Contents

Manufacturing Insight: Metal Injection Molded

Precision Sheet Metal Fabrication for Demanding Applications

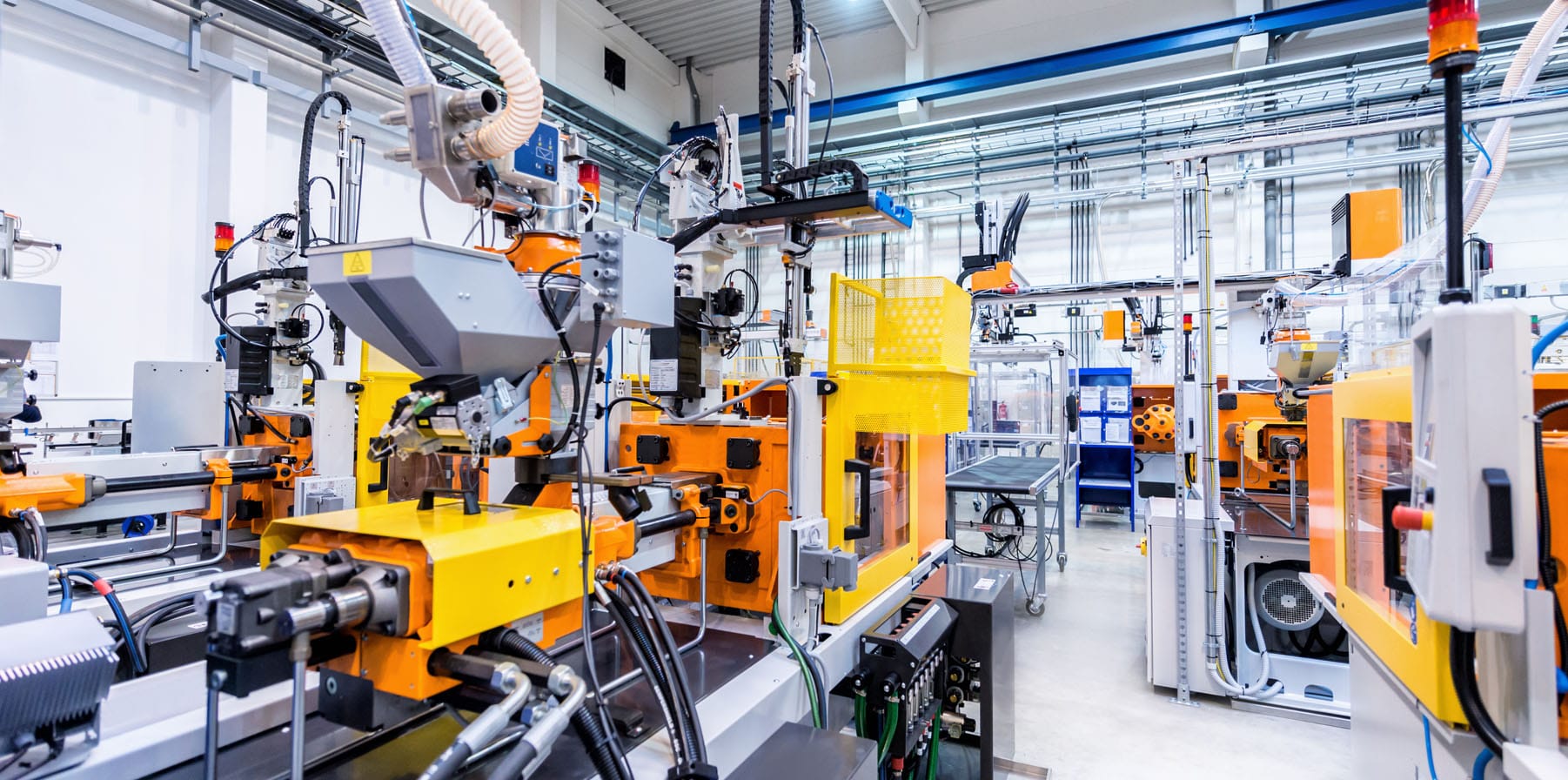

At Honyo Prototype, we engineer mission-critical sheet metal components where dimensional accuracy, material integrity, and rapid turnaround define success. While Metal Injection Molding (MIM) serves niche applications for complex miniature geometries, Honyo specializes in high-precision sheet metal fabrication for structural, enclosure, and functional parts across aerospace, medical, and industrial sectors. Our integrated capabilities—including laser cutting, CNC punching, precision bending, welding, and finishing—transform raw materials like stainless steel, aluminum, and copper alloys into production-ready components with tolerances held to ±0.005 inches.

