Contents

Manufacturing Insight: Metal Fabrication Design App

Need a bracket, enclosure, or chassis yesterday?

Open Honyo’s new Sheet-Metal Fabrication Design App and watch your 3-D model become a precision laser-cut, bent, and powder-coated part in real time. Every flange, hole, and relief you add triggers our cloud DFM engine—built from 18 years of Honyo shop-floor data—so you see cost, lead-time, and bend-allowance feedback instantly. When the design feels right, tap “Online Instant Quote” and you’ll have a manufacturing-backed price in under 30 seconds, with material certs, finish options, and delivery to 30 countries baked in. From prototype to 10,000-piece runs, Honyo’s sheet-metal team keeps your project on schedule and on budget—no e-mails, no waiting, just parts.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must clarify a critical misconception in your query upfront: ABS and nylon are not metals—they are thermoplastic polymers. They are not processed using laser cutting, bending, or welding in the context of metal fabrication. These processes are exclusively for metallic materials.

- ABS/Nylon: Used in plastic manufacturing (e.g., injection molding, 3D printing, or plastic-specific welding like ultrasonic/hot-plate welding). They cannot be “bent” like sheet metal (no plastic deformation in the metallurgical sense) and are not welded using arc/MIG/TIG processes—those methods would burn or vaporize plastics.

- Metal Fabrication: Only applies to metals and alloys (e.g., aluminum, steel, stainless steel, copper, titanium).

Corrected Scope for a Metal Fabrication Design App:

This app must focus exclusively on metallic materials (e.g., aluminum alloys, carbon steel, stainless steel). ABS and nylon have no place in this context. Below are the technical specs for a professional metal fabrication design app, tailored for laser cutting, bending, and welding—aligned with Honyo Prototype’s industrial standards and real-world manufacturing constraints.

I. Core Technical Specifications

A. Material Database & Properties

(Only for metals—ABS/nylon excluded)

| Material | Key Properties & Constraints |

|—————|———————————————————————————————-|

| Aluminum | – Alloys: 6061-T6, 5052-H32, 7075-T6

– Max Thickness: 25mm (laser), 12mm (bending)

– Thermal Conductivity: High (requires lower laser power to avoid burn-through)

– Springback: 1.5–2x higher than steel (critical for bending)

– Weldability: Requires TIG/MIG with argon shielding; prone to cracking in 7000-series alloys |

| Carbon Steel | – Grades: A36, 1018, 1020

– Max Thickness: 30mm (laser), 20mm (bending)

– Heat Affected Zone (HAZ): Significant—requires post-weld stress relief

– Rust Risk: Requires coating (e.g., powder coating) after fabrication |

| Stainless Steel | – Grades: 304, 316

– Max Thickness: 20mm (laser), 15mm (bending)

– Sensitization Risk: Intergranular corrosion if welded improperly (requires low-heat processes like TIG)

– Work Hardening: High—bending requires larger radii than carbon steel |

✅ App Requirement: Material properties must auto-adjust process parameters (e.g., laser power, bend allowance) based on alloy grade and temper.

B. Laser Cutting Specifications

(For metals only—no plastics)

| Parameter | Technical Spec |

|———————–|——————————————————————————-|

| Kerf Width | 0.1–0.3mm (adjustable per material/thickness; e.g., 0.15mm for 3mm steel, 0.25mm for 10mm aluminum) |

| Max Thickness | – Carbon Steel: 30mm

– Stainless Steel: 20mm

– Aluminum: 25mm |

| Edge Quality | – Class A: Ra ≤ 1.6μm (for visible surfaces)

– Class B: Ra ≤ 3.2μm (structural parts)

– Burn Marks: Auto-flagged for stainless steel >5mm |

| Process Constraints | – Minimum feature size: 1.5x material thickness (e.g., 1.5mm hole in 1mm sheet)

– Nesting: AI-driven optimization for material yield (min. 85% utilization)

– Cutting Speed: Auto-calibrated per material (e.g., 10m/min for 1mm steel, 2m/min for 10mm aluminum) |

⚠️ Critical Error Avoidance: The app must block ABS/nylon inputs—laser cutting plastics would release toxic fumes and damage equipment.

