Introduction: Navigating the Global Market for metal fabrication china

Navigating the global market for metal fabrication in China presents a unique set of challenges for international B2B buyers. With a plethora of manufacturers offering diverse services, sourcing high-quality metal parts that meet specific project requirements can be daunting. This comprehensive guide aims to demystify the intricacies of metal fabrication in China, covering essential aspects such as types of fabrication processes, applications across various industries, effective supplier vetting strategies, and a detailed analysis of cost considerations.

International buyers from Africa, South America, the Middle East, and Europe—particularly those in Germany and Brazil—will find actionable insights throughout this guide. Whether you are looking for custom sheet metal components for aerospace applications or durable enclosures for construction projects, this resource empowers you to make informed purchasing decisions. By understanding the nuances of the fabrication process and leveraging best practices for supplier engagement, you can enhance your procurement strategies and ensure that you receive high-quality products tailored to your specifications.

The information provided in this guide is designed to streamline your sourcing efforts and optimize your supply chain. From evaluating manufacturing capabilities to understanding lead times and logistics, you will gain the knowledge necessary to navigate the competitive landscape of metal fabrication in China effectively.

Understanding metal fabrication china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Sheet Metal Fabrication | Tailored solutions with high precision; uses various materials. | Aerospace, Automotive, Construction | Pros: Customization, precision; Cons: Longer lead times for unique designs. |

| CNC Metal Fabrication | Automated processes ensuring high accuracy and repeatability. | Electronics, Machinery, Industrial Equipment | Pros: Consistency, efficiency; Cons: Initial setup costs can be high. |

| Laser Cutting | High-speed cutting with minimal material waste and clean edges. | Signage, Decorative Items, Prototyping | Pros: Speed, precision; Cons: Limited thickness capacity for some materials. |

| Welding Services | Variety of welding techniques (TIG, MIG, robotic) for strong joints. | Structural Fabrication, Automotive Parts | Pros: Strong, durable connections; Cons: May require post-weld finishing. |

| Stamping | Mass production of parts through high-speed presses. | Automotive Components, Appliances | Pros: Cost-effective for large volumes; Cons: Limited design flexibility. |

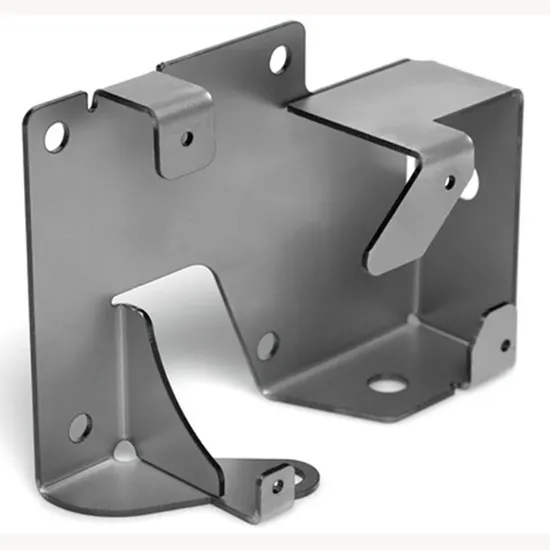

What are the Characteristics of Custom Sheet Metal Fabrication?

Custom sheet metal fabrication is characterized by its ability to produce tailored solutions that meet specific design requirements. This method allows for the use of a variety of materials, including stainless steel, aluminum, and carbon steel, which can be manipulated into complex shapes. B2B buyers should consider the precision levels offered, often reaching tolerances of ±0.05mm. While the customization aspect is a significant advantage, buyers should be aware that unique designs may lead to longer lead times compared to standard products.

How Does CNC Metal Fabrication Stand Out?

CNC (Computer Numerical Control) metal fabrication employs automated machinery to ensure high accuracy and repeatability in manufacturing processes. This technology is particularly beneficial for producing intricate parts used in electronics and machinery. Buyers should consider the efficiency gains and consistency in quality that CNC offers, although initial setup costs can be higher than traditional methods. This method is ideal for businesses seeking to scale production without compromising on quality.

What are the Advantages of Laser Cutting?

Laser cutting is recognized for its speed and precision, making it an excellent choice for applications requiring clean edges and minimal waste. This method is especially suitable for producing signage, decorative items, and prototypes. B2B buyers should appreciate the rapid turnaround times associated with laser cutting; however, it is essential to note that there are limitations regarding the thickness of materials that can be processed. Understanding these constraints can help buyers align their projects with the right fabrication technique.

What Types of Welding Services are Available?

Welding services encompass a range of techniques, including TIG, MIG, and robotic welding, which are employed to create strong joints in metal components. This service is crucial for structural fabrication and automotive parts, where durability is paramount. Buyers should evaluate the strength and quality of the welds produced, keeping in mind that some welding processes may require additional finishing. The choice of welding technique can significantly impact the final product’s performance and longevity.

How Does Stamping Fit into Metal Fabrication?

Stamping is a high-speed manufacturing process used to produce large volumes of parts, making it cost-effective for industries like automotive and appliances. This method involves pressing metal sheets into specific shapes, allowing for rapid production rates. While stamping is advantageous for mass production, it may limit design flexibility. B2B buyers should weigh the benefits of reduced costs against the potential constraints in design when considering stamping for their projects.