Unlike conventional suppliers constrained by legacy workflows, Honyo leverages state-of-the-art fiber laser systems and automated bending cells to eliminate bottlenecks in prototyping and low-to-mid volume production. Every process is validated through AS9100 and ISO 13485 frameworks, ensuring repeatability from first article to full-scale runs. Crucially, our Online Instant Quote platform provides validated DFM feedback and lead time transparency within minutes, not days. Upload your STEP or DXF file to receive a technically vetted quote with material optimization insights—accelerating your path from design to certified hardware.

For engineering teams prioritizing speed without compromise, Honyo Prototype delivers the confluence of advanced manufacturing science and responsive partnership. Explore how our sheet metal expertise solves your toughest fabrication challenges at honyoprototype.com.

Technical Capabilities

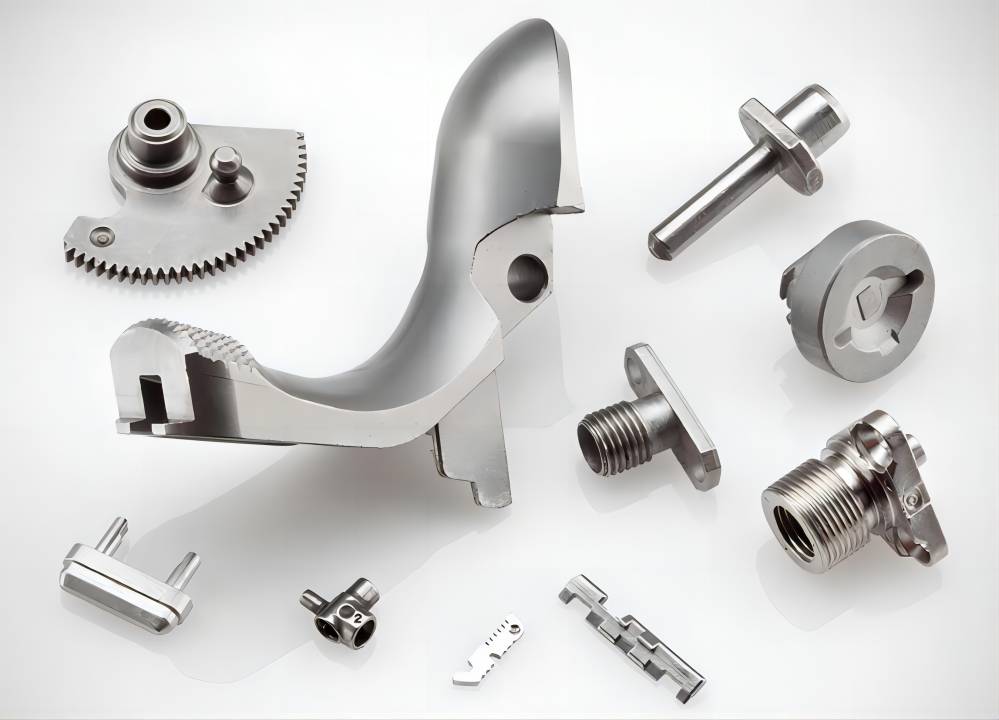

Metal Injection Molding (MIM) is a manufacturing process that combines the shape-making complexity of plastic injection molding with the material flexibility of powdered metal sintering. It is typically used for small, intricate, high-volume metal components. However, laser cutting, bending, and welding are generally post-processing or alternative fabrication techniques applied either to MIM parts or to sheet metal forms. Below is a technical overview of how these processes interact with common materials, including Aluminum, Steel, ABS, and Nylon. Note that ABS and Nylon are not applicable to MIM as they are polymers, but are included for comparative context in hybrid or secondary operations.

| Process | Applicable Materials | Technical Specifications | Compatibility with MIM Parts | Notes |

|---|---|---|---|---|

| Laser Cutting | Steel, Aluminum | Uses high-power laser (typically fiber or CO2) to cut sheet metal with precision (±0.1 mm). Kerf width: 0.1–0.3 mm. Max thickness: up to 25 mm for steel, 15 mm for aluminum depending on laser power. | Limited – used for trimming or modifying MIM feeders/frames, not typical for net-shape MIM parts. | Not a primary MIM process; used for sheet-based fabrication or post-MIM support removal. ABS and Nylon can be laser cut but are not MIM materials. |

| Bending | Steel, Aluminum | Performed on sheet metal using press brakes. Tolerances: ±0.25° angular, ±0.2 mm linear. Minimum bend radius typically 0.5–1x material thickness. | Low – MIM produces near-net shape parts; bending is not applicable post-sintering. | Used in secondary fabrication. Not relevant for thermoplastics like ABS/Nylon in MIM context. |

| Welding | Steel, Aluminum | Common methods: TIG, MIG, laser welding. Joint strength approaches base material. Pre/post-heat treatment may be needed for steel. Aluminum requires shielding gas (argon). | Moderate – MIM parts can be welded to other components, but joint design must account for sintered microstructure. | ABS and Nylon can be ultrasonically welded or glued but not fusion welded like metals. Not part of MIM process. |

Material Notes:

Aluminum & Steel: Primary metals used in MIM. MIM aluminum alloys (e.g., 6061, 7075) and steels (e.g., 17-4 PH, 316L) are available in powdered form for injection molding.

