting the optimal alloy depends on your application’s performance, cost, and regulatory needs. Our AI platform analyzes your design in real-time to guide you—no guesswork required:

Strength & Durability: For high-stress aerospace or automotive parts, Titanium Ti6Al4V or Inconel 718 deliver superior fatigue resistance.

Corrosion Resistance: Stainless Steel 316L (with passivation) excels in marine/chemical environments; Aluminum AlSi10Mg requires anodizing for long-term protection.

Thermal Management: Aluminum AlSi10Mg is the go-to for heat sinks, cooling channels, and thermal management systems.

Biocompatibility: Medical implants require Titanium Ti6Al4V or 316L stainless steel certified to ISO 13485 standards.

Cost Efficiency: Aluminum offers the best value for non-critical structural parts; Inconel is reserved for extreme conditions where performance justifies the investment.

💡 Instant, AI-Powered Decision Support

Upload your CAD file to our platform for real-time material recommendations and pricing. Our AI analyzes geometry, tolerances, and functional requirements to suggest the perfect alloy and finish—eliminating guesswork and accelerating your design cycle. Get a quote in seconds with no engineering consultation needed.

Why Honyo Delivers Results Faster

3–5 Day Lead Times: Standard turnaround for most parts, with expedited options available for urgent projects.

Global Quality Control: ISO 9001-certified processes ensure consistent quality from Shenzhen to your doorstep.

Zero Capital Investment: Access industrial-grade metal printing without purchasing multi-million-dollar equipment—scale production as your business grows.

Ready to innovate? Get an instant quote in under 60 seconds—no strings attached.

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload Your CAD File

Drag-and-Drop Simplicity: Support for all major CAD formats (STL, STEP, IGES, etc.)

Cloud-Based Platform: Start instantly from any device – no software installation needed

2. Instant AI-Powered Quote

Real-Time Cost Analysis: Get a transparent, itemized quote in seconds – including material, labor, and processing fees

Metal-Specific Optimization: AI analyzes DMLS geometry, powder requirements, and thermal constraints for precision pricing

No Hidden Fees: See exactly what you’re paying for – no surprises, no manual quotes

3. Expert DFM Analysis & Optimization

AI-Driven Design Checks: Automated detection of wall thickness, overhangs, and support structures for manufacturability

Engineer Collaboration: Our specialists provide actionable feedback to reduce costs and improve part performance

Rapid Iteration: Revise designs and re-quote in minutes – accelerate your prototyping cycle

4. Precision Production & Delivery

DMLS Metal Printing: Aerospace-grade precision (<0.05mm tolerance) with ISO-certified quality control

End-to-End Visibility: Track your order in real-time via our portal – from build to delivery

Fast Turnaround: Deliver complex metal parts in as little as 3 business days – faster than traditional manufacturing

Start Your Project with Honyo

Start Your Project with Honyo

Skip the high costs and long lead times of traditional manufacturing. Honyo Prototype’s metal sintering 3D printing service delivers complex, high-strength parts with unparalleled speed and precision—so you can iterate faster and bring products to market quicker.

Key Advantages for Your Project

🚀 Instant Online Quotes

AI-driven platform analyzes your CAD file and provides real-time pricing, material options, and feasibility insights in seconds—no manual quotes, no hidden costs.

⚡ Rapid Turnaround

Prototypes ready in 3–5 business days, production-scale parts within weeks. Designed for agile workflows and urgent deadlines.

🔍 Engineer-Driven Expertise

Founder Susan Leo and our industrial engineering team optimize designs for strength, cost-efficiency, and manufacturability—ensuring aerospace, medical, and industrial-grade results.

Get Started Today

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🌏 Visit: Our Shenzhen/Dongguan facilities for hands-on consultation and technical collaboration

Innovate with confidence. Let’s build the future—faster.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.