Introduction: Navigating the Global Market for metal printing service

In today’s competitive landscape, sourcing reliable metal printing services poses a significant challenge for B2B buyers, especially those operating across diverse international markets such as Africa, South America, the Middle East, and Europe. The complexity of selecting the right technology—be it Direct Metal Laser Sintering (DMLS) or Binder Jetting—alongside the need for quality assurance and cost-effectiveness can overwhelm even the most seasoned procurement professionals. This guide offers a comprehensive exploration of metal printing services, detailing various types of technologies, their applications, and the essential criteria for supplier vetting.

From understanding the nuances of different metal materials to evaluating post-processing options, this resource is designed to equip international buyers with the insights necessary for informed purchasing decisions. It addresses critical factors such as lead times, production capabilities, and quality certifications, which are paramount when navigating the global market. By leveraging this guide, B2B buyers can streamline their sourcing process, mitigate risks, and ultimately enhance their supply chain efficiency. Whether you are looking to produce prototypes, functional parts, or complex geometries, this guide empowers you to make strategic decisions that align with your business goals in the evolving landscape of metal printing services.

Understanding metal printing service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Metal Laser Sintering (DMLS) | Uses a laser to fuse metallic powder layer by layer, producing fully dense parts. | Aerospace, automotive, medical devices | Pros: High precision, excellent mechanical properties. Cons: Higher cost, longer lead times. |

| Metal Binder Jetting | Deposits a binding agent onto metal powder, followed by sintering, allowing for complex shapes. | Prototyping, tooling, low-volume production | Pros: Cost-effective for large parts, fast production. Cons: Parts may require additional strength treatment. |

| Selective Laser Melting (SLM) | Similar to DMLS, focuses on melting metal powder to create highly detailed parts. | High-performance applications, aerospace | Pros: Superior mechanical properties, excellent for complex geometries. Cons: Expensive setup and material costs. |

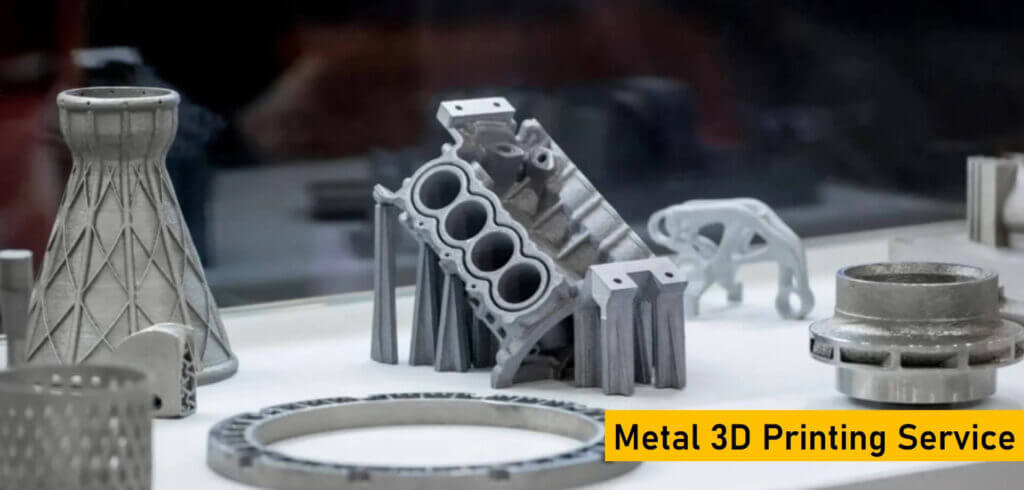

| Metal 3D Printing (General) | Encompasses various methods to create metal parts using additive manufacturing techniques. | Custom parts across industries | Pros: Versatile, can produce complex designs. Cons: Not all methods yield the same mechanical properties. |

| Powder Bed Fusion | Utilizes a laser or electron beam to fuse metal powder in a bed, allowing for intricate designs. | Aerospace, energy sectors | Pros: High design freedom, suitable for large-scale production. Cons: Slower than other methods, potential for powder contamination. |

What is Direct Metal Laser Sintering (DMLS) and Its B2B Relevance?

DMLS is a leading method in metal printing that employs a laser to fuse metallic powders, creating robust and fully dense parts. This process is particularly advantageous for industries requiring high precision and durability, such as aerospace and medical devices. When considering DMLS, B2B buyers should evaluate factors such as material costs, lead times, and the specific mechanical properties required for their applications, as it can be more expensive than other methods but offers unmatched quality.

How Does Metal Binder Jetting Differ in Applications?

Metal binder jetting is a cost-effective alternative that involves applying a binding agent to metal powder before sintering. This method excels in producing complex geometries and is ideal for prototyping and tooling applications. For B2B buyers, the key considerations include the need for post-processing to enhance strength and the potential trade-off between cost and mechanical performance, making it suitable for low-volume production runs where speed and affordability are prioritized.

What Advantages Does Selective Laser Melting (SLM) Offer?

Selective Laser Melting is closely related to DMLS, focusing on melting metal powder for high-detail outputs. This technique is highly regarded for applications requiring superior mechanical properties and is commonly used in high-performance sectors such as aerospace. B2B buyers should consider SLM for projects that demand intricate designs and exceptional material performance, despite the higher costs associated with the setup and materials.

Why Consider General Metal 3D Printing?

Metal 3D printing encompasses various technologies, allowing for the production of custom parts across multiple industries. Its versatility enables the creation of complex designs that traditional manufacturing methods may not achieve. B2B buyers should assess the specific printing technology that best aligns with their needs, as not all methods deliver the same level of mechanical properties, which could impact the final product’s performance.

What is the Role of Powder Bed Fusion in Metal Printing?