Key Industrial Applications of metal fabrication china

| Industry/Sector | Specific Application of Metal Fabrication China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom aluminum and steel parts for aircraft | High precision and lightweight components improve fuel efficiency and performance. | Ensure compliance with aviation standards and certifications. |

| Automotive | Manufacturing of body panels and structural components | Cost-effective production of high-quality parts enhances vehicle safety and aesthetics. | Look for suppliers with advanced welding and stamping capabilities. |

| Construction | Fabrication of structural steel and sheet metal for buildings | Durable and reliable materials ensure safety and longevity of structures. | Verify the supplier’s experience with local building codes and regulations. |

| Electronics | Production of enclosures for electrical devices | Customizable designs protect sensitive components and improve product lifespan. | Check for capabilities in rapid prototyping and surface finishing options. |

| Energy | Fabrication of components for renewable energy systems | Supports sustainability goals with lightweight and durable materials. | Assess the supplier’s expertise in specialized materials like stainless steel and aluminum. |

How is Metal Fabrication Used in Aerospace Applications?

In the aerospace sector, metal fabrication from China plays a crucial role in producing custom aluminum and steel parts for aircraft. These components must meet stringent safety and performance standards while being lightweight to enhance fuel efficiency. International buyers should prioritize suppliers that comply with aviation regulations and possess relevant certifications. The ability to provide high-precision parts with a maximum processing accuracy of ±0.05mm is essential for maintaining the integrity of aerospace applications.

What are the Benefits of Metal Fabrication in the Automotive Industry?

The automotive industry leverages metal fabrication services to manufacture body panels, fenders, and structural components. By sourcing these parts from China, businesses can benefit from cost-effective production without compromising quality. The high-quality fabrication techniques ensure that components are durable and enhance vehicle safety and aesthetics. Buyers should focus on suppliers with advanced welding and stamping capabilities to ensure the delivery of high-performance automotive parts.

Why is Metal Fabrication Important for Construction Projects?

In construction, metal fabrication is vital for producing structural steel and sheet metal components used in buildings and infrastructure. These materials offer durability and reliability, ensuring the safety and longevity of structures. For international buyers, it is essential to work with suppliers who understand local building codes and regulations. A supplier’s experience in providing custom solutions for various construction applications can significantly impact project success.

How Does Metal Fabrication Enhance Electronics Manufacturing?

Metal fabrication is integral to the electronics industry, particularly in producing enclosures for electrical devices. These enclosures protect sensitive components while allowing for customizable designs that can improve product lifespan. International buyers seeking metal fabrication services should evaluate suppliers based on their rapid prototyping capabilities and surface finishing options, ensuring that the final product meets both aesthetic and functional requirements.

What Role Does Metal Fabrication Play in Energy Solutions?

In the energy sector, particularly in renewable energy systems, metal fabrication contributes by providing lightweight and durable components that support sustainability goals. The use of high-quality materials, such as stainless steel and aluminum, enhances the efficiency and longevity of energy systems. Buyers should assess suppliers for their expertise in specialized materials and their ability to handle complex fabrication processes, ensuring that they meet the specific requirements of energy applications.

3 Common User Pain Points for ‘metal fabrication china’ & Their Solutions

Scenario 1: Navigating Quality Control in Metal Fabrication

The Problem: International buyers often face the challenge of ensuring consistent quality when sourcing metal fabrication from China. This concern is amplified by differences in manufacturing standards, language barriers, and varying quality control practices. For example, a company in Europe may receive parts that do not meet their specifications, resulting in production delays and increased costs. This issue can lead to mistrust between buyers and suppliers, ultimately jeopardizing long-term partnerships.

The Solution: To mitigate quality control issues, buyers should establish clear quality specifications and inspection criteria before placing orders. Communicating these standards effectively, possibly with the aid of a bilingual representative, can bridge any language gaps. It is also beneficial to request samples before committing to larger orders. Engaging third-party inspection services can further ensure that the products meet the required standards before they leave the factory. By building a relationship with suppliers that emphasizes transparency and consistent feedback, buyers can cultivate a reliable supply chain that prioritizes quality.

Scenario 2: Managing Lead Times and Delivery Reliability

The Problem: Delays in production and shipping can significantly disrupt supply chains, causing frustration for buyers who rely on timely delivery. A manufacturer in South America may experience extended lead times when working with a Chinese metal fabricator, affecting their ability to meet customer demands. Such unpredictability can lead to lost sales, increased shipping costs, and damage to the company’s reputation in the market.

The Solution: To better manage lead times, buyers should clearly communicate their project timelines and establish realistic delivery expectations with their suppliers. It is advisable to include buffer times in project planning to account for potential delays. Utilizing vendors that offer real-time tracking and transparency in production schedules can also help buyers stay informed about their orders’ status. Regular follow-ups during the manufacturing process can help identify any issues early, allowing for proactive solutions. Choosing suppliers with a proven track record of reliability and timely deliveries is essential for maintaining a smooth supply chain.

Scenario 3: Overcoming Language and Cultural Barriers

The Problem: Language and cultural differences can pose significant challenges in communication between international buyers and Chinese manufacturers. Misunderstandings regarding project specifications, timelines, and payment terms can lead to costly errors and delays. For instance, a buyer from Africa might struggle to articulate their needs effectively, resulting in incorrect product specifications that do not align with their requirements.

