Contents

Manufacturing Insight: Metal Printing Service

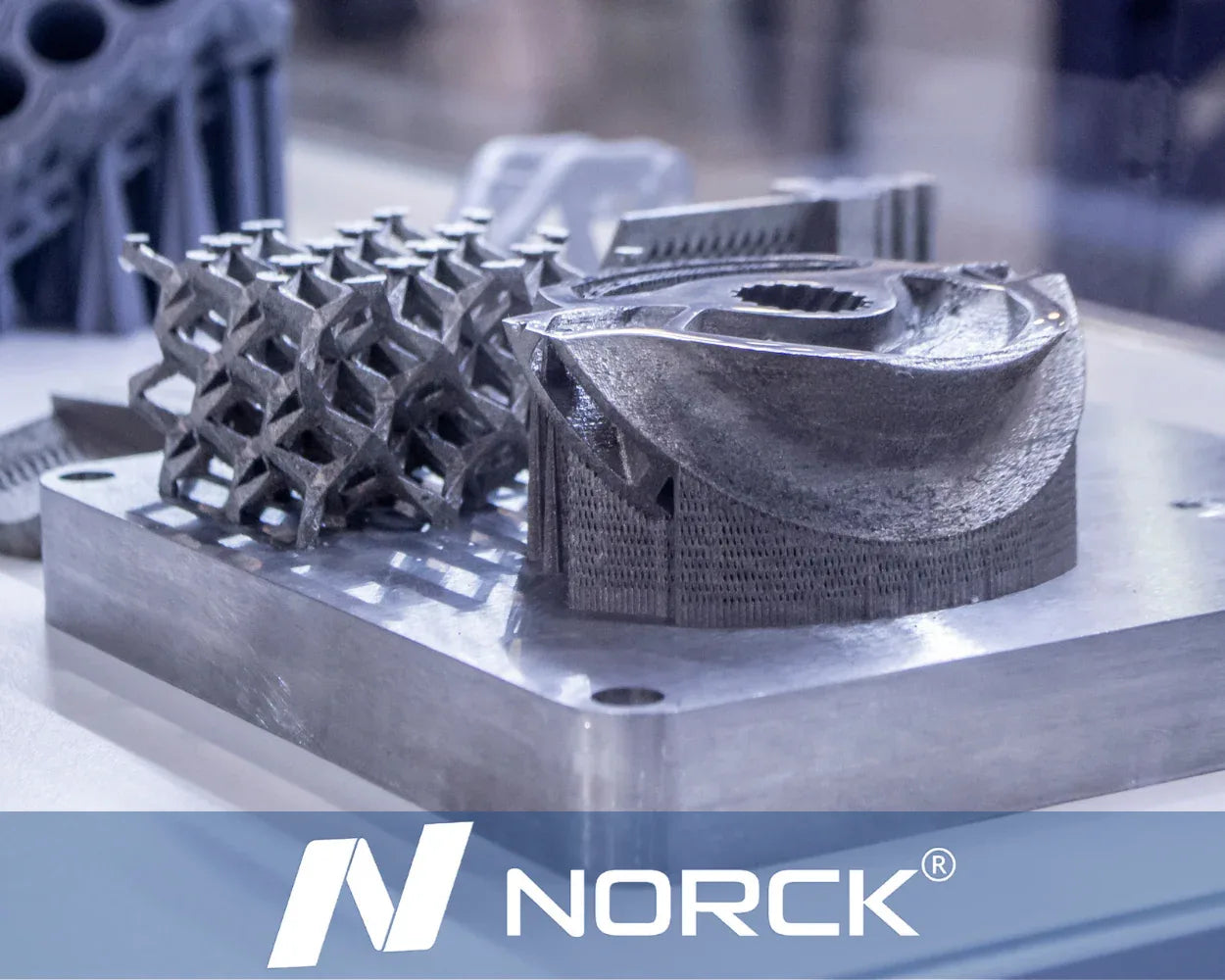

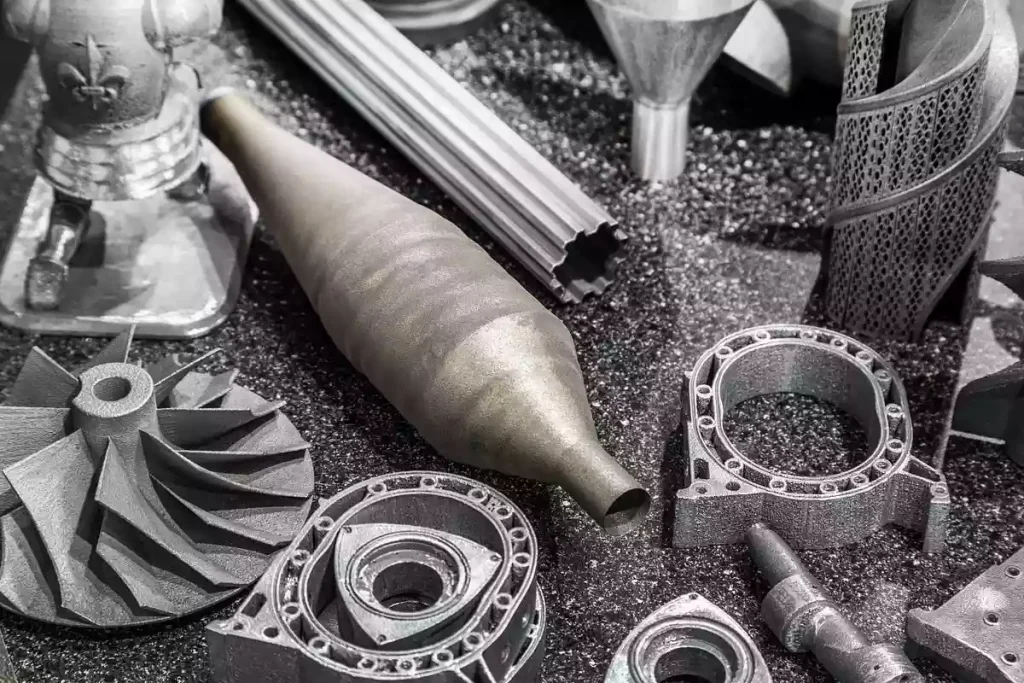

Industrial Metal 3D Printing Services for Demanding Applications

Honyo Prototype delivers advanced industrial metal additive manufacturing solutions engineered to transform complex design concepts into mission-critical components. Our state-of-the-art metal printing capabilities leverage high-precision laser powder bed fusion and binder jetting technologies to produce end-use parts with exceptional mechanical properties, intricate geometries, and rigorous repeatability. We specialize in processing aerospace-grade alloys including Inconel 718, titanium Ti-6Al-4V, stainless steel 17-4 PH, and aluminum AlSi10Mg, ensuring materials meet stringent industry standards for performance in extreme environments.

Our end-to-end service integrates design validation, process optimization, and post-processing expertise to address challenges across aerospace, medical, energy, and high-performance automotive sectors. Every build adheres to AS9100-certified quality protocols, with in-house metrology and metallurgical analysis guaranteeing dimensional accuracy and material integrity. This commitment to industrial-grade output eliminates traditional supply chain bottlenecks while accelerating time-to-market for functional prototypes and low-volume production runs.

Accelerate your development timeline with Honyo Prototype’s Online Instant Quote platform. Upload your CAD file to receive a detailed, no-obligation cost and lead time estimate within minutes—enabling rapid iteration and informed decision-making without procurement delays. Experience the convergence of industrial-scale metal printing precision and digital procurement efficiency.

