Introduction: Navigating the Global Market for metal fab parts

Navigating the complexities of sourcing metal fabrication parts can be a daunting challenge for international B2B buyers, especially when considering the diverse needs of industries across Africa, South America, the Middle East, and Europe. Understanding the intricacies of metal fab parts—from DOM tubing and bushing kits to specialized fasteners—requires not only knowledge of product specifications but also insight into regional suppliers and market trends. This guide aims to equip you with the essential tools and insights needed to make informed purchasing decisions.

Within these pages, we delve into various types of metal fabrication parts, their applications in different sectors, and the critical aspects of supplier vetting. We provide actionable advice on evaluating costs, quality standards, and delivery timelines, ensuring that you can optimize your procurement process. Whether you are looking to streamline your supply chain or enhance the performance of your projects, our comprehensive approach addresses the unique challenges faced by B2B buyers in diverse markets.

By leveraging this guide, you will gain a deeper understanding of the global metal fab parts market, allowing you to identify reliable suppliers and make strategic decisions that align with your business objectives. With a focus on quality, efficiency, and cost-effectiveness, this resource empowers you to navigate the complexities of sourcing metal fabrication parts with confidence.

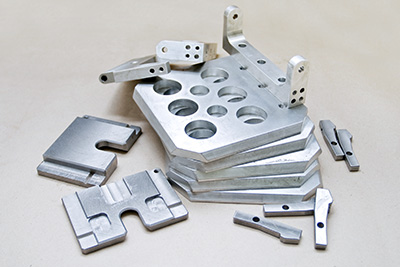

Understanding metal fab parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DOM Tubing | High strength, seamless steel tubing | Off-road vehicle fabrication, structural supports | Pros: Durable, versatile; Cons: May require specific fittings. |

| Fabrication Kits | Pre-packaged components for specific builds | Custom vehicle builds, machinery construction | Pros: Saves time, includes all necessary parts; Cons: Limited customization. |

| Bushings | Isolators made from rubber or poly materials | Automotive suspension systems, machinery mounts | Pros: Reduces vibration, improves longevity; Cons: Material choice affects performance. |

| Fasteners | Includes bolts, nuts, and specialized fasteners | General assembly, structural connections | Pros: Essential for structural integrity; Cons: Quality varies widely. |

| Sheet Metal Parts | Customizable flat or formed metal components | HVAC systems, enclosures, automotive parts | Pros: Highly customizable, quick production; Cons: Requires precise specifications. |

What are the characteristics of DOM Tubing and its applications in B2B sectors?

DOM (Drawn Over Mandrel) tubing is a type of steel tubing known for its high strength and uniform wall thickness. This seamless construction makes it ideal for applications requiring durability and reliability, such as off-road vehicle fabrication and structural supports in construction projects. When purchasing DOM tubing, buyers should consider the required dimensions, wall thickness, and compatibility with existing components, as the right fit is crucial for performance.

How do fabrication kits streamline the metal fabrication process for businesses?

Fabrication kits are comprehensive packages that include all necessary components for specific builds, such as off-road vehicle modifications or machinery construction. These kits save valuable time and effort for B2B buyers, as they eliminate the need to source individual parts. However, businesses should assess the kit’s compatibility with their projects and the level of customization available to ensure it meets their unique requirements.

What are the advantages of using bushings in automotive and machinery applications?

Bushings serve as isolators that reduce vibration and wear between moving parts, significantly enhancing the longevity of automotive suspension systems and machinery mounts. Available in various materials, including rubber and poly, the choice of bushing material can impact performance. B2B buyers should evaluate the specific application requirements, such as load-bearing capacity and environmental factors, to select the most suitable bushing type for their needs.

Why are fasteners critical in metal fabrication and assembly?

Fasteners, including bolts, nuts, and specialized connectors, are essential for ensuring structural integrity in various applications, from general assembly to complex machinery construction. They come in numerous grades and materials, which can affect performance and durability. Buyers need to consider the specific load requirements and environmental conditions when selecting fasteners, as these factors will influence the long-term success of their projects.

How do sheet metal parts contribute to customization in industrial applications?

Sheet metal parts offer a high degree of customization, allowing businesses to create components tailored to their specific needs, such as HVAC systems, enclosures, or automotive parts. The ability to quickly produce these parts through processes like laser cutting and bending makes them ideal for time-sensitive projects. B2B buyers should ensure they provide precise specifications to achieve the desired results, as accuracy is paramount in metal fabrication.

Key Industrial Applications of metal fab parts

| Industry/Sector | Specific Application of metal fab parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom chassis and suspension components | Enhances vehicle performance and durability | Quality certifications, material specifications, lead times |

| Construction | Structural framing and support systems | Ensures safety and stability of structures | Compliance with local regulations, sourcing of local materials |

| Oil & Gas | Pipeline and storage tank fabrication | Increases operational efficiency and safety | Resistance to corrosion, compliance with industry standards |

| HVAC Systems | Ductwork and ventilation components | Improves air quality and energy efficiency | Customization options, delivery timelines, material grades |

| Aerospace | Aircraft structural components and brackets | Ensures safety and performance at high altitudes | Certification for aerospace standards, lightweight materials, precision manufacturing |

How Are Metal Fab Parts Used in Automotive Manufacturing?

