Contents

Manufacturing Insight: Metal Fabrication Blueprints

Precision Metal Fabrication Begins with Your Blueprint

Translating complex metal fabrication blueprints into high-integrity production components demands advanced capabilities beyond conventional subtractive methods. At Honyo Prototype, we specialize in industrial-grade metal additive manufacturing, specifically leveraging Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) to transform intricate CAD data into fully functional, end-use parts with exceptional geometric freedom and material properties. Our process eliminates traditional tooling constraints, enabling the production of lightweight lattice structures, internal cooling channels, and consolidated assemblies directly from your digital blueprint—reducing lead times while maintaining strict adherence to AS9100 and ISO 9001 quality standards.

Honyo Prototype’s industrial 3D printing services utilize certified aerospace and medical-grade alloys—including Inconel 718, Ti-6Al-4V, and 17-4 PH stainless steel—to achieve mechanical properties matching or exceeding cast equivalents. Each build undergoes rigorous in-process monitoring and post-processing validation, ensuring dimensional accuracy to ±0.05 mm and surface finishes suitable for critical applications in aerospace, medical device, and energy sectors. Unlike legacy fabrication, our technology integrates seamlessly with your existing design workflow, providing actionable design-for-manufacturability feedback during the quotation phase to optimize part performance and cost efficiency.

Accelerate your prototyping and low-volume production cycles with our Online Instant Quote platform. Simply upload your STEP or IGES file, specify material and quantity requirements, and receive a detailed technical assessment with pricing and lead time within minutes—not days. This transparent, data-driven approach empowers engineering teams to iterate rapidly while maintaining full traceability from blueprint to certified component.

| Key Capability | Industrial 3D Printing Advantage |

|---|---|

| Geometric Complexity | Produce internal features and organic shapes impossible via CNC |

| Lead Time Reduction | Eliminate tooling; achieve first-article parts in 5–10 business days |

| Material Utilization | Near-net shape builds reduce waste by up to 90% vs. milling |

| Supply Chain Resilience | Consolidate multi-part assemblies into single printed components |

Elevate your metal fabrication outcomes by bridging the gap between blueprint intent and manufacturing reality. Honyo Prototype delivers the precision, speed, and technical partnership required for mission-critical metal components—starting with your next innovation.

Technical Capabilities

The term “metal fabrication blueprints” typically refers to engineering drawings used in traditional metalworking processes such as cutting, bending, and assembling sheet metal or structural components. However, the technologies referenced—SLA, SLS, MJF, and DMLS—are additive manufacturing (3D printing) methods, not conventional metal fabrication techniques. Among these, only DMLS is primarily used for metal parts; the others are more commonly associated with polymers or prototyping.

Below is a technical comparison of these additive manufacturing processes as they relate to material compatibility and application in prototyping or production, with emphasis on metals (Aluminum, Steel) and engineering plastics (ABS, Nylon) relevant to industrial manufacturing environments.

| Process | Full Name | Primary Materials | Compatible with Aluminum | Compatible with Steel | Compatible with ABS | Compatible with Nylon | Layer Resolution (Typical) | Build Volume (Typical Range) | Key Applications |

|---|---|---|---|---|---|---|---|---|---|

| SLA | Stereolithography | Photopolymer resins (e.g., standard, engineering, castable) | No | No | No | No | 25–100 µm | 150 x 150 x 200 mm to 1400 x 700 x 500 mm | High-detail prototypes, master patterns, visual models |

| SLS | Selective Laser Sintering | Nylon-based powders (e.g., PA11, PA12, glass-filled), TPU | No | No | No | Yes | 80–120 µm | 200 x 200 x 300 mm to 700 x 380 x 580 mm | Functional prototypes, end-use parts, complex geometries |

| MJF | Multi Jet Fusion | Nylon powders (PA11, PA12, black PA12, glass-filled) | No | No | No | Yes | 80–100 µm | 380 x 280 x 380 mm | Production-grade plastic parts, mechanical components, housings |

| DMLS | Direct Metal Laser Sintering | Metal alloys including Stainless Steel, Tool Steel, Aluminum (AlSi10Mg), Titanium, Inconel | Yes (AlSi10Mg) | Yes (316L, 17-4 PH, etc.) | No | No | 20–50 µm | 250 x 250 x 325 mm to 420 x 420 x 420 mm | Aerospace, medical, tooling, high-strength metal components |

Notes:

DMLS (Direct Metal Laser Sintering) is the only process listed that fabricates functional metal parts directly from metal powder, making it relevant for true metal component production. It supports aluminum alloys such as AlSi10Mg and various steel grades including stainless steel (316L, 17-4 PH) and tool steels.