Powder bed fusion techniques, including DMLS and SLM, utilize lasers or electron beams to fuse metal powder in a bed, enabling intricate designs. This method is particularly beneficial in sectors such as aerospace and energy, where design freedom is critical. B2B buyers must weigh the advantages of high design capability against potential challenges like slower production speeds and the risk of powder contamination, ensuring that their choice aligns with project timelines and quality standards.

Key Industrial Applications of metal printing service

| Industry/Sector | Specific Application of metal printing service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight, complex components for aircraft | Reduces weight and improves fuel efficiency; enables rapid prototyping | Certification requirements (e.g., AS9100), material traceability |

| Automotive | Custom tooling and production parts | Shortens lead times and enhances design flexibility | Material selection, post-processing options, production volume |

| Medical Devices | Patient-specific implants and surgical tools | Customization for improved patient outcomes; reduced inventory costs | Regulatory compliance (e.g., FDA), biocompatibility of materials |

| Oil & Gas | Custom valve and pump components | Enhances durability in harsh environments; reduces downtime | Material performance in extreme conditions, part validation |

| Industrial Machinery | Replacement parts for legacy equipment | Minimizes downtime with on-demand production; reduces inventory costs | Tolerance specifications, lead times, and post-processing needs |

How is Metal Printing Service Applied in Aerospace?

In the aerospace sector, metal printing services are utilized to create lightweight and complex components that contribute to overall aircraft efficiency. Parts such as brackets, support structures, and fuel nozzles can be produced with intricate geometries that traditional manufacturing methods cannot achieve. This capability not only reduces weight, leading to improved fuel efficiency but also accelerates the prototyping phase, allowing for faster iterations. International buyers must consider certification requirements, especially AS9100, and ensure material traceability to meet stringent industry standards.

What Role Does Metal Printing Service Play in the Automotive Industry?

The automotive industry leverages metal printing services for custom tooling and production parts, significantly shortening lead times. Components like jigs, fixtures, and production-ready parts can be produced on-demand, enhancing design flexibility and reducing the need for extensive inventory. This is particularly beneficial for manufacturers in regions like South America and Africa, where supply chain disruptions can be more frequent. Buyers should focus on material selection and post-processing options to ensure that the final products meet performance and durability standards.

How is Metal Printing Service Transforming Medical Device Manufacturing?

In medical device manufacturing, metal printing services enable the production of patient-specific implants and surgical tools. This customization enhances patient outcomes by providing tailored solutions that fit individual anatomical needs. Additionally, the ability to produce these components on-demand reduces inventory costs and waste. International buyers must navigate regulatory compliance, such as FDA requirements in the U.S. and CE marking in Europe, while ensuring that the materials used are biocompatible.

What are the Benefits of Metal Printing Service in Oil & Gas?

The oil and gas industry benefits from metal printing services through the production of custom valve and pump components designed to withstand harsh environments. The durability of metal 3D-printed parts helps to minimize downtime and maintenance costs, which are critical in this sector. Buyers in this industry should prioritize material performance specifications and part validation to ensure reliability under extreme conditions, especially when sourcing from international suppliers.

How Does Metal Printing Service Help in Industrial Machinery?

Metal printing services are invaluable for producing replacement parts for legacy industrial machinery. This application allows companies to minimize downtime by producing parts on-demand, thereby reducing inventory costs associated with traditional manufacturing methods. Buyers should pay close attention to tolerance specifications and lead times, as these factors can significantly impact operational efficiency. By ensuring that their sourcing partners can meet these needs, businesses can maintain their equipment more effectively and reduce operational disruptions.

3 Common User Pain Points for ‘metal printing service’ & Their Solutions

Scenario 1: Navigating Complex Part Designs for Functional Applications

The Problem: B2B buyers often struggle with designing complex parts that meet specific functional requirements. Traditional manufacturing methods can limit design freedom, leading to parts that are either too bulky or contain multiple components that increase the risk of failure. Buyers may find it challenging to visualize how their designs can be effectively produced using metal printing technologies, which can lead to frustration and delays in the product development process.

The Solution: To overcome this challenge, buyers should engage with metal printing service providers early in the design phase. Utilizing design software compatible with metal 3D printing can help visualize the part’s feasibility and performance. Collaborating with engineers who specialize in additive manufacturing allows buyers to leverage their expertise in optimizing designs for processes like Direct Metal Laser Sintering (DMLS) or Binder Jetting. By conducting Design for Additive Manufacturing (DfAM) workshops, buyers can explore innovative design possibilities that enhance functionality while reducing material waste and assembly complexity. This proactive approach ensures that the parts produced are not only functional but also cost-effective and timely.

Scenario 2: Managing Quality Assurance and Compliance Standards

The Problem: Buyers often face uncertainty regarding the quality and compliance of metal printed parts, especially when dealing with stringent industry standards such as ISO 9001:2015 or AS9100D. This concern is particularly prevalent in sectors like aerospace and medical, where the integrity of components is critical. Without clear insights into the manufacturing processes and certification status of their suppliers, buyers risk costly rejections and delays in their supply chain.

The Solution: To address these quality assurance challenges, buyers should prioritize sourcing metal printing services from certified providers with transparent quality management systems. Requesting detailed documentation of certifications, material properties, and post-processing techniques is crucial. Buyers can also implement a robust supplier evaluation process that includes audits and performance metrics related to quality control. Establishing a clear communication channel with the provider allows for ongoing updates on production status and quality checks. Moreover, utilizing pilot runs for critical components can help validate quality before full-scale production, ensuring compliance with industry standards and minimizing risks.

Scenario 3: Overcoming Cost and Lead Time Challenges in Metal Printing

The Problem: Many B2B buyers are deterred by the perceived high costs and lengthy lead times associated with metal printing services. This hesitation can stem from a lack of understanding of the total cost of ownership, which includes not only the printing process but also material selection, post-processing, and logistics. Additionally, buyers may fear that extended lead times will negatively impact their project timelines, especially in fast-paced industries.