In automotive manufacturing, metal fabrication parts such as custom chassis and suspension components are crucial for enhancing vehicle performance and durability. These parts must withstand various stress factors while providing precise fitment. For international buyers, especially from regions like Africa and South America, sourcing high-quality, certified components is vital to ensure compliance with safety regulations and performance standards. Additionally, considerations around lead times and the ability to customize parts to fit specific vehicle models can significantly impact operational efficiency.

What Role Do Metal Fab Parts Play in Construction?

In the construction industry, metal fab parts are extensively used in structural framing and support systems. These components are essential for ensuring the safety and stability of buildings and infrastructure. Buyers from Europe and the Middle East should prioritize suppliers who comply with local building codes and regulations. Additionally, sourcing locally can mitigate shipping delays and reduce costs. It is also crucial to assess the quality of materials used to avoid issues related to structural integrity in the long term.

How Are Metal Fab Parts Utilized in the Oil & Gas Sector?

In the oil and gas sector, metal fabrication parts are integral for pipeline and storage tank fabrication. These components are engineered to enhance operational efficiency and safety, particularly in harsh environments. International buyers must consider the resistance of materials to corrosion and extreme weather conditions. Compliance with industry standards, such as API and ASME, is also critical to ensure reliability. Buyers should seek suppliers with proven experience in the oil and gas industry to mitigate risks associated with sourcing.

What Are the Applications of Metal Fab Parts in HVAC Systems?

Metal fab parts are fundamental in HVAC systems for creating ductwork and ventilation components. These parts contribute to improved air quality and energy efficiency in buildings. Buyers should look for customization options that cater to specific building layouts and airflow requirements. Furthermore, international buyers from diverse climates must consider material grades that withstand varying temperature conditions. Timely delivery and the ability to provide bulk orders are also key factors in sourcing for HVAC projects.

How Are Metal Fab Parts Essential in Aerospace Applications?

In the aerospace industry, metal fabrication parts such as aircraft structural components and brackets are critical for ensuring safety and performance at high altitudes. These parts must meet stringent certification standards to guarantee their reliability. Buyers, particularly from Europe and the Middle East, should prioritize suppliers that adhere to aerospace manufacturing standards, such as AS9100. The use of lightweight materials is essential to enhance fuel efficiency, and precision manufacturing capabilities are crucial for fitting complex designs.

3 Common User Pain Points for ‘metal fab parts’ & Their Solutions

Scenario 1: Difficulty in Customization and Sourcing for Unique Projects

The Problem: B2B buyers often face challenges when sourcing metal fabrication parts that meet specific project requirements. For example, a manufacturer in South America may need custom-sized DOM tubing or unique mounting brackets for a specialized piece of machinery. The challenge arises when standard suppliers do not offer customization options or the lead times for custom orders extend beyond acceptable limits, leading to project delays and increased costs. This situation can be particularly frustrating for companies operating in competitive markets where time-to-market is critical.

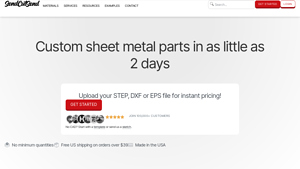

The Solution: To tackle this issue, buyers should seek suppliers who specialize in custom fabrication services with flexible options for customization. Companies like SendCutSend offer instant pricing for custom parts, allowing businesses to upload CAD files or sketches and receive tailored solutions within days. By partnering with a supplier that offers rapid prototyping and short lead times, buyers can ensure they receive the exact parts they need without significant delays. Additionally, establishing a relationship with a reliable supplier can enhance communication and streamline future orders, allowing for quicker adjustments to design changes or unforeseen project requirements.

Scenario 2: Quality Concerns with Imported Metal Fabrication Parts

The Problem: For international buyers, particularly those in Africa and the Middle East, sourcing metal fabrication parts can be risky due to concerns about quality and compliance with local standards. A buyer may order parts from a foreign manufacturer only to find that the materials do not meet specified engineering tolerances or that the components fail to perform under operational stress, resulting in costly rework and project delays.

The Solution: To mitigate quality issues, buyers should prioritize sourcing from reputable manufacturers that have established quality control processes. Look for suppliers that provide detailed certifications for their materials and manufacturing processes, such as ISO 9001 certifications. Additionally, buyers can request samples or conduct small initial orders to evaluate product quality before committing to larger purchases. Engaging in thorough due diligence by checking customer reviews, case studies, and asking for references from other B2B buyers can also help ensure that the chosen supplier meets the necessary standards.

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem: B2B buyers often grapple with managing inventory levels and supply chain disruptions, especially in the volatile global market. A company in Europe may experience delays in receiving essential metal fabrication parts due to geopolitical issues or natural disasters, impacting production schedules and potentially leading to lost contracts. The inability to maintain adequate inventory levels can strain relationships with customers and suppliers alike.

The Solution: To effectively manage inventory and mitigate supply chain risks, businesses should adopt a proactive approach by diversifying their supplier base. Engaging multiple suppliers across different regions can provide backup options in case of disruptions. Additionally, implementing an inventory management system can help track usage patterns and forecast demand, allowing for timely reorders. Buyers can also consider establishing safety stock for critical parts to cushion against unexpected delays. Leveraging technology, such as predictive analytics, can further enhance decision-making related to inventory levels and supplier management, ensuring smoother operations even during challenging times.

Strategic Material Selection Guide for metal fab parts

What are the Key Properties of Common Materials for Metal Fabrication Parts?