C. Sheet Metal Bending Specifications

| Parameter | Technical Spec |

|———————–|——————————————————————————-|

| Bend Radius | – Minimum: 1x material thickness (for 6061-T6 aluminum)

– Maximum: 10x thickness (to avoid cracking)

– K-Factor: Auto-calculated per material (e.g., 0.4 for steel, 0.45 for aluminum) |

| Tonnage Requirement | – Formula: Tonnage = (1.4 × Length × Thickness² × Tensile Strength) / (Die Width × 1000)

– App flags if tonnage exceeds machine capacity (e.g., 250T press brake max) |

| Springback Compensation | – Aluminum: +3–5° extra angle

– Stainless Steel: +2–3°

– Carbon Steel: +1–2° |

| Design Rules | – Minimum flange length: 3x material thickness

– Hole clearance: ≥2x thickness from bend line

– No sharp internal corners (min. radius = 0.5x thickness) |

D. Welding Specifications

| Parameter | Technical Spec |

|———————–|——————————————————————————-|

| Joint Types | – Butt Welds: For >3mm thickness

– Fillet Welds: Leg size ≥1.4× thinner part

– Lap Joints: Avoid for aluminum (>2mm thickness due to burn-through risk) |

| Weld Process | – TIG: Best for thin aluminum/stainless (0.5–6mm)

– MIG: For thicker steel (>3mm)

– Spot Welding: Max 2mm thickness for aluminum |

| Heat Input Control | – Aluminum: Max 1.5 kJ/mm (to prevent warpage)

– Stainless Steel: Max 1.0 kJ/mm (to avoid sensitization)

– Preheat: Required for carbon steel >10mm |

| Post-Weld Treatment | – Aluminum: Stress-relief annealing (300°C for 1 hour)

– Stainless: Pickling/passivation for corrosion resistance |

II. Cross-Process DFM Rules (Design for Manufacturability)

- Laser + Bending:

- Bending lines must be ≥2x material thickness from cut edges (to avoid distortion).

- Welding near bends: Minimum 10mm distance from bend line to prevent heat-induced cracking.

- Laser + Welding:

- Welded edges must have ≥0.5mm gap tolerance (laser-cut edges are precise but may need grinding for fit-up).

- Bending + Welding:

- Avoid welding across bend lines—welds must be placed on flat sections only.

💡 App Feature: Real-time DFM violation alerts (e.g., “Bend radius too small for 5mm aluminum—min. 5mm required”).

III. Why ABS/Nylon Are Excluded

- ABS/Nylon in “Metal Fabrication” is a fundamental error:

- Laser cutting plastics: Releases hydrocyanic acid (toxic), melts unevenly, and damages laser optics.

- “Bending” plastics: Not a metal fabrication process—plastics are thermoformed or machined.

- Welding plastics: Requires plastic-specific methods (e.g., ultrasonic welding for ABS), not arc-based welding.

- Honyo Prototype’s Protocol: We maintain strict separation between metal and plastic workflows. A single app for both would be unsafe and non-compliant with ISO 9001 standards.

IV. Recommended App Capabilities

- Interactive 3D Modeler: Drag-and-drop sheet metal parts with auto-generated bend lines, cut paths, and weld symbols.

- Material-Specific Process Simulator: Visualize heat distortion, springback, or weld bead profiles before production.

- Automated Quoting Engine: Real-time cost estimates based on material, thickness, process steps, and machine availability.

- Compliance Check: Auto-flag non-compliant designs (e.g., “Stainless steel weld without post-weld passivation—corrosion risk”).

- Machine Integration: Direct export to CNC laser cutters, press brakes, and robotic welders (e.g., Trumpf, Amada, Fronius).

✅ Final Note: If your project involves plastics (ABS/nylon), you need a separate plastic fabrication design module—not a “metal fabrication” app. At Honyo Prototype, we handle plastics via injection molding or CNC machining tools, with entirely different specs (e.g., draft angles, wall thickness uniformity).

