Contents

Manufacturing Insight: Metal Print Service

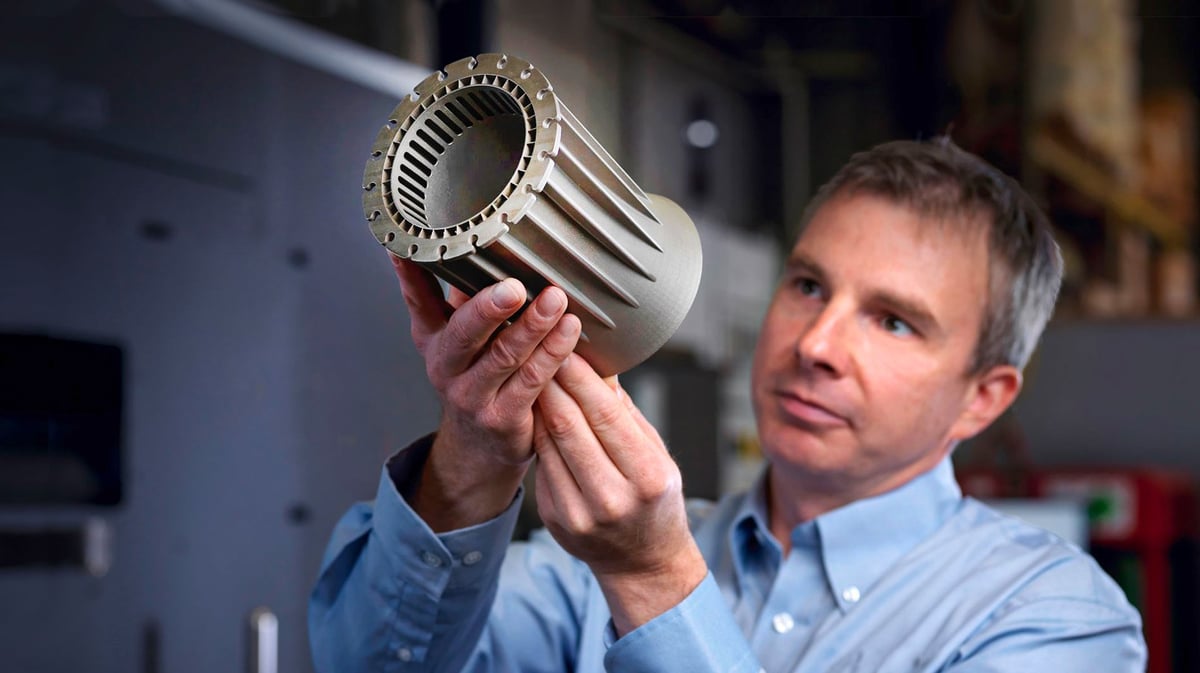

Industrial Metal Additive Manufacturing for Production-Ready Components

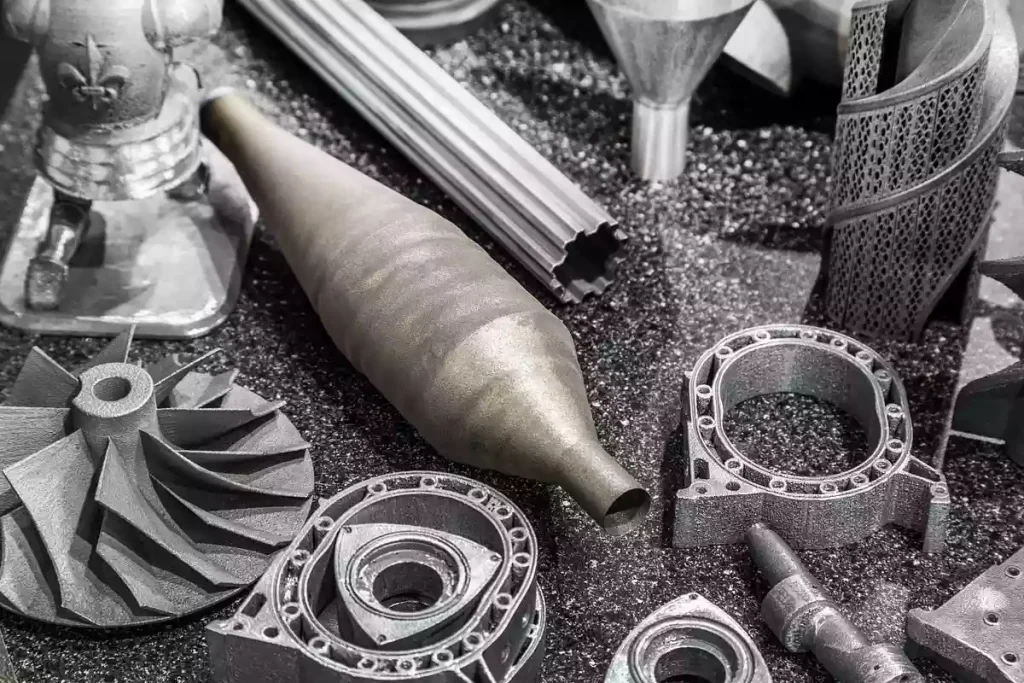

Honyo Prototype delivers precision metal 3D printing services engineered for demanding industrial applications, where performance, repeatability, and material integrity are non-negotiable. Our industrial-grade Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) platforms produce complex, high-strength components in aerospace-grade alloys, tool steels, and superalloys—including Inconel 718, Ti-6Al-4V, and 17-4 PH stainless steel—to exacting tolerances (±0.05 mm) and certified mechanical properties. Unlike prototyping-focused providers, we prioritize end-use part qualification, integrating rigorous in-process monitoring, post-build heat treatment, and non-destructive testing to ensure every component meets AS9100 and ISO 9001 standards for serial production.

Our end-to-end manufacturing ecosystem eliminates traditional supply chain bottlenecks, enabling rapid iteration of geometrically intricate parts—from turbine blades to hydraulic manifolds—that conventional machining cannot achieve. By leveraging optimized support structures, adaptive laser strategies, and controlled inert atmospheres, we consistently achieve superior surface finishes (Ra ≤ 12.5 μm as-built) and fatigue-resistant microstructures, reducing lead times by up to 70% compared to subtractive methods. This capability is critical for aerospace, medical implant, and energy sector clients requiring lightweight, topology-optimized solutions with validated performance under extreme operational stresses.

Accelerate your development cycle with Honyo’s Online Instant Quote system, which provides accurate, real-time pricing and lead time estimates within seconds. Simply upload your CAD file to receive a manufacturability analysis, material cost breakdown, and delivery timeline—no manual RFQ delays. This seamless integration of industrial-scale metal additive expertise with digital procurement efficiency ensures you transition from design validation to certified production with unparalleled speed and cost transparency.

