Contents

Manufacturing Insight: Metal Injection Molding Materials

Introduction to Metal Injection Molding Materials and Honyo’s Precision Sheet Metal Fabrication Capabilities

While Metal Injection Molding (MIM) serves specific high-volume, complex geometries in powder metallurgy, Honyo Prototype specializes in high-precision Sheet Metal Fabrication for rapid prototyping and low-to-mid volume production. This distinction is critical: MIM excels for miniature, intricate components, whereas sheet metal fabrication delivers superior strength, thermal stability, and cost efficiency for enclosures, brackets, chassis, and structural parts. At Honyo, we leverage industry-leading CNC laser cutting, precision bending, and comprehensive finishing to transform raw sheet metal into mission-critical components with tight tolerances (±0.05mm) and rapid turnaround.

Our sheet metal expertise spans diverse materials, each optimized for mechanical performance and manufacturability. Below is a comparison of commonly processed alloys:

| Material Grade | Key Properties | Typical Applications | Max Thickness (mm) |

|---|---|---|---|

| Aluminum 5052-H32 | Excellent corrosion resistance, weldability | Enclosures, marine hardware | 6.0 |

| Stainless Steel 304 | High strength, temperature resistance | Medical devices, food processing | 4.0 |

| Cold Rolled Steel 1018 | Cost-effective, superior formability | Brackets, frames, automotive | 3.0 |

| Brass C36000 | Machinability, aesthetic finish | Electrical contacts, decorative | 2.5 |

Honyo Prototype eliminates procurement delays with our Online Instant Quote system. Upload your STEP or DXF file, specify material, quantity, and finishing requirements, and receive a detailed technical assessment and competitive pricing within minutes—not days. This seamless integration of engineering validation and quoting ensures your sheet metal projects move from design to production with zero friction.

For applications demanding robust, geometrically versatile metal components, trust Honyo’s sheet metal fabrication—where material science meets manufacturing agility. Initiate your project today via our instant quote portal and experience precision engineered for speed.

Technical Capabilities

Metal Injection Molding (MIM) is primarily used to produce complex, high-volume metal components with excellent dimensional accuracy and mechanical properties. However, MIM materials are not typically used directly in laser cutting, bending, or welding processes, as these are usually applied during secondary operations or when integrating MIM parts into larger assemblies. The materials listed—Aluminum, Steel, ABS, and Nylon—include both metals suitable for MIM (Aluminum, Steel) and thermoplastics (ABS, Nylon), which are not MIM materials but may be used in related manufacturing contexts such as overmolding or hybrid assemblies.

Below is a technical comparison focused on process compatibility with laser cutting, bending, and welding for each material, with relevance to MIM and secondary fabrication:

| Material | MIM Compatible | Laser Cutting Suitability | Bending Characteristics | Welding Compatibility | Notes |

|---|---|---|---|---|---|

| Aluminum (e.g., Al-6061, Al-7075) | Yes (limited grades) | Good – clean cuts with fiber lasers; high reflectivity requires parameter control | Moderate – limited formability in MIM form; sheet forms bend well | Good – laser and TIG welding effective; preheat may be needed | MIM aluminum offers lower density and good corrosion resistance; post-sintered parts may require machining |

| Steel (e.g., 17-4 PH, 316L, 420) | Yes – widely used in MIM | Excellent – CO₂ or fiber lasers cut efficiently with high precision | Limited – MIM steel parts are near-net shape; bending not typical post-sintering | Excellent – laser and resistance welding commonly used | High strength and wear resistance; 316L is weldable and corrosion-resistant; 17-4 PH is precipitation-hardened |

| ABS (Acrylonitrile Butadiene Styrene) | No – thermoplastic, not MIM | Good – easily cut with CO₂ lasers; melts rather than vaporizes | Good – flexible and formable in sheet form; not applicable to MIM | Poor – not weldable via metal methods; ultrasonic or adhesive joining used | Used in plastic injection molding; may be overmolded with MIM metal parts |

| Nylon (e.g., PA6, PA12) | No – thermoplastic, not MIM | Moderate – CO₂ lasers can cut but may char edges; melt behavior requires control | Good – flexible and tough; used in flexible hinges | Poor – not weldable with metal techniques; hot plate or vibration welding used | Often used in engineering plastics; PA12 is common in powder bed fusion; may serve as matrix in hybrid systems |

Technical Notes:

MIM processes are designed for metals such as stainless steels, low-alloy steels, and specialty alloys including some aluminum and titanium grades. Thermoplastics like ABS and Nylon are incompatible with MIM feedstock and sintering cycles.

Laser cutting is typically applied to sheet forms of metals (not sintered MIM parts), used in fabrication prior to assembly.

Bending is not a standard operation for finished MIM components, which are net-shape. However, if integrated into sheet metal assemblies, aluminum and steel sheets exhibit standard forming behavior.

Welding of MIM parts follows standard metal welding practices. 316L stainless steel MIM components, for example, are often laser welded in medical and automotive applications due to their consistent density and composition.

For hybrid designs, MIM metal parts may be overmolded with ABS or Nylon using plastic injection molding, where laser cutting or ultrasonic welding could apply to the plastic portion of the assembly.