SLA is a resin-based process and is not suitable for metal fabrication; it is often used for creating patterns or molds that may later be used in investment casting for metal parts.

SLS and MJF are polymer-based additive technologies ideal for functional prototyping and end-use parts in nylon materials. They support engineering-grade nylons (PA11, PA12) and composites but do not process metals or ABS thermoplastics directly. ABS-like properties can be mimicked using specific SLS nylons or through post-processing.

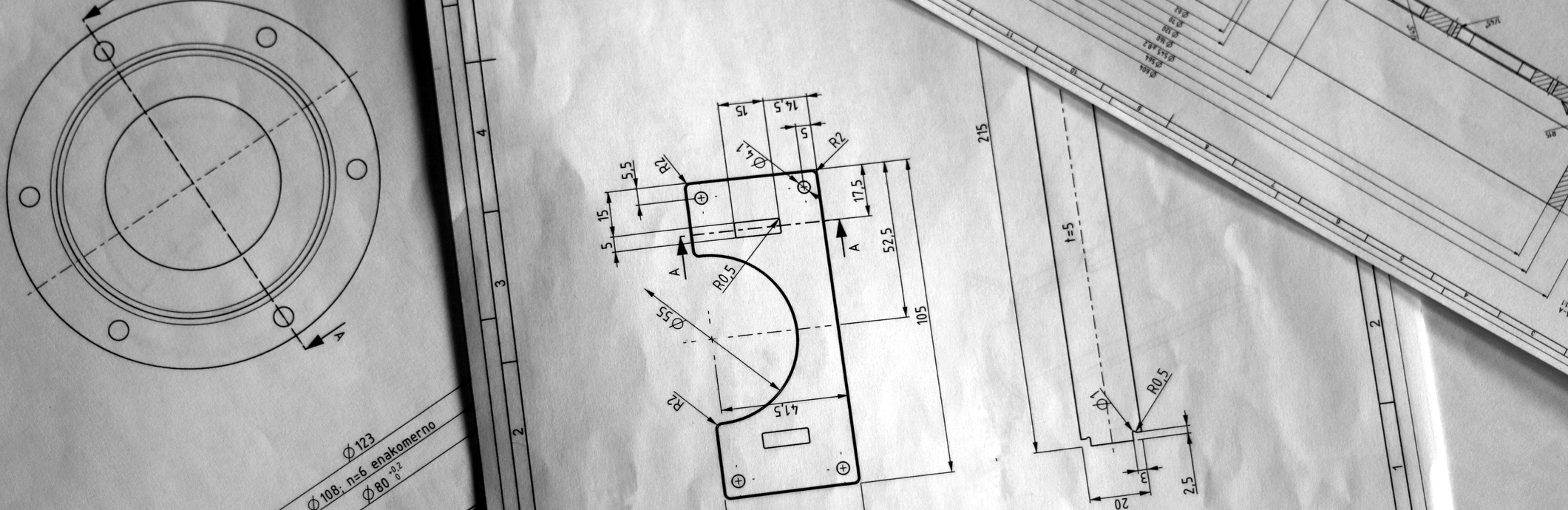

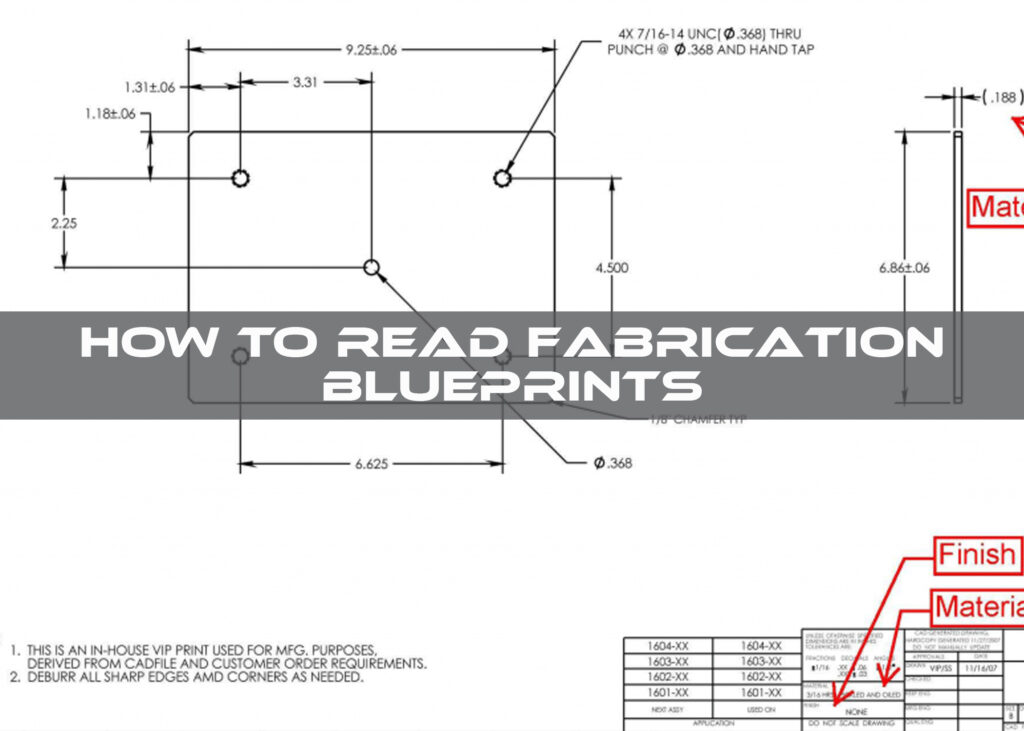

For actual metal fabrication blueprints—such as those used in CNC bending, laser cutting, or welding—dimensional tolerances, weld symbols, bend lines, and material callouts (e.g., 5052-H32 Aluminum, 304 Stainless Steel) are specified per ASME Y14.5 standards. These differ significantly from 3D printing build files, which rely on STL or 3MF formats rather than 2D technical drawings.

From CAD to Part: The Process

Honyo Prototype Metal Fabrication Blueprint Process

Our end-to-end metal fabrication workflow begins with secure client CAD submission and concludes with certified delivery, engineered for precision and efficiency. Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SOLIDWORKS, Fusion 360) via our encrypted customer portal. All data undergoes automated validation for file integrity and geometric completeness before entering the quoting phase.

AI-Powered Quoting System