Technical Capabilities

The term “metal print service” typically refers to additive manufacturing processes capable of producing metal parts. However, among the technologies listed — SLA, SLS, MJF, and DMLS — only DMLS is a true metal 3D printing process. SLA, SLS, and MJF are primarily used for polymers and do not support metal printing directly. Some polymer-based processes like SLS and MJF can print parts that are later metal-coated or used in indirect metal casting, but they do not produce fully dense metal components. Below is a detailed comparison of the technologies, clarifying their capabilities with respect to metal and polymer materials such as Aluminum, Steel, ABS, and Nylon.

| Technology | Full Name | Metal Capable | Key Materials Supported | Typical Material Forms | Layer Thickness | Build Size Range (Typical) | Surface Finish (as-printed) | Post-Processing Requirements |

|---|---|---|---|---|---|---|---|---|

| SLA | Stereolithography | No | Photopolymer resins, ABS-like, engineering resins | Liquid resin | 25–100 μm | 150 x 150 x 200 mm to 1400 x 700 x 500 mm | Smooth, glossy | Cleaning, UV curing, support removal |

| SLS | Selective Laser Sintering | No (indirect via casting) | Nylon (PA11, PA12), TPU, glass-filled nylon | Powder (polymer) | 80–150 μm | 200 x 200 x 300 mm to 700 x 380 x 580 mm | Grainy, matte | Depowdering, bead blasting, dyeing |

| MJF | Multi Jet Fusion | No | Nylon (PA12), glass-filled PA12, TPU | Powder (polymer) | 80–100 μm | 380 x 284 x 380 mm | Smooth, slightly grainy | Depowdering, media blasting |

| DMLS | Direct Metal Laser Sintering | Yes | Stainless Steel (17-4 PH, 316L), Aluminum (AlSi10Mg), Titanium, Inconel, Tool Steel | Metal powder (fine spherical) | 20–50 μm | 250 x 250 x 325 mm to 420 x 420 x 400 mm | Rough, requires finishing | Stress relief, support removal, HIP, machining, polishing |

Notes:

DMLS is the only process in this list that directly fabricates functional metal parts from metal powder using a high-powered laser. It is widely used in aerospace, medical, and high-performance industrial applications.