In the realm of metal fabrication, selecting the right material is crucial for ensuring product performance and longevity. Below, we analyze four common materials used in metal fab parts: carbon steel, stainless steel, aluminum, and brass. Each material has distinct properties that influence its suitability for various applications.

How Does Carbon Steel Perform in Metal Fabrication?

Carbon steel is a widely used material in metal fabrication due to its excellent strength and versatility. Key properties include high tensile strength and good machinability, making it suitable for applications requiring durability. However, it has a lower corrosion resistance compared to other materials, which can be a drawback in humid or corrosive environments.

Pros: Carbon steel is relatively inexpensive, easily available, and can be fabricated into complex shapes. Its high strength-to-weight ratio makes it ideal for structural applications.

Cons: The primary limitation is its susceptibility to rust and corrosion, necessitating protective coatings in certain applications. Additionally, it may not perform well at elevated temperatures.

Impact on Application: Carbon steel is suitable for applications involving mechanical stress but may not be ideal for environments exposed to moisture or chemicals.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, particularly in regions like Europe and the Middle East, where material specifications are critical.

What Advantages Does Stainless Steel Offer in Metal Fabrication?

Stainless steel is renowned for its corrosion resistance and aesthetic appeal. Its key properties include excellent durability, high-temperature resistance, and low maintenance requirements, making it suitable for a wide range of applications, from kitchen equipment to industrial machinery.

Pros: Stainless steel’s resistance to rust and staining makes it ideal for environments where hygiene is paramount, such as food processing and medical applications. It also has good weldability and formability.

Cons: The primary disadvantage is its higher cost compared to carbon steel. Additionally, it can be more challenging to machine, requiring specialized tools.

Impact on Application: Stainless steel is compatible with a variety of media, including water and chemicals, making it versatile for many industries.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel required for their applications and ensure compliance with international standards, such as ISO or ASTM.

How Does Aluminum Compare in Metal Fabrication Applications?

Aluminum is lightweight and has excellent corrosion resistance, making it a popular choice for applications where weight savings are critical. Key properties include high strength-to-weight ratio and good thermal conductivity.

Pros: Its lightweight nature allows for easier handling and reduced shipping costs. Aluminum is also highly resistant to corrosion, which extends the lifespan of components.

Cons: The main limitation is its lower strength compared to steel, which may not be suitable for high-stress applications. Additionally, aluminum can be more expensive than carbon steel.

Impact on Application: Aluminum is ideal for applications in aerospace, automotive, and marine industries where weight is a significant concern.

Considerations for International Buyers: Buyers should consider the specific alloy of aluminum required for their application and ensure compliance with relevant standards, such as JIS in Japan or EN in Europe.

What Role Does Brass Play in Metal Fabrication?

Brass, an alloy of copper and zinc, is known for its excellent machinability and corrosion resistance. Its key properties include good electrical conductivity and aesthetic appeal, making it suitable for decorative applications as well as plumbing and electrical fittings.

Pros: Brass is easy to machine and can be cast into intricate shapes. Its resistance to corrosion makes it suitable for plumbing applications.

Cons: Brass can be more expensive than steel and aluminum, and its strength is lower than that of steel, which may limit its use in structural applications.

Impact on Application: Brass is ideal for applications requiring good electrical conductivity and corrosion resistance, such as fittings and connectors.

Considerations for International Buyers: Buyers should ensure that the brass alloys meet local standards and regulations, particularly in the plumbing and electrical sectors.

Summary Table of Material Selection for Metal Fabrication Parts

| Material | Typical Use Case for metal fab parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components | High strength and low cost | Susceptible to corrosion | Low |

| Stainless Steel | Food processing equipment | Excellent corrosion resistance | Higher cost and difficult to machine | High |

| Aluminum | Aerospace and automotive parts | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Brass | Plumbing fittings and electrical parts | Excellent machinability | Higher cost and lower strength | Medium |

This strategic material selection guide provides insights into the properties, advantages, and limitations of common materials used in metal fabrication. By understanding these factors, international B2B buyers can make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal fab parts

What Are the Main Stages of Manufacturing Metal Fabrication Parts?

The manufacturing of metal fabrication parts involves several key stages that ensure the final product meets the stringent requirements of various industries. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

-

Material Preparation

The first stage involves selecting the appropriate raw materials, typically metals such as steel, aluminum, or alloys. This selection is critical as it affects the part’s strength, weight, and corrosion resistance. Suppliers often utilize advanced cutting techniques such as laser cutting or waterjet cutting to prepare the materials to specific dimensions. Additionally, the materials may undergo processes like deburring and surface cleaning to remove any contaminants that could affect quality. -

Forming

Once the materials are prepared, the next step is forming. Techniques such as bending, stamping, and machining are employed to shape the metal into the desired form. For instance, CNC (Computer Numerical Control) machines are commonly used for precision shaping, allowing for intricate designs and tight tolerances. This stage is vital in ensuring that the parts not only fit together correctly but also function as intended in their final applications. -

Assembly

After forming, the components are assembled. This can involve welding, riveting, or using fasteners to join different parts together. The choice of assembly method can impact the part’s durability and performance. For B2B buyers, understanding the assembly techniques used is crucial as they can influence maintenance needs and the overall lifespan of the fabricated parts. -

Finishing

The final stage in the manufacturing process is finishing, which may include processes such as powder coating, anodizing, or plating. These finishing techniques are not just for aesthetic purposes; they also enhance properties like corrosion resistance and surface durability. The choice of finishing method can vary based on the intended use of the metal parts and the environmental conditions they will face.

