Introduction: Navigating the Global Market for metal sign cutter

In an increasingly competitive global marketplace, sourcing the right metal sign cutter is a pivotal challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As businesses strive to enhance their branding and communication strategies, the demand for high-quality, precision metal signage solutions continues to grow. This guide is designed to provide comprehensive insights into the various types of metal sign cutters available, their applications across different industries, and the critical factors to consider when selecting a supplier.

Navigating the complexities of metal sign cutter procurement can be daunting. Buyers must evaluate a range of options, including laser cutting technologies, machine specifications, and supplier reliability. This guide empowers international B2B buyers with actionable information that facilitates informed purchasing decisions. By exploring key considerations such as cost analysis, supplier vetting processes, and the latest advancements in cutting technology, businesses can streamline their sourcing efforts and enhance their operational efficiency.

Whether you’re based in bustling markets like Nigeria or Saudi Arabia, this resource aims to equip you with the knowledge needed to make strategic investments in metal sign cutters. By understanding the landscape of available options and the nuances of supplier partnerships, you can ensure that your business remains at the forefront of innovation and quality in metal signage production.

Understanding metal sign cutter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser Cutters | Utilizes gas lasers for cutting and engraving. | Sign making, decorative panels, arts and crafts. | Pros: Good for non-metal materials; Cons: Slower cutting speed for metals. |

| Fiber Laser Cutters | Employs solid-state lasers, ideal for metals. | Industrial signage, automotive parts, precision cuts. | Pros: High speed and precision; Cons: Higher initial investment. |

| Plasma Cutters | Uses high-temperature plasma to cut through metals. | Large-scale fabrication, construction signage. | Pros: Effective for thick materials; Cons: Less precise than laser cutters. |

| Waterjet Cutters | Employs high-pressure water mixed with abrasives. | Custom shapes, intricate designs in various materials. | Pros: No heat-affected zone; Cons: Slower process. |

| CNC Routers | Uses rotary bits for cutting and engraving. | Wood signs, composite materials, soft metals. | Pros: Versatile for various materials; Cons: Limited to softer metals. |

What Are the Key Characteristics of CO2 Laser Cutters?

CO2 laser cutters are highly versatile machines that excel in cutting and engraving non-metal materials, but they can also handle thin metals. These machines utilize gas lasers, which allow for intricate designs and high-quality finishes. B2B buyers in the sign-making industry often find CO2 lasers ideal for creating decorative panels and crafts due to their ability to provide smooth edges and detailed engravings. However, they are generally slower than other metal cutting technologies when it comes to thicker materials.

How Do Fiber Laser Cutters Stand Out in Metal Sign Production?

Fiber laser cutters are revolutionizing metal sign production with their high-speed cutting capabilities and exceptional precision. These machines are particularly effective for cutting various metals, including stainless steel and aluminum, making them a popular choice in industrial applications. B2B buyers looking for efficiency and accuracy in signage will appreciate the reduced operational costs over time, despite the higher initial investment. Fiber lasers are suitable for high-volume production runs, offering a quick turnaround on custom orders.

What Are the Advantages of Using Plasma Cutters?

Plasma cutters utilize a high-temperature plasma arc to slice through metals, making them particularly effective for thicker materials. This type of cutter is favored in industries such as construction and large-scale fabrication where robust and heavy-duty signs are required. B2B buyers should consider plasma cutting for its ability to handle a variety of metals and thicknesses; however, they should be aware that the precision may not match that of laser cutting technologies, which could affect the final appearance of the signage.

Why Choose Waterjet Cutters for Intricate Designs?

Waterjet cutters use a high-pressure stream of water mixed with abrasives to cut through materials, making them ideal for creating complex shapes and designs without introducing heat that could warp the material. This technology is beneficial for B2B applications requiring custom shapes in various materials, including metals, glass, and stone. While the cutting process can be slower compared to laser or plasma cutters, the absence of heat-affected zones ensures a high-quality finish, making waterjet cutting a worthwhile investment for detailed projects.

What Makes CNC Routers a Versatile Choice for Signage?

CNC routers are equipped with rotary bits that can cut, carve, and engrave a variety of materials, including softer metals, wood, and composite materials. These machines are particularly useful in crafting signs that require intricate detailing and varied textures. B2B buyers seeking flexibility across different materials will find CNC routers advantageous; however, they should note the limitations in cutting harder metals, which may necessitate additional equipment for comprehensive metal sign production.

Key Industrial Applications of metal sign cutter

| Industry/Sector | Specific Application of metal sign cutter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Hospitality | Custom signage for storefronts and interiors | Enhances brand visibility and customer engagement | Durability, weather resistance, and design flexibility |

| Construction and Real Estate | Directional and informational signage | Improves navigation and safety on construction sites | Compliance with local regulations and materials used |

| Manufacturing and Industrial | Safety and operational signage | Promotes workplace safety and efficiency | Material strength, visibility, and customization options |

| Events and Promotions | Temporary and permanent signage for events | Increases event awareness and enhances attendee experience | Portability, ease of installation, and design options |

| Automotive and Transportation | Branding and identification signs for vehicles | Strengthens brand presence and aids in vehicle identification | Material choice for durability and aesthetic appeal |

How is a Metal Sign Cutter Used in Retail and Hospitality?