The Solution: To effectively manage costs and lead times, buyers should take a comprehensive approach to planning their metal printing projects. Engaging in early discussions with service providers about material choices can reveal options that balance performance with cost-effectiveness. For example, selecting a less expensive alloy that still meets the required specifications can significantly reduce expenses. Implementing a just-in-time (JIT) manufacturing strategy can also help mitigate lead time concerns by aligning production schedules with demand forecasts. Additionally, buyers should explore partnerships with local service providers to reduce shipping times and costs. By analyzing the entire project lifecycle and adopting a strategic sourcing approach, buyers can achieve a more predictable and cost-efficient metal printing process.

Strategic Material Selection Guide for metal printing service

What Are the Key Properties of Common Materials Used in Metal Printing Services?

When selecting materials for metal printing services, understanding the properties and suitability of each option is crucial for B2B buyers. Here, we analyze four common materials: Stainless Steel, Aluminum, Inconel, and Titanium, focusing on their performance characteristics, advantages, disadvantages, and implications for international buyers.

How Does Stainless Steel Perform in Metal Printing?

Key Properties: Stainless Steel, particularly grades like 17-4 PH and 316L, offers excellent corrosion resistance, high strength, and good machinability. It can withstand high temperatures and pressures, making it suitable for a variety of applications, including aerospace and medical devices.

Pros & Cons: The durability of stainless steel is a significant advantage, as it can withstand harsh environments. However, it tends to be more expensive than other materials, and its manufacturing complexity can increase costs. While it is suitable for functional parts, the weight may be a drawback for applications where lightweight components are essential.

Impact on Application: Stainless steel’s corrosion resistance makes it ideal for applications exposed to moisture or chemicals. Buyers in industries such as food processing or pharmaceuticals will find this material particularly beneficial.

Considerations for International Buyers: Compliance with standards like ASTM and ISO is critical. Buyers from regions such as Africa and South America should ensure that the stainless steel used meets local regulations regarding quality and safety.

What Are the Advantages of Using Aluminum in Metal Printing?

Key Properties: Aluminum, especially the AlSi10Mg alloy, is known for its lightweight nature, excellent thermal conductivity, and good corrosion resistance. It is suitable for applications requiring high strength-to-weight ratios.

Pros & Cons: The primary advantage of aluminum is its lower cost compared to stainless steel, along with faster production times. However, it may not perform as well in high-temperature applications and can be less durable than steel in certain environments.

Impact on Application: Aluminum is commonly used in the automotive and aerospace industries, where weight reduction is crucial. Its compatibility with various media makes it versatile for multiple applications.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades and their compliance with international standards, such as JIS and DIN, which may vary by region.

Why Choose Inconel for High-Performance Applications?

Key Properties: Inconel, particularly Inconel 718, is a nickel-chromium alloy known for its exceptional strength and oxidation resistance at high temperatures. It can withstand extreme environments, making it ideal for aerospace and gas turbine applications.

Pros & Cons: The high performance of Inconel comes at a cost; it is one of the more expensive materials for metal printing. Additionally, its complex manufacturing process can lead to longer lead times, which may not be suitable for all projects.

Impact on Application: Inconel is particularly effective in applications involving high temperatures and corrosive environments, such as jet engines and chemical processing plants.

Considerations for International Buyers: Compliance with aerospace and industrial standards is essential. Buyers from the Middle East and Europe should ensure that their suppliers can meet stringent quality certifications.

What Makes Titanium a Preferred Choice in Certain Industries?

Key Properties: Titanium, especially Ti6Al4V, boasts excellent strength, low density, and outstanding corrosion resistance. It is highly biocompatible, making it ideal for medical implants and aerospace applications.

Pros & Cons: The lightweight nature and strength of titanium are significant advantages. However, it is one of the most expensive materials available for metal printing, and its machining can be complex, leading to higher production costs.

Impact on Application: Titanium is widely used in aerospace, medical devices, and high-performance automotive applications where weight and strength are critical.

Considerations for International Buyers: Buyers should be aware of the specific grades and their compliance with international standards, particularly in the medical field, where regulations are stringent.

Summary Table of Material Properties for Metal Printing Services

| Material | Typical Use Case for metal printing service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace, medical devices | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Aluminum | Automotive, aerospace | Lightweight and cost-effective | Less durable at high temperatures | Medium |

| Inconel | Aerospace, gas turbines | Exceptional strength at high temperatures | High cost and longer lead times | High |

| Titanium | Medical implants, aerospace | High strength-to-weight ratio | Very high cost and complex machining | High |

This guide provides a comprehensive overview of material options for metal printing services, enabling B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal printing service

What Are the Main Stages of the Manufacturing Process for Metal Printing Services?

