Introduction: Navigating the Global Market for metal cutting laser for sale

In today’s rapidly evolving manufacturing landscape, sourcing the right metal cutting laser can be a daunting challenge for international B2B buyers. With an array of technologies, including fiber, CO2, and crystal lasers, each offering distinct advantages and applications, the decision-making process becomes complex. This guide aims to demystify the global market for metal cutting lasers for sale, providing valuable insights into the various types of machines available, their specific applications across industries, and the critical factors to consider when vetting suppliers.

From understanding the nuances of machine specifications to evaluating cost implications and operational efficiencies, this comprehensive resource empowers businesses in Africa, South America, the Middle East, and Europe—such as Brazil and Vietnam—to make informed purchasing decisions. By exploring the latest advancements in laser technology and industry best practices, buyers can identify equipment that aligns with their production needs while maximizing return on investment.

Moreover, the guide addresses essential considerations like maintenance, training, and support services, ensuring that organizations not only invest wisely but also enhance their operational capabilities. As the demand for precision and efficiency in metal fabrication continues to rise, this guide serves as a crucial tool for navigating the intricacies of sourcing metal cutting lasers in a competitive global marketplace.

Understanding metal cutting laser for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fiber Laser Cutting | Utilizes a solid-state laser for high efficiency and precision | Automotive, Aerospace, Metal Fabrication | Pros: High speed, low operating costs; Cons: Higher initial investment. |

| CO2 Laser Cutting | Uses gas lasers, ideal for a wide range of materials | Woodworking, Textile, Plastic, Metal | Pros: Versatile, good for non-metal materials; Cons: Slower than fiber lasers. |

| Crystal Laser Cutting | Employs high-powered solid-state lasers for specific materials | Medical Devices, Ceramics, Specialized Parts | Pros: Excellent for high-density materials; Cons: Limited to specific applications. |

| Hybrid Laser Cutting | Combines fiber and CO2 technologies for enhanced flexibility | Mixed Material Applications, Prototyping | Pros: Versatile for various materials; Cons: Complexity in operation. |

| Portable Laser Cutting | Compact and mobile systems for on-site applications | Construction, Repair, Maintenance | Pros: Flexible usage, easy transport; Cons: Lower power and speed compared to industrial models. |

What Are the Key Characteristics of Fiber Laser Cutting Machines?

Fiber laser cutting machines are known for their efficiency and precision. They utilize a solid-state laser, which allows for faster cutting speeds and lower operating costs compared to traditional methods. Suitable for a variety of metals, including reflective materials, fiber lasers are ideal for industries such as automotive and aerospace. When considering a fiber laser cutter, B2B buyers should evaluate the power output and cutting capacity to ensure it meets their production needs.

How Do CO2 Laser Cutting Machines Differ?

CO2 laser cutting machines utilize gas lasers, making them highly versatile for cutting not only metals but also non-metal materials like wood and plastics. They are particularly effective for thicker materials, although they generally operate at slower speeds compared to fiber lasers. B2B buyers should consider the range of materials they plan to cut and whether the slower cutting speed aligns with their production timelines.

What Is Unique About Crystal Laser Cutting Technology?

Crystal laser cutting machines employ high-powered solid-state lasers, making them suitable for processing materials that require intense power, such as ceramics and specialized metals. These machines are often used in the medical industry and for manufacturing intricate components. Buyers should assess the types of materials they need to work with, as these machines are not as versatile as fiber or CO2 lasers but excel in high-density applications.

Why Consider Hybrid Laser Cutting Systems?

Hybrid laser cutting systems combine the strengths of fiber and CO2 laser technologies, offering flexibility for cutting various materials. This adaptability makes them suitable for mixed material applications and prototyping. However, the complexity of operation may require additional training for staff. B2B buyers should weigh the benefits of versatility against the need for specialized training and potential maintenance costs.

What Are the Advantages of Portable Laser Cutting Machines?

Portable laser cutting machines offer flexibility and ease of transport, making them ideal for on-site applications in construction and maintenance. While they provide convenience, they typically have lower power and speed compared to stationary industrial models. Buyers considering portable options should evaluate their specific on-site needs and whether the trade-offs in power and speed are acceptable for their operations.

Key Industrial Applications of metal cutting laser for sale

| Industry/Sector | Specific Application of metal cutting laser for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Cutting intricate components for vehicle assembly | Enhances precision and reduces waste | Consider power capacity, cutting speed, and software compatibility. |

| Aerospace | Fabrication of lightweight structural parts | Improves fuel efficiency and performance | Ensure compliance with industry standards and material versatility. |

| Electronics | Manufacturing circuit boards and enclosures | Facilitates high precision and reduces lead times | Look for machines that can handle various materials and intricate designs. |

| Construction and Fabrication | Custom metal framing and structural supports | Allows for rapid prototyping and customization | Evaluate machine size, cutting area, and adaptability to different metals. |

| Medical Devices | Producing surgical instruments and implants | Ensures high precision and biocompatibility | Focus on hygiene standards and the ability to cut advanced materials. |

How is Metal Cutting Laser Used in Automotive Applications?