How is Quality Assurance Implemented in Metal Fabrication?

Quality assurance (QA) is paramount in the manufacturing of metal fab parts, especially for B2B transactions where reliability is critical. Here are the key aspects of QA in this sector.

-

International Standards

Compliance with international quality standards such as ISO 9001 is essential for suppliers. ISO 9001 outlines criteria for a quality management system (QMS) and emphasizes customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE marking for European markets and API standards for the oil and gas sector are also important, providing assurance that products meet specific regulatory requirements. -

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages to catch defects early.

– Final Quality Control (FQC): A comprehensive inspection of the finished product before shipment, verifying that all specifications and standards are met. -

Common Testing Methods

Various testing methods are employed to ensure the integrity and performance of metal parts. Non-destructive testing (NDT) methods, such as ultrasonic testing, magnetic particle testing, and dye penetrant testing, allow for the detection of flaws without damaging the part. Additionally, tensile strength tests, hardness tests, and fatigue tests are commonly performed to evaluate the material properties.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some effective strategies:

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing and quality assurance processes. During an audit, buyers can assess the supplier’s facilities, equipment, and adherence to quality standards firsthand. -

Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can help buyers understand their QA processes and results. These reports should include information on past performance, defect rates, and compliance with relevant standards. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be conducted at various stages of the manufacturing process and can help ensure that the products meet the necessary standards before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the QC and certification landscape can be complex for international B2B buyers. Here are some nuances to consider:

-

Understanding Regional Standards

Different regions may have varying standards and certifications. For instance, European buyers may prioritize CE marking, while buyers from the Middle East may look for compliance with Gulf Cooperation Council (GCC) standards. It is essential for buyers to be aware of these differences and ensure that their suppliers meet the necessary certifications for their specific markets. -

Cultural and Regulatory Differences

Cultural attitudes towards quality and regulatory compliance can vary significantly between regions. For instance, some regions may have a more rigorous enforcement of standards, while others may have a more lenient approach. Understanding these nuances can help buyers navigate supplier relationships more effectively. -

Building Long-Term Relationships

Establishing a long-term partnership with suppliers can facilitate better communication regarding quality control and compliance issues. Regular updates, feedback loops, and collaborative problem-solving can enhance the overall quality and reliability of the supplied products.

By understanding the manufacturing processes and quality assurance measures associated with metal fabrication parts, B2B buyers can make informed decisions, ensuring they select suppliers who meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal fab parts’

Introduction

Sourcing metal fabrication parts can be a complex process, particularly for international B2B buyers. This guide provides a step-by-step checklist to help you navigate the procurement of metal fab parts effectively. By following these steps, you will ensure that you choose the right suppliers, materials, and products to meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for successful sourcing. These specifications should include dimensions, material types, tolerances, and any relevant industry standards. This step helps to ensure that the parts you procure will fit seamlessly into your existing projects or machinery.

- Consider application requirements: Different applications may require specific materials or finishes, so be clear about your needs.

- Document your requirements: Create a detailed specification sheet to share with potential suppliers.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers that specialize in metal fabrication parts. Look for companies with a strong reputation in the industry and the capability to meet your specifications.

- Utilize online directories and trade shows: Platforms such as Alibaba or specialized trade fairs can help you find reputable suppliers.

- Seek recommendations: Consult industry peers or professional networks for supplier referrals.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation will help you gauge the supplier’s reliability and expertise.

- Check for certifications: Ensure that suppliers have the necessary quality certifications, such as ISO 9001, to validate their quality management practices.

- Assess their production capabilities: Confirm that the supplier can handle your order volume and complexity.

Step 4: Request Samples

Requesting samples is an essential step to verify the quality of the metal fab parts. Evaluate the samples against your specifications to ensure they meet your requirements.

- Conduct testing: If applicable, perform tests on the samples to assess their performance under real-world conditions.

- Review finish and appearance: Check for any defects or inconsistencies in the finish, as these can impact the final product’s quality.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier and evaluated their products, it’s time to negotiate terms and pricing. This process is vital to ensure that you receive competitive pricing without compromising quality.

- Discuss payment terms: Consider options like deposits, payment upon delivery, or credit terms that suit your cash flow.

- Clarify lead times and delivery schedules: Ensure that the supplier can meet your timelines, particularly if you are operating on a tight schedule.

Step 6: Finalize the Purchase Agreement

Before placing your order, finalize a purchase agreement that outlines all terms, including pricing, delivery schedules, quality standards, and penalties for non-compliance. A well-documented agreement protects both parties and establishes clear expectations.

- Include clauses for quality assurance: Specify how quality will be measured and what remedies are available in case of defects.

- Ensure compliance with international regulations: Confirm that all parts meet any relevant import/export regulations for your region.

Step 7: Establish a Relationship for Future Orders

Building a long-term relationship with your supplier can lead to better pricing, priority service, and tailored solutions. Regular communication can help you stay informed about new products and innovations in metal fabrication.

- Provide feedback: Share your experience with the supplier, which can help improve their service and product offerings.

- Stay engaged: Periodically check in with your supplier to discuss future needs and potential collaborations.