In the retail and hospitality sectors, metal sign cutters are used to create custom signage that enhances the visual appeal of storefronts and interiors. These signs can include brand logos, promotional messages, and directional signage, all of which are critical for attracting customers and enhancing their shopping experience. The precision cutting capabilities of metal sign cutters ensure that signs are not only aesthetically pleasing but also durable enough to withstand outdoor elements, particularly in regions with extreme weather conditions, such as parts of Africa and the Middle East. B2B buyers must consider the material’s resistance to corrosion and fading to ensure longevity.

What Role Does Metal Sign Cutting Play in Construction and Real Estate?

In construction and real estate, metal sign cutters are essential for producing directional and informational signage that improves navigation and safety on job sites. These signs can display safety warnings, site information, and directional arrows, ensuring that workers and visitors can move safely and efficiently. B2B buyers in this sector should prioritize compliance with local regulations regarding signage size and visibility, as well as the materials used to ensure they meet safety standards. Additionally, the ability to customize signs to reflect corporate branding can enhance the professional image of construction firms.

How Does Metal Sign Cutting Enhance Safety in Manufacturing and Industrial Settings?

Metal sign cutters are pivotal in manufacturing and industrial settings for creating safety and operational signage. These signs communicate crucial safety protocols, operational procedures, and emergency information, thereby promoting a safer work environment. The ability to cut durable materials such as stainless steel and aluminum ensures that the signs can withstand harsh industrial conditions without deteriorating. International buyers must consider factors such as the visibility of the signs from various distances and angles, as well as the potential need for reflective materials in low-light environments.

Why are Metal Sign Cutters Important for Events and Promotions?

For events and promotions, metal sign cutters facilitate the production of both temporary and permanent signage that enhances event awareness and attendee experience. Custom signs can include event branding, schedules, and directional signage to guide participants. B2B buyers in this sector should look for sign solutions that are portable and easy to install, as well as those that can be customized for different themes and branding needs. The ability to create eye-catching designs can significantly impact the overall success of an event, making this a vital application of metal sign cutting technology.

How is Metal Sign Cutting Utilized in the Automotive and Transportation Sector?

In the automotive and transportation sector, metal sign cutters are employed to create branding and identification signs for vehicles. These signs can include company logos, vehicle identification numbers, and regulatory information, which strengthen brand presence and aid in vehicle identification. Buyers in this sector must prioritize material choices that offer durability and aesthetic appeal, as vehicles are often exposed to various environmental conditions. Additionally, the ability to produce signs that comply with transportation regulations is essential for international buyers, especially in regions with specific compliance requirements.

3 Common User Pain Points for ‘metal sign cutter’ & Their Solutions

Scenario 1: Navigating High Initial Investment Costs

The Problem: For many B2B buyers, particularly in regions such as Africa and South America, the upfront costs associated with purchasing a metal sign cutter can be a significant barrier. These machines often represent a substantial financial investment, and buyers may struggle to justify the expenditure without a clear understanding of the return on investment (ROI). This uncertainty is exacerbated by a lack of financing options and the potential for fluctuating currency values, which can complicate budgeting.

The Solution: To mitigate these concerns, buyers should conduct a thorough cost-benefit analysis before making a purchase. This analysis should factor in not only the initial cost of the machine but also the long-term savings it can provide through increased efficiency and reduced labor costs. Additionally, exploring financing options or leasing agreements can spread the cost over time, making the investment more manageable. Partnering with reputable suppliers who offer warranties and service agreements can also provide peace of mind, ensuring that the equipment remains operational without incurring excessive maintenance costs. Furthermore, buyers should seek testimonials and case studies from similar businesses to understand the potential ROI better.

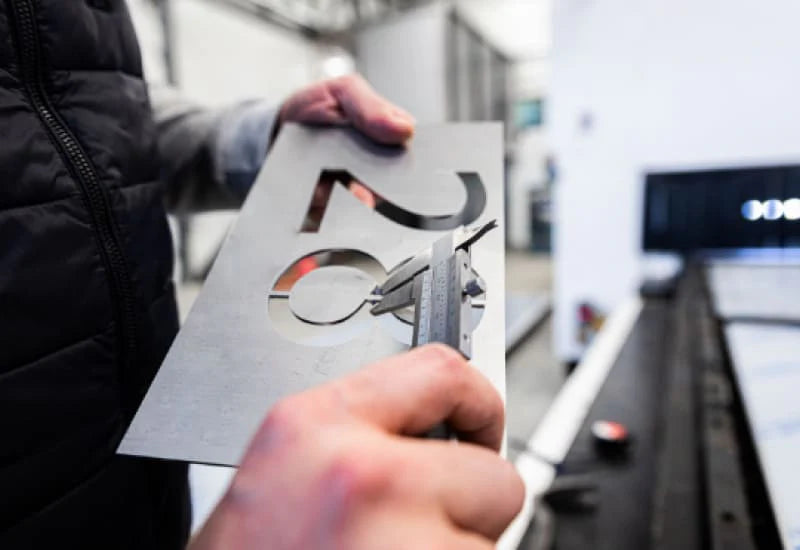

Scenario 2: Ensuring Precision and Quality in Metal Cutting

The Problem: A common pain point for B2B buyers is the challenge of achieving precise cuts and high-quality finishes when using a metal sign cutter. Inconsistent results can lead to wasted materials, increased production time, and ultimately dissatisfied customers. Buyers may find themselves frustrated when they invest in technology that fails to deliver the expected performance, especially when working with intricate designs or varying metal types.