Uploaded designs are processed through our proprietary AI quoting engine, which analyzes 3D geometry, material specifications, and geometric complexity against real-time machine capabilities, material costs, and shop floor utilization. The system generates a preliminary quote within 2 hours for standard parts, including detailed cost breakdowns for material, labor, finishing, and logistics. Critical parameters such as material grade, tolerances, and secondary operations are cross-referenced against our historical production database to ensure accuracy. Human engineering oversight validates all AI outputs, with complex geometries escalated to senior process engineers for manual review.

Engineer-Led DFM Analysis

Every design undergoes mandatory Design for Manufacturability (DFM) review by our in-house manufacturing engineers. This phase identifies cost drivers and potential production risks through systematic evaluation of key parameters:

| Parameter Category | Key Evaluation Criteria | Honyo Standard Thresholds |

|---|---|---|

| Geometric Complexity | Bend counts, hole density, feature accessibility | >5 bends or <2mm clearance triggers redesign recommendation |

| Tolerances | Critical dimension callouts per ISO 2768-mK | Tighter than ±0.1mm requires secondary machining assessment |

| Material Utilization | Nesting efficiency, kerf loss | <85% sheet utilization prompts alternative layout proposal |

| Secondary Operations | Welding, threading, surface treatment requirements | >3 secondary ops per part evaluated for process consolidation |

Engineers provide actionable feedback via annotated 3D markups and formal DFM reports within 24 hours, including cost-impact analysis for suggested modifications. Client approval of the finalized blueprint and DFM recommendations is required before production release.

