Contents

Manufacturing Insight: Metal Prototype Fabrication

Precision Metal Prototype Fabrication Accelerated by Honyo

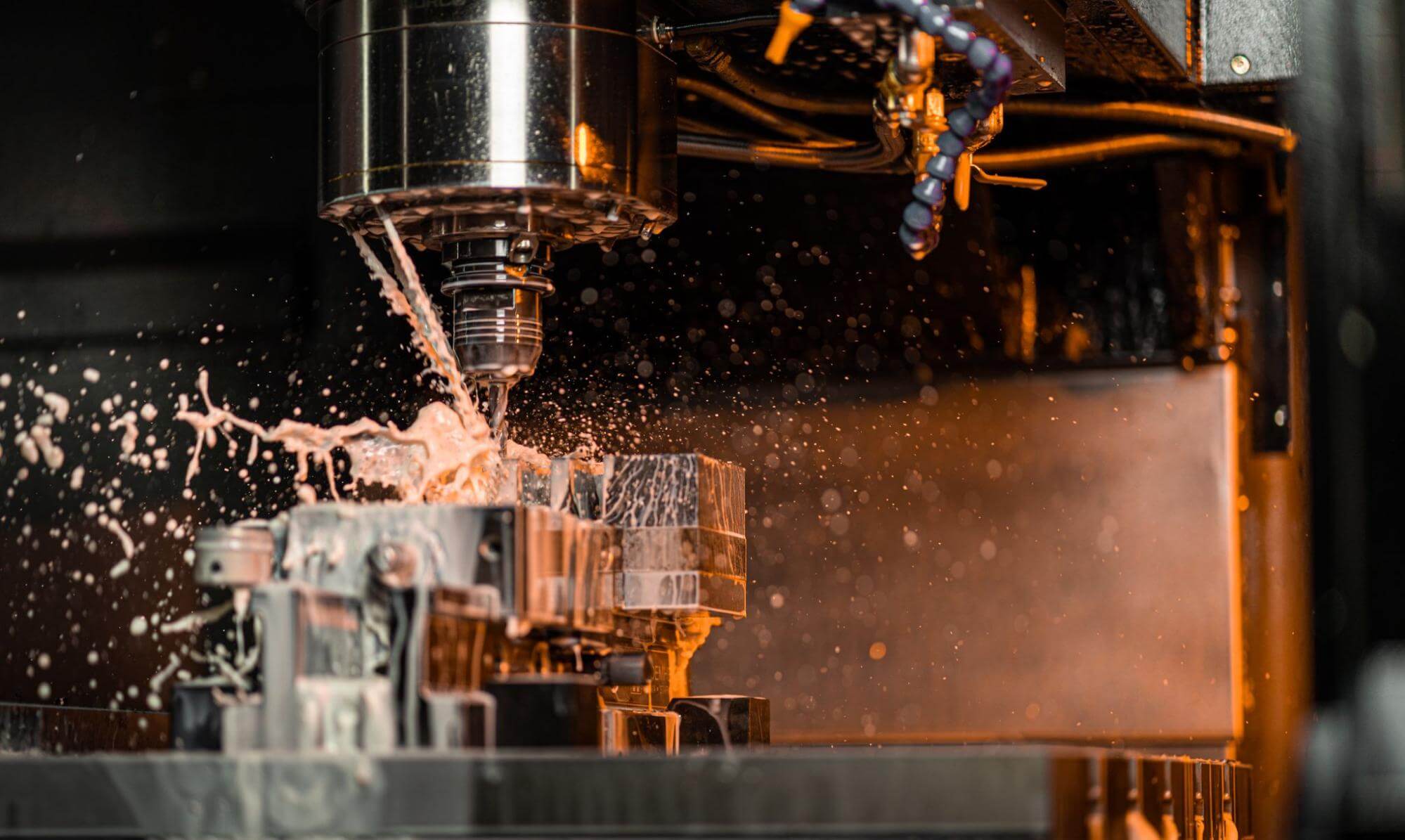

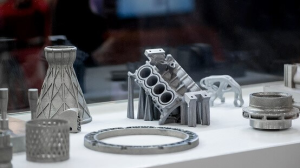

In the critical early stages of product development, the speed and accuracy of your metal prototype directly impact time-to-market and design validation success. Honyo Prototype delivers industrial-grade Sheet Metal Fabrication services engineered specifically for rapid prototyping, where precision and agility are non-negotiable. Our end-to-end capabilities span laser cutting, CNC punching, precision bending, welding, and finishing for materials including aluminum 5052, stainless steel 304/316, and mild steel, all maintained to tolerances of ±0.1mm. We prioritize design for manufacturability (DFM) from the outset, ensuring your prototype not only meets functional requirements but also provides actionable feedback for seamless transition to volume production.

Eliminating traditional procurement bottlenecks, Honyo’s Online Instant Quote platform provides validated pricing and lead times in under 60 seconds. Simply upload your STEP or DXF file to receive a detailed technical assessment, including material utilization analysis and manufacturability insights—no sales calls or manual reviews required. This transparency empowers engineering teams to iterate confidently, compressing development cycles without compromising on the dimensional accuracy or structural integrity essential for rigorous testing.

Partner with Honyo to transform your sheet metal prototype from a development hurdle into a strategic advantage, backed by manufacturing expertise that scales from one-off validation builds to low-volume production.