From CAD to Part: The Process

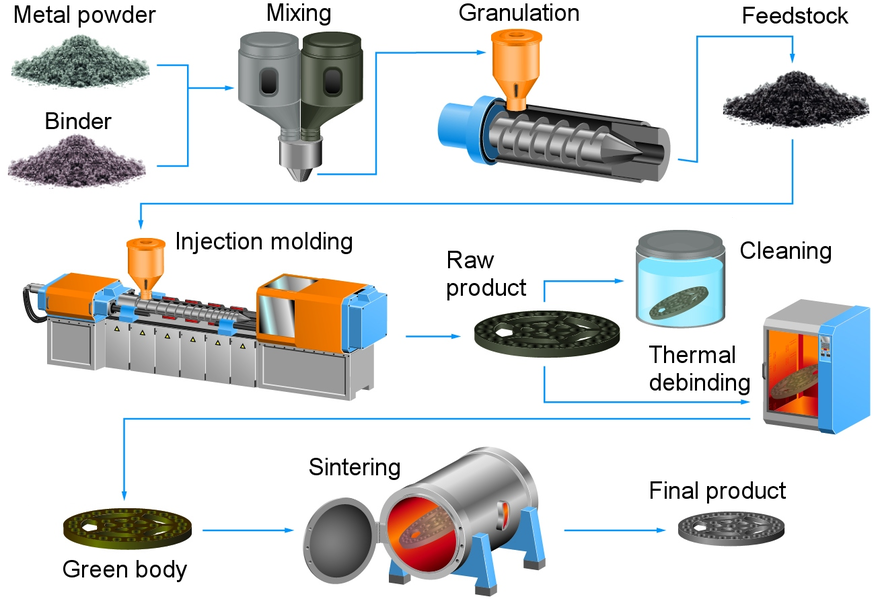

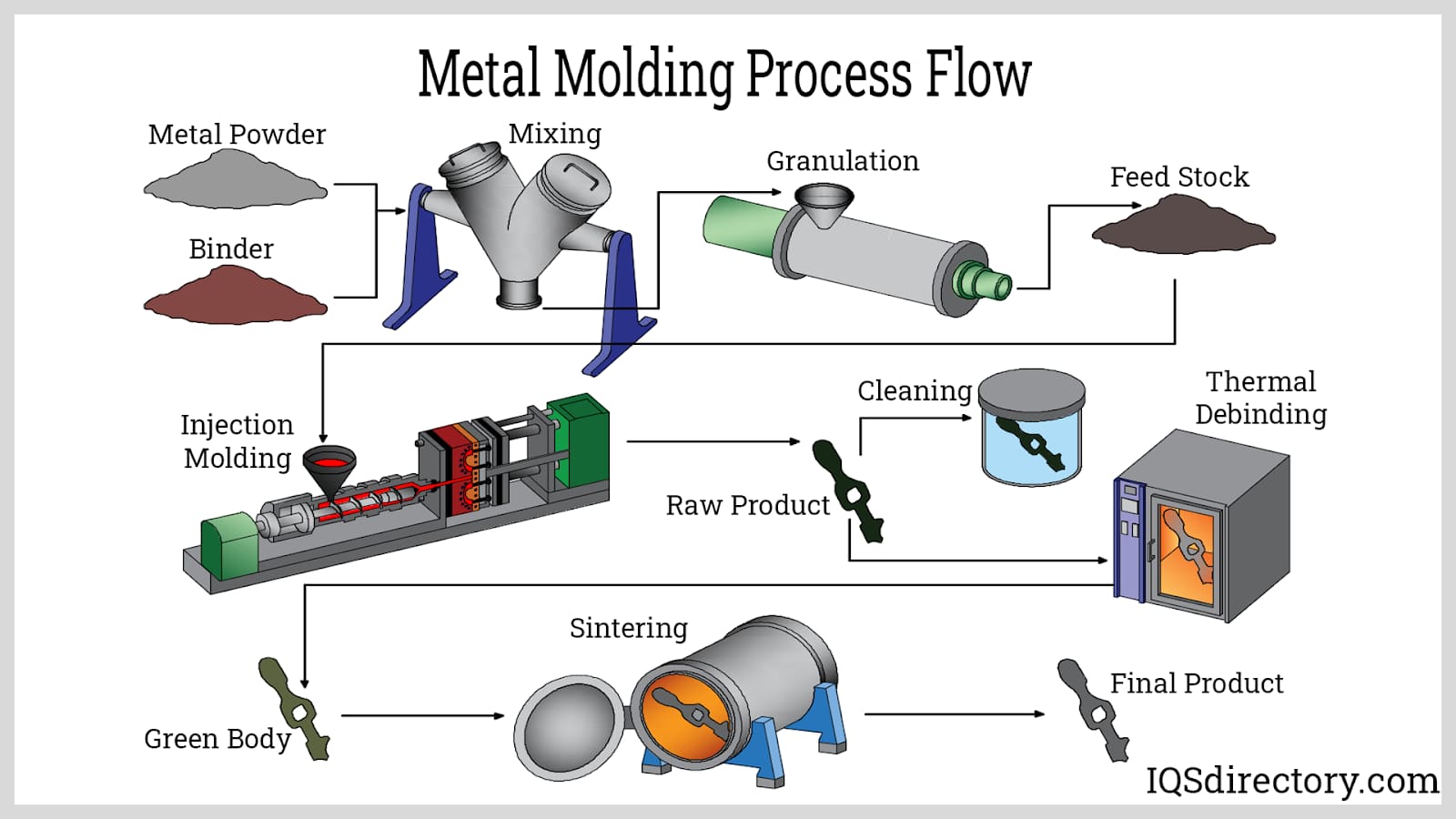

Honyo Prototype Metal Injection Molding Material Process Flow

Honyo Prototype executes a rigorously controlled Metal Injection Molding (MIM) process optimized for precision, material integrity, and rapid turnaround. Our workflow begins with digital validation and concludes with certified delivery, ensuring adherence to ASTM B962 and MPIF Standard 35 requirements for all MIM components. Below is the detailed sequence for MIM material projects.

CAD Upload & Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats) via our secure customer portal. Our system performs an immediate geometric validation check, confirming watertightness, minimum wall thickness compliance (≥0.5mm for standard MIM alloys), and identification of undercuts or features requiring secondary operations. Non-conforming geometries trigger automated feedback within 2 hours, specifying required adjustments to ensure moldability.

AI-Powered Quoting with Material Intelligence

Validated CAD data feeds into our proprietary AI quoting engine, which cross-references over 200 MIM feedstock formulations against project specifications. The system analyzes material compatibility (e.g., 17-4PH stainless steel, 316L, or Ti-6Al-4V), volume, tolerances, and secondary operations to generate a preliminary quote within 4 business hours. Critical material parameters—including sintered density targets (≥98% theoretical), shrinkage factors (15–20%), and ASTM F2885 powder characteristics—are auto-populated to ensure cost accuracy. Human engineers review all AI outputs to validate material selection against application requirements like biocompatibility (ASTM F138) or magnetic permeability.

Engineering-Driven DFM with Material Science Focus

Our senior MIM engineers conduct a dual-phase Design for Manufacturability review. Phase 1 addresses geometric feasibility: gate placement optimization, draft angle verification (≥2° per side), and identification of stress concentration zones requiring radii adjustments. Phase 2 focuses exclusively on material behavior—evaluating feedstock flow dynamics (using Moldflow simulations), predicting sintering distortion based on part symmetry, and specifying critical dimensions requiring post-sintering coining or sizing. Clients receive a marked-up DFM report with actionable recommendations, typically within 24–48 hours of quote acceptance. Material-specific tolerances (e.g., ±0.3% for 316L in dimensions <50mm per MPIF 35) are explicitly defined at this stage.

Precision Production with Traceable Materials