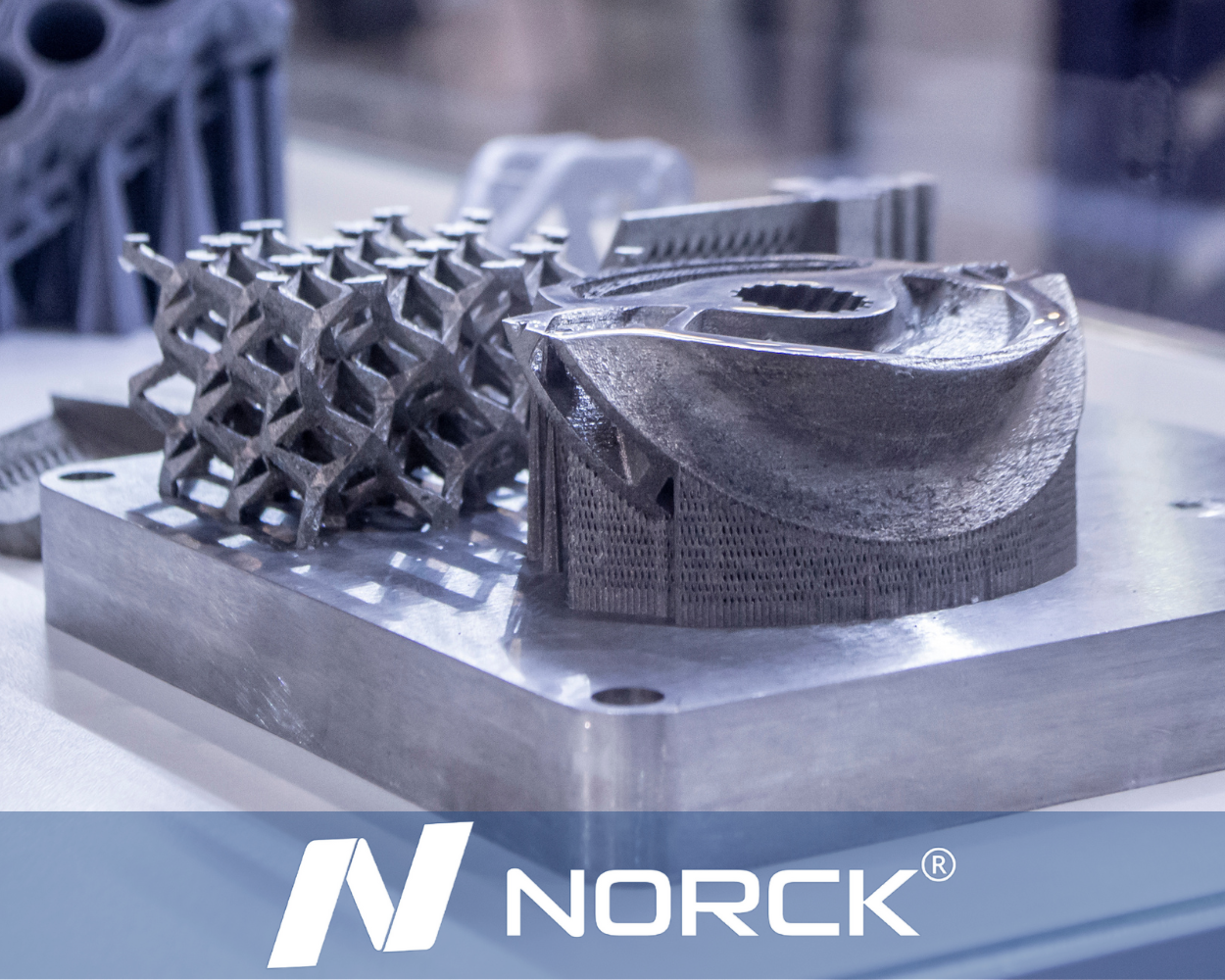

Metal printing services primarily utilize advanced additive manufacturing techniques, notably Direct Metal Laser Sintering (DMLS) and Binder Jetting. The manufacturing process can be broken down into several key stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Metal 3D Printing?

The journey begins with material preparation, where metal powders are selected based on the desired mechanical properties and application requirements. Common materials include stainless steel, titanium, aluminum, and Inconel. The powders must meet stringent specifications regarding particle size, distribution, and purity to ensure optimal flow and sintering characteristics.

Once the appropriate powder is chosen, it undergoes a pre-processing phase that may include sieving to eliminate oversized particles and ensure uniformity. This preparation is critical, as any inconsistencies can affect the final part’s quality and performance.

What Techniques Are Used in Forming Metal Parts?

Forming is the next phase, where the prepared metal powder is layer by layer transformed into a solid part. In DMLS, a high-powered laser selectively melts the metal powder according to the part design specified in a CAD file. The process is highly precise, allowing for the creation of complex geometries and intricate designs that traditional manufacturing methods struggle to achieve.

In the case of Binder Jetting, a binding agent is selectively applied to the powder bed to hold the metal particles together. After the layer is completed, the part is cured and then sintered in a furnace to achieve the desired strength. Both methods can produce parts with isotropic mechanical properties, suitable for demanding applications.

What Are the Key Finishing Processes After Metal Printing?

Finishing processes are essential to enhance the mechanical and aesthetic qualities of the printed parts. Common post-processing techniques include:

- Support Removal: Any support structures used during printing are carefully removed.

- Surface Finishing: Techniques such as sanding, polishing, and bead blasting are employed to improve surface quality and reduce layer lines.

- Heat Treatment: Parts may undergo heat treatment to relieve residual stresses and enhance mechanical properties.

- Coating: Protective coatings can be applied for corrosion resistance or aesthetic purposes.

These finishing processes ensure that the final products meet the high standards required for various applications.

How Is Quality Assurance Implemented in Metal Printing Services?

Quality assurance (QA) is a critical component of the metal printing process, ensuring that the final products meet specified standards and customer expectations. Adherence to international and industry-specific standards, such as ISO 9001:2015, is paramount for establishing a robust quality management system.

What Are the Relevant International Standards for Metal Printing?

ISO 9001:2015 focuses on quality management principles that drive continual improvement and customer satisfaction. For industries with specific requirements, certifications like AS9100D for aerospace and API (American Petroleum Institute) standards for oil and gas may also apply. These certifications indicate that the supplier adheres to rigorous quality and safety protocols.

What Are the Key Quality Control Checkpoints in Metal Printing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, ensuring that each stage meets predefined quality criteria. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial step verifies the quality of raw materials before they enter the production process. Suppliers must provide documentation proving that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, various parameters such as temperature, laser power, and layer thickness are monitored to ensure consistency and quality. Regular checks can help identify deviations early, allowing for corrective actions.

-

Final Quality Control (FQC): Once the parts are completed, they undergo a thorough inspection that may include dimensional checks, surface integrity assessments, and mechanical property testing. This ensures that the final product adheres to customer specifications.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to validate the quality of metal printed parts, including:

-

Dimensional Inspection: Utilizes coordinate measuring machines (CMM) and laser scanners to confirm that parts meet specified dimensions and tolerances.