The Solution: To overcome these barriers, it is crucial to utilize clear and concise documentation, supplemented by visual aids such as diagrams and prototypes. Engaging a local intermediary or a sourcing agent who understands both the cultural context and the technical aspects of the project can facilitate smoother communication. Additionally, employing project management tools that allow for collaborative input and feedback can enhance clarity and foster a better understanding. Investing time in building a strong relationship with suppliers, based on mutual respect and understanding, can help bridge cultural gaps and lead to more successful collaborations.

Strategic Material Selection Guide for metal fabrication china

What Are the Key Properties of Common Materials Used in Metal Fabrication in China?

When considering metal fabrication in China, international B2B buyers must evaluate materials based on their specific applications and performance requirements. Here, we analyze four common materials: stainless steel, aluminum, carbon steel, and galvanized steel, focusing on their properties, advantages, disadvantages, and implications for various markets.

How Does Stainless Steel Perform in Metal Fabrication?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and durability, making it ideal for applications in harsh environments. It typically withstands temperatures up to 800°C (1472°F) and pressures associated with various industrial processes.

Pros: Its resistance to rust and staining makes it suitable for food processing, medical equipment, and marine applications. Additionally, stainless steel is easy to clean and maintain, enhancing its appeal for hygiene-sensitive industries.

Cons: The primary drawback is its higher cost compared to other metals, which can impact budget-sensitive projects. Moreover, stainless steel can be more challenging to machine and weld, requiring specialized equipment and skills.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, chemicals, and gases, making it versatile for diverse industrial applications.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM A240 or EN 10088, which dictate the quality and specifications of stainless steel products.

What Advantages Does Aluminum Offer in Metal Fabrication?

Aluminum is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It is suitable for applications requiring low weight and high strength, such as in the aerospace and automotive industries.

Pros: Its low density allows for easier handling and transportation, which can reduce shipping costs. Aluminum is also highly malleable, making it easy to fabricate into complex shapes.

Cons: Despite its advantages, aluminum has a lower strength compared to steel and can be more expensive depending on the alloy used. Additionally, it has a lower melting point, which may limit its use in high-temperature applications.

Impact on Application: Aluminum’s compatibility with various media, including water and some chemicals, makes it a popular choice for marine and automotive applications.

Considerations for International Buyers: Buyers should be aware of the relevant standards like ASTM B221 for aluminum extrusions and ensure that their suppliers can meet these specifications.

What Role Does Carbon Steel Play in Metal Fabrication?

Carbon steel is a widely used material due to its high strength and versatility. It typically has a temperature rating of up to 400°C (752°F) and is suitable for various structural applications.

Pros: It is cost-effective and offers excellent mechanical properties, making it suitable for construction, automotive, and manufacturing applications. Carbon steel can also be easily welded and machined.

Cons: Its primary limitation is susceptibility to corrosion, which can lead to rusting if not properly treated or coated. This necessitates additional surface treatments, which can increase manufacturing complexity.

Impact on Application: Carbon steel is compatible with a variety of media but is best suited for dry environments or where protective coatings are applied.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or EN 10025 is essential for ensuring quality and performance, particularly in construction and heavy machinery.

How Does Galvanized Steel Enhance Durability in Metal Fabrication?

Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. It is often used in outdoor applications where exposure to moisture is a concern.

Pros: The zinc coating provides a protective barrier against rust, significantly extending the lifespan of the material. It is also relatively cost-effective compared to stainless steel and can be easily fabricated.

Cons: While galvanized steel is durable, the zinc coating can be damaged through scratching or abrasion, which may expose the underlying steel to corrosion. Additionally, it may not be suitable for high-temperature applications due to the melting point of zinc.

Impact on Application: Galvanized steel is commonly used in construction, roofing, and automotive applications, where moisture exposure is prevalent.

Considerations for International Buyers: Buyers should ensure that their suppliers adhere to standards such as ASTM A123 for hot-dip galvanizing to guarantee quality and performance.

Summary of Material Selection for Metal Fabrication in China

| Material | Typical Use Case for metal fabrication china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost, machining complexity | High |

| Aluminum | Aerospace, automotive | Lightweight, easy to fabricate | Lower strength, cost variability | Medium |

| Carbon Steel | Construction, manufacturing | Cost-effective, strong | Susceptible to corrosion | Low |

| Galvanized Steel | Roofing, outdoor structures | Enhanced corrosion resistance | Zinc coating vulnerability | Medium |

This guide serves as a comprehensive resource for international B2B buyers to make informed decisions regarding material selection in metal fabrication projects in China.

In-depth Look: Manufacturing Processes and Quality Assurance for metal fabrication china

What Are the Main Stages of Manufacturing in Metal Fabrication in China?

In the metal fabrication industry, particularly in China, the manufacturing process is divided into several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets the required specifications and quality standards.

How Is Material Prepared for Metal Fabrication?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate materials based on the specifications of the project. Common materials include stainless steel, aluminum, carbon steel, and galvanized steel. Once selected, these materials undergo cutting, which can be performed using various techniques such as laser cutting, plasma cutting, or water jet cutting. Laser cutting is particularly favored for its precision and ability to handle intricate designs.

After cutting, the materials are typically deburred and cleaned to remove any sharp edges or contaminants. This ensures that the subsequent forming processes can be carried out smoothly and without defects.

