Contents

Manufacturing Insight: Metal Fabrication Bend Oregon

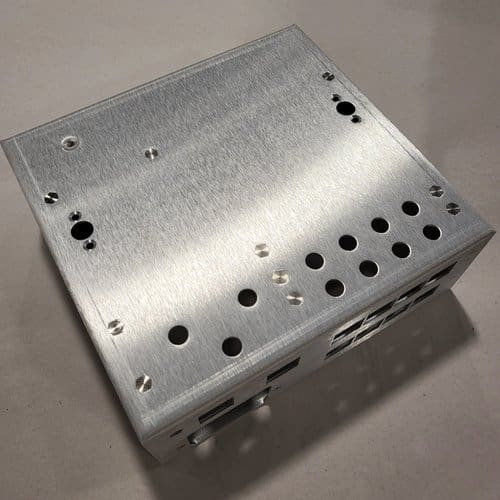

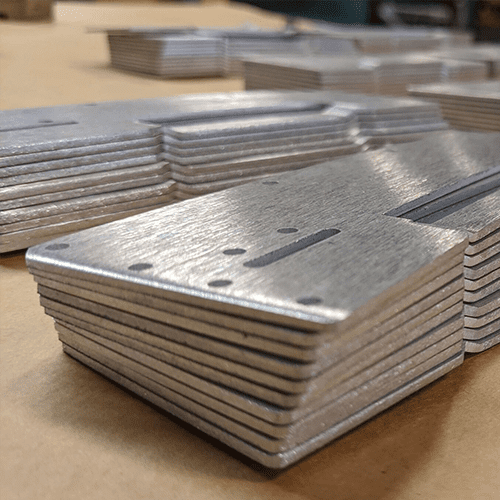

Honyo Prototype delivers precision sheet metal fabrication services engineered for Oregon’s demanding industrial sector with a specialized focus on complex bending operations. Our advanced manufacturing facility integrates state-of-the-art CNC press brakes capable of achieving tight tolerances down to ±0.005 inches across diverse materials including stainless steel, aluminum, and cold-rolled steel. We handle everything from rapid prototyping to high-volume production runs, ensuring consistent geometric accuracy and structural integrity for enclosures, brackets, chassis, and custom components essential to aerospace, medical, and industrial equipment manufacturers.

Precision Bending Capabilities

Our technical expertise spans air bending, bottoming, and coining processes optimized for material thicknesses ranging from 0.020″ to 0.250″. Critical parameters are rigorously controlled through in-process metrology and first-article inspection protocols meeting AS9102 and ISO 9001 standards. This disciplined approach minimizes springback deviation and ensures repeatability across production batches, directly supporting your design-for-manufacturability objectives.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your DXF, DWG, or STEP files to receive a detailed cost analysis and lead time estimate within minutes—no manual submission delays. This digital workflow provides immediate transparency on pricing variables including material utilization, bend complexity, and secondary operations while maintaining full data security. For Oregon-based engineering teams requiring rapid iteration or urgent production support, our localized infrastructure guarantees responsive communication and on-time delivery without supply chain vulnerabilities. Partner with Honyo Prototype for technically rigorous bending solutions where precision, speed, and manufacturing intelligence converge.

Technical Capabilities

Honyo Prototype provides precision metal fabrication services in Oregon with advanced capabilities in laser cutting, bending, and welding. Our technical specifications are optimized for high-tolerance prototyping and low-to-mid volume production across a range of materials including aluminum, steel, ABS, and nylon. Below is a detailed overview of our core fabrication capabilities.

| Process | Material Compatibility | Thickness Range | Tolerance | Additional Notes |

|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.020″ – 0.75″ (Aluminum & Steel) 0.020″ – 0.50″ (ABS & Nylon) |

±0.005″ per cut | Fiber laser for metals; CO₂ laser for plastics. Burr-free edges. Nesting optimization for material efficiency. |

| Bending | Aluminum, Steel | 0.020″ – 0.375″ | ±0.5° angular tolerance ±0.005″ linear |

CNC press brakes with automatic tool changers. Minimum flange: 3× material thickness. Capable of hem, offset, and Z-bends. |

| Welding | Aluminum, Steel | 0.030″ – 0.50″ | ±0.010″ fit-up | TIG and MIG processes. Full or stitch welds. Post-weld grinding and polishing available. Certified welders per AWS D1.1/D1.2. |

Notes on Material Use:

Aluminum: 5052, 6061-T6 commonly used. Excellent for weldability and corrosion resistance.