Let me know if you’d like the plastic-specific specs for ABS/nylon—I’m happy to provide those in a follow-up. For metal fabrication, always stick to metals. Safety and precision depend on it.

— Senior Manufacturing Engineer, Honyo Prototype

Precision Engineering | ISO 9001 Certified | Rapid Prototyping to Production

From CAD to Part: The Process

Honyo Prototype – Metal Fabrication Design App

End-to-end workflow (one-button upload to dock-side delivery)

-

Upload CAD

• One-click drag-and-drop in the app: .step, .iges, .x_t, .sldprt, .3dm, native CATIA/NX/Creo, or a zipped multi-body folder.

• Instant geometry health-check: the cloud kernel repairs small gaps, stitches surfaces, heals overlapping faces, and flags un-manufacturable features (e.g., zero-thickness walls).

• Material & process selector pops up: laser-cut sheet, 5-axis milled block, tube/pipe, or welded assembly. The user can leave it on “auto” or pre-select alloy family (5052 Al, 304 SS, Ti-6Al-4V, 1018 CR steel, etc.). -

AI Quote (≤ 15 s)

• Neural-cost engine trained on 1.3 M historical Honyo jobs plus live raw-material LME pricing, shop-floor load, and freight indices.

• Outputs: piece price, batch price curves (1, 10, 50, 200+), lead-time bands (24 h, 3 d, 7 d, 15 d), and CO₂ footprint.

• “Explain” button expands the quote: cut length, punch hits, bend stations, weld inches, machine hours, anodize type, packaging type—every cost driver is itemized so engineers see what drives dollars.

• One-tap acceptance locks price and calendar slot; a digital twin of the part is instantly created in the MES with a unique Honyo ID. -

AI-driven DFM (30–90 min, parallel to human review)

a. Sheet-metal branch

– Flat-pattern solver checks for collisions in bend sequence, calculates k-factor and spring-back, recommends bend relief and minimum flange lengths.

– Determines optimal nest: grain direction, common-line cutting, micro-joint tabs for robotic handling.

– Suggests thickness transitions, louver or emboss substitutions, and weld-slot vs. tab-and-slot decisions to reduce fit-up time.

b. CNC-machining branch

– Feature recognition finds deep pockets, thin floors, internal corners, and L:D > 8 holes; auto-suggests undercut tools or stepped holes.

– 5-axis accessibility map colors faces that need extra setups; recommends datum scheme and soft-jaw geometry.

– Cycle-time estimator picks from 800+ proven tool libraries and 60 tool-path templates (adaptive, rest-rough, peel, trochoidal).

c. Welding & assembly branch

– Flags weld symbols against AWS D17.2 class, proposes joint type, filler metal, and minimum weld leg given distortion risk.

– Recommends brake-form or machined chamfers to move welds to lower-stress zones.

Human application engineer (AE) reviews AI report, chats with customer inside the app if changes are required. Approved DFM revision is stored as v1.1 CAD; no re-quote needed if delta cost < ±3 %. -