Approved designs advance to production using certified MIM feedstocks from pre-qualified suppliers (Carpenter, BASF, or Sandvik). Each batch includes full material traceability:

Lot-specific CoC (Certificate of Conformance) with chemical composition

Particle size distribution reports (D50 ≤ 22μm for standard grades)

Rheology test data for injection consistency

The process sequence includes debinding (catalytic or thermal), sintering in controlled atmosphere furnaces (±2°C uniformity), and optional secondary operations like HIP or precision grinding. In-process checks at sintering verify density (Archimedes method) and dimensional stability per the DFM plan.

Delivery with Full Material Certification

All shipments include comprehensive documentation:

Final inspection report with CMM data (GD&T per ASME Y14.5)

Material traceability matrix linking part serial numbers to feedstock lots

Sintered mechanical property test results (tensile, hardness) per ASTM E8

PPAP Level 3 documentation for automotive/medical clients

Standard lead time from DFM approval to delivery is 15–25 days, depending on complexity and material grade. Expedited options reduce this to 10–18 days with priority furnace scheduling.

Typical MIM Project Timeline

| Phase | Duration | Key Deliverables |

|——-|————|——————|

| CAD Upload to Quote | ≤4 business hours | Validated geometry, preliminary cost |

| DFM Approval | 1–2 business days | Actionable engineering recommendations |

| Production | 12–22 business days | Traceable parts with in-process certifications |

| Delivery | Final 3 days | Complete documentation package, CoC |

This integrated approach ensures MIM components meet stringent material performance criteria while minimizing time-to-market. Honyo maintains ISO 13485 certification for medical devices and IATF 16949 for automotive applications, with all MIM materials conforming to industry-specific regulatory frameworks.

Start Your Project

Looking for high-performance metal injection molding materials for your next project? Honyo Prototype offers advanced MIM materials with excellent density, strength, and dimensional accuracy—ideal for complex, high-volume precision components.

Our manufacturing facility in Shenzhen ensures tight process control, rapid prototyping, and scalable production to meet your specifications. Whether you’re developing medical devices, automotive components, or consumer electronics, we provide material solutions tailored to your performance requirements.

Contact Susan Leo today at [email protected] to discuss your material needs and discover how our metal injection molding expertise can support your product development goals.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.