The Solution: To ensure precision and quality, buyers should prioritize investing in advanced fiber laser cutting technology, which is known for its accuracy and versatility across different metal types, including stainless steel and aluminum. When selecting a machine, it is crucial to consider its specifications, such as the wattage and cutting speed, as these factors significantly impact the quality of the cuts. Additionally, buyers should seek training and support from the manufacturer or supplier to optimize machine settings for different materials and thicknesses. Implementing a robust quality control process throughout the cutting workflow can also help identify and address issues early, ensuring that the final products meet customer expectations.

Scenario 3: Adapting to Diverse Client Needs

The Problem: B2B buyers often face the challenge of adapting their metal sign cutting capabilities to meet diverse client demands. As businesses expand their offerings to include custom signage solutions, they may struggle with the flexibility of their existing equipment, which can limit their ability to take on new projects or respond to client requests for unique designs.

The Solution: To effectively adapt to varying client needs, buyers should consider investing in multifunctional metal sign cutters that can handle a range of materials and design complexities. Features such as adjustable cutting heads and customizable software can provide the versatility needed to produce unique signs efficiently. Establishing a close relationship with clients through regular communication can also help identify emerging trends and specific requirements, allowing businesses to tailor their services accordingly. Additionally, investing in a skilled workforce that is proficient in design software and machine operation will enhance the team’s ability to innovate and deliver high-quality custom solutions quickly. By proactively addressing client demands, businesses can improve customer satisfaction and strengthen their market position.

Strategic Material Selection Guide for metal sign cutter

What Are the Key Properties and Considerations for Common Materials Used in Metal Sign Cutting?

When selecting materials for metal sign cutting, it is essential to consider the properties and performance characteristics of each material. Here, we analyze four common materials used in the industry: stainless steel, aluminum, mild steel, and brass. Each material has unique advantages and limitations that can significantly impact the manufacturing process and final product suitability.

How Does Stainless Steel Perform in Metal Sign Cutting Applications?

Stainless steel is renowned for its corrosion resistance and durability, making it a popular choice for outdoor signage. It can withstand harsh environmental conditions, including high humidity and salt exposure. Its temperature rating is excellent, allowing it to maintain structural integrity under varying thermal conditions.

Pros: Stainless steel offers exceptional strength and longevity, making it ideal for high-traffic areas. It also has a sleek appearance that enhances aesthetic appeal.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, the cutting process can be more complex due to its hardness, requiring specialized equipment.

Impact on Application: Stainless steel is suitable for applications requiring durability and a polished finish, such as corporate signage and architectural elements.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 or EN 10088 for stainless steel grades. Countries like Nigeria and Saudi Arabia may have specific regulations regarding the use of stainless steel in outdoor environments.

What Advantages Does Aluminum Offer for Metal Sign Cutting?

Aluminum is lightweight and resistant to corrosion, making it an excellent choice for both indoor and outdoor signage. Its low density allows for easy handling and installation, while its natural resistance to oxidation ensures longevity.

Pros: Aluminum is relatively inexpensive and can be easily fabricated. It also allows for vibrant finishes and colors, enhancing visual appeal.

Cons: While it is durable, aluminum is softer than stainless steel, which may lead to dents and scratches in high-impact situations.

Impact on Application: Aluminum is often used for signage that requires frequent updates, such as promotional displays, due to its ease of modification.

Considerations for International Buyers: Compliance with standards like ASTM B209 is crucial. In regions like South America, preferences may lean towards aluminum for its cost-effectiveness and versatility.

How Does Mild Steel Compare in Terms of Cost and Application Suitability?

Mild steel is a cost-effective option that provides good strength and durability for various applications. It is easy to cut and weld, making it a preferred choice for custom sign designs.

Pros: The primary advantage of mild steel is its low cost and ease of fabrication. It is also readily available in various thicknesses.

Cons: Mild steel is prone to rust and corrosion if not properly coated or treated, limiting its use in outdoor applications without protective finishes.

Impact on Application: Mild steel is best suited for indoor signage or temporary outdoor displays where budget constraints are a priority.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to meet local environmental standards. Compliance with standards like ASTM A36 is also advisable.

What Role Does Brass Play in Metal Sign Cutting and Design?

Brass is an alloy of copper and zinc, known for its unique aesthetic appeal and corrosion resistance. It is often used for decorative signs and plaques due to its warm, golden appearance.

Pros: Brass offers excellent machinability and can be polished to a high shine, making it visually appealing for upscale applications.

Cons: The cost of brass is relatively high compared to other metals, and it is softer, which may lead to wear over time.

Impact on Application: Brass is ideal for custom engraved signs and decorative elements in both residential and commercial settings.

Considerations for International Buyers: Compliance with standards such as ASTM B36 is essential. In Europe, buyers may prefer brass for its aesthetic qualities in high-end applications.

