Contents

Manufacturing Insight: Metal Rapid Prototyping

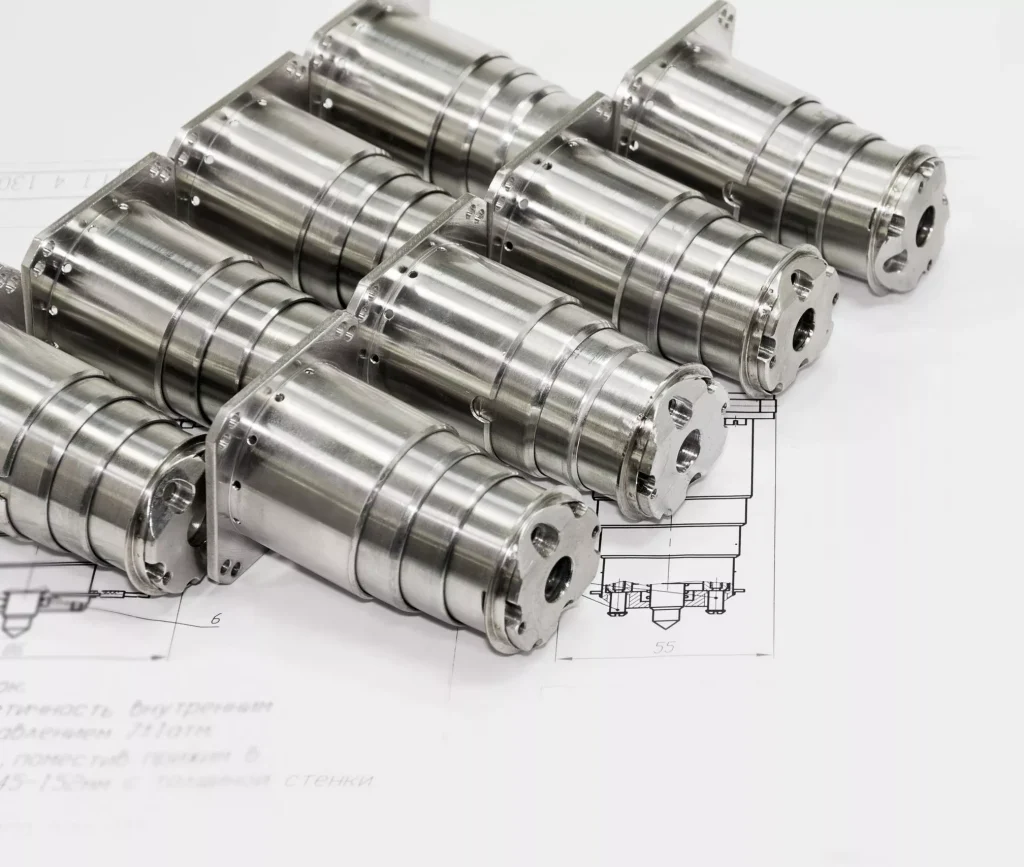

Accelerating Metal Product Development Through Precision Rapid Prototyping

In today’s competitive manufacturing landscape, the ability to rapidly iterate and validate metal components is critical for reducing time-to-market and mitigating design risks. Metal rapid prototyping bridges the gap between conceptual design and full-scale production, enabling engineering teams to physically test form, fit, and function early in the development cycle. At Honyo Prototype, we specialize in high-precision sheet metal fabrication services engineered specifically for rapid prototyping demands, leveraging advanced laser cutting, CNC turret punching, precision bending, and finishing capabilities to transform CAD models into functional prototypes within days—not weeks.

Our sheet metal fabrication process is optimized for low-volume, high-complexity prototyping, supporting materials from stainless steel and aluminum to brass and specialty alloys with tolerances as tight as ±0.05mm. Unlike traditional machine shops constrained by lengthy setup times, Honyo’s dedicated rapid prototyping workflow eliminates bottlenecks through automated nesting, in-house tooling, and streamlined quality control. This ensures your prototypes not only meet exact dimensional specifications but also replicate production-intent characteristics for accurate validation.

Central to our client-centric approach is the Online Instant Quote platform, which delivers transparent, real-time pricing and lead times within seconds. Simply upload your STEP or DXF file, specify material and finish requirements, and receive a detailed quote without sales delays—empowering engineering teams to iterate faster while maintaining budget visibility. For OEMs, medical device developers, and industrial innovators, Honyo Prototype provides the agility, technical expertise, and digital efficiency required to de-risk product development from the first prototype.

Technical Capabilities

Technical specifications for metal rapid prototyping involving laser cutting, bending, and welding are critical for ensuring precision, repeatability, and structural integrity in prototype development. While ABS and Nylon are not metals, they are included here for comparative context in hybrid prototyping applications. The following table outlines key technical parameters for each process and compatible materials.