What Techniques Are Used for Forming Metal Components?

The forming stage is where the prepared materials are shaped into the desired components. Key techniques in this phase include bending, stamping, and welding.

-

Bending: This process involves using CNC (Computer Numerical Control) machines to create precise angles and curves in the metal sheets. Advanced CNC bending machines can accommodate various thicknesses and types of metal.

-

Stamping: Stamping involves pressing metal sheets into molds to create specific shapes. This technique is efficient for producing large quantities of identical parts.

-

Welding: Various welding techniques, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, are employed to join metal parts together. Robotic welding systems are increasingly utilized for their speed and precision, particularly in high-volume production settings.

How Is Assembly Conducted in Metal Fabrication?

Once the individual components are formed, they are assembled into the final product. This stage may involve manual assembly or the use of automated systems. Quality assurance during assembly is crucial, as it ensures that all parts fit together correctly and function as intended. Additional processes such as riveting or inserting nuts and bolts may also be employed to secure components.

What Finishing Processes Are Common in Metal Fabrication?

The final stage of the manufacturing process is finishing, which enhances the appearance and durability of the metal products. Common finishing techniques include:

-

Surface Treatment: This includes processes like powder coating, anodizing, or galvanizing to protect the metal from corrosion and wear.

-

Deburring and Polishing: These processes are essential for achieving a smooth surface finish, which is particularly important for aesthetic components or those that require a high level of cleanliness.

-

Quality Control (QC): A thorough inspection is conducted at this stage to ensure that all products meet the specified quality standards before they are shipped to customers.

What Quality Assurance Practices Are Common in Metal Fabrication?

Quality assurance (QA) is a vital aspect of the metal fabrication process. Manufacturers in China often adhere to international standards, such as ISO 9001, to ensure consistent quality across all production stages. Additionally, industry-specific certifications like CE or API may be required depending on the end application.

What Are the Key QC Checkpoints in Metal Fabrication?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials upon delivery to ensure they meet the required specifications.

-

In-Process Quality Control (IPQC): This ongoing inspection occurs during the manufacturing stages, where critical dimensions and parameters are monitored to catch any deviations early.

-

Final Quality Control (FQC): Before shipping, a thorough inspection is conducted to verify that the finished products meet all specifications and quality standards.

What Testing Methods Are Commonly Used in Metal Fabrication?

Various testing methods are employed to ensure product integrity and performance. Common tests include:

-

Dimensional Inspection: Using calipers, micrometers, and other tools to measure the dimensions of the fabricated parts.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection are used to detect internal flaws without damaging the product.

-

Material Testing: This can include tensile testing, hardness testing, and corrosion resistance testing to ensure that the materials meet the required specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of a Chinese metal fabrication supplier is essential. Here are several strategies to ensure that suppliers meet your quality expectations:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into the quality control processes in place and overall operational efficiency.

-

Request Quality Control Reports: Suppliers should be able to provide documentation demonstrating their compliance with international standards and the results of any quality tests conducted.

-

Engage Third-Party Inspectors: Employing third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing metal fabrication services from China, B2B buyers should be aware of certain nuances related to quality control and certification:

-

Cultural Differences: Communication styles and business practices may vary, leading to potential misunderstandings. Establish clear expectations and maintain open lines of communication.

-

Local Standards vs. International Standards: Some suppliers may be certified to local standards, which may not align with international expectations. Ensure that the supplier’s certifications are recognized in your region.

-

Flexibility in Production: Chinese manufacturers are often capable of adapting to specific requirements, but this may require clear and detailed specifications from the buyer.

In summary, understanding the manufacturing processes and quality assurance practices in metal fabrication in China is crucial for international B2B buyers. By being informed about the stages of production, quality checkpoints, and verification methods, buyers can make more informed decisions and ensure high-quality outcomes for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal fabrication china’

Introduction

Navigating the complexities of sourcing metal fabrication services from China can be daunting for international B2B buyers. This guide provides a practical, step-by-step checklist to streamline your procurement process, ensuring that you select a reliable supplier who meets your specific needs. By following these steps, you can mitigate risks, enhance communication, and ultimately secure high-quality metal fabrication products.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, it’s essential to have a clear understanding of your technical requirements. This includes dimensions, tolerances, materials, and finishes required for your project.

– Considerations: Define the specific type of metal (e.g., stainless steel, aluminum), thickness, and any specialized processes (e.g., laser cutting, welding) that may be necessary.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong track record in metal fabrication. Utilize platforms like Alibaba, Global Sources, and industry-specific directories to compile a list of potential candidates.

– Key Factors: Look for suppliers with relevant experience in your industry, positive customer reviews, and a robust portfolio showcasing their capabilities.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications and quality management systems. Certifications such as ISO 9001 indicate adherence to international quality standards.

– What to Look For: Request copies of certifications, assess their manufacturing processes, and inquire about quality control measures to ensure compliance with your specifications.

Step 4: Request Samples and Prototypes

Before placing a large order, request samples or prototypes of your desired products. This step allows you to assess the quality of the materials and workmanship firsthand.

– Importance: Sampling helps identify any potential issues with design or manufacturing processes before committing to a full production run, saving time and costs.

Step 5: Assess Communication and Responsiveness

Effective communication is vital in the sourcing process. Evaluate how promptly and clearly potential suppliers respond to your inquiries.