Summary Table of Material Selection for Metal Sign Cutting

| Material | Typical Use Case for metal sign cutter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Corporate signage, architectural elements | Exceptional durability and corrosion resistance | Higher cost and complex cutting process | High |

| Aluminum | Indoor/outdoor signage, promotional displays | Lightweight and cost-effective | Softer, prone to dents and scratches | Medium |

| Mild Steel | Indoor signage, temporary outdoor displays | Low cost and easy fabrication | Prone to rust without protective coating | Low |

| Brass | Decorative signs, custom plaques | Aesthetic appeal and machinability | High cost and softer material | High |

This strategic material selection guide provides essential insights for B2B buyers in diverse international markets, ensuring informed decisions that align with project requirements and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for metal sign cutter

What Are the Main Stages in the Manufacturing Process of Metal Sign Cutters?

The manufacturing process of metal sign cutters involves several critical stages designed to ensure precision, durability, and quality. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, such as stainless steel, aluminum, or carbon steel. Suppliers should source materials that comply with international standards to ensure longevity and performance. Materials are then cut to size using advanced techniques, including laser or plasma cutting, which minimizes waste and optimizes the use of resources.

-

Forming: This stage involves shaping the metal into the desired form. Techniques such as laser cutting and CNC machining are commonly used to achieve intricate designs and precise dimensions. Fiber laser technology is particularly advantageous in this phase due to its speed and accuracy, enabling manufacturers to create complex shapes that meet specific customer requirements.

-

Assembly: Once the components are formed, they are assembled. This may involve welding, bolting, or fastening parts together, depending on the design and intended use of the cutter. The assembly process must be carried out with precision to ensure that all components fit correctly and function seamlessly.

-

Finishing: The final stage involves surface treatment processes such as powder coating, anodizing, or galvanizing, which enhance the durability and aesthetic appeal of the metal sign cutters. Finishing not only protects against corrosion but also adds a professional look to the equipment, which is crucial for end-users in the B2B space.

How Do Quality Assurance Standards Apply to Metal Sign Cutters?

Quality assurance (QA) is vital in the manufacturing of metal sign cutters to ensure that products meet both customer expectations and international standards. Adherence to recognized QA standards such as ISO 9001 is essential, as it provides a framework for consistent quality management practices.

-

International Standards: ISO 9001 focuses on quality management systems and requires manufacturers to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Compliance with this standard is crucial for B2B buyers who operate in global markets, as it assures them of the reliability of their suppliers.

-

Industry-Specific Certifications: Depending on the market, additional certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) certifications for specific industrial applications may be necessary. These certifications signify that products comply with relevant safety, health, and environmental standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are implemented at various stages of the manufacturing process to ensure that products meet established standards before they reach the market. The primary QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Manufacturers should verify that materials meet specified standards and perform tests to detect any defects before proceeding to the next stage.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing checks are conducted to monitor the quality of work at various stages. This includes measuring dimensions, checking for defects, and ensuring that production processes adhere to established protocols.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is performed to ensure that each metal sign cutter meets quality and performance standards. This may involve functional testing and visual inspections to confirm that the product is free from defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct thorough due diligence to verify the quality control practices of their suppliers. Here are several effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control systems, and overall operations. During these audits, buyers should look for evidence of compliance with international standards and certifications.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance reports that outline their QC processes, testing methods, and results. These reports should include information on any deviations from standards and how they were addressed.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can conduct inspections at various stages of production and provide detailed reports on compliance with industry standards.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control:

-

Understanding Regional Standards: Different regions may have varying standards and regulations. Buyers should familiarize themselves with local compliance requirements to ensure that the products they source meet these standards.

-

Cultural Considerations: Communication styles and business practices can differ significantly across regions. Establishing clear expectations regarding quality control and delivery timelines can help mitigate misunderstandings.

-

Logistical Challenges: International shipping can introduce risks such as damage during transport. Buyers should ensure that suppliers have robust packaging and handling procedures in place to protect products during transit.

By understanding the manufacturing processes and quality assurance protocols associated with metal sign cutters, B2B buyers can make informed decisions when sourcing equipment. Prioritizing quality control not only enhances product reliability but also builds trust between buyers and suppliers, facilitating long-term business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal sign cutter’

To assist international B2B buyers in sourcing a metal sign cutter effectively, this guide provides a structured checklist. By following these steps, you can ensure that you choose the right equipment and supplier for your specific needs.

Step 1: Define Your Technical Specifications

Before starting your search, outline the technical requirements for your metal sign cutter. Consider factors such as the types of materials you plan to cut (e.g., stainless steel, aluminum, brass), the thickness of these materials, and the desired cutting precision. This step is crucial as it helps narrow down options and ensures the equipment meets your production needs.

- Material Compatibility: Ensure the cutter can handle the specific metals you intend to work with.

- Cutting Thickness: Identify the maximum thickness of metal you will be cutting to select an appropriate machine.

Step 2: Research Different Technologies

Familiarize yourself with the various cutting technologies available, such as CO2 laser, fiber laser, and plasma cutting. Each technology has its advantages and limitations regarding speed, precision, and material compatibility. Understanding these differences will help you make an informed decision based on your production requirements.