By following this checklist, B2B buyers can streamline the sourcing process for metal fabrication parts, ensuring quality, compliance, and value in their procurement efforts.

Comprehensive Cost and Pricing Analysis for metal fab parts Sourcing

What Are the Key Cost Components in Metal Fabrication Parts Sourcing?

When sourcing metal fabrication parts, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. Common materials include steel, aluminum, and specialty metals. Prices can fluctuate based on market demand and availability, so it’s essential to stay informed about current market trends.

-

Labor: Labor costs are influenced by the complexity of the parts being fabricated. Highly skilled labor may command higher wages, particularly for custom or precision work. Understanding regional labor costs can aid in identifying the most cost-effective sourcing options.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower overhead, which can translate to lower prices for buyers.

-

Tooling: Tooling costs involve the creation and maintenance of molds, dies, and other equipment necessary for production. Custom tooling can be expensive but is often essential for high-volume runs or specialized parts.

-

Quality Control (QC): Ensuring product quality often requires investments in testing and inspection processes. A robust QC program can prevent costly errors and rework, ultimately providing better value for buyers.

-

Logistics: Shipping costs can vary widely based on the distance between the supplier and the buyer, as well as the shipping method. International buyers must consider customs duties, tariffs, and import regulations that may affect the total cost.

-

Margin: Suppliers typically add a margin to their costs to achieve profitability. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect Metal Fab Parts Costs?

Several factors can influence the pricing of metal fabrication parts, particularly for international B2B buyers:

-

Volume/MOQ: Bulk orders often result in lower per-unit prices. Understanding minimum order quantities (MOQ) can help buyers negotiate better pricing for larger orders.

-

Specifications and Customization: Custom parts with specific design requirements can incur additional costs. Clear communication regarding specifications can help avoid misunderstandings and unexpected expenses.

-

Materials and Quality Certifications: The choice of materials impacts not only cost but also quality. Certifications (e.g., ISO, AS9100) may add to the price but can assure buyers of the product’s reliability and compliance with industry standards.

-

Supplier Factors: Supplier reputation, reliability, and financial stability can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can significantly impact the total landed cost.

What Tips Can Help Buyers Optimize Their Metal Fabrication Parts Costs?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of your needs and budget. Be prepared to discuss volume commitments or long-term contracts in exchange for better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider maintenance, lifecycle, and replacement costs. A higher upfront investment may lead to lower long-term costs if the part offers greater durability and performance.

-

Understand Pricing Nuances: Different markets may have unique pricing structures influenced by local regulations, tariffs, and labor costs. Conduct thorough research on suppliers in target regions to identify competitive pricing.

-

Leverage Technology: Utilize digital platforms for instant pricing and quotes, allowing for quick comparisons among suppliers. This can streamline the procurement process and ensure you receive the best possible rates.

Disclaimer on Pricing

Prices for metal fabrication parts can vary based on numerous factors, including market conditions, order volume, and specific part requirements. Always consult with suppliers for the most accurate and current pricing tailored to your needs.

Alternatives Analysis: Comparing metal fab parts With Other Solutions

In the competitive landscape of fabrication and manufacturing, businesses often seek alternatives to traditional metal fabrication parts. Understanding the options available can empower B2B buyers to make informed decisions that align with their operational needs and budget constraints. This section presents a comparison of metal fabrication parts with two viable alternatives: custom 3D printing and prefabricated modular components.

Comparison Table

| Comparison Aspect | Metal Fab Parts | Custom 3D Printing | Prefabricated Modular Components |

|---|---|---|---|

| Performance | High strength, durability, and precision in custom builds. | Suitable for complex geometries, but may lack the strength of metals. | Quick assembly and reliable performance, but may limit customization. |

| Cost | Typically moderate to high, depending on material and complexity. | Can be cost-effective for low-volume runs, but expensive for large quantities. | Generally lower cost due to mass production, but can incur shipping and storage fees. |

| Ease of Implementation | Requires skilled labor for assembly and installation. | User-friendly design software; can be complex for large-scale production. | Quick installation, but may require site adjustments. |

| Maintenance | Durable with low maintenance if properly fabricated. | Less durable; may require more frequent replacements. | Low maintenance, but repairs can be challenging if parts are damaged. |

| Best Use Case | Custom projects requiring specific specifications and strength. | Prototyping and low-volume production of intricate designs. | High-volume production where standardization is key. |

What Are the Advantages and Disadvantages of Custom 3D Printing?

Custom 3D printing is an innovative alternative to traditional metal fabrication, particularly useful for creating complex parts with intricate designs. The primary advantage of 3D printing is its ability to rapidly produce prototypes, allowing for design iterations at a fraction of the cost of metal fabrication. However, while it excels in design flexibility, the materials used may not always offer the same strength and durability as metal components, which could be a critical factor in applications requiring high-performance parts.

How Do Prefabricated Modular Components Compare to Metal Fab Parts?

Prefabricated modular components present a different approach, emphasizing quick installation and ease of use. These components are manufactured in bulk, ensuring consistency and reducing costs per unit. They are particularly advantageous in projects that require rapid deployment, such as construction or assembly lines. However, the downside is that these components may not meet specific customization needs, and repairs can be cumbersome if a part becomes damaged.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate solution, B2B buyers should consider their specific project requirements, including performance needs, budget constraints, and timelines. Metal fabrication parts are ideal for custom, high-strength applications, while custom 3D printing may be more suitable for prototyping and intricate designs. Alternatively, prefabricated modular components can save time and costs in high-volume projects. Ultimately, understanding the unique advantages and limitations of each option will enable buyers to make strategic decisions that best serve their operational goals.