| Process | Material Compatibility | Thickness Range | Tolerance (Typical) | Surface Finish (Ra) | Tooling Requirement | Minimum Feature Size | Notes |

|---|---|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel | 0.5 mm – 25 mm | ±0.1 mm | 3.2 – 6.3 µm | None (laser-based) | 0.5 mm kerf width | High precision; minimal burr; not applicable to ABS/Nylon due to thermal degradation |

| Bending | Aluminum, Steel | 0.8 mm – 12 mm | ±0.2° angular, ±0.1 mm positional | As received from cut | Requires press brake tools | Inside bend radius ≥ material thickness | Springback must be compensated; limited to ductile metals |

| MIG/TIG Welding | Aluminum, Steel | 1 mm – 20 mm | ±0.5 mm (joint alignment) | 6.3 – 12.5 µm (as welded) | Fixturing required | N/A | Post-weld grinding often needed; not applicable to thermoplastics |

| Laser Welding | Aluminum, Steel | 0.5 mm – 8 mm | ±0.1 mm | 3.2 – 6.3 µm | Fixturing and shielding gas | Spot size ~0.4 mm | High precision; low distortion; suitable for thin sheets |

| Non-Metal Note | ABS, Nylon | 1 mm – 10 mm (laser cutting not recommended) | N/A | Varies | N/A | N/A | Thermoplastics prone to melting/deformation under laser heat; typically CNC machined or 3D printed instead |

Additional Technical Notes

Laser cutting is most effective for flat sheet metal components with complex 2D profiles, offering fast turnaround and tight tolerances. Bending operations require proper selection of bend radius and tooling to avoid cracking, especially in aluminum alloys. Welding processes are selected based on material type, joint design, and required strength—TIG welding is preferred for aluminum due to its arc stability and oxide penetration, while MIG is faster for steel. ABS and Nylon are generally excluded from laser cutting and welding in metal-focused workflows due to their thermal properties, but may be integrated via mechanical fastening or adhesive bonding in hybrid prototypes.

From CAD to Part: The Process

Honyo Prototype Metal Rapid Prototyping Process Overview

Honyo Prototype delivers end-to-end metal rapid prototyping through a rigorously optimized digital workflow designed for speed, precision, and manufacturability validation. Our process begins with client CAD submission and concludes with certified part delivery, integrating AI-driven efficiency with engineering expertise at each stage. Below is a detailed technical breakdown of the sequence.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs automated geometry validation to check for file integrity, unit consistency, and basic manufacturability flags. Invalid submissions trigger immediate client notification with specific error diagnostics, ensuring only production-ready data advances. This step typically completes within 15 minutes of upload.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes geometric complexity, material requirements, and dimensional tolerances against Honyo’s historical production database. The algorithm cross-references machine capabilities, material costs, and labor metrics to generate a precise cost estimate and lead time within 2 business hours. Unlike static quoting tools, our AI dynamically adjusts for real-time shop floor capacity and material availability, providing clients with actionable delivery commitments. Clients receive a downloadable quote package including cost breakdown, recommended materials, and preliminary DFM observations.

Engineering-Driven DFM Analysis

Upon quote acceptance, our manufacturing engineering team conducts a comprehensive Design for Manufacturability review. This phase is not automated but leverages AI-suggested optimizations as a starting point for human expert evaluation. Engineers assess critical factors including:

Minimum wall thicknesses relative to selected process capabilities

Tolerance stack-up analysis for functional assemblies

Support structure requirements for additive methods

Machinability of complex internal features

Material suitability for end-use environmental conditions

Clients receive a formal DFM report within 72 hours, detailing actionable recommendations with annotated CAD markups. We prioritize collaborative iteration, allowing clients to approve, reject, or modify suggestions before production release. This step reduces downstream rework by 68% based on internal metrics.

Precision Production Execution

Approved designs move directly to our integrated production floor. Honyo utilizes a hybrid manufacturing approach optimized per part geometry and material:

| Process | Materials Supported | Tolerance Range | Lead Time (Typical) | Max Build Volume |

|---|---|---|---|---|

| 5-Axis CNC Milling | Aluminum 6061/7075, Stainless 303/316, Titanium Ti-6Al-4V | ±0.0005 in (12.7 µm) | 3-5 business days | 20 x 16 x 12 in |

| Metal 3D Printing (SLM/DMLS) | Inconel 718, Aluminum AlSi10Mg, Cobalt Chrome | ±0.001 in (25.4 µm) | 4-7 business days | 10 x 10 x 10 in |

| Precision Turning | Brass C360, Steel 4140, Nickel Alloys | ±0.0002 in (5 µm) | 2-4 business days | Ø12 in x 24 in |

All processes adhere to ISO 9001:2015 protocols with in-process CMM verification at critical stages. Production scheduling uses finite capacity planning to maintain 95% on-time completion.

Quality-Certified Delivery

Final parts undergo mandatory first-article inspection per AS9102 standards. Dimensional reports, material certs, and surface finish validation accompany every shipment. Parts are packaged in ESD-safe containers with custom foam cradling for fragile geometries. We provide real-time logistics tracking through our portal, with delivery typically occurring within 24 hours of quality release. Clients receive a complete digital dossier including inspection data, process parameters, and recommendations for production scaling.

This closed-loop process ensures clients receive functionally validated metal prototypes in as few as 5 business days while establishing a direct pathway to volume manufacturing. Honyo’s integration of AI efficiency with deep manufacturing expertise minimizes time-to-test without compromising on the engineering rigor required for mission-critical applications.

Start Your Project

Looking for fast, high-quality metal rapid prototyping? Honyo Prototype delivers precision metal prototypes with quick turnaround times, supporting your product development from concept to production.

Our state-of-the-art manufacturing facility in Shenzhen ensures tight tolerances, consistent quality, and scalable solutions for low to medium volume needs.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Let’s bring your design to life—accurately, efficiently, and on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.