- Fiber Laser vs. CO2: Fiber lasers are generally faster and more efficient for metals, while CO2 lasers excel with non-metal materials.

- Application Suitability: Match the technology to your intended use, whether for intricate designs or high-volume production.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your technical and operational requirements. Request company profiles, product catalogs, and client references, especially from businesses in similar regions or industries. This evaluation is critical to avoid future issues with reliability and support.

- Reputation and Experience: Look for suppliers with a proven track record in the metal sign cutting industry.

- Customer Feedback: Seek testimonials or case studies that highlight their service quality and machine performance.

Step 4: Check Compliance and Certifications

Verify that the suppliers and their machines comply with relevant international safety and quality standards. Certifications such as ISO, CE, or specific industry standards indicate that the equipment has met rigorous testing and quality assurance processes.

- Local Regulations: Ensure that the equipment meets the regulations in your country, especially regarding safety and emissions.

- Warranty and Support: Check what warranties are offered and the availability of after-sales support and spare parts.

Step 5: Request Demonstrations and Samples

Whenever possible, request live demonstrations of the metal sign cutter or samples of its work. This will provide insight into the machine’s performance, ease of use, and the quality of the finished products. Observing the equipment in action can help you assess whether it meets your expectations.

- Production Speed: Evaluate how quickly the machine can produce the desired cuts.

- Quality of Cuts: Inspect the precision and finish of the sample cuts to ensure they align with your quality standards.

Step 6: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Ensure you understand all costs involved, including shipping and installation fees. Clear agreement on these terms is essential to avoid unexpected expenses.

- Bulk Discounts: Inquire about pricing tiers for larger orders, which can reduce overall costs.

- Payment Options: Discuss flexible payment terms that suit your cash flow.

Step 7: Finalize Your Purchase and Plan for Installation

After concluding negotiations, finalize your purchase and prepare for installation. Work with the supplier to coordinate delivery and setup, ensuring that your team is trained on the machine’s operation and maintenance. A well-planned installation will facilitate a smooth transition into production.

- Training Requirements: Confirm that the supplier offers adequate training for your staff on the new equipment.

- Maintenance Plans: Discuss ongoing maintenance services to ensure long-term operational efficiency.

By following this checklist, you can navigate the procurement process for a metal sign cutter with confidence, ensuring that you invest in the right equipment and supplier for your business needs.

Comprehensive Cost and Pricing Analysis for metal sign cutter Sourcing

What Are the Key Cost Components in Metal Sign Cutter Sourcing?

When sourcing metal sign cutters, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of materials used significantly influences the price. Common metals include stainless steel, aluminum, and brass, each with varying costs based on market demand and availability. Specialty materials or custom specifications can further increase expenses.

-

Labor: Labor costs encompass both direct manufacturing labor and indirect costs associated with skilled workers who operate and maintain cutting machines. In regions with higher labor costs, such as Europe, this can represent a significant portion of the overall price.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and indirect labor. These overhead costs can vary based on the operational efficiency of the manufacturer.

-

Tooling: The initial investment in tooling for precision cutting machines can be substantial. This includes the cost of dies, molds, and other specialized equipment necessary for producing high-quality metal signs.

-

Quality Control: Ensuring that products meet specified standards requires investment in QC processes, which can add to the overall cost. Certifications for quality assurance, especially in regulated markets, may further increase expenses.

-

Logistics: Transporting metal sign cutters involves additional costs. Factors such as shipping distance, mode of transport, and Incoterms (the international commercial terms) can significantly affect logistics expenses.

-

Margin: Finally, suppliers will include a profit margin in their pricing, which can vary based on market competition and perceived value.

How Do Price Influencers Affect Metal Sign Cutter Costs?

Several factors can influence the pricing of metal sign cutters, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs due to economies of scale. Manufacturers are typically more willing to negotiate pricing for bulk orders.

-

Specifications and Customization: Custom designs or advanced specifications can increase costs. Buyers should consider whether standard models meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO standards) generally command higher prices. However, investing in quality can lead to lower maintenance and replacement costs in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge a premium, but they can also offer better service and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, all of which can impact the total cost of acquisition.

What Are Essential Buyer Tips for Cost-Efficiency in Metal Sign Cutter Sourcing?

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should consider several strategies for cost-efficient sourcing:

-

Negotiate Effectively: Leverage volume purchases and long-term contracts to negotiate better pricing. Building a strong relationship with suppliers can also lead to more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price to consider maintenance, operational costs, and potential downtime. A cheaper cutter may have higher long-term costs due to lower efficiency or durability.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on local market conditions, currency fluctuations, and geopolitical factors. Buyers should conduct thorough market research to understand these dynamics.

-

Request Quotes from Multiple Suppliers: Obtaining multiple quotes allows buyers to compare prices and terms, ensuring they receive the best deal.

-

Stay Informed on Market Trends: Keeping abreast of trends in metal prices, labor costs, and technological advancements can help buyers make informed decisions and anticipate price changes.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing metal sign cutter With Other Solutions

Exploring Alternatives to Metal Sign Cutters for Signage Production

In the competitive world of signage production, businesses often seek the most efficient and effective methods for creating high-quality signs. While metal sign cutters are a popular choice, various alternative technologies and methods can achieve similar outcomes. This analysis will compare metal sign cutters with laser cutting machines and CNC routers, highlighting their respective strengths and weaknesses.