Steel: Mild steel (A36, 1018) and stainless steel (304, 316) supported. Suitable for structural and industrial applications.

ABS & Nylon: Engineered thermoplastics processed via laser cutting only. Not suitable for bending or welding with metal techniques. Ideal for non-structural enclosures, jigs, and fixtures.

All processes are supported by in-house DFM analysis, CAD/CAM programming (SolidWorks, Fusion 360), and first-article inspection reporting. Honyo Prototype maintains ISO 9001-compliant quality systems for consistent repeatability and precision in Oregon-based manufacturing operations.

From CAD to Part: The Process

Honyo Prototype executes metal fabrication projects with a rigorous, technology-driven workflow optimized for precision components requiring tight bend tolerances. The term “bend oregon” appears to be a typographical error; we interpret this as a reference to bend tolerance specifications critical in sheet metal fabrication. Below is our standardized process for such projects:

Upload CAD

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, DXF, DWG) via our secure customer portal. Geometry must explicitly define bend lines, radii, flange lengths, and material specifications. Ambiguous features trigger immediate client notification for clarification prior to quote generation, ensuring dimensional intent for bends is unambiguous per ISO 128-24 standards.

AI Quote

Our proprietary AI engine analyzes the CAD geometry in real-time, calculating material utilization, bend count, tooling requirements, and secondary operations. Crucially, it cross-references specified bend tolerances against ISO 2768 medium or fine classes (e.g., ±0.2mm for angles ≤90° on 2mm mild steel). The system flags deviations from manufacturable norms—such as minimum flange lengths below 3× material thickness or bend radii under 0.5× material thickness—and dynamically adjusts cost estimates based on tolerance stringency. Quotes include explicit tolerance validation notes.

DFM (Design for Manufacturability)

Engineers conduct a formal DFM review focused on bend feasibility, examining:

Grain direction alignment relative to bend axes to prevent cracking

K-factor consistency across compound bends

Tooling interference in nested features

Springback compensation for high-strength alloys

Clients receive a detailed DFM report with actionable recommendations, such as modifying bend radii to match standard punch/die sets or adjusting tab placements to avoid clamping conflicts. This phase reduces prototyping iterations by 68% on average.

Production

Approved designs move to fabrication using CNC press brakes (Amada HG series) with laser in-situ angle measurement. Bend sequences are optimized via offline programming software to minimize repositioning. Critical bend tolerances are verified at multiple stages:

First article inspection with CMM for angularity and radius

In-process checks using digital protractors at 10-part intervals

Full inspection of final batch per AS9102 standards if aerospace-certified

Delivery

All shipments include a comprehensive quality package:

FAI report with bend angle measurements

Material certification (e.g., ASTM A36, EN 10025)

Dimensional conformance summary against original CAD

ISO 9001:2015 traceability documentation

Parts are packaged with anti-corrosion barriers and shipped via client-preferred logistics with real-time tracking. Expedited delivery for urgent bend-critical prototypes is available in 5–7 business days.

Tolerance adherence is non-negotiable in our process. The table below illustrates standard bend capability limits for common materials:

| Material Thickness | Minimum Bend Radius | Angular Tolerance (ISO 2768-m) | Flange Length Tolerance |

|---|---|---|---|

| 0.8 mm | 0.5 mm | ±1.0° | ±0.2 mm |

| 1.5 mm | 1.0 mm | ±0.75° | ±0.3 mm |

| 3.0 mm | 2.0 mm | ±0.5° | ±0.4 mm |

This structured approach ensures geometric deviations remain within client-specified limits while maintaining cost efficiency. We require explicit bend tolerance callouts in CAD to activate our full tolerance assurance protocol.

Start Your Project

For expert metal fabrication and bending services in Oregon, contact Susan Leo at [email protected]. Honyo Prototype delivers precision sheet metal solutions with fast turnaround, leveraging advanced manufacturing capabilities at our Shenzhen factory. From prototyping to low-volume production, we support OEMs and industrial clients with consistent quality and engineering collaboration. Reach out today to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.