In the automotive industry, metal cutting lasers are utilized to cut intricate components such as brackets, frames, and body panels with exceptional accuracy. This technology addresses common challenges like material waste and inconsistent cuts, which can lead to costly rework. Buyers in this sector should prioritize sourcing lasers with high power capacity and speed, as well as compatibility with CAD/CAM software to streamline production processes.

What Role Does Metal Cutting Laser Play in Aerospace Manufacturing?

Aerospace applications often require the fabrication of lightweight and complex structural parts, where metal cutting lasers excel. These systems provide precision cuts that are critical for aerodynamics and structural integrity, ultimately enhancing fuel efficiency. International buyers must consider compliance with stringent industry standards and the machine’s ability to handle various materials, including high-strength alloys.

How is Metal Cutting Laser Used in Electronics Production?

In the electronics sector, metal cutting lasers are essential for manufacturing circuit boards and enclosures. The technology allows for high precision, enabling the creation of intricate designs that are crucial for modern electronic devices. Buyers should focus on sourcing lasers that can accommodate different materials and offer quick changeovers to maintain production efficiency.

What Benefits Does Metal Cutting Laser Offer in Construction and Fabrication?

Metal cutting lasers are increasingly used in construction for creating custom metal framing and structural supports. This application allows for rapid prototyping and customization, meeting the dynamic needs of construction projects. When sourcing, businesses should evaluate the machine’s size and cutting area to ensure it meets their specific project requirements, as well as its adaptability to various metals.

How is Metal Cutting Laser Important in Medical Device Manufacturing?

In the medical device industry, precision is paramount for producing surgical instruments and implants. Metal cutting lasers enable manufacturers to achieve the high levels of accuracy necessary for biocompatibility and functionality. Buyers should prioritize sourcing equipment that adheres to hygiene standards and is capable of cutting advanced materials, ensuring the production of safe and effective medical devices.

3 Common User Pain Points for ‘metal cutting laser for sale’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Laser Cutting Technology

The Problem:

Many B2B buyers struggle to choose the right type of laser cutting technology for their specific needs. With various options available, such as fiber, CO2, and crystal lasers, the decision can be overwhelming. Each type has unique capabilities, advantages, and limitations, which can lead to buyer’s remorse if the wrong choice is made. For instance, a company looking to cut reflective materials like aluminum may opt for a fiber laser, but without adequate knowledge, they might mistakenly choose a CO2 laser, leading to inefficiencies and increased operational costs.

The Solution:

To make an informed decision, buyers should conduct a comprehensive needs analysis that outlines their specific applications and material types. Start by evaluating the materials you will primarily cut, their thickness, and the complexity of the designs. Engage with suppliers who offer hands-on demonstrations or trials of different laser cutting technologies. Additionally, consider the total cost of ownership, including energy consumption, maintenance, and potential downtime. By gathering this information, you can create a well-rounded comparison chart to facilitate your decision-making process and ensure that the selected laser cutter aligns with your production goals.

Scenario 2: High Operational Costs Due to Inefficient Equipment

The Problem:

A common pain point for international buyers is the high operational costs associated with outdated or inefficient laser cutting equipment. This issue is particularly pressing for companies in regions with fluctuating energy prices or where operational efficiency is crucial for maintaining competitive pricing. Inefficient machines can lead to excessive energy consumption, longer cutting times, and increased wear and tear, ultimately affecting the bottom line.

The Solution:

Investing in modern, energy-efficient laser cutting machines can significantly reduce operational costs. When searching for “metal cutting lasers for sale,” prioritize models that feature advanced technology such as variable beam intensity and automatic material thickness adjustments. These features optimize cutting speeds and energy usage. Additionally, consider sourcing from suppliers that offer robust after-sales support and maintenance packages to minimize downtime and ensure the equipment operates at peak efficiency. Regular training for operators on best practices can also enhance machine utilization and longevity, further lowering overall costs.

Scenario 3: Challenges in Integration with Existing Systems

The Problem:

Many businesses face integration challenges when incorporating new laser cutting technology into their existing production systems. This can be especially problematic for companies with established workflows, as the introduction of new machinery often requires adjustments to software, training, and sometimes even the physical layout of the production floor. These disruptions can lead to delays in production and a temporary dip in productivity.

The Solution:

To mitigate integration challenges, it is crucial to work with suppliers who understand your existing systems and can provide tailored solutions. Before making a purchase, discuss compatibility with your current software and machinery with potential vendors. Opt for laser cutting machines that come with user-friendly interfaces and comprehensive training programs for your staff. Furthermore, consider a phased implementation strategy that allows for gradual integration, minimizing disruptions. This approach enables your team to adapt to the new technology without overwhelming your current operations, ensuring a smoother transition and sustained productivity.

Strategic Material Selection Guide for metal cutting laser for sale

When considering the purchase of a metal cutting laser, understanding the properties and applications of various materials is crucial for optimizing performance and ensuring compliance with international standards. Below, we analyze four common materials that are frequently processed using metal cutting lasers: carbon steel, stainless steel, aluminum, and brass. Each material has unique characteristics that influence its suitability for different applications.

What are the Key Properties of Carbon Steel for Laser Cutting?

Carbon steel is one of the most widely used materials in industrial applications due to its strength and versatility. It is characterized by its high tensile strength and excellent machinability, making it suitable for various cutting processes. However, it is prone to corrosion if not properly treated.