-

Mechanical Testing: Includes tensile strength, hardness, and fatigue testing to ensure that parts can withstand operational stresses.

-

Non-Destructive Testing (NDT): Techniques such as X-ray or ultrasonic testing are used to detect internal flaws without damaging the part.

These testing methods provide a comprehensive understanding of the part’s quality and performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality systems, and compliance with international standards.

-

Requesting Quality Reports: Suppliers should provide detailed reports on quality checks performed throughout the manufacturing process, including IQC, IPQC, and FQC data.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s quality control measures and the final product’s integrity.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B transactions often involve navigating different regulatory landscapes and quality expectations. Buyers should be aware of the following nuances:

-

Certification Recognition: Not all certifications are recognized universally. Buyers should verify that the supplier’s certifications are acknowledged in their specific industry and region.

-

Cultural Differences: Understanding cultural attitudes towards quality and compliance can help buyers gauge the reliability of suppliers in different regions.

-

Communication: Clear communication about quality expectations and standards at the outset of the business relationship can prevent misunderstandings and ensure alignment.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting metal printing service providers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal printing service’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure metal printing services. Metal 3D printing has emerged as a transformative technology for various industries, allowing for complex designs, rapid prototyping, and production of durable parts. This checklist will help you navigate the sourcing process effectively to ensure you partner with the right service provider.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project requirements. Consider aspects such as part dimensions, material types, and desired tolerances. Specificity in your specifications ensures that suppliers can accurately assess your needs and provide appropriate solutions.

- Key considerations: Maximum dimensions, layer thickness, and surface finish preferences.

- Example: If you require parts with intricate geometries, specify the need for advanced techniques like Direct Metal Laser Sintering (DMLS).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the metal printing space. Look for companies with a proven track record in your industry, as experience can significantly influence the quality of the final product.

- Where to look: Online directories, industry forums, and trade shows.

- What to assess: Company reputation, customer reviews, and portfolio of past projects.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant certifications. Certifications such as ISO 9001:2015 and AS9100D indicate a commitment to quality management systems and adherence to industry standards.

- Why it matters: Certified suppliers are more likely to maintain consistent quality and reliability.

- Ask for documentation: Request copies of certifications to confirm their validity.

Step 4: Assess Material Options and Properties

Understand the range of materials available for metal printing and their respective properties. Different metals offer varied mechanical properties, which can affect the performance of the final parts.

- Material types to consider: Stainless steel, aluminum, titanium, and Inconel.

- Performance metrics: Review tensile strength, yield stress, and elongation percentages to match your application needs.

Step 5: Request Detailed Quotes

Reach out to potential suppliers to obtain detailed quotes that encompass all aspects of the service, including material costs, production lead times, and post-processing options.

- What to include: Ensure the quote covers any additional services such as finishing, assembly, or shipping.

- Why this step is crucial: A comprehensive quote allows for better comparison between suppliers and prevents unexpected costs later in the process.

Step 6: Inquire About Lead Times and Production Capacity

Discuss lead times and the supplier’s production capacity to ensure they can meet your project deadlines. Understanding their workflow will help you gauge whether they can accommodate urgent requests.

- Production capabilities: Ask about their typical turnaround times for prototypes versus production parts.

- Flexibility: Determine their ability to scale up production if your demand increases.

Step 7: Check References and Case Studies

Before finalizing your decision, ask for references or case studies from previous clients, particularly those in similar industries or regions. This will provide insights into the supplier’s performance and reliability.

- Focus on: Quality of work, adherence to timelines, and customer service experiences.

- Follow-up: Contact references directly to gain firsthand feedback about their experiences with the supplier.

By following this checklist, B2B buyers can make informed decisions when sourcing metal printing services, ensuring that they partner with a reliable provider capable of meeting their specific needs.

Comprehensive Cost and Pricing Analysis for metal printing service Sourcing

What Are the Key Cost Components of Metal Printing Services?

When sourcing metal printing services, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of metal significantly impacts cost. Common materials such as aluminum and stainless steel are generally more affordable, while specialized alloys like Inconel or titanium can drive prices up due to their enhanced properties and sourcing challenges.

-

Labor: Skilled labor is essential for operating advanced printing machinery and conducting post-processing operations. Labor costs can vary by region, with labor being more expensive in developed countries compared to emerging markets.

-

Manufacturing Overhead: This includes the operational costs associated with running the printing facility, such as utilities, maintenance, and equipment depreciation. High-capacity machines that offer faster turnaround times may have higher overhead due to their initial investment.

-

Tooling: While metal printing is often touted for its lack of tooling costs compared to traditional manufacturing, certain applications may still require specific tooling or fixtures, which can add to the overall expense.

-

Quality Control (QC): Ensuring that printed parts meet quality standards incurs costs related to inspection processes, certifications, and testing. Quality assurance is particularly important for industries like aerospace or medical, where compliance with international standards is mandatory.

-

Logistics: Shipping costs, especially for international transactions, can be significant. Factors such as shipping method, destination, and customs duties must be considered when evaluating total costs.

-

Margin: Suppliers will typically add a profit margin to cover their risks and ensure sustainability. This margin can vary widely based on the supplier’s reputation, market demand, and the complexity of the project.

How Do Volume and Specifications Affect Pricing in Metal Printing?

Pricing in metal printing services is heavily influenced by several factors:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Suppliers may offer price breaks for bulk orders, making it more cost-effective for businesses with ongoing needs.

-

Specifications and Customization: Complex designs or custom specifications may incur additional costs. Parts that require intricate geometries or specific tolerances can lead to longer processing times and increased labor, impacting overall pricing.

-

Material Selection: The choice of material is one of the most significant price influencers. High-performance materials, while offering better mechanical properties, come at a premium compared to standard options.