Comparison Table

| Comparison Aspect | Metal Sign Cutter | Laser Cutting Machine | CNC Router |

|---|---|---|---|

| Performance | High precision for metal materials | Exceptional accuracy and speed | Good precision, but slower for metals |

| Cost | Moderate to high initial investment | High initial investment | Moderate initial investment |

| Ease of Implementation | Requires specific training and setup | User-friendly with software integration | Requires skilled operators |

| Maintenance | Regular blade changes and upkeep | Low maintenance, occasional lens replacement | Regular maintenance required |

| Best Use Case | Custom metal signage and durable branding | Intricate designs and fast production | Versatile applications, including wood and plastics |

Detailed Breakdown of Alternatives

Laser Cutting Machines

Laser cutting machines utilize focused beams of light to cut through various materials, including metals. They offer exceptional precision and speed, making them ideal for intricate designs and high-volume production. One of the primary advantages of laser cutters is their ability to create detailed and complex shapes that would be challenging with traditional methods. However, the initial investment is significantly higher, and while maintenance is low, it may require occasional lens replacements. Laser cutting is best suited for businesses that prioritize intricate design work and fast turnaround times.

CNC Routers

CNC routers are versatile machines that can cut, carve, and engrave a variety of materials, including wood, plastics, and some metals. While they are slower when it comes to cutting metals compared to laser cutters, they excel in detailed carving and shaping of softer materials. The initial investment for CNC routers is moderate, and they can be a cost-effective solution for businesses that require versatility across multiple materials. However, CNC routers require skilled operators for programming and operation, which can be a consideration for companies with limited technical expertise. They are best used for signage projects that involve wood or composite materials.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a solution for metal signage production, B2B buyers must consider their specific requirements, including the types of materials used, desired precision, production volume, and budget constraints. Metal sign cutters are excellent for durable, custom metal signage, while laser cutting machines offer speed and intricacy for detailed projects. CNC routers provide versatility for a broader range of materials but may not be the best choice for metal cutting. By evaluating these alternatives against their operational needs, buyers can make informed decisions that align with their business goals and enhance their signage offerings.

Essential Technical Properties and Trade Terminology for metal sign cutter

What Are the Key Technical Properties of Metal Sign Cutters?

When evaluating metal sign cutters, understanding specific technical properties is crucial for B2B buyers. These specifications not only influence the performance of the equipment but also affect the quality and durability of the final products.

1. Material Grade

The material grade refers to the type of metal that can be processed by the cutter. Common materials include stainless steel, mild steel, aluminum, and brass. Each material has unique properties that can affect the cutter’s performance, such as cutting speed, precision, and the finish quality of the cut. For businesses, selecting the right material grade is essential to ensure compatibility with their product needs and to maintain a competitive edge in the market.

2. Cutting Thickness

This specification indicates the maximum thickness of the material that can be effectively cut by the machine. For example, a fiber laser cutter may handle materials up to 20mm thick, while a CO2 cutter may be limited to thinner materials. Knowing the cutting thickness is vital for businesses to determine if the machine meets their production requirements and can handle the materials they intend to use.

3. Tolerance

Tolerance refers to the allowable variation in the dimensions of the cut. High-precision machines may offer tolerances as tight as ±0.01mm. In the B2B sector, precision is critical, especially for applications requiring intricate designs or exact measurements. Understanding tolerance helps buyers ensure that the equipment will meet their quality standards and reduce waste.

4. Power Rating

The power rating, typically measured in watts, indicates the strength of the laser beam. Higher wattage allows for faster cutting speeds and the ability to cut through thicker materials. For B2B buyers, selecting a machine with an appropriate power rating is essential to meet production demands and enhance efficiency.

5. Speed

Cutting speed is a measure of how quickly the machine can cut through materials, usually expressed in meters per minute. Speed is a significant factor for businesses looking to optimize production times and reduce costs. A faster machine can lead to higher throughput and better profit margins.

6. Cooling System

The cooling system is crucial for maintaining optimal operating temperatures during prolonged cutting operations. Effective cooling prevents overheating, which can damage both the machine and the materials being cut. For B2B buyers, understanding the cooling capabilities of a metal sign cutter can influence maintenance costs and machine longevity.

What Common Trade Terms Should B2B Buyers Know?

Navigating the purchasing process for metal sign cutters involves familiarity with industry jargon and trade terms that are essential for effective communication and negotiation.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of metal sign cutters, understanding OEM relationships can help buyers assess the quality and reliability of the machines they are considering, as reputable OEMs often guarantee parts and service.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ is crucial for budgeting and inventory management, as it can impact cash flow and storage capacity.

3. RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers requesting pricing for specific products or services. This process is essential for obtaining competitive pricing and understanding the market landscape for metal sign cutters.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and delivery points. Familiarity with Incoterms helps B2B buyers avoid misunderstandings regarding shipping and logistics.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses, understanding lead times is vital for planning production schedules and managing customer expectations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right metal sign cutter that aligns with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the metal sign cutter Sector

What Are the Key Trends Shaping the Metal Sign Cutter Market?

