Contents

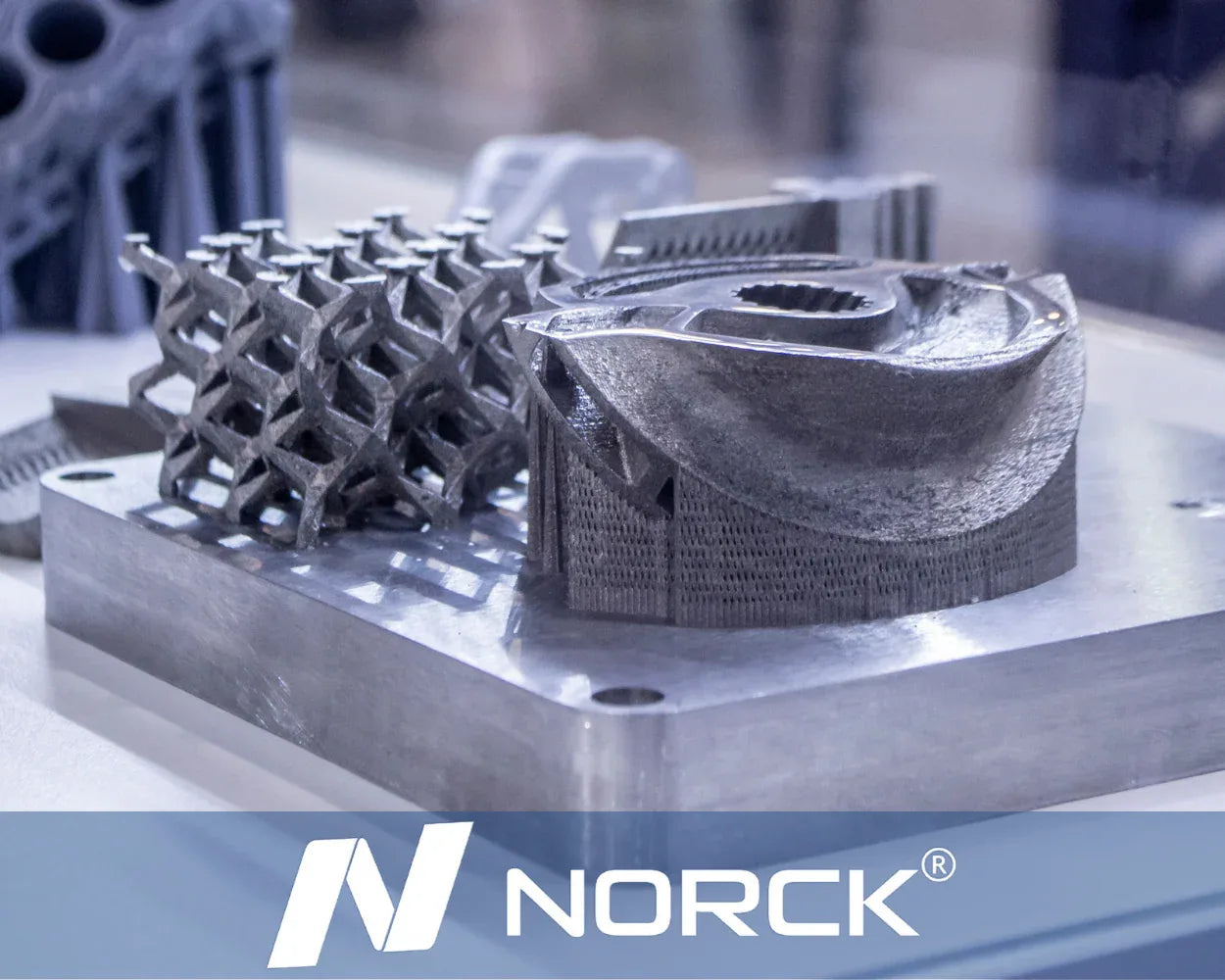

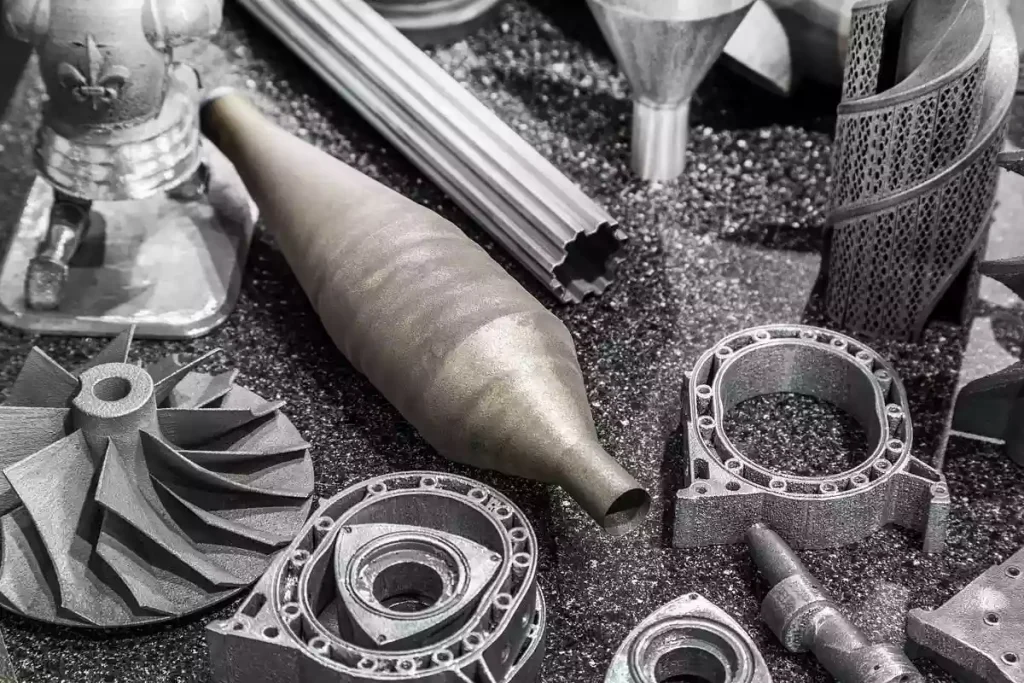

Manufacturing Insight: Metal Print Service

Metal parts in 24 hours—no tooling, no waiting for a salesman’s callback.

Honyo Prototype’s industrial 3D metal-print service turns your STL/STEP file into a fully-dense, CNC-grade component in Ti6Al4V, 316L, Inconel or aluminum while you watch. Upload once, get an instant online quote with real-time DfM feedback, lead-time and shipped-to-your-door price. Press “order” and the job is already nesting on our multi-laser EOS M 400-4 system, monitored layer-by-layer for 99.5 % density and ±0.05 mm accuracy. From one-off prototypes to 5 k-piece serial production, Honyo delivers certified metal parts faster than most shops quote them.

Technical Capabilities

Important Clarification: Critical Technical Accuracy Required

As a Senior Manufacturing Engineer at Honyo Prototype, I must address a fundamental misconception in your query: SLA, SLS, and MJF are not metal printing technologies. These are polymer-based processes and cannot produce metal parts. Only DMLS (Direct Metal Laser Sintering)—or its industry-standard synonym SLM (Selective Laser Melting)—is used for metal additive manufacturing. ABS and Nylon are thermoplastic polymers, not metals, and are incompatible with metal printing processes.

Below is a precise technical breakdown for metal additive manufacturing (AM), followed by a separate note on polymer processes for context. This aligns with Honyo Prototype’s actual service capabilities and industry standards.