-

Quality and Certifications: Parts requiring specific certifications (e.g., ISO, AS9100) will typically cost more due to the additional quality assurance processes involved. Buyers should assess whether these certifications are necessary for their application.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but can offer greater reliability.

-

Incoterms: The chosen Incoterms can influence logistics costs and responsibilities. For instance, DDP (Delivered Duty Paid) terms may include higher costs upfront, whereas EXW (Ex Works) might lower initial costs but increase buyer responsibility for logistics.

What Strategies Can International Buyers Use to Optimize Costs?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a good relationship can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors like shipping, lead times, and potential delays, which can affect overall project costs.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Asia may offer lower prices compared to those in Europe, but consider quality and service levels.

-

Local Suppliers: Investigate local suppliers who may reduce shipping and logistics costs. While they may not have the same capabilities, they can provide competitive pricing for less complex projects.

-

Leverage Technology: Utilize online quoting tools and platforms that allow for quick comparisons of costs across multiple suppliers, helping to identify the best value options.

Conclusion

In the evolving landscape of metal printing services, understanding the cost components and pricing influencers is essential for B2B buyers. By considering these factors and applying strategic sourcing techniques, companies can achieve significant savings while ensuring high-quality outcomes. It is important to note that prices can vary widely based on the mentioned factors, and potential buyers should seek tailored quotes for accurate budgeting.

Alternatives Analysis: Comparing metal printing service With Other Solutions

When evaluating manufacturing solutions for metal parts, it’s essential to consider various options available in the market. Each method has unique characteristics, advantages, and limitations that may cater to specific business needs. This analysis compares metal printing services with traditional CNC machining and metal casting, two prevalent alternatives.

| Comparison Aspect | Metal Printing Service | CNC Machining | Metal Casting |

|---|---|---|---|

| Performance | High precision, complex geometries, isotropic properties | High dimensional accuracy, limited to simpler shapes | Good for large parts, but less precise than machining |

| Cost | Higher initial costs but reduces assembly costs | Moderate to high, with tooling costs | Lower for high-volume production, but costly for low volumes |

| Ease of Implementation | Quick turnaround, minimal setup required | Longer setup time, requires tooling | Complex mold creation, time-consuming |

| Maintenance | Low maintenance, technology-dependent | Regular maintenance on machines required | Moderate maintenance, molds can wear out |

| Best Use Case | Prototyping, complex geometries, low-volume production | High precision parts, high-volume production | Large parts, low-volume production |

What Are the Key Advantages and Disadvantages of CNC Machining?

CNC machining is a traditional subtractive manufacturing process that excels in producing high-precision components. One of its primary advantages is the ability to achieve tight tolerances and smooth finishes on a variety of materials. This method is particularly effective for high-volume production runs, where the initial investment in tooling can be justified by the lower per-part costs over time. However, CNC machining is limited to simpler geometries, and the setup time can be extensive, making it less efficient for rapid prototyping or low-volume production. Additionally, the need for tooling can increase costs for small batches.

How Does Metal Casting Compare as an Alternative?

Metal casting is a well-established method for producing parts, especially when large quantities are needed. The process involves pouring molten metal into a mold, which can be a cost-effective solution for high-volume manufacturing. One of the advantages of metal casting is the ability to create large and complex shapes that might be difficult or impossible to achieve with machining. However, the setup costs for creating molds can be high, and the precision of cast parts may not match that of machined components. Furthermore, casting can be time-consuming, as it requires curing and cooling periods, which can delay production timelines.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right manufacturing solution depends on several factors, including the specific application, production volume, budget, and required lead time. For businesses looking to produce complex geometries or require rapid prototyping, metal printing services offer distinct advantages despite their higher costs. Conversely, if the goal is high-volume production of straightforward parts, CNC machining or metal casting may be more suitable. B2B buyers should assess their project requirements, considering factors such as material properties, design complexity, and production timelines to make an informed decision that aligns with their operational needs.

Essential Technical Properties and Trade Terminology for metal printing service

What Are the Key Technical Properties of Metal Printing Services?

When considering metal printing services, understanding specific technical properties is crucial for making informed decisions. Here are some essential specifications:

1. Material Grade

Material grade refers to the specific classification of the metal used in printing, such as stainless steel, aluminum, or titanium. Each grade has distinct mechanical properties, such as tensile strength and corrosion resistance, which directly affect the performance of the final part. For B2B buyers, selecting the appropriate material grade is vital to ensure that the produced parts meet the required durability and functional specifications for their applications.

2. Tolerance

Tolerance defines the permissible limit of variation in a part’s dimensions. It is typically expressed in terms of ±X mm or ±X inches. Tight tolerances are crucial for applications where precision is paramount, such as aerospace or medical devices. Understanding tolerances helps buyers anticipate the fit and function of parts within larger assemblies, minimizing the risk of costly reworks or failures in the field.

3. Layer Thickness

Layer thickness refers to the height of each layer in the additive manufacturing process. Thinner layers generally yield finer detail and smoother surface finishes, while thicker layers can speed up production time. B2B buyers should consider the balance between detail and efficiency based on their specific project requirements, as this can impact both lead times and costs.

4. Surface Finish

Surface finish describes the texture and quality of a part’s exterior after printing. Options may range from rough to polished surfaces, each suitable for different applications. A smoother finish might be necessary for aesthetic components, while a rougher texture might be acceptable for functional parts. Buyers should assess their end-use requirements to select the appropriate finish, impacting the part’s performance and customer satisfaction.

5. Mechanical Properties

Mechanical properties include characteristics such as tensile strength, yield strength, and elongation. These properties determine how a material reacts under stress and are critical for applications that involve load-bearing or high-impact environments. Buyers need to evaluate these properties based on their specific application to ensure reliability and performance.

What Common Trade Terms Should B2B Buyers Understand in Metal Printing?

