Contents

Manufacturing Insight: Metal Injection Molding Companies

Strategic Manufacturing Partnerships for Complex Metal Components

While metal injection molding (MIM) remains a vital solution for high-volume, intricate small parts, many industrial applications demand the geometric flexibility, structural robustness, and rapid scalability only achievable through precision sheet metal fabrication. At Honyo Prototype, we specialize in bridging this gap for OEMs and contract manufacturers seeking end-to-end metal component solutions beyond MIM’s limitations. Our advanced sheet metal fabrication services—including laser cutting, CNC bending, precision welding, and finishing—deliver exceptional repeatability for enclosures, brackets, chassis, and structural assemblies across aerospace, medical, and industrial automation sectors.

Leveraging state-of-the-art Amada and Trumpf machinery alongside rigorous AS9100 and ISO 13485-compliant processes, Honyo transforms complex 3D models into mission-critical components with tolerances down to ±0.05mm. Unlike MIM, our sheet metal capabilities excel in medium-to-high volumes with minimal tooling investment, accelerating time-to-market for dynamic design iterations. Crucially, Honyo eliminates procurement delays through our industry-leading Online Instant Quote platform, providing detailed manufacturability feedback and competitive pricing within hours—not days—for DXF/DWG/STEP files.

Partner with Honyo Prototype to consolidate your metal component supply chain, reduce NRE costs, and leverage seamless integration between prototyping and volume production. Experience engineering-grade sheet metal fabrication backed by 20+ years of high-mix manufacturing expertise. Submit your design today for an immediate quote and precision-engineered results.