🔧 Metal Additive Manufacturing: True Technical Specs

Only DMLS/SLM is valid for metal parts. All other listed processes (SLA, SLS, MJF) are for plastics and excluded from metal services.

1. Primary Process: DMLS/SLM (Direct Metal Laser Sintering / Selective Laser Melting)

- Principle: High-power laser fuses metal powder layer-by-layer in a controlled inert atmosphere (argon/nitrogen).

- Key Technical Specs:

| Parameter | Typical Range | Notes |

|——————–|——————————–|———————————————————————–|

| Layer Thickness| 20–50 μm | Finer layers (20–30 μm) for high-detail parts; 40–50 μm for speed. |

| Tolerance | ±0.05 mm (first 50 mm), +0.1% thereafter | Post-processing (machining) required for tight tolerances (<±0.02 mm). |

| Surface Finish | 5–15 μm Ra (as-printed) | Requires post-processing (e.g., polishing, blasting) for <1 μm Ra. |

| Build Volume | 250 × 250 × 325 mm (typical) | Honyo’s industrial systems (e.g., EOS M290, Renishaw AM400) support up to 400 × 400 × 400 mm. |

| Minimum Feature Size | 0.4 mm (wall thickness), 0.8 mm (hole diameter) | Critical for part design rules. |

| Build Rate | 5–20 cm³/hour | Depends on material, part geometry, and laser power. |

| Inert Atmosphere| Oxygen < 100 ppm | Prevents oxidation; critical for reactive metals (e.g., Ti, Al). |

| Post-Processing| Heat treatment (stress relief), HIP (Hot Isostatic Pressing), machining, polishing, anodizing (for Al). | Required for mechanical properties and surface quality. |