Technical Capabilities

Honyo Prototype offers advanced metal and polymer additive manufacturing services utilizing industry-leading technologies including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). While SLA, SLS, and MJF are primarily polymer-based processes, DMLS is specifically designed for metal printing. Below is a detailed technical specification table outlining key parameters, supported materials, and capabilities across these technologies.

| Technology | Process Type | Material Options | Layer Thickness Range | Build Volume (Typical) | Dimensional Accuracy | Surface Finish (Ra) | Key Applications |

|---|---|---|---|---|---|---|---|

| SLA | Photopolymer Resin (Vat Photopolymerization) | ABS-like resins, Engineering resins, Castable resins | 25–100 μm | 1450 x 750 x 500 mm (varies by machine) | ±0.1 mm (first 100 mm), ±0.05 mm thereafter | 0.8–2.0 μm | Prototypes, Master patterns, Investment casting |

| SLS | Powder Bed Fusion (Polymer) | Nylon (PA 11, PA 12), Glass-filled Nylon, TPU | 80–120 μm | 380 x 380 x 430 mm | ±0.3 mm | 10–20 μm (as-built) | Functional prototypes, End-use parts, Complex geometries |

| MJF | Powder Bed Fusion (Polymer) | Nylon (PA 12), Glass-filled PA 12, TPU | 80 μm | 380 x 280 x 380 mm | ±0.3 mm | 6–15 μm (as-built) | High-volume functional parts, Durable enclosures |

| DMLS | Powder Bed Fusion (Metal) | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Tool Steel (Maraging), Titanium (Ti6Al4V) | 20–50 μm | 250 x 250 x 325 mm | ±0.1 mm | 10–25 μm (as-built), can be improved with post-processing | Aerospace, Medical implants, Tooling, High-stress components |

Notes:

SLA is not a metal printing technology but is included for comparative context. It delivers high-resolution parts ideal for visual prototypes and patterns.