Essential Technical Properties and Trade Terminology for metal fab parts

What Are the Essential Technical Properties of Metal Fabrication Parts?

Understanding the technical properties of metal fabrication parts is crucial for B2B buyers looking to make informed purchasing decisions. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the classification of metals based on their mechanical and chemical properties. Common grades include mild steel, stainless steel, and aluminum alloys. The choice of material grade impacts the part’s strength, durability, and corrosion resistance. For example, selecting a higher-grade stainless steel may be necessary for applications exposed to harsh environments, enhancing product longevity and reducing maintenance costs.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension or measurement. In metal fabrication, tighter tolerances often translate to higher costs due to increased precision during manufacturing. Understanding tolerance requirements is vital for ensuring parts fit correctly within assemblies, which is especially important in applications like automotive or aerospace where safety and performance are paramount.

3. Surface Finish

Surface finish describes the texture and appearance of a part’s surface. Common finishes include powder coating, anodizing, and polishing. The right surface finish can enhance corrosion resistance, improve aesthetics, and reduce friction in moving parts. For B2B buyers, specifying the correct finish is essential for meeting both functional and branding needs.

4. Weight

The weight of fabricated metal parts can significantly impact shipping costs and application performance. Lighter materials may be preferred for automotive components to enhance fuel efficiency, while heavier materials may be necessary for structural integrity in construction applications. Understanding weight specifications helps buyers optimize logistics and overall project costs.

5. Yield Strength

Yield strength is the amount of stress a material can withstand before deforming permanently. This property is critical in determining the suitability of a metal part for specific applications, especially in load-bearing scenarios. For instance, components in construction must have high yield strength to support significant loads without failure.

6. Machinability

Machinability refers to how easily a material can be cut, shaped, or otherwise processed. Materials with high machinability can reduce manufacturing time and costs, making them preferable for high-volume production runs. B2B buyers should consider machinability when selecting materials to ensure efficient production processes.

What Are the Common Trade Terms in Metal Fabrication?

Familiarity with industry jargon can facilitate smoother transactions and communication. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers as it can impact product quality and compatibility within their systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B transactions, where purchasing in bulk can lead to cost savings. Buyers must assess their needs against MOQs to optimize inventory levels and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. This process helps buyers compare prices, terms, and capabilities, ensuring they select the best vendor for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international transactions. These terms clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, helping to prevent misunderstandings in cross-border transactions.

5. CAD (Computer-Aided Design)

CAD refers to software used to create precision drawings or technical illustrations. CAD files are essential in the metal fabrication industry for designing parts and facilitating communication between designers and manufacturers.

6. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for planning production schedules and managing inventory effectively.

By grasping these essential technical properties and trade terminologies, B2B buyers can enhance their purchasing strategies and foster better supplier relationships in the metal fabrication industry.

Navigating Market Dynamics and Sourcing Trends in the metal fab parts Sector

What Are the Current Market Dynamics and Key Trends in the Metal Fabrication Parts Sector?

The global market for metal fabrication parts is witnessing significant transformation driven by technological advancements and evolving buyer preferences. Notable trends include the increasing adoption of automation and Industry 4.0 practices, which enhance efficiency and precision in manufacturing processes. B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are leveraging digital platforms for sourcing, enabling them to streamline procurement and reduce lead times. The rise of e-commerce in the metal fabrication sector allows for instant pricing, order tracking, and rapid delivery, reshaping traditional buying behaviors.

Furthermore, there is a growing emphasis on customization, with suppliers offering bespoke solutions that cater to specific project requirements. Buyers are increasingly seeking suppliers that can provide not only standard parts but also custom fabrication services. This trend is particularly relevant in the automotive and industrial machinery sectors, where tailored components are essential for optimizing performance.

The global supply chain is also under pressure due to geopolitical tensions, fluctuating material costs, and environmental regulations. Buyers must navigate these dynamics by establishing relationships with reliable suppliers who can provide consistent quality and availability of materials. As a result, strategic partnerships and long-term contracts are becoming critical for maintaining supply chain stability.

How Is Sustainability and Ethical Sourcing Influencing B2B in the Metal Fabrication Sector?

Sustainability is no longer a peripheral consideration; it has become a central pillar in the sourcing strategies of B2B buyers in the metal fabrication industry. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to prioritize ethical sourcing and environmentally friendly practices. Buyers are increasingly demanding transparency in their supply chains, looking for suppliers who demonstrate a commitment to sustainability.

This shift towards ethical sourcing includes the use of recycled materials and sustainable production methods. Certifications such as ISO 14001 and adherence to standards set by organizations like the Global Reporting Initiative (GRI) are becoming essential for suppliers looking to gain a competitive edge. Buyers are also interested in materials that have lower carbon footprints, such as aluminum and certain high-strength steels, which can significantly reduce the environmental impact of their projects.

Moreover, the integration of ‘green’ certifications into procurement processes is gaining traction. B2B buyers are actively seeking partnerships with suppliers that can demonstrate compliance with sustainability standards, as this not only enhances their corporate social responsibility (CSR) profile but also mitigates risks associated with environmental regulations.