– Tips: During initial communications, note their willingness to answer questions and provide detailed information. A responsive supplier is likely to be more reliable throughout the manufacturing process.

Step 6: Review Pricing and Payment Terms

Once you have shortlisted suppliers, request detailed quotations that outline costs, payment terms, and any additional fees (e.g., shipping, customs).

– Advice: Compare not just the prices but also the value offered in terms of quality, lead times, and after-sales support. Ensure the payment terms align with your financial policies.

Step 7: Conduct a Factory Visit or Audit

If feasible, visit the supplier’s facility to gain insights into their operational capabilities and quality control processes. If a visit is not possible, consider hiring a third-party auditor.

– Benefits: A factory visit allows you to assess the production environment, equipment, and workforce, providing confidence in the supplier’s ability to meet your needs.

By following this checklist, you can enhance your sourcing process for metal fabrication in China, ensuring you partner with a supplier that aligns with your business objectives and quality expectations.

Comprehensive Cost and Pricing Analysis for metal fabrication china Sourcing

What Are the Key Cost Components in Metal Fabrication Sourcing from China?

When sourcing metal fabrication services from China, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials like aluminum, stainless steel, and carbon steel vary in price based on market demand and quality. For example, high-grade stainless steel may incur higher costs but offers better durability and corrosion resistance.

-

Labor: Labor costs in China are relatively lower than in Western countries, which can lead to significant savings. However, labor expenses can fluctuate based on the complexity of the fabrication process and the skill level required.

-

Manufacturing Overhead: This includes costs associated with factory operation such as utilities, equipment maintenance, and administrative expenses. Advanced manufacturing facilities often have higher overhead due to investments in technology and quality control.

-

Tooling: Tooling costs can vary widely depending on the complexity of the parts being fabricated. Custom tooling may be necessary for specific designs, adding to the initial investment but potentially lowering costs for high-volume orders.

-

Quality Control (QC): Ensuring that products meet international quality standards can add to costs. Factories that implement rigorous QC processes may charge more but can provide greater assurance of product reliability.

-

Logistics: Shipping costs are a critical factor in the total cost of ownership. Incoterms (international commercial terms) such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence pricing and responsibilities for shipping costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on their business model, market conditions, and competition.

How Do Price Influencers Impact Metal Fabrication Costs?

Several factors can influence the final price of metal fabrication services:

-

Volume/MOQ: Higher order volumes typically lead to lower per-unit costs due to economies of scale. Manufacturers may set Minimum Order Quantities (MOQ) that can significantly impact pricing.

-

Specs/Customization: Custom designs or specific tolerances can increase costs. Standardized products often come with lower prices due to streamlined production processes.

-

Materials: The choice of material affects both the cost and the lead time. Specialty materials may require longer lead times or higher costs, impacting the overall budget.

-

Quality/Certifications: Meeting international quality standards (e.g., ISO certification) can increase costs, but it is essential for buyers in regulated industries to ensure compliance.

-

Supplier Factors: The reputation, experience, and reliability of the supplier can affect pricing. Established suppliers with a proven track record may charge more but offer better service and quality assurance.

-

Incoterms: Understanding shipping terms is crucial. Prices can vary based on who bears the shipping costs, insurance, and freight responsibilities, impacting the overall cost structure.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing?

International B2B buyers should consider several strategies to enhance cost-efficiency:

-

Negotiate Pricing: Engage in discussions with suppliers about pricing structures. Many manufacturers are open to negotiations, especially for larger orders.

-

Assess Total Cost of Ownership: Look beyond initial quotes. Consider logistics, potential tariffs, and quality assurance costs to evaluate the true cost of sourcing.

-

Understand Pricing Nuances: Recognize that prices may fluctuate based on seasonal demand, raw material prices, and global economic conditions. Being informed can help in timing your purchases effectively.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and priority service, especially during high-demand periods.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Obtaining quotes from multiple manufacturers allows for comparative analysis and better negotiation leverage.

Disclaimer on Pricing

Prices for metal fabrication services can vary widely based on the factors discussed above. The information provided is indicative and should be verified through direct communication with suppliers for accurate and current pricing.

Alternatives Analysis: Comparing metal fabrication china With Other Solutions

Exploring Alternatives to Metal Fabrication in China

In the realm of metal fabrication, international buyers often seek solutions that deliver high quality, cost-effectiveness, and efficient production times. While metal fabrication in China has gained popularity for its competitive advantages, several alternative solutions exist that may better suit specific business needs. This analysis compares “metal fabrication China” against other viable options, enabling B2B buyers to make informed decisions.

| Comparison Aspect | Metal Fabrication China | Local Fabrication Shops | Advanced Automated Fabrication |

|---|---|---|---|

| Performance | High precision (±0.05mm) with diverse materials | Varies by shop; often lower precision | Extremely high precision and efficiency with robotics |

| Cost | Generally low due to economies of scale | Higher due to smaller scale and local labor costs | Moderate to high; initial investment can be substantial |

| Ease of Implementation | Quick setup; often requires shipping logistics | Simple; local sourcing minimizes shipping | Complex; requires significant setup and training |

| Maintenance | Low; typically managed by the supplier | Varies; often requires ongoing local support | High; requires skilled technicians for upkeep |

| Best Use Case | Mass production of custom parts | Small batch production, localized needs | High-volume, complex components requiring precision |

What Are the Advantages and Disadvantages of Local Fabrication Shops?