Navigating the metal printing landscape involves familiarity with specific jargon and trade terminology. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of metal printing, OEMs often require custom parts for their products. Understanding OEM relationships is vital for buyers to ensure they are sourcing quality components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In metal printing, MOQs can vary significantly based on the complexity of the part and the material used. Buyers should be aware of MOQs to effectively plan their production needs and manage costs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for specific products or services. In the metal printing industry, RFQs are crucial for obtaining competitive bids and evaluating potential suppliers based on pricing, capabilities, and lead times.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the delivery of goods. Understanding Incoterms is essential for B2B buyers, as they clarify who bears the costs and risks associated with shipping and delivery, thereby impacting the overall cost structure.

5. DMLS (Direct Metal Laser Sintering)

DMLS is a specific metal 3D printing technology that uses a laser to fuse metal powder into solid parts. It is known for producing high-density and high-strength components suitable for demanding applications. Familiarity with DMLS helps buyers choose the right technology for their needs, ensuring optimal performance and quality.

In summary, grasping these technical properties and trade terms is imperative for B2B buyers in the metal printing industry. This knowledge enables better decision-making, leading to successful procurement and enhanced product performance.

Navigating Market Dynamics and Sourcing Trends in the metal printing service Sector

What Are the Current Market Dynamics and Key Trends in Metal Printing Services?

The global metal printing service market is witnessing robust growth, driven by advancements in additive manufacturing technologies and increasing demand for customized, high-performance parts. This surge is particularly evident in industries such as aerospace, automotive, and healthcare, where complex geometries and lightweight components are essential. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly looking to metal 3D printing as a solution to reduce lead times, lower production costs, and enhance product design capabilities.

Emerging technologies such as Direct Metal Laser Sintering (DMLS) and Metal Binder Jetting are gaining traction, offering distinct advantages like improved material properties and design flexibility. The adoption of these technologies allows companies to streamline their supply chains by reducing the number of parts in an assembly, thus lowering the risk of failure points. Furthermore, the integration of digital platforms for online quoting and order management is transforming how buyers interact with suppliers, making sourcing more efficient and transparent.

Market dynamics are also influenced by geopolitical factors and supply chain disruptions, prompting international buyers to seek local or regional suppliers to mitigate risks. The shift towards Industry 4.0, characterized by digitalization and automation, is encouraging manufacturers to invest in advanced machinery and processes to meet the rising demand for rapid prototyping and production of end-use parts.

How Are Sustainability and Ethical Sourcing Impacting the Metal Printing Service Sector?

Sustainability is becoming a focal point for businesses in the metal printing service sector. The environmental impact of traditional manufacturing processes has led to a growing emphasis on ethical sourcing and the use of eco-friendly materials. Metal 3D printing can significantly reduce waste compared to conventional subtractive manufacturing methods, as it builds parts layer by layer from metal powders, minimizing excess material.

B2B buyers are increasingly prioritizing suppliers that adhere to sustainability practices, including the use of recycled materials and certifications such as ISO 14001. These certifications indicate a commitment to environmental management and sustainable practices throughout the supply chain. Furthermore, the demand for “green” materials in metal printing, such as aluminum alloys that can be recycled and reused, is on the rise.

The importance of ethical supply chains cannot be overstated; buyers are keen to partner with manufacturers who ensure fair labor practices and responsible sourcing of raw materials. This trend not only aligns with corporate social responsibility goals but also enhances brand reputation among consumers who are increasingly aware of and concerned about sustainability issues.

What Is the Evolution of Metal Printing Services and Its Significance for B2B Buyers?

The evolution of metal printing services can be traced back to the development of additive manufacturing technologies in the 1980s. Initially, these technologies were limited to prototyping applications, but advancements in materials and processes have transformed metal 3D printing into a viable option for producing functional end-use parts.

The introduction of Direct Metal Laser Sintering (DMLS) and Binder Jetting has marked a significant turning point, enabling the production of complex geometries that were previously unattainable with traditional manufacturing techniques. This shift has opened new avenues for innovation in product design and manufacturing efficiency, positioning metal printing as a critical component in modern supply chains.

For B2B buyers, understanding this evolution is essential. It highlights the ongoing advancements in technology and material science that continue to shape the landscape of metal printing services. This knowledge empowers buyers to make informed decisions, ensuring they select the right partners and technologies to meet their specific needs and drive competitive advantage in their markets.

Frequently Asked Questions (FAQs) for B2B Buyers of metal printing service

-

1. How do I choose the right metal printing service provider?

When selecting a metal printing service provider, consider their certifications (like ISO 9001), capabilities in terms of materials and technologies (such as DMLS or Binder Jetting), and their experience in your industry. Evaluate their turnaround time, pricing structure, and customer service. Additionally, request samples or case studies to assess the quality of their work. It’s also beneficial to verify their international shipping options and understand any potential import regulations that might apply to your region. -

2. What are the advantages of using metal 3D printing for prototyping?

Metal 3D printing offers significant advantages for prototyping, including the ability to create complex geometries that traditional methods cannot achieve. It allows for rapid production, reducing lead times to as little as a week, which is crucial for fast-paced markets. The technology also supports iterative design, enabling modifications to be made quickly and efficiently. Moreover, metal 3D printing can produce parts with isotropic properties, ensuring consistent strength and durability throughout the component. -

3. What materials are commonly used in metal 3D printing?

Common materials for metal 3D printing include stainless steel (such as 17-4 PH and 316L), aluminum (like AlSi10Mg), titanium (Ti6Al4V), Inconel (718), and cobalt chrome. Each material has unique mechanical properties and applications, so it’s essential to choose one that aligns with your project requirements. For example, titanium is favored for aerospace applications due to its strength-to-weight ratio, while stainless steel is often used for industrial components due to its corrosion resistance. -