How Has the Metal Fabrication Parts Sector Evolved Over Time?

The metal fabrication parts sector has evolved significantly over the past few decades, adapting to technological advancements and changing market demands. Initially characterized by manual processes and limited customization, the industry has transitioned towards automation and digitalization, enabling faster production times and enhanced precision.

In the early days, fabrication was primarily focused on large-scale manufacturing, with suppliers producing standardized parts in bulk. However, the advent of computer-aided design (CAD) and advanced manufacturing technologies has allowed for more intricate designs and the ability to produce small batches of customized parts efficiently. This evolution has opened new markets and applications, particularly in automotive, aerospace, and construction sectors.

Today, the focus is not only on the efficiency of production but also on sustainability and ethical sourcing, reflecting broader societal changes. As B2B buyers continue to prioritize responsible practices, the sector is poised for further innovation, ensuring that it meets the demands of a rapidly changing global landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of metal fab parts

-

How do I choose the right metal fabrication parts for my project?

Choosing the right metal fabrication parts depends on your specific application and requirements. First, assess the mechanical properties needed, such as strength and durability. Determine the environment in which the parts will operate, as factors like temperature and corrosion resistance are crucial. Additionally, consider the manufacturing processes involved, such as welding or machining. Collaborating with suppliers who offer customization options can help tailor parts to your needs, ensuring optimal performance in your application. -

What types of materials are commonly used in metal fabrication?

Common materials in metal fabrication include steel, aluminum, stainless steel, and brass. Steel is favored for its strength and versatility, while aluminum is lightweight and corrosion-resistant, making it ideal for automotive and aerospace applications. Stainless steel offers excellent resistance to rust and is often used in food processing and medical equipment. Brass is utilized for its machinability and aesthetic appeal in decorative applications. Selecting the appropriate material is essential to meet performance and budgetary requirements. -

What are the typical lead times for metal fabrication parts?

Lead times for metal fabrication parts can vary based on factors such as complexity, quantity, and supplier capabilities. Generally, standard parts may take anywhere from 2 to 4 weeks, while custom parts could require 4 to 6 weeks or more. International buyers should account for additional time for customs clearance and shipping, especially when sourcing from regions like the U.S. or Europe. Establishing clear communication with suppliers regarding timelines can help set realistic expectations for project completion. -

What should I consider when vetting a supplier for metal fabrication?

When vetting a supplier, assess their industry experience, reputation, and certifications. Look for suppliers with proven track records in quality assurance and customer service. It’s also beneficial to request samples of their work to evaluate craftsmanship. Additionally, inquire about their manufacturing capabilities and whether they can accommodate your specific requirements, including customization and delivery timelines. Finally, consider the supplier’s location, as proximity can impact shipping costs and lead times. -

What are the minimum order quantities (MOQs) for metal fabrication parts?

Minimum order quantities (MOQs) for metal fabrication parts can vary significantly between suppliers. Some may offer low MOQs for standard parts, while custom components may require larger orders to offset setup costs. It’s essential to discuss your project needs with potential suppliers to understand their MOQ policies. If you anticipate lower volume needs, consider suppliers that specialize in small-batch production or those who offer flexibility in their order quantities. -

What payment terms are typically offered by metal fabrication suppliers?

Payment terms can vary based on the supplier and the buyer’s relationship. Common arrangements include net 30 or net 60 days, where payment is due within 30 or 60 days after delivery. Some suppliers may require upfront deposits, especially for custom orders. It’s essential to clarify payment expectations early in negotiations, including any additional costs related to shipping, taxes, or tariffs for international transactions. Establishing clear terms can help avoid misunderstandings and ensure smooth transactions. -

How do I ensure quality control for metal fabrication parts?

Ensuring quality control in metal fabrication involves implementing thorough inspection processes at various stages of production. Start by requesting detailed specifications from your supplier, including material certifications and machining tolerances. During production, regular inspections can help catch defects early. After receiving the parts, conduct final inspections to verify adherence to your quality standards. Partnering with suppliers who prioritize quality assurance and offer warranties can further safeguard your investment. -

What logistics considerations should I keep in mind when sourcing metal fabrication parts internationally?

When sourcing metal fabrication parts internationally, consider shipping methods, customs regulations, and potential tariffs. Choose reliable logistics partners who can provide timely updates on shipment status. Understand the import/export regulations in your country and the supplier’s country to ensure compliance. It’s also wise to factor in lead times for customs clearance, which can vary by region. Collaborating with suppliers experienced in international trade can help navigate these complexities and ensure efficient delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Metal Fab Parts Manufacturers & Suppliers List

1. Barnes 4WD – DIY Off Road Fabrication Parts

Domain: barnes4wd.com

Registered: 2006 (19 years)

Introduction: DIY Off Road Fabrication Parts from Barnes 4WD include a variety of items such as:

– Battery Box

– DOM Tubing (1.50 OD, 1 ID, 1/4 Wall, 4 Foot Section)

– Grade Eight Nuts and Bolts (various sizes)

– Gussets (2 x 2 Solid 90 Degree Gusset)

– Poly Bushings and Bushing Kits

– Cage & Crossmember Components

– Weld Washers

– Bolt Head Protectors

– Bumper Build Essentials

Key products with prices include…

2. Midnight 4×4 – Aluminum Set Up Bushings

Domain: midnight4x4.com

Registered: 2004 (21 years)