Local fabrication shops offer the benefit of proximity, which can significantly reduce shipping times and costs. They often provide personalized service and flexibility, accommodating small batch sizes or custom orders more easily than larger manufacturers. However, performance can vary widely based on the capabilities of each shop, and they may not match the precision or production speed of Chinese manufacturers. Additionally, local shops typically face higher labor costs, which can inflate the final price of fabricated parts.

How Does Advanced Automated Fabrication Compare?

Advanced automated fabrication employs cutting-edge technology, such as robotics and AI-driven machinery, to create high-quality metal parts with exceptional precision. This method is particularly effective for high-volume production runs where uniformity and speed are critical. While it offers great efficiency and accuracy, the initial investment for such technology can be high, and the complexity of setup requires skilled technicians. Maintenance and operational costs can also add up, making this option less feasible for smaller operations or those with limited budgets.

Conclusion: How to Choose the Right Metal Fabrication Solution?

Selecting the right metal fabrication solution hinges on understanding your specific needs, including production volume, budget constraints, and the required precision of the components. Metal fabrication in China presents a compelling option for mass production with cost efficiency, while local fabrication shops may better serve businesses needing smaller, customized runs. Advanced automated fabrication stands out for high-volume, precision-driven projects but comes with higher initial costs and complexity. By evaluating these alternatives against your operational requirements, you can make a strategic decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for metal fabrication china

What Are the Key Technical Properties in Metal Fabrication from China?

Understanding the essential technical properties in metal fabrication is crucial for international B2B buyers seeking high-quality products. Here are some critical specifications:

1. Material Grade

Material grade specifies the composition and characteristics of the metal used in fabrication. Common materials include stainless steel (grades 304, 316), aluminum (grades 5052, 6061), and carbon steel. The material grade affects durability, corrosion resistance, and suitability for specific applications. Buyers must consider the material grade to ensure that the fabricated components meet performance requirements for their industry.

2. Tolerance

Tolerance refers to the allowable deviation from a specified measurement. It is critical in metal fabrication, as even small discrepancies can lead to assembly issues or affect the functionality of a product. A typical tolerance range for sheet metal parts might be ±0.05mm. Understanding tolerance levels helps buyers assess the precision of the fabrication process and its alignment with their project specifications.

3. Thickness

The thickness of metal sheets influences strength, weight, and application suitability. For instance, thinner sheets (0.5mm to 3mm) may be used for lightweight applications, while thicker sheets (up to 20mm) are suitable for heavy-duty components. Buyers should select the appropriate thickness based on structural requirements and weight considerations, particularly in industries like automotive and aerospace.

4. Surface Finish

Surface finish describes the texture and treatment applied to the metal surface, which can affect aesthetics and performance. Common finishes include powder coating, anodizing, and galvanizing. A good surface finish can enhance corrosion resistance and appearance, making it vital for buyers to specify their desired finish in RFQs (Requests for Quotations).

5. Mechanical Properties

Mechanical properties such as tensile strength, yield strength, and elongation determine how a material behaves under stress. These properties are essential for applications that involve bending, stretching, or other forms of mechanical loading. Buyers need to understand these properties to ensure that their components can withstand operational stresses without failure.

6. Welding Techniques

Different welding techniques (TIG, MIG, spot welding) can significantly impact the strength and quality of the final product. Each method has its advantages and is suited for specific applications. For instance, TIG welding is often preferred for its precision in thin materials, while MIG welding is suitable for thicker sections. Buyers should inquire about the welding techniques used to ensure they align with their quality standards.

What Are Common Trade Terms in Metal Fabrication?

Familiarity with trade terminology is vital for effective communication and negotiation in metal fabrication.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of metal fabrication, an OEM might contract a Chinese manufacturer to produce components that they will incorporate into their final products. Understanding OEM relationships can help buyers identify reliable partners for custom fabrication needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers to understand as it affects inventory management and cost efficiency. Knowing the MOQ helps buyers make informed decisions about their purchasing strategy and budget allocation.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. It typically includes detailed specifications, quantities, and deadlines. Submitting an RFQ allows buyers to compare different manufacturers’ offerings and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for buyers to understand their obligations and risks in the procurement process.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the finished product. This includes manufacturing time and shipping duration. Understanding lead times is critical for buyers to manage their project timelines and ensure timely delivery of components.

6. Tolerance Level

As previously mentioned, tolerance levels indicate the permissible limits of variation in a manufacturing process. This term is often used in conjunction with quality control measures. Buyers should specify tolerance levels in their orders to ensure that products meet their precise requirements.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of metal fabrication in China, ensuring that they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the metal fabrication china Sector

What Are the Current Market Dynamics and Key Trends in the Metal Fabrication Sector in China?

The metal fabrication sector in China continues to evolve, driven by several global and local factors. One of the primary drivers is the increasing demand for high-precision components across diverse industries, including automotive, aerospace, and electronics. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek reliable manufacturing partners, they are increasingly drawn to Chinese suppliers due to their advanced technology and cost-effective solutions.