Technical Capabilities

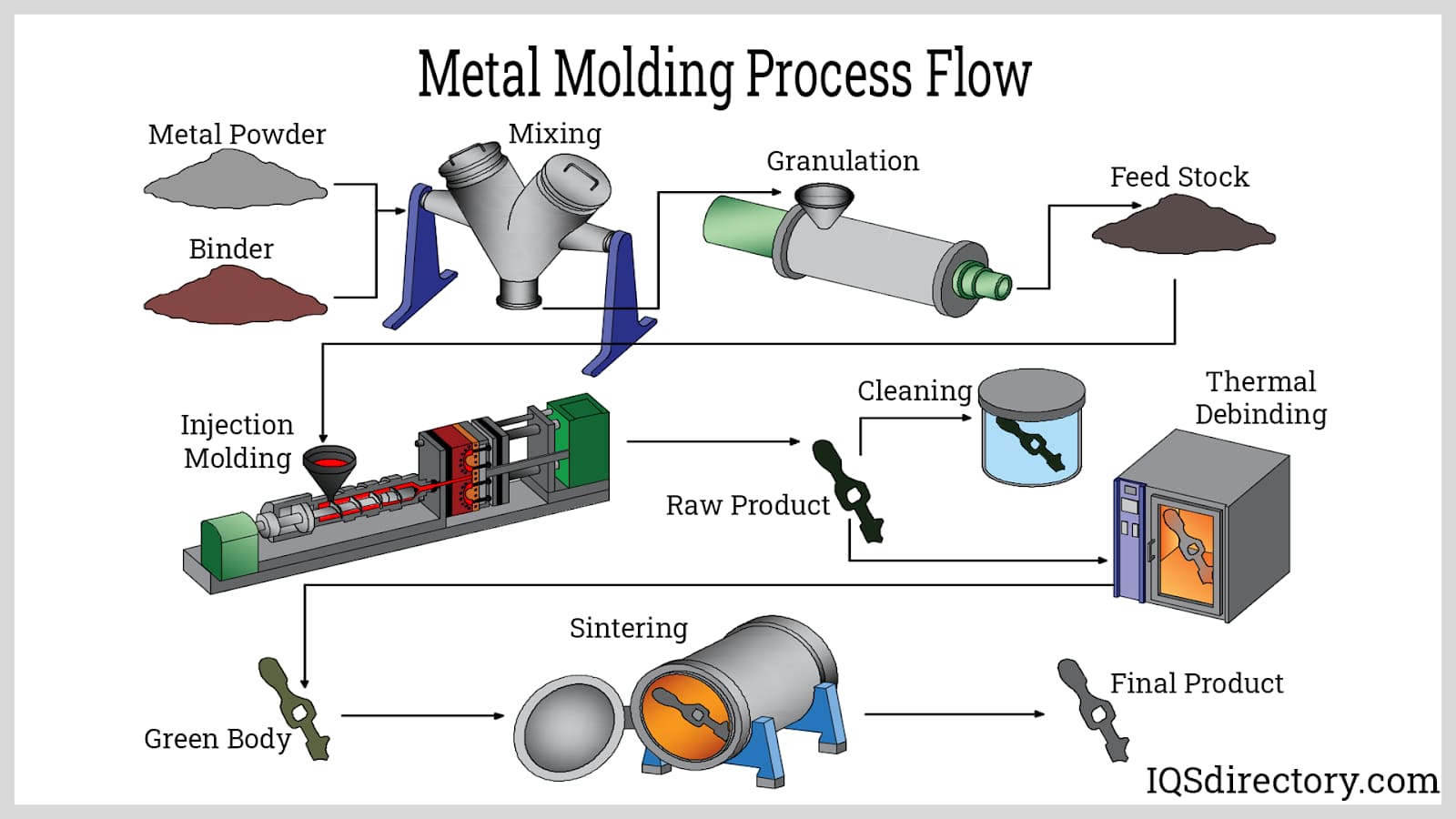

Metal Injection Molding (MIM) is primarily a powder metallurgy process used to produce small, complex, high-volume metal components. However, MIM companies often integrate secondary operations such as laser cutting, bending, and welding to finish or assemble parts. While MIM itself does not typically involve plastics like ABS or Nylon, these materials may be used in hybrid assemblies or for non-structural components in conjunction with metal parts.

Below are the technical capabilities and material compatibilities relevant to laser cutting, bending, and welding—commonly offered as value-added services by MIM companies or their manufacturing partners.

| Process | Material Compatibility | Thickness Range | Tolerance (Typical) | Key Equipment Used | Application Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel (Stainless, Carbon) | 0.5 mm – 25 mm | ±0.1 mm | Fiber Laser Cutting Machines (e.g., Trumpf, Amada) | Used for cutting flat blanks or features in MIM part supports; high precision and edge quality |

| Bending | Aluminum, Steel (Stainless, Low Carbon) | 0.8 mm – 6 mm | ±0.2° angular, ±0.1 mm linear | CNC Press Brakes (e.g., Bystronic, LVD) | Common for secondary forming of housings or brackets integrated with MIM components |

| Welding | Aluminum, Steel (Stainless, Carbon) | 0.5 mm – 10 mm | ±0.05 mm joint accuracy | Fiber Laser Welders, TIG, MIG, Spot Welders | Used for assembly of MIM parts into larger subunits; hermetic seals possible with laser welding |

| Hybrid Assembly (Non-MIM) | ABS, Nylon (Plastics) | Varies by molding process | ±0.1 mm | Ultrasonic Welding, Adhesive Bonding, Overmolding | Plastics used in overmolded assemblies with MIM parts; not processed via MIM, but integrated post-production |

Notes:

Aluminum and Steel are the primary metals used in both MIM and secondary fabrication processes. MIM alloys include 17-4 PH stainless steel, 316L, and low-carbon steels; aluminum MIM is less common due to oxidation challenges.

ABS and Nylon are engineering thermoplastics used in overmolding or assembly with MIM parts but are not processed via metal injection molding. They may be laser marked or ultrasonically welded in hybrid systems.

Secondary operations like laser cutting, bending, and welding are typically performed on sheet metal components that interface with MIM parts, rather than on the MIM parts themselves due to their small size and sintered microstructure.