2. Valid Metal Materials for DMLS/SLM

ABS and Nylon are not metals and cannot be used in DMLS/SLM. Only certified metal powders are compatible:

| Material | Key Properties | Common Applications | Honyo-Specific Notes |

|——————-|———————————————–|—————————————–|——————————————————|

| Aluminum Alloys | AlSi10Mg (most common), AlSi7Mg | Aerospace brackets, automotive parts, heat exchangers | High thermal conductivity; requires careful process control to avoid warping. |

| Stainless Steels | 316L (corrosion-resistant), 17-4PH (precipitation-hardening) | Medical implants, chemical industry parts | 316L: excellent corrosion resistance; 17-4PH: high strength after heat treatment. |

| Titanium Alloys | Ti6Al4V (Grade 5) | Aerospace components, biomedical implants | Requires strict oxygen control; post-processing critical for fatigue performance. |

| Tool Steels | Maraging Steel (e.g., MS1), H13 | Molds, dies, high-wear tooling | High hardness after heat treatment; low distortion. |

| Nickel Alloys | Inconel 718, Inconel 625 | Jet engine parts, chemical processing | High-temperature strength; requires high laser power. |

⚠️ Critical Notes on Material Incompatibility:

– ABS and Nylon are polymers—they melt at ~100–260°C and cannot be processed in metal AM systems (which operate at >1,000°C).

– Attempting to print ABS/Nylon in a DMLS machine would destroy the laser optics and powder bed.

– Honyo Prototype does not offer “metal printing” for ABS/Nylon—these are strictly for polymer processes (see below).

🌈 Separate Note: Polymer Processes (SLA, SLS, MJF) for Context

These are not metal services but are part of Honyo’s broader prototyping portfolio. They use different materials and specs:

| Process | Material Compatibility | Key Technical Specs | Typical Applications |

|———|————————|————————————————–|——————————-|

| SLA | Photopolymer resins (e.g., ABS-like, clear, flexible) | Layer thickness: 25–100 μm; Tolerance: ±0.05 mm; Surface finish: Smooth (1–5 μm Ra) | Prototypes, optical parts, dental models |

| SLS | Nylon 11, Nylon 12, TPU | Layer thickness: 80–120 μm; Tolerance: ±0.3 mm; Surface finish: Slightly grainy (10–20 μm Ra) | Functional prototypes, jigs, low-volume end-use parts |

| MJF | Nylon 12, PA 12, TPU | Layer thickness: 80 μm; Tolerance: ±0.3 mm; Surface finish: Uniform (8–15 μm Ra) | Production-ready parts, complex geometries, consumer goods |

✅ Honyo’s Policy: We strictly separate metal and polymer services in our quoting, design guidelines, and production. Metal parts are only processed via DMLS/SLM with certified metal powders. Polymer parts use dedicated SLS/MJF/SLA machines.

💡 Why This Accuracy Matters

- Client Risk: Mislabeling ABS/Nylon as “metal materials” or SLA/SLS as “metal processes” could cause catastrophic part failures (e.g., a “metal” bracket printed in ABS would melt under heat loads).

- Regulatory Compliance: Medical/aerospace parts require certified metal processes—polymer processes cannot meet these standards.

- Honyo’s Commitment: We enforce strict material/process separation in all documentation to ensure safety, quality, and regulatory compliance.

For metal parts: Only DMLS/SLM with certified metal powders (Al, Steel, Ti, etc.) is valid. For polymers: SLA/SLS/MJF with ABS, Nylon, or resins is separate.

If you need detailed specs for a specific metal or polymer service, I’m happy to provide them—just clarify the exact requirements. Let’s ensure every project starts with technical accuracy. 🔍

From CAD to Part: The Process

Honyo Prototype – Metal Print Service

End-to-end workflow in one sentence:

“Upload a CAD file today, get an AI-generated, DFM-checked quote in minutes, and hold fully-dense metal parts in as little as 72 h.”

Step-by-step explanation

-

Upload CAD

• Portal accepts any common 3-D format (STEP, IGES, Parasolid, STL, 3MF).