4. What is the typical lead time for metal 3D printing services?

Lead times for metal 3D printing can vary based on the complexity of the design, the chosen material, and the service provider. Generally, you can expect turnaround times of 5 to 10 business days for prototypes and potentially longer for production runs. It’s advisable to communicate your project timelines clearly with the provider and inquire about any expedited services they may offer, especially if you are working under tight deadlines. -

5. Are there minimum order quantities (MOQs) for metal printing services?

Minimum order quantities can vary significantly among metal printing service providers. Some companies may accept single-part orders, especially for prototyping, while others might require a minimum number of parts for production runs. Always clarify MOQs with your chosen provider and consider the implications on cost and logistics, especially if you are sourcing parts for a larger production scale or multiple projects. -

6. How do I ensure quality assurance in my metal printed parts?

To ensure quality assurance in metal printed parts, choose a provider that follows stringent quality control processes, such as ISO-certified practices. Request detailed documentation of their QA protocols, including material certifications, inspection reports, and any post-processing methods used. Additionally, consider asking for samples or conducting independent testing for critical components to verify their mechanical properties and dimensional accuracy. -

7. What payment terms should I expect when sourcing metal printing services internationally?

Payment terms for international orders can differ based on the supplier and your location. Generally, you may encounter options such as upfront payments, partial payments, or payment upon delivery. It’s advisable to discuss and agree upon terms before placing an order. Be aware of any currency exchange implications and ensure that you understand all costs involved, including shipping, customs duties, and taxes, to avoid unexpected expenses. -

8. What logistics considerations should I keep in mind when sourcing metal printing services?

When sourcing metal printing services internationally, consider logistics factors such as shipping methods, delivery timelines, and customs regulations in your country. Evaluate the provider’s ability to handle international shipping and any associated costs. Additionally, ensure that the provider can package parts adequately to prevent damage during transit. It’s beneficial to establish clear communication regarding tracking information and potential delays to keep your supply chain running smoothly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Metal Printing Service Manufacturers & Suppliers List

1. Proto Labs – Direct Metal Laser Sintering (DMLS)

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Direct Metal Laser Sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. It is used for prototyping in production-grade materials, creating complex geometries, producing functional end-use parts, and reducing metal components in an assembly. The service is certified with ISO 9001:2015, AS9100D, and ITAR.

2. in3Dtec – Metal 3D Printing Services

Domain: in3dtec.com

Registered: 2017 (8 years)

Introduction: Metal 3D Printing Service using Direct Metal Laser Sintering (DMLS) technology. Key features include:

– Wide material options: Aluminum-AlSi10Mg, Stainless Steel 316L, Stainless Steel 17-4PH, Maraging Steel (18Ni300), Titanium Ti64 Grade 5, Nickel Alloy, Cobalt-chrome, Copper.

– Rapid turnaround: Parts can be produced in 4 days or less.

– High complexity: Capable of producing complex features and …

3. Craftcloud – 3D Printing & Manufacturing Services

Domain: craftcloud3d.com

Registered: 2018 (7 years)

Introduction: Craftcloud offers a variety of manufacturing services including 3D Printing, CNC Machining, Sheet Metal Fabrication, and Casting & Molding. They provide over 170 unique materials for 3D printing, such as SLS Nylon PA12, 316L Stainless Steel, HP® MJF Nylon PA12, PLA, and Standard Resin. The platform supports more than 35 file formats for model uploads and offers a wide range of finishes and color o…

4. 3D Metal Printing – Stainless Steel Parts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is looking for 3D metal printing services, specifically for steels, stainless steel, or aluminum. They mention a stainless steel part (connecting rod) with dimensions of 40mm length, 4mm thickness, and 5mm holes on each side. Pricing examples include: PCBWay at around $50 plus shipping, JLCPCB at approximately $12 including shipping, and Craftcloud starting at $15 plus $20+ shipping. Craftclo…

5. PCBWay – Metal 3D Printing Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: Metal 3D printing services offered by PCBWay include:

1. **Materials Available:**

– Aluminum: Corrosion-resistant, non-magnetic, heat treatable.

– Stainless Steel: Good corrosion resistance, heat resistance, and polishing properties; maintains excellent physical and mechanical properties at high temperatures.

– Titanium (TC4): Highest strength-to-weight ratio, ideal for lightweight appli…

6. Shapeways – 3D Printing Services

Domain: shapeways.com

Registered: 2008 (17 years)

Introduction: 3D Printing Service Online; Manufacturing Technologies: Additive Manufacturing, Selective Laser Sintering (SLS), Binder Jetting, Multi Jet Fusion (MJF), Stereolithography (SLA), Selective Laser Melting (SLM), Material Jetting, Fused Deposition Modeling (FDM), Wax Casting; Materials: Nylon 12 (PA12), Nylon 11 (PA11), Thermoplastic Elastomer (TPE), Stainless Steel 17-4 PH, Stainless Steel 316L, Full…

Strategic Sourcing Conclusion and Outlook for metal printing service

In the evolving landscape of manufacturing, metal printing services present a unique opportunity for international B2B buyers to enhance their production capabilities. The ability to produce complex geometries, reduce component count, and achieve rapid turnaround times makes metal 3D printing a strategic asset. With processes like Direct Metal Laser Sintering (DMLS) and Binder Jetting, companies can select the right method tailored to their specific needs, ensuring high-quality, functional parts that meet rigorous industry standards.

Strategic sourcing in metal printing not only optimizes costs but also fosters innovation and agility in supply chains. By partnering with experienced providers, businesses can leverage advanced technologies and diverse material options, enhancing their competitive edge in global markets.

As the demand for customized, efficient manufacturing solutions grows, international buyers—particularly from regions like Africa, South America, the Middle East, and Europe—are encouraged to explore these transformative services. Embrace the future of manufacturing by integrating metal printing into your sourcing strategy, and position your business at the forefront of technological advancement. Engage with reliable suppliers today to unlock the potential of metal 3D printing for your operational needs.