Integration of MIM with laser welding allows for precise joining in medical, automotive, and aerospace applications where miniaturization and reliability are critical.

These capabilities enable MIM companies to deliver fully finished, complex assemblies combining high-precision metal parts with structural and functional integration through advanced fabrication techniques.

From CAD to Part: The Process

Honyo Prototype Metal Injection Molding Service Workflow

Honyo Prototype delivers end-to-end Metal Injection Molding (MIM) solutions through a streamlined digital workflow designed for precision, speed, and manufacturability. The process begins with CAD file submission and concludes with certified part delivery, integrating AI-driven efficiency with rigorous engineering oversight.

Clients initiate the process by uploading 3D CAD models via Honyo’s secure online portal. We accept industry-standard formats including STEP, IGES, and native SOLIDWORKS files. Our system performs an immediate automated validation check for geometry integrity, unit consistency, and minimum feature size compliance with MIM capabilities. Files failing validation trigger instant feedback detailing required corrections, preventing downstream delays.

The validated CAD model enters Honyo’s proprietary AI quoting engine. This system analyzes over 50 geometric and material parameters against a database of 10,000+ historical MIM projects to generate an accurate, real-time cost estimate. Unlike manual quoting, the AI accounts for material density, cavity count optimization, secondary operation sequencing, and regional supply chain variables. Clients receive a granular breakdown within 2 business hours, including material cost, tooling amortization, and estimated lead time.

Following quote acceptance, the design undergoes a dual-phase Design for Manufacturability (DFM) review. First, Honyo’s AI DFM module performs a rapid scan for MIM-specific risks: wall thickness transitions below 0.5mm, draft angles under 1°, or unsupported thin ribs. Critical flags trigger automatic geometry suggestions. Second, a senior MIM process engineer conducts a manual review, focusing on parting lines, gate locations, and sintering distortion mitigation. Clients receive a collaborative DFM report with annotated recommendations and trade-off analysis for design modifications, typically within 3 business days.

Approved designs advance to production under Honyo’s ISO 9001-certified workflow. We utilize vacuum-degassed 17-4PH, 316L, or custom alloy feedstocks with ≤15μm particle distribution. Molding occurs on 50-300 ton electric presses with real-time cavity pressure monitoring. Sintering follows in hydrogen-controlled furnaces with ±2°C thermal uniformity. Every lot includes in-process checks: green part dimensional verification, sintered density testing per ASTM B962, and final CMM reports against GD&T callouts. Material certifications and traceability logs accompany all shipments.

Final parts undergo laser etching for traceability and packaging in ESD-safe containers with humidity indicators. Honyo manages global logistics via DHL/FedEx partnerships, providing automated shipment tracking and customs documentation. Delivery timelines are strictly adhered to through our production control system, which prioritizes rush orders in dedicated tooling cells. All shipments include first-article inspection reports and sintering curve validation.

Typical Timeline Breakdown for Standard MIM Projects

| Process Stage | Duration | Key Milestones |

|---|---|---|

| CAD Validation & AI Quote | 0.5-2 days | Geometry check, real-time cost breakdown |

| DFM Review | 2-4 days | AI scan + engineer review, collaborative report |

| Tooling & Production | 18-25 days | Mold fabrication, 3-stage MIM process, testing |

| Final Delivery | 3-5 days | Packaging, logistics, documentation handover |

This integrated approach reduces time-to-part by 35% compared to traditional MIM suppliers while ensuring first-pass yield rates exceed 92%. Honyo maintains full transparency via client portal access to production dashboards and real-time engineering collaboration channels throughout the workflow.

Start Your Project

For precision metal injection molding solutions, contact Susan Leo at [email protected]. Honyo Prototype offers high-quality manufacturing services with a dedicated factory located in Shenzhen, ensuring fast turnaround and strict quality control. Partner with us for reliable, scalable production of complex metal components. Reach out today to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.