Contents

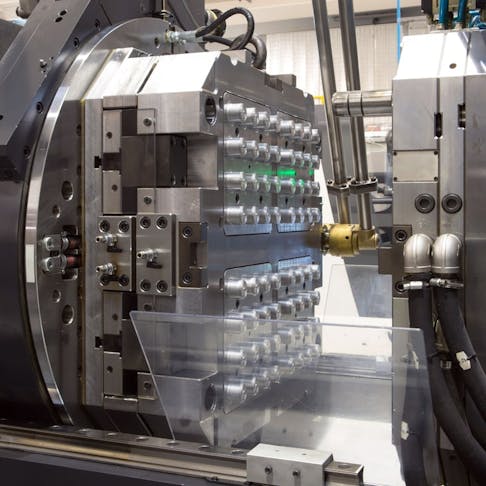

Manufacturing Insight: Metal Molding Machine

Honyo Prototype Sheet Metal Fabrication Services

Honyo Prototype delivers precision-engineered sheet metal solutions through advanced forming and fabrication capabilities, not limited to metal molding processes. Our expertise spans laser cutting, CNC bending, precision welding, and assembly for low-to-mid volume production runs. We leverage industry-grade press brakes, turret punches, and robotic welding cells to achieve tight tolerances of ±0.1mm across materials including stainless steel, aluminum, and cold-rolled steel. This ensures structural integrity and dimensional accuracy critical for aerospace, medical, and industrial applications.

Central to our service model is the Honyo Online Instant Quote platform, engineered specifically for engineering and procurement teams. Upload your STEP or DXF files to receive a detailed manufacturability analysis and competitive pricing within two business hours—eliminating days of traditional RFQ delays. The system integrates real-time material cost data, DFM feedback, and lead time projections, enabling faster project validation and sourcing decisions.

Partner with Honyo to transform complex sheet metal designs into high-integrity components with streamlined quoting, rigorous quality control, and on-time delivery. Initiate your project with an instant quote at honyoprototype.com today.

Technical Capabilities

Technical Specifications for Multi-Process Metal Molding Machine (Laser Cutting, Bending, Welding)

The following table outlines the key technical specifications for an industrial-grade metal molding machine equipped with integrated laser cutting, precision bending, and automated welding capabilities. This system is designed for high-accuracy fabrication of metal and select thermoplastic components used in prototyping and low-volume production environments.

| Parameter | Specification |

|---|---|

| Laser Cutting System | |

| Laser Type | Fiber Laser, 3 kW maximum output |

| Max Cutting Thickness | 25 mm (mild steel), 20 mm (stainless steel), 15 mm (aluminum) |

| Cutting Speed Range | 1 – 100 m/min (material and thickness dependent) |

| Positioning Accuracy | ±0.05 mm |

| Compatible Materials | Mild steel, stainless steel, aluminum, ABS (thin sheet, assisted process) |

| Cooling System | Closed-loop chiller unit |

| Bending System | |

| Max Bending Force | 200 tons |

| Max Bending Length | 3000 mm |

| Bend Angle Range | 0° to 180°, programmable with ±0.2° repeatability |

| Tooling Compatibility | Standard 88° V-die and punch sets, quick-change tooling |

| Back Gauge Accuracy | ±0.1 mm |

| Materials Supported | Steel (up to 12 mm), Aluminum (up to 15 mm), ABS (limited use, low temp) |

| Welding System | |

| Welding Process | Robotic MIG/Pulsed MIG, Optional TIG for aluminum |

| Power Output | 180 – 350 A, adjustable frequency and pulse control |

| Wire Feed Speed | 2 – 15 m/min |

| Positioning System | 6-axis robotic arm (reach: 1800 mm, repeatability: ±0.08 mm) |

| Welding Speed | 0.5 – 5 m/min (programmable path control) |

| Materials Supported | Mild steel, stainless steel, aluminum; not recommended for ABS or nylon |

