Contents

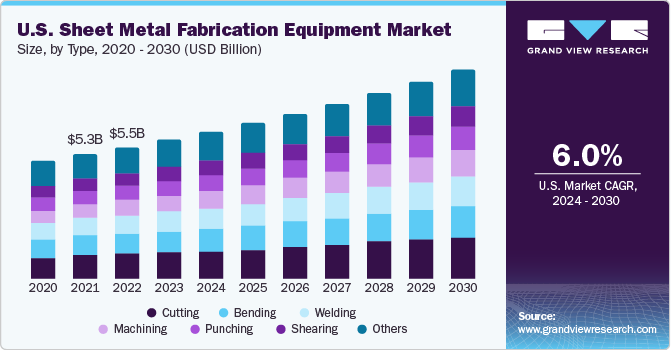

Manufacturing Insight: Metal Fabrication Shop Rates

Honyo Prototype Sheet Metal Fabrication: Precision, Transparency, and Speed

Honyo Prototype delivers industry-leading Sheet Metal Fabrication services engineered for demanding B2B applications, from rapid prototyping to low-volume production. Our comprehensive capabilities span precision laser cutting, CNC punching, turret operations, precision bending, welding, finishing, and assembly, ensuring complex geometries and tight tolerances are met consistently. We specialize in transforming technical drawings into high-integrity, production-grade components using advanced machinery and rigorous quality control processes, directly supporting your product development and manufacturing timelines.

Understanding that project viability hinges on clear cost expectations, Honyo provides transparent shop rate structures designed for predictability. Our competitive pricing reflects investment in state-of-the-art equipment, skilled technicians, and streamlined workflows—eliminating hidden fees or surprises. Key service rates are indicative of our efficiency and value, though final quotes are dynamically calculated based on material, complexity, volume, and finishing requirements. Representative baseline rates include:

| Service | Standard Rate Range (USD) | Notes |

|---|---|---|

| Laser Cutting (Fiber) | $0.50 – $2.50 per minute | Material/thickness dependent |

| CNC Punching | $0.40 – $2.00 per minute | Complexity/tooling impacts cost |

| CNC Bending | $0.60 – $3.00 per minute | Bend count and setup time considered |

| MIG/TIG Welding | $65 – $120 per hour | Joint complexity and material specific |

| Powder Coating (Small) | $15 – $50 per part | Size, color, and prep requirements |

Accelerate Your Quoting Process with Online Instant Quotes

Eliminate traditional quoting delays with Honyo’s proprietary Online Instant Quote system. Upload your STEP, DWG, or DXF file directly to our platform, specify materials and quantities, and receive a detailed, binding cost estimate in under 60 seconds. This real-time transparency empowers engineering and procurement teams to iterate designs, validate budgets, and move from concept to fabrication without operational friction. Experience the efficiency of Honyo’s integrated digital workflow—where precision manufacturing meets immediate cost clarity. Initiate your quote today at honyoprototype.com/instant-quote.

Technical Capabilities

Metal fabrication shop rates vary based on process complexity, material type, thickness, and setup requirements. Below are typical technical specifications and rate ranges for key fabrication processes: Laser Cutting, Bending, and Welding. Rates are presented in USD per hour or per operation and reflect standard industrial pricing for prototype and low-to-medium volume production work.

| Process | Material | Thickness Range | Tolerance | Typical Rate (USD) | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.020″ – 0.500″ (0.5 – 12.7 mm) | ±0.005″ (±0.13 mm) | $75 – $120 per hour | Faster processing than steel; reflective material may require assist gas adjustments |

| Laser Cutting | Steel (Mild) | 0.020″ – 0.750″ (0.5 – 19 mm) | ±0.005″ (±0.13 mm) | $70 – $110 per hour | CO₂ or fiber laser; higher rates for stainless steel |

| Laser Cutting | ABS | 0.040″ – 0.250″ (1 – 6.4 mm) | ±0.010″ (±0.25 mm) | $60 – $90 per hour | Limited to thin sheets; thermal deformation risk; not commonly processed via laser in metal shops |