• Geometry is immediately run through a mesh-repair engine to close gaps & stitch surfaces.

• Pre-check flags obvious show-stoppers (zero-thickness walls, non-manifold edges) before the file enters the quote engine. -

AI Quote (real-time)

• Neural-net estimator trained on 400 k+ past builds predicts build time, support mass, laser-on hours, powder consumption, post-CNC hours, heat-treat cycles and yield risk.

• Multi-variable optimizer chooses the most economical combination of:

– Alloy (316 L, 17-4 PH, AlSi10Mg, Ti-6Al-4V, Inconel 718, CuCrZr, etc.)

– Machine (EOS M290, M400-4, SLM 800, GE Additive X-Line)

– Layer thickness (20–90 µm)

– Build orientation & nesting density

• Secondary cost engine adds HIP, machining, heat-treat, surface finish, inspection level and logistics.

• Customer sees a binding price in <60 s, with automatic tiered pricing for Qty 1, 5, 20, 100. -

DFM (Design-for-Additive-Manufacturing)

• Upon order acceptance, the same AI model hands the geometry to a human AM application engineer for a 15-point DFM gate:- Min wall / min pin Ø / aspect ratio check

- Overhang & support feasibility (≤45° self-supporting threshold)

- Internal channel accessibility for powder removal

- Warp & residual-stress simulation (ANSYS Additive Science)

- HIP & heat-treat distortion compensation (pre-deform model)

- Datum selection for 5-axis CNC finish

- GD&T stack-up vs. as-built vs. as-machined

- Surface roughness allowance (Ra 6–25 µm as-built, Ra 0.4 µm after CNC)

• Customer receives an interactive 3-D report; one-click approval or request revision.

• If changes are needed, Honyo will re-quote within 30 min at no extra cost.

-

Production

a. Prep & Nest

– Parts are oriented for lowest support mass + best Z-strength.

– 1–2 mm thick Ti-6Al-4V build plates are pre-heated to 80–200 °C.

b. Print

– Parameters locked to Honyo’s material cards (laser power 200–1000 W, hatch 80–120 µm).

– In-situ melt-pool monitoring (EOS EOSTATE) creates layer-by-layer heat-map; auto-pause if lack-of-fusion detected.

c. Rapid Cooling & Powder Recovery

– Build chamber floods with Ar until <40 °C; loose AlSi10Mg or Ti powder is sieved to 45 µm and recycled <5 times.

d. Stress-Relief & HIP

– 316 L & Ti: 2 h @ 650 °C in vacuum; Al: 2 h @ 300 °C.

– HIP 1000 bar, 920 °C (Ti) or 1150 °C (Inconel) to close internal porosity <0.1 %.

e. CNC Finish & Threads

– Critical surfaces, bores, threads, sealing faces are 3-axis or 5-axis machined to ±25 µm.

f. Post-Processing Menu

– Shot-peen, tumble, electropolish, anodize (Al), PVD, DLC, passivate, laser-mark, helium-leak test, CT scan.

g. In-Process Quality

– CMM report (ISO 2768-f or customer’s drawing), AS9102 FAI on request.

– Full material certs (chemistry, tensile, hardness) included. -

Delivery

• Parts vacuum-sealed with desiccant; Ti and Al parts wrapped in acid-free paper to prevent galvanic corrosion.

• Courier options: 24 h global express (DHL, FedEx), or weekly consolidated airfreight for volume orders.

• Digital traveler (build photos, parametric log, QC data) sent as password-protected PDF + raw data (CSV, XLS).

• Feedback loop: customer dimensional data automatically ingested to retrain the AI quote engine—continuous cost-down for repeat orders.

Typical lead-times

• AlSi10Mg, 316 L: 3–5 days

• Ti-6Al-4V, 17-4 PH: 5–7 days

• Inconel 718, CuCrZr: 7–10 days

(Add 1–2 days if HIP + CNC finish required.)

Result: a seamless, data-driven path from CAD file to flight-ready metal components, with zero human quoting delays and repeatable aerospace-grade quality.

Start Your Project

Ready to elevate your projects with precision metal prints?

📞 Contact Susan Leo at [email protected]

📍 Precision manufacturing from Honyo Prototype’s Shenzhen factory—fast, reliable, and quality-assured.

(Simple, action-driven, and highlights key value points: expertise, location, and reliability.)

🚀 Rapid Prototyping Estimator