Pros: Carbon steel is relatively inexpensive and offers good durability, making it ideal for structural applications and components that require high strength.

Cons: Its susceptibility to rust can lead to increased maintenance costs and reduced lifespan if not adequately protected. Additionally, the cutting process can produce heat-affected zones that may weaken the material.

Impact on Application: Carbon steel is commonly used in construction, automotive, and manufacturing sectors. Buyers in regions with high humidity, such as parts of Africa and South America, should consider protective coatings to enhance longevity.

How Does Stainless Steel Perform in Laser Cutting Applications?

Stainless steel is renowned for its corrosion resistance and aesthetic appeal. It retains its strength at high temperatures and is often used in environments where hygiene is critical, such as food processing and medical equipment.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, making it suitable for a wide range of applications, including those exposed to harsh conditions.

Cons: The cost of stainless steel is higher than that of carbon steel, and its cutting can be more complex due to the need for specialized laser settings to prevent warping.

Impact on Application: Stainless steel is compliant with various international standards, making it a preferred choice in Europe and the Middle East where quality assurance is paramount.

What are the Benefits and Limitations of Aluminum in Laser Cutting?

Aluminum is lightweight and has excellent thermal conductivity, which makes it a popular choice for applications requiring precision and reduced weight, such as aerospace and automotive industries.

Pros: The key advantage of aluminum is its ability to be cut quickly and efficiently, resulting in lower processing times and costs. Its lightweight nature also contributes to fuel efficiency in transportation applications.

Cons: However, aluminum can be more expensive than carbon steel, and it may require more frequent maintenance due to its softer nature, which can lead to scratches and dents.

Impact on Application: Buyers in regions like Brazil and Vietnam should consider the specific grades of aluminum that meet local standards for quality and performance.

Why is Brass Considered for Metal Cutting Applications?

Brass, an alloy of copper and zinc, is valued for its machinability and corrosion resistance. It is commonly used in decorative applications and precision instruments due to its aesthetic qualities.

Pros: Brass offers excellent corrosion resistance and is easy to machine, which can lead to a smoother finish in laser-cut products.

Cons: Its higher cost compared to other metals can be a limiting factor for large-scale applications. Additionally, brass can be more challenging to cut due to its thermal properties.

Impact on Application: International buyers should ensure compliance with specific alloy standards, as brass is often used in electronic components and plumbing fixtures.

Summary Table of Material Properties for Metal Cutting Lasers

| Material | Typical Use Case for metal cutting laser for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components, automotive parts | Inexpensive and durable | Prone to corrosion | Low |

| Stainless Steel | Medical equipment, food processing machinery | Corrosion resistant and durable | Higher cost and complex cutting | High |

| Aluminum | Aerospace components, automotive applications | Lightweight and efficient cutting | Higher cost and frequent maintenance | Medium |

| Brass | Decorative items, precision instruments | Excellent machinability and finish | Higher cost and challenging to cut | Medium |

This strategic material selection guide provides an essential overview for international B2B buyers, enabling informed decisions that align with their specific operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metal cutting laser for sale

What Are the Main Stages in the Manufacturing Process of Metal Cutting Lasers?

Manufacturing metal cutting lasers involves several critical stages that ensure the final product meets both performance and quality standards. The main stages of production include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, typically including steel, aluminum, or specialized alloys. These materials are subjected to rigorous quality checks to confirm their composition and structural integrity. Suppliers often use advanced techniques such as spectrometry to analyze material properties before they proceed to the forming stage.

-

Forming: This stage involves shaping the raw materials into the desired components for the laser systems. Common techniques include CNC machining, laser cutting, and bending. The use of CNC machines ensures precise dimensions and tolerances, which are critical for the assembly of complex laser systems. Fiber lasers, in particular, require high precision during the forming stage to ensure optimal cutting performance.

-

Assembly: Once the components are formed, they are assembled into the laser cutting system. This stage may include the installation of various subsystems such as the laser source, optics, and cooling systems. The assembly process is often automated, but skilled technicians oversee the operation to ensure that all components are correctly aligned and functioning.

-

Finishing: The final stage involves polishing, coating, and quality checks of the assembled laser systems. Finishing techniques can include anodizing or powder coating to enhance durability and aesthetic appeal. This stage is crucial for ensuring that the lasers can withstand operational stresses and environmental factors during their lifecycle.

How Is Quality Assurance Implemented in Metal Cutting Laser Manufacturing?

Quality assurance (QA) is vital in the manufacturing of metal cutting lasers to ensure that the products meet international standards and customer expectations. Various quality control measures and international standards are implemented throughout the manufacturing process.

-

International Standards and Certifications: Manufacturers typically adhere to ISO 9001, which outlines the criteria for a quality management system. In addition to ISO standards, other relevant certifications include CE marking for products sold in Europe and API standards for specific industrial applications. These certifications demonstrate compliance with safety and quality regulations.

-

Quality Control Checkpoints: Quality control checkpoints are integrated at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production line.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that components meet specified tolerances and performance criteria as they are being manufactured.

– Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the complete laser system to verify functionality, safety, and performance. This may include operational tests, safety inspections, and performance evaluations under different conditions. -

Common Testing Methods: Various testing methods are employed to assess the performance and reliability of metal cutting lasers. These include:

– Laser Power Testing: Measures the output power of the laser to ensure it meets specifications.

– Cutting Quality Testing: Assesses the quality of cuts made by the laser on different materials, checking for kerf width, edge smoothness, and accuracy.

– Thermal Imaging: Used to monitor the cooling systems and ensure that the equipment operates within safe temperature ranges.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers to ensure they are investing in reliable and high-performing equipment.

-

Supplier Audits: Conducting supplier audits is a crucial step. Buyers can assess the manufacturing facilities, review quality control processes, and verify compliance with international standards. This may include checking the documentation of quality management systems and certifications.

-

Requesting Quality Reports: Buyers should ask suppliers for quality assurance documentation, including test reports and inspection certificates. These documents provide insights into the supplier’s commitment to quality and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspections can be conducted at various stages of production and provide additional assurance that the products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider regarding quality control:

-

Understanding Regional Regulations: Different regions may have varying regulations and standards. Buyers should familiarize themselves with local compliance requirements, especially when importing machinery. This may include understanding tariffs, safety regulations, and environmental considerations.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary by region. Buyers must communicate their expectations clearly and ensure that suppliers understand the specific quality standards required for their market.

-

Building Long-Term Relationships: Establishing a long-term relationship with suppliers can lead to improved quality assurance over time. Regular communication and feedback can help suppliers align their processes with buyer expectations and enhance overall product quality.

-

Logistics and Supply Chain Considerations: Quality control does not stop at manufacturing. Buyers should also consider logistics and supply chain factors that could impact the quality of the delivered product. This includes ensuring proper handling during transportation and storage.

By understanding the manufacturing processes and implementing robust quality assurance measures, B2B buyers can make informed decisions when purchasing metal cutting lasers, ensuring that they receive high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal cutting laser for sale’

In today’s competitive manufacturing landscape, sourcing the right metal cutting laser is essential for optimizing production efficiency and precision. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively, ensuring they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Before exploring suppliers, it’s vital to outline your specific requirements. Consider factors such as the types of metals you will be cutting (e.g., aluminum, stainless steel, brass), the thickness of the materials, and the desired cutting speed and precision. This clarity will help you identify the right machine type—be it fiber, CO2, or crystal lasers—tailored to your operations.

Step 2: Set a Realistic Budget

Establishing a budget is crucial in guiding your purchasing decisions. Include not just the initial cost of the laser cutter but also potential operational costs such as maintenance, consumables, and energy consumption. Be aware that while high-quality machines may have a higher upfront cost, they often provide better long-term value through efficiency and durability.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in metal cutting lasers. Look for manufacturers with a proven track record in your industry. Utilize online platforms, trade shows, and industry forums to gather information. Create a shortlist of suppliers based on their reputation, product offerings, and customer reviews.

Step 4: Verify Supplier Certifications and Standards

Confirm that your shortlisted suppliers adhere to international quality standards and certifications, such as ISO 9001. This validation ensures that the equipment meets industry benchmarks for safety and performance. Additionally, inquire about their compliance with local regulations in your region to avoid future operational hurdles.

Step 5: Request Detailed Quotations

Reach out to your shortlisted suppliers for detailed quotations. Ensure these quotes include all relevant costs, such as shipping, installation, and training. Compare not only the prices but also the value-added services offered, such as warranties, after-sales support, and training programs for your operators.

Step 6: Evaluate After-Sales Support and Maintenance Options

After-sales support can significantly impact your operational efficiency. Inquire about the supplier’s service agreements, response times for repairs, and availability of spare parts. A reliable support system can minimize downtime and ensure your laser cutter operates at peak performance.

Step 7: Conduct a Final Assessment and Make Your Purchase

Before finalizing your purchase, conduct a comprehensive assessment of all gathered information. Consider factors such as supplier responsiveness, product specifications, and after-sales support. Once you’re confident that the supplier meets your criteria, proceed with the purchase and ensure that you have a clear contract outlining all agreed terms.

By following this checklist, B2B buyers can streamline the process of sourcing a metal cutting laser, ultimately enhancing their operational capabilities and contributing to their business success.

Comprehensive Cost and Pricing Analysis for metal cutting laser for sale Sourcing

When sourcing metal cutting lasers, understanding the comprehensive cost structure and pricing dynamics is essential for making informed purchasing decisions. Various components contribute to the overall cost, and several factors influence the price. Here’s a detailed analysis tailored for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Metal Cutting Lasers?

-

Materials: The primary materials used in the manufacturing of metal cutting lasers, such as high-quality optics, lasers, and structural components, significantly impact the overall price. The choice of materials can vary based on the machine’s specifications and intended use, affecting durability and performance.

-

Labor: Skilled labor is necessary for both manufacturing and assembling metal cutting lasers. Labor costs can differ dramatically based on geographic location and expertise. Regions with a strong engineering workforce may offer more competitive pricing due to higher efficiency and lower defect rates.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, utilities, and administrative expenses. Manufacturers in regions with lower operational costs may provide more competitive pricing, but it is crucial to ensure that quality is not compromised.