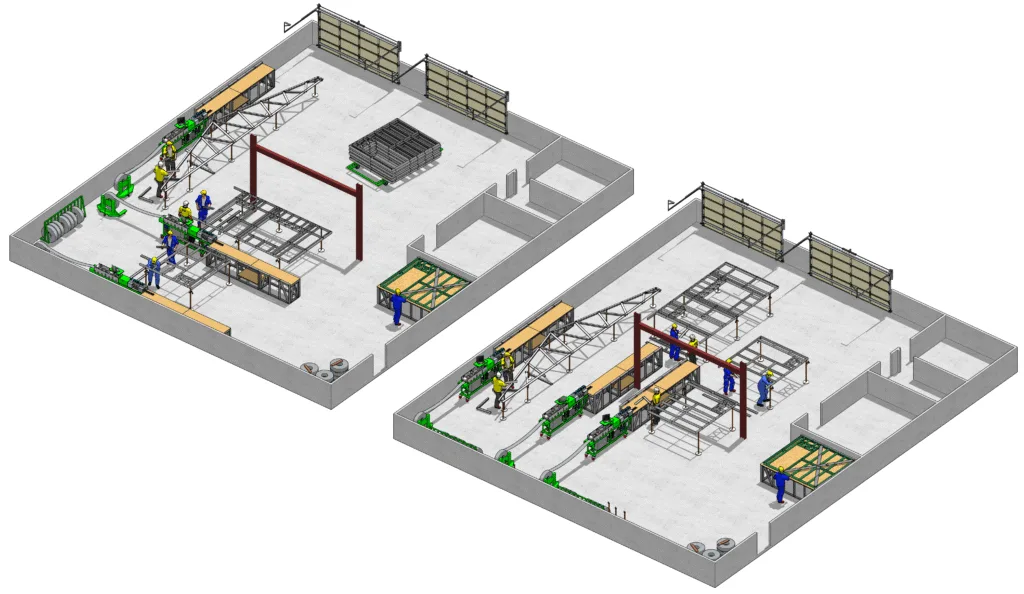

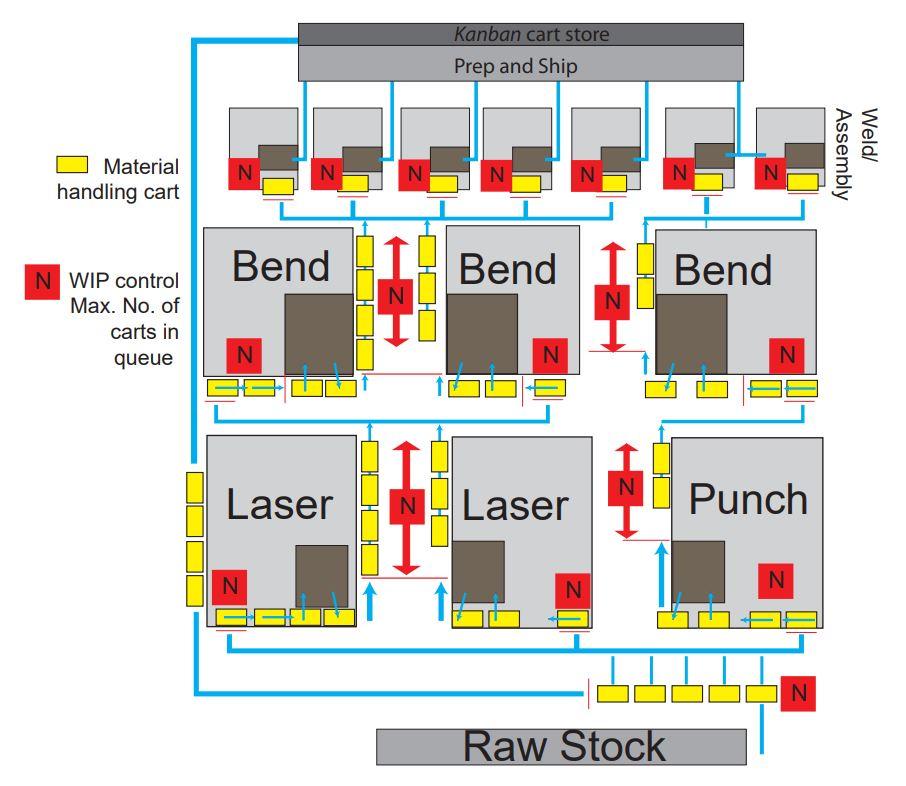

Precision Production Execution

Approved designs move to our integrated manufacturing floor, where digital work orders synchronize with CNC punch presses, laser cutters (up to 15kW fiber), press brakes (up to 300-ton capacity), and robotic welding cells. Each part receives a unique serialized QR code for full traceability, logging real-time data including material heat numbers, machine parameters, and operator certifications. In-process inspections at critical stages (post-cutting, post-bending) verify conformance to blueprint tolerances using calibrated CMMs and optical comparators. All non-conformances trigger automated engineering hold procedures with root-cause analysis.

Certified Delivery Protocol

Completed orders undergo final QA verification against the approved blueprint, including first-article inspection reports (FAIR) for new designs and batch certification for repeats. Parts are packaged per Mil-STD-2073 standards with anti-corrosion protection for metal components, accompanied by digital delivery documentation (material certs, inspection reports, packing lists) via client portal. Standard lead time from DFM approval to shipment is 5–7 business days for quantities under 500 units, with global logistics partners providing trackable delivery with carbon footprint reporting. This closed-loop process ensures 99.2% on-time delivery while reducing client rework costs by an average of 37% through proactive DFM intervention.

Start Your Project

For detailed metal fabrication blueprints and precision prototyping services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, rapid turnaround, and full compliance with technical specifications. Partner with Honyo Prototype for end-to-end support from design review to production-ready fabrication.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.