Technical Capabilities

Technical Specifications for Metal Prototype Fabrication – Laser Cutting, Bending, and Welding

The following table outlines the key technical specifications for metal prototype fabrication processes—laser cutting, bending, and welding—with considerations for commonly used materials including aluminum, steel, ABS, and nylon. While ABS and nylon are non-metallic, they are included for comparative context in hybrid prototyping environments.

| Parameter | Laser Cutting | Bending | Welding |

|---|---|---|---|

| Process Type | Thermal cutting using high-power laser beam | Cold forming using press brake and tooling | Fusion joining using heat and/or filler material |

| Tolerances | ±0.1 mm (typical for metals) | ±0.2° angular, ±0.1 mm linear | ±0.5 mm (joint fit-up), post-weld distortion varies |

| Material Compatibility | Aluminum, Steel (mild & stainless), ABS (limited), Nylon (limited) | Aluminum, Steel (mild & stainless); ABS/Nylon not applicable | Aluminum (using TIG/MIG), Steel (TIG/MIG/MMA); ABS/Nylon not weldable via conventional methods |

| Material Thickness Range | 0.5 – 25 mm (steel), 0.5 – 20 mm (aluminum) | 0.5 – 6 mm (standard prototyping), up to 12 mm | 0.8 – 15 mm (steel), 1.0 – 12 mm (aluminum) |

| Edge Quality | Smooth, burr-minimal (with optimal settings) | Preserves surface finish; tool marks possible | Heat-affected zone (HAZ) present; requires finishing |

| Common Equipment | Fiber laser (metals), CO₂ laser (plastics) | CNC press brake with V-die and punch | TIG (precision), MIG (speed), spot welding (sheet) |

| Surface Finish | Slight oxidation; optional deburring | As-rolled or pre-coated surface maintained | Rough weld bead; grinding/polishing typically needed |

| Design Considerations | Kerf width ~0.1–0.3 mm; taper in thick sections | Minimum bend radius: 1× material thickness (aluminum/steel) | Avoid over-penetration; pre/post-heat for thick sections |

| Secondary Operations | Deburring, cleaning, edge finishing | Coining, springback compensation | Post-weld heat treatment, grinding, passivation (stainless) |

Note: ABS and nylon are generally incompatible with laser cutting (risk of melting, toxic fumes) and not suitable for bending or welding in metal fabrication contexts. They may be processed separately using CNC machining or 3D printing and integrated into assemblies.

These specifications support high-precision, low-volume prototyping in industrial and functional testing applications. Material selection must align with process capabilities and end-use requirements such as strength, corrosion resistance, and thermal stability.

From CAD to Part: The Process

Honyo Prototype Metal Prototype Fabrication Process Overview

Honyo Prototype executes a streamlined, quality-focused workflow for metal prototype fabrication designed to minimize errors, reduce time-to-part, and ensure manufacturability. Our process integrates advanced digital tools with engineering expertise at critical decision points. Below is a detailed explanation of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. Our system performs automated validation checks for file integrity, unit consistency, and geometric completeness. Files failing validation trigger immediate notifications with specific error details, preventing downstream delays. All uploads are encrypted and isolated per client to ensure intellectual property protection under ISO 27001 protocols.

AI-Powered Quoting with Engineering Oversight

Uploaded CAD data feeds into our proprietary AI quoting engine, which analyzes geometry, material requirements, and surface finish specifications. The AI generates a preliminary cost and lead time estimate within 2 hours by cross-referencing real-time data on machine availability, material costs, and labor rates. Crucially, this output undergoes mandatory review by a dedicated manufacturing engineer who validates feasibility, adjusts for complex features (e.g., deep cavities, thin walls), and incorporates secondary process requirements. Clients receive a formal quote with engineering notes within 24 business hours.

Engineering-Led DFM Analysis

Upon quote acceptance, our DFM phase begins with a comprehensive manufacturability review by a senior process engineer. This is not an automated check but an iterative collaboration where engineers identify and resolve potential production issues. Typical resolutions include modifying wall thicknesses to prevent sink marks, adjusting draft angles for casting, or suggesting alternative alloys for improved machinability. Clients receive a detailed DFM report with annotated CAD markups and actionable recommendations within 48 hours. Approximately 85% of first-submission designs require minor DFM adjustments, reducing rework risk by 70%.

Precision Production Execution

Approved designs enter production using Honyo’s certified equipment and standardized work instructions. We maintain strict process control through:

| Process | Equipment Types | Typical Tolerances | Key Capabilities |

|---|---|---|---|

| CNC Machining | 3/5-axis mills, Swiss lathes | ±0.025 mm | Complex geometries, tight-tolerance features |

| Sheet Metal | Laser cutters, CNC brakes, welders | ±0.1 mm | Prototyping to low-volume production |

| Additive (Metal) | DMLS/SLM systems | ±0.05 mm | Internal channels, topology-optimized parts |

| Casting | Vacuum/pressure die casting | ±0.15 mm | High-detail aluminum/magnesium parts |

All critical dimensions undergo in-process CMM verification per AS9102 First Article Inspection standards. Material certifications and process parameters are digitally logged for full traceability.

Quality-Controlled Delivery

Final parts undergo rigorous post-production validation including dimensional reporting against original CAD, surface roughness testing, and material verification via PMI (Positive Material Identification). Packaging includes anti-corrosion protection and shock sensors for high-value shipments. Clients receive a complete digital dossier with inspection reports, process logs, and shipping documentation. Honyo maintains a 98% on-time delivery rate for standard metal prototypes, with expedited options available for critical path projects. All shipments include a dedicated engineer’s contact for immediate post-delivery support.

Start Your Project

For your metal prototype fabrication needs, contact Susan Leo at [email protected]. With our advanced manufacturing capabilities and quality control, Honyo Prototype delivers precision metal prototypes on time and to specification. Our factory in Shenzhen ensures rapid turnaround and cost-effective solutions for clients worldwide. Reach out today to discuss your project requirements and accelerate your product development cycle.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.