-

Tooling: Specialized tools required for the production of lasers add to the overall cost. High-precision tooling is essential for maintaining the high standards expected in laser cutting technology.

-

Quality Control (QC): Ensuring that every machine meets strict quality standards involves additional costs. Advanced QC processes can increase manufacturing costs but are vital for maintaining reliability and performance.

-

Logistics: Shipping and handling costs can vary based on the destination and the shipping method chosen. International buyers should consider these costs, as they can significantly affect the total purchase price.

-

Margin: The manufacturer’s profit margin also plays a role in the final price. Established brands with proven track records may command higher prices due to perceived quality and reliability.

How Do Price Influencers Impact the Cost of Metal Cutting Lasers?

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts, making it crucial for companies to assess their needs accurately. Suppliers often offer better pricing for larger orders, which can lower the cost per unit.

-

Specifications and Customization: Tailoring a laser cutter to specific operational needs can increase costs. Custom features often require specialized manufacturing processes, which can lead to higher pricing.

-

Materials: The choice of materials not only influences performance but also pricing. Higher-grade materials may be more expensive but can result in greater longevity and efficiency.

-

Quality and Certifications: Machines that come with industry certifications (e.g., ISO) or enhanced warranties may have higher upfront costs but can provide better long-term value. Buyers should evaluate the potential for reduced maintenance and operational downtime.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better customer support and warranties, which can justify higher prices.

-

Incoterms: The agreed shipping terms (e.g., FOB, CIF) can significantly impact the total cost. Understanding these terms is essential for international buyers to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost Efficiency in Metal Cutting Laser Purchases?

-

Negotiate: Always engage in price negotiations with suppliers. Understanding the cost components can provide leverage during discussions, potentially leading to better pricing or added value.

-

Consider Total Cost of Ownership (TCO): While the initial purchase price is important, evaluating the TCO—including maintenance, energy consumption, and potential downtime—will provide a clearer picture of long-term value.

-

Research and Compare: Take the time to compare multiple suppliers and models. This research can reveal significant pricing variations and help identify the best option for specific needs.

-

Be Aware of Pricing Nuances: International buyers should be conscious of currency fluctuations, import duties, and local taxes, which can affect the final cost. Understanding these factors in advance can prevent budget overruns.

Disclaimer

Prices for metal cutting lasers can vary widely based on specifications, supplier, and market conditions. The figures mentioned are indicative and should be validated through direct consultations with manufacturers or suppliers to ensure accuracy and relevance to specific purchasing scenarios.

Alternatives Analysis: Comparing metal cutting laser for sale With Other Solutions

Introduction to Alternatives in Metal Cutting Solutions

When considering metal cutting technologies, it’s essential to explore various alternatives to determine the best fit for specific operational needs. While ‘metal cutting lasers for sale’ present a highly efficient and precise method, alternatives such as plasma cutting and waterjet cutting also offer unique advantages. This analysis will compare these methods based on performance, cost, ease of implementation, maintenance, and best use cases, helping B2B buyers make informed decisions.

| Comparison Aspect | Metal Cutting Laser For Sale | Plasma Cutting | Waterjet Cutting |

|---|---|---|---|

| Performance | High precision with minimal kerf; ideal for intricate designs. | Moderate precision; faster for thicker materials but less detailed. | Excellent precision; effective on a wide range of materials. |

| Cost | Higher initial investment; long-term savings on material and labor. | Lower initial cost; consumables can add up. | Higher operational costs due to water and abrasive materials. |

| Ease of Implementation | Requires skilled operators and setup; integration with CAD/CAM systems. | Easier to set up; less training required. | Moderate complexity; requires proper handling of water and abrasives. |

| Maintenance | Lower maintenance needs; components are durable. | Regular maintenance needed for consumables; more wear on parts. | High maintenance due to water systems and abrasive use. |

| Best Use Case | Ideal for thin sheets, complex shapes, and high-volume production. | Best for thicker materials and faster cutting speeds. | Suitable for thick materials, sensitive applications, and materials that cannot withstand heat. |

Detailed Breakdown of Alternatives

Plasma Cutting: Pros and Cons

Plasma cutting utilizes a high-velocity jet of ionized gas to melt and remove material. It excels in speed, making it suitable for cutting thicker materials, often at a lower initial cost than laser systems. However, plasma cutting tends to produce a rougher edge compared to laser cutting, which may require additional finishing. The operational costs can increase due to the need for consumables like electrodes and nozzles, as well as the energy consumption of the plasma arc.

Waterjet Cutting: Pros and Cons

Waterjet cutting employs a high-pressure jet of water, often mixed with abrasives, to cut through materials. This method is particularly advantageous for its versatility, as it can cut a broad range of materials, including metals, plastics, and ceramics, without introducing heat, thus avoiding warping. However, the setup costs can be significant, and the maintenance of the water system can lead to higher operational expenses. Additionally, while waterjet cutting provides excellent precision, the cutting speed is generally slower compared to laser and plasma methods.