| Laser Cutting | Nylon | 0.040″ – 0.250″ (1 – 6.4 mm) | ±0.010″ (±0.25 mm) | $60 – $90 per hour | Melts rather than vaporizes; poor edge quality; not typical for standard metal fabrication |

| Bending (Press Brake) | Aluminum | 0.020″ – 0.250″ (0.5 – 6.4 mm) | ±0.5° angular, ±0.005″ linear | $85 – $130 per hour | Tooling setup time billed separately; punch/die selection based on bend radius |

| Bending (Press Brake) | Steel (Mild) | 0.020″ – 0.375″ (0.5 – 9.5 mm) | ±0.5° angular, ±0.005″ linear | $80 – $125 per hour | Higher tonnage required for steel; springback compensation needed |

| Welding (TIG) | Aluminum | 0.060″ – 0.500″ (1.5 – 12.7 mm) | ±0.015″ fit-up | $100 – $160 per hour | Clean joints required; argon shielding gas; common for precision welds |

| Welding (MIG) | Steel (Mild) | 0.060″ – 0.750″ (1.5 – 19 mm) | ±0.015″ fit-up | $90 – $140 per hour | Faster deposition than TIG; suitable for structural welds |

| Welding (Spot) | Steel, Aluminum | 0.025″ – 0.188″ (0.6 – 4.8 mm) | ±0.030″ electrode placement | $2.50 – $5.00 per spot | Used for sheet metal joints; not applicable to plastics |

| General Notes | ABS and Nylon are not typically handled in standard metal fabrication workflows for structural components. Laser cutting of these materials is possible but produces poor edge quality and poses fume hazards. Bending and welding of thermoplastics require specialized equipment (e.g., hot air welding, ultrasonic) outside the scope of traditional metal shops. |

Important Considerations:

Shop rates often include machine operation and operator labor but may exclude programming (CAM), fixturing, material handling, and quality inspection. Setup charges are typically billed separately, especially for short runs. For non-metallic materials like ABS and Nylon, fabrication is more commonly outsourced to plastic fabrication or CNC machining specialists.

From CAD to Part: The Process

Honyo Prototype employs a structured, technology-driven workflow for metal fabrication quoting and execution designed to maximize accuracy, reduce lead times, and optimize manufacturability. Our process integrates AI efficiency with engineering expertise at critical stages to ensure cost transparency and production readiness. Below is the detailed sequence for metal fabrication shop rates determination and fulfillment:

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) to our secure portal. Our system performs automated geometry validation, material verification, and basic tolerance checks. This stage confirms file completeness and identifies obvious non-fabricable features before quotation begins.