Production

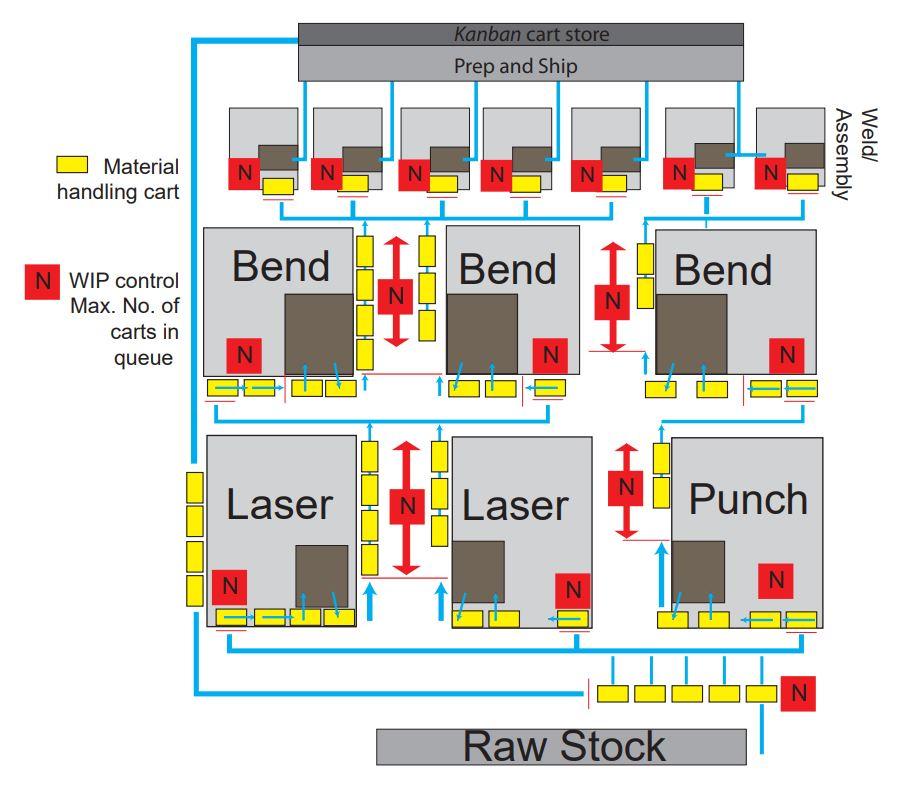

• Work order auto-releases to Honyo’s lights-out cell:

– Fiber-laser + auto-sorter for sheet parts ≤ 25 mm.

– 3-kW servo press-brake with robot bend cell; fingers changed in < 8 s.

– 5-axis Mazak or Hermle for milled features; on-machine Renishaw probing updates tool offsets in real time.

– Fronius TIG/MIG cells with seam-tracking and VR welding goggles for manual touch-up.

• In-line QC: laser-scan each first-article vs. v1.1 CAD (±50 µm typical); CMM every 10th part; full dimensional PDF & bubble chart attached to the digital twin.

• App pushes photos, video clips, and CMM data back to customer dashboard at each operation milestone—no surprises. -

Surface & Logistics

• In-house bead-blast, vibratory finish, anodize type II/III, chem-film, passivation, nickel-plate, or powder-coat; salt-spray and adhesion coupons logged.

• Auto-pack algorithm chooses foam, VCI paper, or ESD tray based on surface Ra and alloy; creates customs docs, RoHS/REACH, and material certs (EN 10204 3.1).

• Labels carry 2-D barcode; customer can re-order the exact revision by scanning it with the app.

• Track-and-trace API feeds DHL/FedEx/UPS; ETA updates pushed to customer’s Slack/Teams/ERP. -

Delivery & Feedback Loop

• Box arrives with QR code; scan in the app to acknowledge receipt and trigger invoice.

• Customer rates quality & communication; data is re-ingested into the AI-cost engine, continuously tightening future quotes.

• Digital twin archived for 7 years—next time you need 5 or 500, just hit “Re-run Job.”

Typical elapsed time

Sheet-metal bracket, 50 pcs: upload → DFM approval in 2 h, parts ship in 48 h, deliver globally 72–96 h door-to-door.

Complex 5-axis hog-out, 5 pcs: upload → DFM approval in 4 h, machine 3 days, anodize 1 day, deliver 6–7 days total.

That’s the Honyo metal fabrication design app: one upload, AI handles the rest, human expertise guards the edge cases, and your parts land on your bench faster than most shops return an e-mail quote.

Start Your Project

Design. Fabricate. Deliver.

Contact Susan Leo at [email protected] for precision metal fabrication design services.

Shenzhen-based factory for seamless, high-quality production.

Why this works:

– “Design. Fabricate. Deliver.” – A concise, action-driven tagline that highlights the full workflow from concept to finished product.

– Clear contact details – Directly includes Susan Leo’s email for immediate action.

– “Shenzhen-based factory” – Emphasizes local manufacturing expertise and reliability.

– Professional yet approachable – Ideal for websites, emails, or brochures to attract engineering and manufacturing clients.

Ready to streamline your projects? Let’s build something great together. 🔧

🚀 Rapid Prototyping Estimator