Conclusion: Choosing the Right Metal Cutting Solution

Selecting the appropriate metal cutting technology hinges on understanding specific operational requirements and constraints. For high-precision needs with intricate designs, ‘metal cutting lasers for sale’ are typically the best choice, despite the higher upfront costs. Plasma cutting may be more suitable for businesses prioritizing speed and lower initial investment, particularly when working with thicker materials. Conversely, waterjet cutting stands out for its versatility and ability to handle sensitive materials without thermal distortion. By evaluating these factors, B2B buyers can strategically align their metal cutting solutions with their production goals, ensuring efficiency and cost-effectiveness in their operations.

Essential Technical Properties and Trade Terminology for metal cutting laser for sale

What Are the Key Technical Properties of Metal Cutting Lasers?

When considering the purchase of a metal cutting laser, understanding its technical specifications is crucial for making informed decisions. Here are several critical properties to evaluate:

1. Laser Power Output (Wattage)

The power output of a laser cutter is measured in watts (W) and indicates its cutting capability. Generally, higher wattage allows for cutting thicker materials and achieving faster processing speeds. For example, a fiber laser with a power range from 1000W to 12000W can cut through metals like stainless steel and aluminum with varying thicknesses. B2B buyers should assess their material needs to select a laser cutter that meets their operational demands.

2. Material Compatibility

Metal cutting lasers can work with various materials, including stainless steel, aluminum, brass, and titanium. Understanding the types of materials that a specific laser can cut is essential for industries such as automotive and aerospace, where material specifications are critical. Buyers should ensure the laser cutter can handle the specific grades and thicknesses relevant to their projects.

3. Cutting Tolerance

Cutting tolerance refers to the precision of the cuts made by the laser. A tolerance of ±0.1 mm is common in high-quality laser cutters, which is vital for applications requiring intricate designs or tight-fitting parts. Poor tolerance can lead to increased waste and rework costs, making this an important consideration for B2B buyers focused on quality and efficiency.

4. Speed of Cutting

The cutting speed, often measured in meters per minute (m/min), indicates how quickly the laser can process materials. Faster cutting speeds improve productivity and reduce operational costs, making it a key factor for manufacturers looking to optimize their production lines. Buyers should compare the speed of different models to ensure they meet their production timelines.

5. Cooling System

A robust cooling system is essential for maintaining optimal operating temperatures and prolonging the life of the laser cutter. Options may include water cooling or air cooling systems. Buyers should consider the environment in which the laser will operate and the level of maintenance they are prepared to undertake.

6. Control System

The control system, often based on CNC technology, allows for precise operation of the laser cutter. Advanced control systems can integrate CAD/CAM software, enabling automation and reducing the need for manual intervention. This is particularly beneficial for high-volume production, as it enhances efficiency and accuracy.

What Are Common Trade Terms Related to Metal Cutting Lasers?

Familiarity with industry jargon can significantly enhance communication and negotiation processes. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of metal cutting lasers, buyers may engage with OEMs to source high-quality components or complete machines tailored to specific needs. Understanding OEM relationships can help in assessing product reliability and support.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cost efficiency. Buyers should confirm MOQs to avoid overcommitting to inventory that may not align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. It typically includes specifications for the desired metal cutting laser, allowing suppliers to provide detailed pricing. This process is essential for comparing costs and ensuring that all vendors understand the buyer’s requirements.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping costs, risk, and insurance. Familiarity with these terms is vital for B2B buyers to avoid misunderstandings during the procurement process, especially when dealing with international suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is crucial for planning and inventory management, as delays can disrupt production schedules. B2B buyers should always inquire about lead times to align procurement with operational needs.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions regarding metal cutting lasers, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the metal cutting laser for sale Sector

What Are the Key Trends Shaping the Metal Cutting Laser Market?

The metal cutting laser market is experiencing significant growth driven by several global factors. The increasing demand for precision manufacturing across various industries, including automotive, aerospace, and electronics, is pushing the adoption of advanced laser cutting technologies. As manufacturers seek to enhance productivity and reduce operational costs, fiber laser cutters have gained prominence due to their energy efficiency, speed, and ability to cut a wide range of materials, including reflective metals.

Emerging technologies such as automation, artificial intelligence, and Industry 4.0 are further transforming the landscape. The integration of CNC (Computer Numerical Control) systems with CAD/CAM software allows for more complex and precise cutting operations, making it easier for businesses to tailor their offerings to specific customer needs. Moreover, the trend toward personalized manufacturing and rapid prototyping is driving demand for versatile metal cutting solutions that can accommodate both high-volume production and custom orders.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate diverse market dynamics. Factors such as economic stability, local regulatory environments, and technological readiness vary widely. Buyers should prioritize suppliers that can provide not only quality machinery but also robust support and training to maximize the efficiency of their investments.

How Important Is Sustainability and Ethical Sourcing in Metal Cutting Laser Purchases?

In today’s business environment, sustainability and ethical sourcing are increasingly important to B2B buyers. The environmental impact of manufacturing processes, including metal cutting, has come under scrutiny. Companies are now expected to adopt practices that minimize waste and energy consumption, aligning with global sustainability goals.

Buyers should seek suppliers who prioritize environmentally friendly practices, such as using renewable energy sources and offering machines that consume less power. Certifications like ISO 14001 can serve as indicators of a supplier’s commitment to environmental management. Furthermore, ethical supply chains that ensure fair labor practices and responsible sourcing of materials are becoming non-negotiable for many organizations.