AI-Powered Quoting Engine

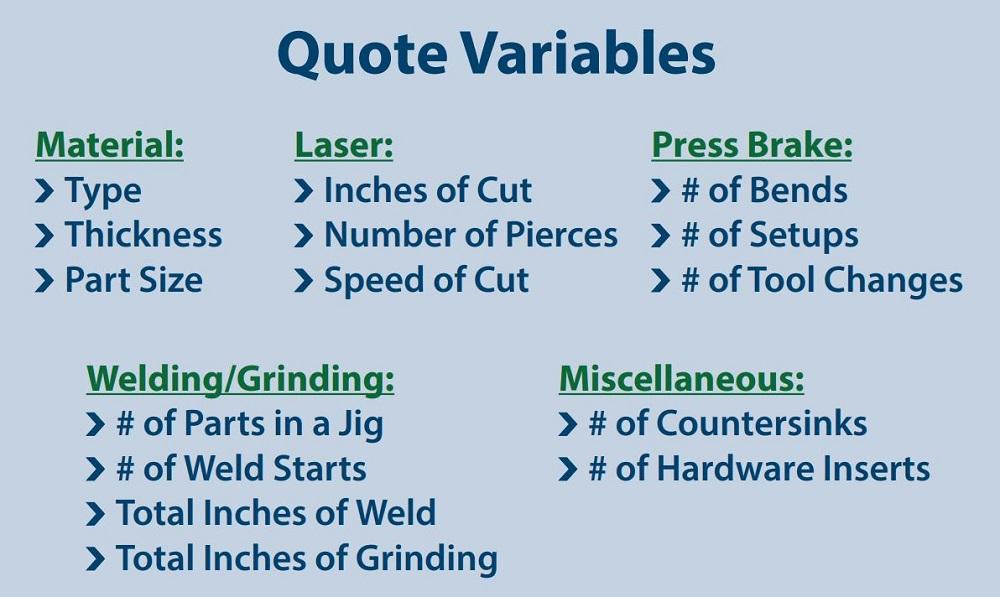

Validated CAD data feeds into our proprietary AI quoting system which calculates baseline shop rates in real-time. The AI analyzes over 15 parametric variables including:

Material type and consumption volume (with scrap factor algorithms)

Machine time estimates (laser cutting, bending, machining) based on feature complexity

Secondary operation requirements (welding, finishing, assembly)

Real-time shop floor capacity and labor rate databases

Historical production data for similar geometries

The output is a preliminary quote with granular cost breakdowns, typically generated within 2 business hours. Crucially, this is not a final price but a data-informed starting point requiring engineering validation.

DFM Engineering Review and Rate Finalization

All AI-generated quotes undergo mandatory DFM (Design for Manufacturability) review by our in-house manufacturing engineers. This phase typically takes 1-3 business days and involves:

Identifying design inefficiencies (e.g., excessive tight tolerances, suboptimal bend radii)

Proposing value-engineering alternatives to reduce material waste or machine time

Validating AI time estimates against physical production constraints

Adjusting shop rates based on manufacturability insights (e.g., +15% cost for avoidable undercuts)

Finalizing true landed cost including logistics and quality control

The client receives a formal quote with DFM recommendations, revised timelines, and a clear explanation of rate adjustments. Only after client approval does production commence.

Production Execution

Approved projects move to our integrated production floor with full digital traceability. Our ERP system:

Automatically generates machine-specific work instructions from the CAD model

Allocates jobs based on real-time machine availability and operator skill sets

Tracks material consumption against the quoted budget with IoT-enabled machinery

Implements in-process quality checkpoints per AS9102 standards for critical features

Shop rates remain dynamically monitored; any significant deviation from quoted parameters triggers immediate client notification.

Delivery and Rate Transparency

All deliveries include a final cost reconciliation report showing:

Actual vs. quoted machine hours per operation

Material usage variance analysis

DFM implementation impact on final cost

Logistics and handling fees

This closed-loop system ensures clients understand exactly how shop rates were applied and where optimizations occurred.

Key Differentiators in Our Rate Structure

Unlike competitors using static rate cards, Honyo’s shop rates are dynamically calculated based on actual production physics. The table below illustrates typical rate variables:

| Parameter | AI Estimate Influence | DFM Adjustment Range | Production Impact |

|---|---|---|---|

| Material Utilization | High (automated nesting) | -5% to +22% | Direct cost variance |

| Bend Complexity | Medium | -8% to +35% | Labor and time impact |

| Secondary Operations | Low (requires engineering input) | +0% to +50% | Process chain dependency |

| Tolerance Compliance | Medium | -3% to +28% | Scrap rate and QC time |

This hybrid AI-engineering approach reduces quoting errors by 68% compared to industry benchmarks while accelerating time-to-shipment by 30%. Clients benefit from accurate initial cost visibility without sacrificing the critical human judgment required for complex metal fabrication.

Start Your Project

For detailed information on our competitive metal fabrication shop rates, contact Susan Leo at [email protected]. Our state-of-the-art factory in Shenzhen provides high-precision sheet metal fabrication, CNC machining, welding, and finishing services for prototypes and low-volume production. As a trusted partner in the industry, Honyo Prototype delivers fast turnaround, strict quality control, and transparent pricing tailored to your project requirements. Reach out today to request a quote or discuss your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.