The metal sign cutter market is experiencing significant growth driven by various global factors. Increased demand for personalized signage in retail and hospitality sectors is a key driver, as businesses seek unique branding solutions to stand out. Technological advancements, particularly in laser cutting technology, are enhancing the precision and efficiency of metal sign production. Fiber laser cutters, such as 1500W models, are becoming increasingly popular due to their ability to cut a variety of metals with high speed and accuracy, making them ideal for custom sign creation.

Moreover, international buyers from regions like Africa, South America, the Middle East, and Europe are capitalizing on e-commerce platforms to source cutting-edge machinery. The trend towards automation in manufacturing processes is also gaining momentum, allowing companies to reduce labor costs and improve output quality. As digital marketing strategies evolve, the need for attractive, high-quality metal signage that can withstand various environmental conditions is paramount, pushing businesses to invest in advanced cutting technologies.

How Are Sustainability and Ethical Sourcing Influencing B2B Buyers?

In today’s market, sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the metal sign cutter sector. The environmental impact of manufacturing processes, particularly those that involve metal, is under increasing scrutiny. Companies are now seeking suppliers who can provide sustainable materials, such as recycled metals or those certified by environmental standards.

Moreover, ethical supply chains are a priority; buyers are more inclined to partner with manufacturers that demonstrate responsible sourcing practices and transparent operations. Certifications such as ISO 14001 for environmental management and the use of eco-friendly coatings can enhance a supplier’s appeal. By prioritizing sustainability, companies not only contribute to environmental conservation but also align their brand with consumer preferences that favor eco-conscious practices. This alignment can lead to improved brand loyalty and competitive advantage in the marketplace.

What Is the Historical Context of Metal Sign Cutters in B2B?

The evolution of metal sign cutters can be traced back to traditional methods of metalworking, which relied heavily on manual labor and rudimentary tools. With the advent of technology in the late 20th century, the introduction of CNC (Computer Numerical Control) machines revolutionized the industry, allowing for greater precision and efficiency.

The 21st century has seen the rise of laser cutting technology, particularly fiber lasers, which have significantly enhanced the capabilities of metal sign production. These advancements have made it possible to create intricate designs and personalized signage at a fraction of the time and cost compared to earlier methods. As the demand for customized solutions continues to grow, the metal sign cutter market is poised for further innovations, ensuring its relevance in an increasingly competitive landscape.

In summary, understanding the market dynamics, sustainability trends, and historical context of metal sign cutters is crucial for B2B buyers looking to make informed sourcing decisions. By aligning with innovative suppliers who prioritize quality and ethical practices, businesses can enhance their brand visibility and operational efficiency in the metal sign industry.

Frequently Asked Questions (FAQs) for B2B Buyers of metal sign cutter

-

How do I choose the right metal sign cutter for my business needs?

Choosing the right metal sign cutter involves evaluating several key factors, including the types of materials you plan to work with (such as stainless steel, aluminum, or brass), the thickness of the materials, and the desired precision of cuts. Additionally, consider the machine’s power specifications (e.g., wattage), speed, and the range of functionalities it offers, such as engraving or marking. It’s also important to assess the machine’s compatibility with software you may already use, as well as the level of customer support and training provided by the supplier. -

What is the best laser cutter for creating custom metal signs?

The best laser cutter for creating custom metal signs is typically a fiber laser cutter, especially models with a minimum of 1500W power. Fiber lasers provide superior precision and speed, making them ideal for intricate designs and detailed cuts on various metals, including stainless steel and aluminum. Look for features like automated settings, compatibility with various software, and user-friendly interfaces. Brands with a proven track record in the industry, along with strong customer support, will help ensure you make an informed investment. -

What are the typical minimum order quantities (MOQs) for metal sign cutters?

Minimum order quantities (MOQs) for metal sign cutters can vary significantly depending on the supplier and the specific model. Some manufacturers may require a MOQ of one unit for standard models, while custom or specialized machines might have higher MOQs. When sourcing, inquire about volume discounts as larger orders often come with reduced prices. It’s also beneficial to discuss future needs, as building a relationship with the supplier can lead to more favorable terms over time. -

What payment terms should I expect when sourcing a metal sign cutter internationally?

Payment terms can vary widely based on the supplier and your location. Common terms include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letter of credit options, which provide additional security for both parties. It is essential to clarify payment methods accepted (e.g., bank transfer, credit card) and inquire about any financing options available, especially for high-ticket items like metal sign cutters. -

How can I verify the reliability of a supplier for metal sign cutters?

To verify a supplier’s reliability, start by checking their business credentials, including company registration and industry certifications. Look for reviews and testimonials from previous clients, and consider requesting references. Engaging in direct communication can provide insight into their responsiveness and customer service. Additionally, visiting the supplier’s facility, if feasible, or reviewing their production processes can further assure you of their capabilities and commitment to quality. -

What customization options are available for metal sign cutters?

Most suppliers offer a range of customization options for metal sign cutters, including specific dimensions, power settings, and additional features such as engraving capabilities. You may also be able to request modifications to the machine’s software for specific design needs. Discuss your requirements with the supplier to explore available options and ensure the cutter aligns with your production goals, as customized solutions can enhance efficiency and output quality. -

What quality assurance practices should I expect from suppliers of metal sign cutters?