Emerging technologies such as automation and artificial intelligence are streamlining production processes, enhancing efficiency, and reducing lead times. For instance, advanced laser cutting and CNC bending techniques are becoming standard, allowing manufacturers to produce complex shapes with tight tolerances. Additionally, the rise of Industry 4.0 has led to greater transparency in the supply chain, enabling buyers to monitor production in real-time and optimize their sourcing strategies.

Moreover, there is a growing trend towards customization. Chinese manufacturers are increasingly offering tailored solutions that cater to specific client needs, which is crucial for companies looking to differentiate themselves in competitive markets. As businesses worldwide pivot towards more agile supply chains, the flexibility and responsiveness of Chinese metal fabricators position them as key players in global sourcing strategies.

How Are Sustainability and Ethical Sourcing Shaping Metal Fabrication in China?

The significance of sustainability and ethical sourcing in the metal fabrication sector cannot be overstated. As environmental concerns gain traction globally, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes using recycled materials, minimizing waste, and adopting energy-efficient production processes.

Furthermore, certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for manufacturers seeking to attract international clients. Buyers are increasingly looking for suppliers who can provide evidence of their sustainability efforts, including the use of green materials and processes that reduce carbon footprints.

Ethical sourcing also plays a critical role in decision-making. Companies from regions like Europe and North America are particularly vigilant about ensuring that their supply chains adhere to ethical labor practices. This trend is prompting Chinese manufacturers to align with global standards, emphasizing fair labor practices and transparency in their operations.

Ultimately, as international buyers navigate their sourcing strategies, aligning with suppliers that prioritize sustainability and ethical practices will not only enhance brand reputation but also meet the growing demand for responsible sourcing among consumers.

What Is the Brief Evolution and History of Metal Fabrication in China?

The history of metal fabrication in China can be traced back to ancient times, where traditional craftsmanship laid the foundation for modern practices. However, the sector saw significant transformation in the late 20th century with the advent of globalization and China’s entry into the World Trade Organization in 2001. This period marked the shift from labor-intensive methods to advanced manufacturing technologies, significantly increasing production capacity and efficiency.

As Chinese manufacturers embraced modernization, they began investing heavily in state-of-the-art machinery and technology. This evolution enabled them to meet the rising global demand for high-quality metal components, positioning China as a leading player in the international metal fabrication market. Today, the sector is characterized by its blend of traditional craftsmanship and cutting-edge technology, offering a wide range of services that cater to diverse industry needs.

Frequently Asked Questions (FAQs) for B2B Buyers of metal fabrication china

-

How can I ensure quality when sourcing metal fabrication from China?

To ensure quality in your metal fabrication sourcing, start by vetting potential suppliers thoroughly. Look for manufacturers with ISO certifications, positive reviews from previous clients, and a proven track record in your specific industry. Request samples of their work and assess their manufacturing processes, machinery, and quality control measures. Additionally, consider visiting the facility or hiring a third-party inspection service to verify compliance with your standards. Clear communication regarding specifications and expectations is also crucial for maintaining quality. -

What are the common materials used in metal fabrication in China?

Chinese metal fabricators commonly work with a variety of materials, including stainless steel, aluminum, carbon steel, and galvanized steel. Each material offers distinct advantages: stainless steel is known for its corrosion resistance, aluminum is lightweight and easy to work with, while carbon steel provides strength and durability. When selecting a material, consider the specific requirements of your project, such as load-bearing capacity, resistance to environmental factors, and cost-effectiveness. -

What is the typical lead time for metal fabrication projects in China?

Lead times for metal fabrication projects in China can vary based on factors such as the complexity of the design, material availability, and production volume. Generally, prototyping can take around 7 days, while mass production typically ranges from 15 to 30 days. It’s essential to communicate your timeline requirements upfront and confirm the supplier’s ability to meet your deadlines. Additionally, factor in potential delays due to customs or shipping, especially for international orders. -

What is the minimum order quantity (MOQ) for metal fabrication in China?

Minimum order quantities (MOQs) for metal fabrication can differ significantly between suppliers and depend on the complexity of the parts being produced. Some manufacturers may have MOQs as low as 50 pieces, while others may require orders of several hundred or more. Always clarify the MOQ during your initial discussions and assess whether it aligns with your project needs. In some cases, you might negotiate lower MOQs for custom designs, particularly if you establish a long-term partnership with the supplier. -

What payment terms should I expect when working with Chinese metal fabricators?

Payment terms with Chinese metal fabricators can vary, but a common structure involves a 30% deposit upfront and the remaining 70% before shipment. Some suppliers may offer flexible terms based on your order size and relationship with them. It’s advisable to discuss payment options early in negotiations and consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. Always ensure that the payment terms are clearly outlined in the contract. -

How can I communicate my design specifications effectively to a Chinese manufacturer?

Effective communication of design specifications is crucial for successful metal fabrication. Start by providing detailed drawings and technical specifications using standard formats like CAD files. Include dimensions, tolerances, materials, and surface finishes. Supplement your designs with photographs or samples of similar products to clarify your expectations. It’s beneficial to have a bilingual representative or use translation services to avoid misunderstandings. Regular updates and feedback during the production process can help ensure alignment with your vision. -

What logistics considerations should I keep in mind when sourcing metal fabrication from China?