The growing focus on sustainability is also reflected in the materials used in metal cutting lasers. Buyers should consider suppliers that utilize eco-friendly components and promote recycling initiatives. By choosing sustainable options, businesses can not only enhance their corporate social responsibility profile but also meet the increasing consumer demand for environmentally friendly products.

What Is the Historical Context of Metal Cutting Lasers in B2B?

The evolution of metal cutting lasers dates back to the early 1960s, when the first laser cutting machines were introduced. Initially, these systems utilized CO2 lasers, which were suitable for cutting various materials but were limited in speed and efficiency. As technology advanced, fiber lasers emerged in the late 20th century, revolutionizing the industry with their ability to cut reflective metals and deliver higher precision.

Over the years, the adoption of CNC technology has further enhanced the capabilities of laser cutting machines. The integration of automation and smart technologies has streamlined processes, allowing for increased productivity and reduced operational costs. Today, the market is characterized by a wide range of options, from entry-level machines suitable for small businesses to high-end systems designed for large-scale industrial applications.

Understanding this historical context is crucial for B2B buyers, as it highlights the rapid advancements in technology and the importance of investing in modern, efficient solutions that can adapt to evolving market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of metal cutting laser for sale

-

How do I choose the right metal cutting laser for my business needs?

Selecting the right metal cutting laser involves assessing your specific requirements, such as the types of materials you will cut, thickness, and production volume. Consider the laser type—fiber lasers are often preferred for their efficiency and ability to cut reflective materials, while CO2 lasers excel in cutting non-metal materials. Evaluate machine specifications, including wattage and cutting speed, to ensure they align with your operational goals. Additionally, look for features like automation capabilities and software integration for enhanced efficiency. -

What are the key factors to consider when sourcing a metal cutting laser supplier?

When sourcing a supplier, investigate their industry reputation, years of experience, and customer reviews. Ensure they offer comprehensive after-sales support, including installation and training. Verify their compliance with international standards and certifications, which can be indicative of quality and reliability. It’s also beneficial to assess their ability to customize machines according to your specifications and their flexibility in minimum order quantities (MOQ). -

What is the typical lead time for ordering a metal cutting laser?

Lead times can vary significantly based on the supplier’s production capabilities, the complexity of the machine, and your specific requirements. Generally, expect a lead time of 6 to 12 weeks for new machines, while customized models may take longer. It’s advisable to discuss timelines with your supplier upfront and factor in additional time for shipping, especially if importing from overseas. Always confirm production schedules to avoid unexpected delays. -

Are there any special considerations for international shipping of metal cutting lasers?

Yes, international shipping of metal cutting lasers requires careful planning. Ensure compliance with both the exporting and importing countries’ regulations, including tariffs, import duties, and safety standards. It’s crucial to work with a logistics partner experienced in handling industrial machinery to manage customs clearance and proper handling during transit. Additionally, consider insurance options to protect your investment during shipping. -

What payment terms are commonly offered for metal cutting laser purchases?

Payment terms can vary by supplier, but common arrangements include partial payments upfront, followed by the balance upon delivery or installation. Some suppliers may offer financing options or leases, which can be beneficial for managing cash flow. Ensure you clarify payment terms and conditions before finalizing the order, and consider using secure payment methods to mitigate risks. -

How can I ensure the quality of the metal cutting laser before purchase?

To ensure quality, request detailed product specifications and certifications from the supplier. If possible, arrange for a factory visit or a demonstration of the machine in operation. You can also ask for samples of materials cut with the laser to evaluate its performance. Additionally, inquire about the warranty and service agreements, which can provide peace of mind regarding long-term reliability. -

Can I customize my metal cutting laser machine?

Yes, many suppliers offer customization options to meet specific operational needs. Customizations can include adjustments in machine size, power capacity, and software configurations. Discuss your requirements with the supplier early in the negotiation process to understand the possibilities and any potential impacts on pricing and lead times. Custom solutions can enhance efficiency and productivity tailored to your unique applications. -

What industries typically use metal cutting lasers, and how can they benefit my business?

Metal cutting lasers are widely used in industries such as automotive, aerospace, electronics, and metal fabrication. The benefits include high precision cutting, reduced waste, and the ability to work with a variety of materials, including reflective metals. By integrating laser cutting technology, businesses can improve production efficiency, reduce operational costs, and enhance product quality, making it a worthwhile investment for modern manufacturing processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Metal Cutting Laser For Sale Manufacturers & Suppliers List