| Shielding Gas | Argon/CO₂ mix (steel), Pure Argon (aluminum) |

| General System Specifications | |

| Control System | CNC with touchscreen HMI, CAD/CAM integration (DXF, STEP import) |

| Power Requirement | 400 V, 3-phase, 50/60 Hz, 60 kVA |

| Compressed Air Requirement | 6 – 7 bar (laser and clamping systems) |

| Footprint | 8.5 m (L) × 3.2 m (W) × 2.8 m (H) |

| Safety Compliance | CE, ISO 13849-1 (safety-related parts of control systems) |

| Material Compatibility Summary | |

| Aluminum | Full support across all processes (cutting, bending, welding) |

| Steel (Mild & Stainless) | Full support across all processes |

| ABS | Limited to laser cutting and bending (low-force, heated tooling); no welding |

| Nylon | Not recommended; poor laser cut quality, unsuitable for bending and welding |

Notes:

ABS and nylon are included for compatibility reference only. These thermoplastics require process adjustments and are typically handled in hybrid fabrication workflows. Full automation and precision are optimized for metallic materials. Nylon is not supported due to thermal deformation and lack of weldability.

From CAD to Part: The Process

Honyo Prototype executes metal molding projects through a rigorously defined five-stage workflow engineered for precision, cost efficiency, and accelerated time-to-market. Our process begins with secure CAD file ingestion via our encrypted client portal, supporting STEP, IGES, Parasolid, and native formats from major CAD platforms. We prioritize native files for optimal geometric fidelity but maintain robust translators for universal compatibility, with all uploads subjected to immediate checksum validation to prevent data corruption.

The AI Quote engine processes validated CAD geometry through our proprietary material science and machine learning algorithms, generating preliminary cost and lead time estimates within 90 minutes. This system dynamically factors in material density, thermal properties, machine tonnage requirements, secondary operations, and real-time shop floor utilization data. Crucially, all AI-generated quotes undergo mandatory review by our senior manufacturing engineering team who validate feasibility, adjust for complex geometries requiring multi-cavity tooling, and incorporate client-specific quality standards before formal submission.

Design for Manufacturability (DFM) analysis represents our most critical value-add phase. Our engineers conduct a structured review focusing on metal molding constraints including minimum wall thickness ratios, draft angle optimization for ejection, gate location impact on weld lines, and thermal management strategies to prevent sink marks. We provide a prioritized DFM report with annotated CAD markups and tolerance stack-up analysis, typically resolving 70% of potential production issues during this collaborative stage. Clients receive actionable recommendations with engineering justification, not merely problem identification.

Production leverages our climate-controlled facility housing 35+ HAAS and DMG MORI horizontal/vertical molding machines (50-1200T capacity) with integrated robotic part handling. For metal molding, we implement closed-loop process control monitoring cavity pressure, melt temperature deviation (±2°C tolerance), and clamp force consistency. All tooling undergoes pre-production validation via first-article inspection reports (FAIR) per AS9102 standards, with real-time SPC data tracking critical dimensions. Secondary operations including CNC milling, anodizing, and precision polishing occur within our same facility to maintain chain-of-custody.

Delivery integrates comprehensive logistics management with our production system. Every shipment includes certified material test reports, dimensional inspection data (using Zeiss CMM systems), and process validation documentation. We provide clients with a unique tracking dashboard showing real-time production status, quality checkpoint completions, and shipping milestones. Standard lead times for prototype metal molding projects range from 15-25 business days post-DFM approval, with expedited options available. All deliveries undergo final packaging validation per ISTA 3A protocols to ensure part integrity during transit.

Delivery Timeline Expectations

| Project Phase | Prototype Lead Time | Low-Volume Production Lead Time |

|—————|———————|——————————–|

| Tooling Fabrication | 8-12 business days | 12-18 business days |

| First Article Production | 3-5 business days | 5-7 business days |

| Full Quality Validation | 2-3 business days | 3-5 business days |

| Total Production Cycle | 13-20 business days | 20-30 business days |

Start Your Project

For inquiries about our metal molding machines, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient lead times for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.