Introduction: {“products”:[{“name”:”Aluminum Set Up Bushings”,”price”:”$16.50″},{“name”:”Delrin Bushings”,”price”:”$14.99″},{“name”:”Zip Tie Tabs”,”price”:”From $3.75″},{“name”:”Bolt Retainer – Bolt On”,”price”:”$2.99″},{“name”:”Optima Series 34 Battery Box – BAT0003″,”price”:”$64.99″},{“name”:”7/8\” Race Series Heim Joint Kit”,”price”:”$106.57″},{“name”:”3/4\” High Misalignment Spacers”,”price”:”$17.99″},{“nam…

3. SendCutSend – Custom Sheet Metal Fabrication Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. Key features include:

– Custom sheet metal parts available in as little as 2 days.

– Instant pricing by uploading STEP, DXF, or EPS files.

– No …

4. Metal-Fab – Venting Solutions

Domain: mtlfab.com

Registered: 1997 (28 years)

Introduction: Metal-Fab manufactures complete and comprehensive venting solutions for Residential, Commercial, and Industrial applications. They focus on product development, improvement, and safety, leveraging over 60 years of experience to maintain a leadership position in the ventilation industry. Founded in 1958, Metal-Fab aims to offer the best products available and deliver them faster than anyone else in…

5. Offroad Anonymous – Adjustable Frame Link Mount Bracket

Domain: offroadanonymous.com

Registered: 2013 (12 years)

Introduction: Fabrication Parts – Offroad Anonymous

Categories:

– Miscellaneous Fabrication Parts (16)

– Tube Flanges & Caps (6)

– Gussets (11)

– Brackets (20)

– Basic Tabs (27)

– Trick Tabs (10)

Key Products:

1. Adjustable Frame Link Mount Bracket – $35.00

2. Angled Link Bracket – $25.00 – $27.50

3. Axle Link Tower Bracket – $32.00 – $35.00

4. Capture / Weld Washer – $3.00 – $33.25

5. Compact Vertical Link …

6. All Metals Fabricating – Metal Parts Fabrication

Domain: ametals.com

Registered: 1998 (27 years)

Introduction: All Metals Fabricating specializes in metal parts fabrication, offering a wide range of capabilities including tube laser cutting, laser cutting, CNC punching, CNC machining, forming, welding (including robotic welding), hardware and electromechanical assembly, powder coating, and silk screening. Established in 1953, the company serves various industries such as telecommunications, electrical encl…

7. FABTECH SOLUTIONS – Metal Fabricating Tools & Equipment

Domain: fabtechsolutions.com

Registered: 2014 (11 years)

Introduction: FABTECH SOLUTIONS offers a wide range of metal fabricating tools, parts, and supplies including: TRUMPF TruTools, HYDMECH Band Saws (Carbide Saw, Double Miter Band Saws, Horizontal Band Saws, Metal Cold Saws, Scissor Style Band Saws, Vertical Band Saws), Piranha equipment (Fiber Lasers, Ironworkers, Plasma Tables, Press Brakes, Shears), Arclight Dynamics Plasma Tables (Arc Pro Elite, Arc Max Elite…

8. Protolabs – Metal Fabrication Services

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Protolabs offers a range of metal fabrication services including soft metals (Aluminum, Magnesium, Brass, Copper) and hard metals (Steel, Stainless Steel, Inconel, Chrome, Titanium). Key manufacturing techniques include machining, casting, molding, and 3D printing. The company provides options for sheet metal fabrication and various post-processing methods for metal parts. Protolabs emphasizes the…

9. Mayhem Metal Works – Air Intake Temp Sensor Weld Bung

Domain: mayhemmetalworks.net

Registered: 2014 (11 years)

Introduction: Fabrication Parts available for DIY fabricators and high volume shops. Quantity discounts offered for large orders. Key products include: 03-12 Dodge CR Cummins Air Intake Temp Sensor Weld Bung ($37.95), 1″ Turbo Spacer Plates (Divided Twin Scroll) ($49.95), 1″ Turbo Spacer Plates (Open configuration) ($49.95), 16 Gauge Dimple Plate Gussets (12″ and 24″ long) starting at ($9.95), 6.7 Cummins Intak…

Strategic Sourcing Conclusion and Outlook for metal fab parts

In the ever-evolving landscape of metal fabrication, strategic sourcing remains paramount for international B2B buyers seeking high-quality parts. By leveraging a diverse array of suppliers, businesses can enhance their operational efficiency, mitigate risks, and secure competitive pricing. As you explore options—from custom sheet metal fabrication to specialized DIY components—focus on suppliers that offer not just products, but also robust support and expertise tailored to your specific needs.

Understanding local market dynamics is essential, particularly for buyers in regions like Africa, South America, the Middle East, and Europe. This awareness enables you to navigate supply chain complexities and optimize procurement strategies. Additionally, prioritizing manufacturers with strong reputations for quality and reliability will ensure that your projects are built on a solid foundation.

Looking ahead, the demand for metal fabrication parts will continue to rise, driven by innovation and technological advancements. Now is the time to engage with suppliers who can adapt to your changing requirements and deliver value. Embrace this opportunity to streamline your sourcing strategy and position your business for success in a competitive global market. Reach out to potential partners today and take the first step toward building a resilient supply chain.