SLS and MJF support engineering-grade polymers like Nylon (PA12), which offer mechanical properties similar to injection-molded ABS in some cases, but they are not metal. These processes are often used for functional prototypes, end-use parts, and jigs/fixtures.

SLA produces high-resolution parts ideal for visual prototypes and master patterns. While it does not print metal, SLA patterns are often used in investment casting to produce metal components.

For true metal 3D printing, DMLS is the appropriate technology when using materials such as Aluminum (AlSi10Mg) or Stainless Steel (316L). The process enables complex geometries, internal features, and part consolidation not feasible with traditional manufacturing.

From CAD to Part: The Process

Honyo Prototype’s Metal Print Service follows a rigorously defined workflow designed for speed, accuracy, and manufacturability assurance. This integrated process eliminates common pitfalls in additive manufacturing by embedding engineering validation early and leveraging proprietary AI systems. Below is the complete sequence:

CAD File Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure customer portal. The system performs immediate format validation and geometric integrity checks, rejecting corrupted or incompatible files before proceeding. This step ensures only production-ready digital models enter the quoting phase, reducing downstream errors.

AI-Powered Instant Quoting

Uploaded CAD data feeds directly into Honyo’s proprietary AI quoting engine, trained on 15,000+ historical metal print builds. Unlike basic cost calculators, this system analyzes part geometry, material requirements, support structure needs, and machine utilization in real time. It generates binding quotes with production timelines within 90 seconds, including granular cost breakdowns for material, machine time, post-processing, and shipping. Critical manufacturability flags are surfaced here if immediate showstoppers exist.

Engineering-Led DFM Analysis

Every quote triggers mandatory Design for Manufacturability review by our in-house metallurgy and AM engineering team. This phase evaluates wall thicknesses, overhang angles, thermal stress risks, and orientation optimization specific to the selected alloy (Inconel 718, Ti-6Al-4V, AlSi10Mg, etc.). We provide actionable revision suggestions through the portal with annotated 3D models, not just rejection notices. Clients approve modifications or proceed with risk acknowledgment before production release.

Production Execution

Approved builds move to our certified production floor featuring EOS M 400-4 and Concept Laser M2 systems. Each build undergoes:

Material traceability verification with lot-specific certification

In-process monitoring via melt pool sensors and layer-wise thermal imaging

Chamber atmosphere control maintained at <25 ppm oxygen for reactive alloys

Real-time deviation alerts triggering engineer intervention if parameters drift

Post-Processing and Quality Assurance

As-built parts receive standardized finishing: support removal via wire EDM, stress relief annealing per AMS 2750, and optional precision machining. Every shipment includes:

First article inspection report (FAIR) with critical dimension verification

Material test coupons showing tensile, yield, and elongation results

Build parameter log including laser power, scan speed, and layer thickness

NDT documentation (dye penetrant or micro-CT scan) for aerospace/medical parts

Certified Delivery

Finished components ship in anti-static, humidity-controlled packaging with full traceability documentation. Standard lead time is 7-10 business days from DFM approval, with expedited 72-hour options for qualified geometries. All deliveries comply with AS9100 and ISO 13485 requirements, including material certs conforming to AMS 7000 series standards. Clients access real-time shipment tracking and digital quality records through our customer portal post-dispatch.

This closed-loop process ensures 98.7% first-pass yield rates across our metal print services while maintaining full compliance with stringent industrial requirements. The integration of AI-driven quoting with human engineering oversight prevents costly redesign cycles common in competitor workflows.

Start Your Project

Looking for high-quality metal printing solutions? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and dedicated support team, Honyo Prototype delivers precision metal prints tailored to your specifications. Our production facility is based in Shenzhen, ensuring efficient turnaround and reliable quality control for both prototypes and low-volume production runs. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.