ABS & Nylon: Thermoplastics used in plastic injection molding, not MIM. They are structurally and thermally incompatible with MIM processing (requires sintering >1300°C).

Summary:

Laser cutting, bending, and welding are not integral to the MIM process but may be used for ancillary operations or integration with other components. MIM excels in producing complex, small-scale metal parts directly, reducing the need for secondary fabrication. Aluminum and steel are suitable for both MIM and the listed processes, while ABS and Nylon fall outside the scope of MIM entirely.

From CAD to Part: The Process

Honyo Prototype Metal Injection Molding Process Overview

Honyo Prototype executes a streamlined Metal Injection Molding (MIM) workflow designed for precision, speed, and manufacturability. Our process begins with client CAD submission and concludes with certified delivery, integrating AI-driven efficiency with expert engineering oversight at critical stages. Below is the detailed sequence.

CAD File Submission

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SLDPRT, IPT) via our secure customer portal. We require fully dimensioned 3D models with geometric tolerances and material specifications. Non-native formats undergo validation to ensure geometry integrity, as MIM part performance is highly sensitive to wall thickness transitions, draft angles, and feature resolution.

AI-Powered Quoting Engine

Uploaded CAD data feeds our proprietary AI quoting system, which performs instant geometric analysis to estimate material usage, cycle times, and secondary operations. The AI cross-references real-time material costs, machine utilization rates, and historical production data to generate a preliminary quote within 2 hours. Crucially, this stage includes automated feasibility flags for high-risk geometries (e.g., aspect ratios >15:1, thin walls <0.5mm), though all quotes undergo final review by a senior process engineer to validate AI outputs and address nuanced manufacturability concerns.

Engineering DFM Analysis

All projects advance to mandatory Design for Manufacturability (DFM) review by our MIM-specialized engineering team. This phase typically completes within 72 business hours and delivers actionable feedback via a structured report. Key DFM interventions include:

| Common Issue Identified | Honyo Engineering Resolution |

|---|---|

| Non-uniform wall thickness causing sink marks | Redesign ribs/gussets with gradual transitions; propose localized material buildup |

| Critical tolerances beyond ±0.3% capability | Recommend post-sintering CNC grinding zones; adjust draft angles for ejection |

| Undercuts requiring complex tooling | Suggest split-core solutions or alternative parting line orientation |

DFM sign-off requires mutual agreement between client and Honyo engineers, ensuring the design aligns with MIM’s unique constraints of feedstock flow, debinding kinetics, and sintering shrinkage (typically 15-18%).

Precision Production Execution

Approved designs enter production under our AS9100-certified workflow:

Feedstock preparation uses gas-atomized metal powders (e.g., 17-4PH, 316L) compounded with proprietary binder systems. Injection molding occurs in climate-controlled cells with real-time cavity pressure monitoring. The critical debinding phase employs multi-stage solvent/thermal processes in vacuum-controlled ovens to prevent part distortion. Sintering utilizes hydrogen-furnaces with zone-specific temperature profiling (±2°C accuracy) and automated atmosphere monitoring to achieve density >98% theoretical. All lots undergo in-process CMM verification at pre-defined checkpoints.

Certified Delivery

Final inspection includes material certification (per ASTM B213, F2885), 100% visual examination, and statistical dimensional validation against client drawings. Parts ship in ESD-safe packaging with serialized traceability tags linking to batch-specific sintering profiles and QC data. Standard lead time from DFM approval to delivery is 12-15 business days for first articles, with production lots scaling to 50,000+ units weekly. Clients receive full documentation packages including PPAP Level 3 reports upon request.

This integrated approach reduces time-to-part by 30% versus industry averages while maintaining first-pass yield rates exceeding 95% through proactive DFM collaboration and closed-loop process control.

Start Your Project

Looking for high-precision metal injection molded components? Partner with Honyo Prototype for reliable, cost-effective manufacturing solutions.

Our advanced Metal Injection Molding (MIM) process delivers complex, net-shape parts with excellent mechanical properties—ideal for automotive, medical, and industrial applications.

With our factory based in Shenzhen, we offer fast turnaround, strict quality control, and scalable production volumes.

Contact Susan Leo today to discuss your MIM project:

Email: [email protected]

Let’s engineer precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.