SLS and MJF support engineering-grade polymers such as Nylon and ABS-like materials, with MJF offering faster build speeds and more uniform mechanical properties.

DMLS enables full-density metal parts with excellent mechanical properties, suitable for demanding industrial applications. Aluminum and steel alloys are commonly used for lightweight and high-strength requirements.

Post-processing options such as heat treatment, HIP (Hot Isostatic Pressing), CNC machining, and surface polishing are available to meet tight tolerance and finish requirements.

For metal printing applications, DMLS is the primary recommended process at Honyo Prototype, while SLS and MJF serve high-performance polymer needs.

From CAD to Part: The Process

Honyo Prototype Metal Printing Service Process Overview

Honyo Prototype delivers end-to-end metal additive manufacturing services with a structured workflow designed for engineering precision and supply chain efficiency. Our process integrates automated intelligence with expert engineering oversight to ensure manufacturability, cost control, and part performance. Below is the detailed sequence from initial upload to final delivery.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or mesh formats (STL, 3MF) via our secure customer portal. All data undergoes AES-256 encryption during transfer and storage. The system automatically validates file integrity, checks for watertight geometry, and confirms unit consistency. This step ensures downstream processes operate on technically sound digital models, eliminating common errors before quoting begins.

AI-Powered Quoting and Feasibility Assessment

Uploaded geometry is processed by our proprietary AI quoting engine, which performs multi-parameter analysis including volume, bounding box, feature complexity, and surface-to-volume ratio. The AI cross-references real-time material costs, machine utilization rates, and post-processing requirements to generate an instant preliminary quote. Crucially, the system also conducts an initial feasibility screen against material-specific constraints (e.g., minimum feature size, overhang angles). Material options are presented with comparative cost and lead time data.

Common material options evaluated during quoting include:

| Material Category | Examples | Key Applications |

|---|---|---|

| Nickel Alloys | Inconel 718, Inconel 625 | Aerospace turbine components, high-temp tooling |

| Titanium Alloys | Ti-6Al-4V (Grade 5), CP Titanium | Medical implants, lightweight structural parts |

| Aluminum Alloys | AlSi10Mg, AlSi7Mg | Automotive heat exchangers, drone components |

| Stainless Steels | 17-4 PH, 316L | Hydraulic manifolds, marine hardware |

Engineering-Driven DFM Analysis

All quotes trigger mandatory Design for Metal Additive Manufacturing (DfAM) review by our senior engineering team. This phase involves:

Orienting the part to minimize support structures while managing residual stress

Optimizing support topology using generative algorithms validated against our material database

Simulating thermal distortion via finite element analysis (FEA) for critical dimensions

Recommending post-processing requirements (e.g., HIP, stress relief, precision machining)

Clients receive a formal DFM report with actionable suggestions, geometric annotations, and tolerance validation against ISO/ASTM standards. This step typically reduces production iterations by 65% based on historical project data.

Production Execution and Quality Control

Approved designs move to our certified production floor featuring EOS M 400-4, Concept Laser M2, and SLM 500 systems operating under ISO 9001:2015 controls. Build parameters are dynamically adjusted using in-situ melt pool monitoring (coaxial thermal imaging and photodiode sensors). Every build includes:

Real-time layer-wise defect detection with automatic corrective actions

Argon atmosphere control maintaining <25 ppm oxygen levels

First-article inspection per AS9102 for aerospace components

Post-processing occurs in our dedicated facility with capabilities including precision CNC machining, vibratory finishing, and fluorescent penetrant inspection. All critical dimensions undergo CMM validation against the original CAD model.

Delivery and Documentation Package

Finished parts ship with a comprehensive quality dossier including:

Material test reports (MTRs) with chemical composition and mechanical properties

Dimensional inspection reports (PDF and XML formats)

Build parameter log and machine calibration certificates

As-built 3D scan data (upon request)

Standard lead time is 7–10 business days from DFM approval, with expedited options available. All shipments include tamper-evident packaging with environmental monitoring for sensitive applications.

This integrated workflow ensures Honyo delivers production-ready metal AM components with validated performance characteristics, eliminating the guesswork often associated with additive manufacturing services. Our closed-loop process from digital model to certified physical part provides the reliability required for mission-critical industrial applications.

Start Your Project

Looking for high-precision metal 3D printing for your next project? Honyo Prototype offers advanced metal additive manufacturing services with fast turnaround and strict quality control. Our Shenzhen-based factory is equipped with state-of-the-art technology to support industrial prototyping and low-volume production.

Contact Susan Leo today to discuss your requirements and get a competitive quote.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.