Reputable suppliers typically implement rigorous quality assurance practices, including standardized testing of machines before shipment, adherence to international manufacturing standards, and detailed documentation of each unit’s specifications. You should expect to receive a quality certificate along with your equipment. It’s also advisable to discuss warranty terms and after-sales support, as these are critical components of ensuring long-term reliability and performance of your metal sign cutter. -

What logistics considerations should I keep in mind when importing a metal sign cutter?

When importing a metal sign cutter, logistics considerations include shipping costs, customs duties, and import regulations specific to your country. Ensure that the supplier can provide necessary documentation for customs clearance. Additionally, consider the lead time for production and shipping, and whether the supplier offers direct shipping to your location. Engaging a reliable freight forwarder can help streamline the process and mitigate any potential delays or complications during transport.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Metal Sign Cutter Manufacturers & Suppliers List

1. CAMFive – Laser Cutters & Engravers

Domain: camfivelaser.com

Registered: 2018 (7 years)

Introduction: Sign Making Laser Cutters & Engravers:

1. CAMFive Laser CO2 Cutter & Engraver Model CMA6348K – 63 x 48 inches, Price: $10,999.00

2. CAMFive Laser Fiber Engraver and Cutter FM70Q/FM80Q/FM100Q – 70W to 100W, Quartz based for Jewelry, Price: $19,999.00

3. CAMFive Laser Fiber Engraver Model FM20P – 20W Source Portable, Engraving and Marking Machine for Hobby and Home Use, Price: $5,390.00

4. CAMFive …

2. OMTech – Fiber Laser Cutters

Domain: omtechlaser.com

Registered: 2020 (5 years)

Introduction: OMTech offers a range of laser cutting machines suitable for creating custom metal signs, including Fiber Laser Cutters like the OMTech FC-22C, FC-22, and FC-510. These machines are designed for high-speed precision cutting of metal materials. The blog emphasizes the importance of preparing the laser cutting design, performing pre-cutting checkups, loading materials, aligning workpieces, configuri…

3. Bodor – Fiber Laser Cutting Machines

Domain: bodor.com

Registered: 2003 (22 years)

Introduction: Bodor offers a “GIVE ME FIVE” promotion, providing a 5-year warranty care for their fiber laser cutting machines. The fiber laser cutting technology is highlighted as the best choice for metal sign fabrication, offering higher precision, faster cutting speeds, better efficiency, and lower operational costs compared to Co2 laser cutters. Bodor’s fiber laser cutters can produce various metal signs i…

4. Laguna Tools – CNC Machines for Sign Making

Domain: lagunatools.com

Registered: 1996 (29 years)

Introduction: CNC Machines for Sign Making by Laguna Tools are designed for speed, precision, and versatility. They can cut, carve, and engrave various materials including wood, plastic, foam, aluminum, chloroplast, Falcon Board, Foam Board, acrylic, and ACM/ACP material. Key features include multi-axis capabilities up to 5D for intricate projects, an integrated optical lens registration system for precision al…

5. Woodland Manufacturing – Custom Metal Letters

Domain: woodlandmanufacturing.com

Registered: 2001 (24 years)

Introduction: Cut Metal Letters – Customizable in any font and size. Made from various materials including Aluminum, Steel, Copper, Bronze, and Brass. Available finishes include brushed satin, rusted, painted, and powder coated. Suitable for indoor and outdoor use. Options for solid metal letters, logos, and numbers. Customer service available for design assistance and material selection. Special discounts avai…

6. SendCutSend – Custom Sheet Metal Fabrication Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom parts with no minimum quantities and free US shipping on orders over $39. Standard production time is 2-…

7. YesWelder – DIY Plasma Cutter Sign

Domain: yeswelder.com

Registered: 2018 (7 years)

Introduction: This company, YesWelder – DIY Plasma Cutter Sign, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Langmuir Systems – FireControl Software

Domain: forum.langmuirsystems.com

Registered: 2017 (8 years)

Introduction: This company, Langmuir Systems – FireControl Software, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for metal sign cutter

How Can Strategic Sourcing Enhance Your Metal Sign Cutting Operations?

In conclusion, strategic sourcing is pivotal for international B2B buyers seeking to optimize their metal sign cutting operations. By aligning with reliable suppliers and leveraging advanced technologies like fiber laser cutting, businesses can achieve exceptional precision, efficiency, and quality in their signage products. The growing demand for customized and durable metal signage across diverse markets, particularly in Africa, South America, the Middle East, and Europe, highlights the importance of sourcing high-quality cutting equipment that meets specific needs.

Investing in state-of-the-art metal sign cutters not only enhances production capabilities but also significantly reduces operational costs over time. As businesses aim to differentiate themselves in competitive markets, the ability to produce bespoke signage that resonates with local cultures and preferences becomes increasingly valuable.

As you explore opportunities for growth, consider strengthening your supplier relationships and investing in innovative cutting technologies. This proactive approach will position your business for success in the evolving landscape of metal signage. Embrace the future of custom metal cutting today and unlock new possibilities for your brand’s visibility and impact.