When sourcing metal fabrication from China, logistics is a critical factor. Consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Work with freight forwarders who have experience in international shipping to facilitate the process. Assess the supplier’s ability to handle packaging and labeling according to your destination country’s requirements. Additionally, factor in the lead time for shipping, which can vary based on your location and the shipping method chosen. -

How do I handle potential disputes with a Chinese metal fabrication supplier?

To handle disputes with a Chinese metal fabrication supplier, start by maintaining open lines of communication and addressing issues as they arise. Clearly document all communications and agreements to reference if needed. If a dispute escalates, consider involving a third-party mediator to facilitate resolution. It’s advisable to include dispute resolution clauses in your contract, specifying the governing law and procedures for resolving conflicts. Building a strong relationship with your supplier can also help prevent misunderstandings and foster cooperation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Metal Fabrication China Manufacturers & Suppliers List

1. Reddit – Aluminum Sheet Metal Parts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Aluminum sheet metal parts, dimensions 5″x3″x3″, designed for initial prototype, requiring small quantities (1-3 units), with a target price under $100.

2. TITAN Metal Fabricators – Reactive Metal Process Equipment

Domain: titanmf.com

Registered: 1999 (26 years)

Introduction: TITAN Metal Fabricators, Wuxi Co Ltd. specializes in the fabrication of Reactive Metal Process Industry Equipment, including:

1. **Titanium Products**:

– Titanium Heat Exchangers

– Titanium Columns

– Titanium Piping

– Titanium Pressure Vessels

– Titanium Reactors

2. **Zirconium Products**:

– Zirconium Heat Exchangers

– Zirconium Columns

– Zirconium Piping

– Zirconium P…

3. China Metalworking – Custom Metal Fabrication Services

Domain: chinametalworking.com

Registered: 2021 (4 years)

Introduction: Custom Metal Fabrication Services including: Sheet Metal Fabrication, Sheet Metal Bending, CNC Sheet Metal Punching, Sheet Metal Stamping (Progressive Die Stamping, Compound Die Stamping, Deep Drawing Stamping), Metal Welding, Laser Cutting, CNC Machining, Aluminum Extrusion, Surface Treatment, and Metal Heat Treatment. Specializes in custom parts for industries such as Aerospace, Automotive, Elec…

4. Yijin Hardware – High-Quality Sheet Metal Fabrication

Domain: yijinsolution.com

Registered: 2019 (6 years)

Introduction: Yijin Hardware: Specializes in high-quality sheet metal fabrication; services include laser cutting (up to 50 mm thickness), plasma cutting (up to 50 mm thickness), metal bending (up to 50 mm thickness), water jet cutting (up to 300 mm thickness), custom fabrication with welding, punching, rolling, stamping, powder coating/plating; handles materials from 0.5mm to 20mm like aluminum, stainless stee…

5. HSJ Fabrication – Custom Industrial Sheet Metal Solutions

Domain: hsjfabrication.com

Registered: 2019 (6 years)

Introduction: HSJ Fabrication offers a variety of custom industrial sheet metal fabrication services, including:

1. Laser Cutting Parts: Precision parts with tolerances of +/- 0.02mm-0.1mm, including laser-cut holes and edges.

2. Sheet Metal Bending Parts: Customized service with tight tolerances, including food-grade bending parts for household appliances.

3. Stamping Parts: Precision stamping with toleranc…

6. MaxTech – Custom Metal Fabrication Services

Domain: maxtech-china.com

Registered: 2015 (10 years)

Introduction: Metal Fabrication Service, Custom Metal Fabricator, Metal Fabricating Service, China Metal Fabrication Company. Services include: Steel Fabrication, Stainless Steel Fabrication, Aluminium Fabrication, Sheet Metal Fabrication, Structural Metal Fabrication, Metal Frame Manufacturing. Additional services: CNC Machining, EDM Machining, Heat Treatment (Hardening, Annealing, Normalizing, Stress Relievin…

7. RPProto – Custom Sheet Metal Fabrication

Domain: rpproto.com

Registered: 2021 (4 years)

Introduction: Sheet Metal Fabrication Service for custom sheet metal parts and prototypes, with production capabilities from 1 to 1000+ parts. Services include bending, punching, and cutting standard gauge metal. Common materials used are aluminum, stainless steel, and brass. The service offers lower initial investment in tooling and fast market entry, with prices over 30% lower than Europe and the US. Suitable…

Strategic Sourcing Conclusion and Outlook for metal fabrication china

In conclusion, engaging in strategic sourcing for metal fabrication in China presents a unique opportunity for international B2B buyers. By leveraging China’s advanced manufacturing capabilities, including precision processes like laser cutting and CNC bending, companies can obtain high-quality, custom metal parts tailored to their specific needs. The ability to access a diverse range of materials, quick turnaround times, and cost-effective solutions makes China a competitive player in the global market.

As businesses in Africa, South America, the Middle East, and Europe look to optimize their supply chains, sourcing from reputable Chinese manufacturers can lead to significant advantages, including enhanced production efficiency and reduced operational costs. Building strong partnerships with experienced fabricators will enable organizations to remain agile and responsive to market demands.

Looking ahead, the landscape of metal fabrication is poised for continued innovation, driven by technological advancements and a focus on sustainability. International buyers should take proactive steps to explore partnerships with leading manufacturers in China to harness these trends and position themselves for success in an increasingly competitive environment. Reach out today to discover how strategic sourcing can elevate your business operations.