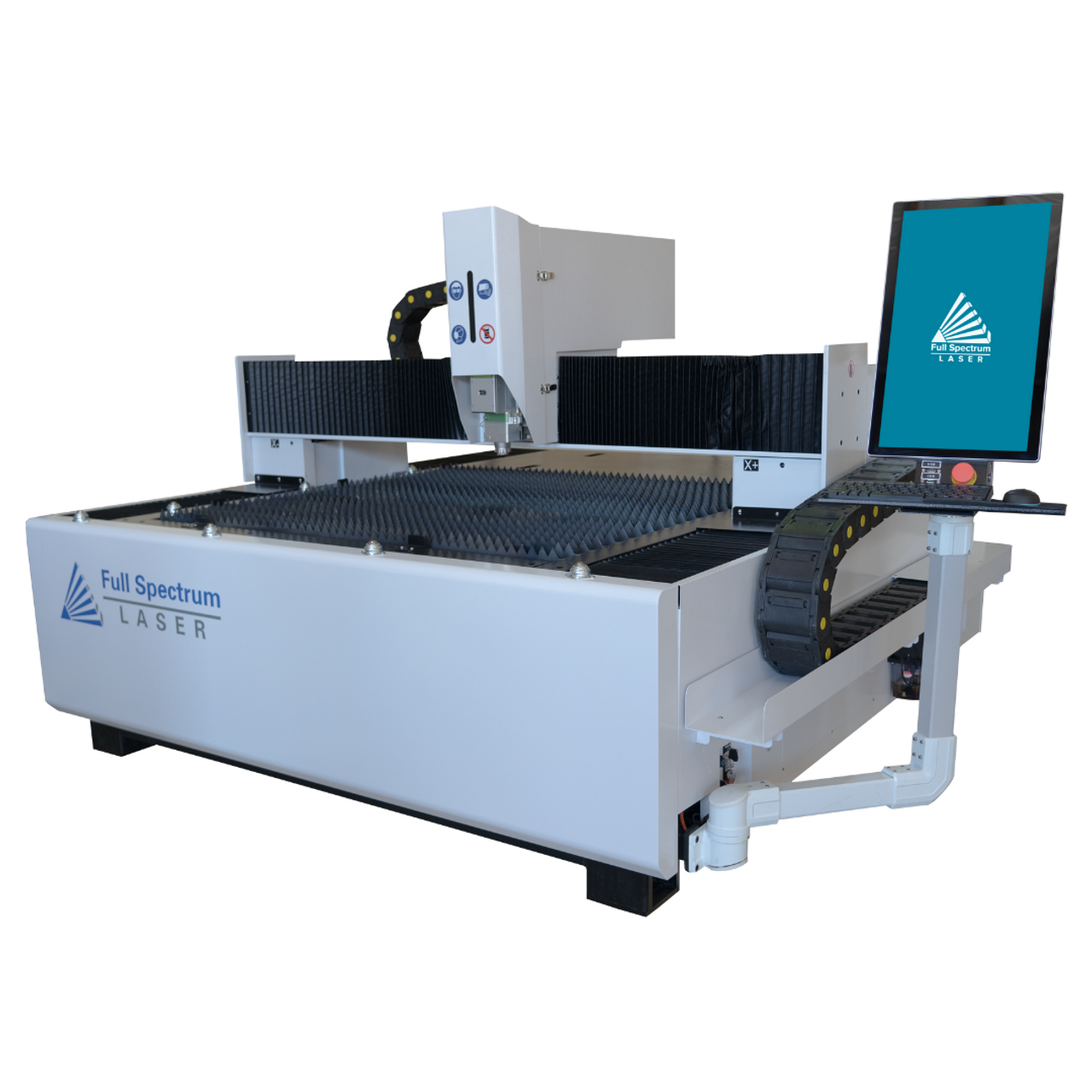

1. Atlas Alloy – Flatbed Metal Cutting Fiber Laser

Domain: fslaser.com

Registered: 2010 (15 years)

Introduction: Atlas Alloy Flatbed Metal Cutting Fiber Laser up to 20kW

– Model Options: 4’x8′ 1000W, 4’x8′ 1500W, 4’x8′ 2000W, 5’x10′ 3000W, 5’x10′ 6000W

– MSRP: $55,000.00

– Cutting Area: 47″ x 95″ (1100 mm x 2400 mm) or 59″ x 118″ (1500 mm x 3000 mm)

– Machine Dimensions: 4’x8′: 173″ x 90″ x 55″ (4.4m x 2.3m x 1.4m); 5’x10′: 197″ x 89″ x 75″ (5010 mm x 2260 mm x 1900 mm)

– Weight: 4’x8′: 6024 lbs (2732 kg); 5…

2. Boss Laser – AccuCut 2kw

Domain: shop.bosslaser.com

Registered: 2012 (13 years)

Introduction: {“products”: [{“name”: “2kw AccuCut”, “price”: “$57,997”, “type”: “CO2 Laser”, “series”: “AccuCut”}, {“name”: “HP-2440”, “sale”: “On Sale!”, “type”: “CO2 Laser”, “series”: “HP-Series”}, {“name”: “LS-Series”, “type”: “CO2 Laser”, “series”: “LS-Series”, “products_count”: 4}, {“name”: “FC-Series”, “type”: “Industrial Fiber Cutter”, “series”: “FC-Series”, “products_count”: 8}, {“name”: “FM-Series”, “t…

3. CNC Laser Cutters – Key Product Details

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: Key Product Details: 1. Types of CNC Laser Cutters: – Gas Laser Cutting – Crystal Laser Cutting – Fiber Laser Cutting 2. Brands: – AMADA (8) – MITSUBISHI (5) – MAZAK (4) – TRUMPF (4) – BYSTRONIC (3) – AP LAZER (2) – BOSS LASER (2) – LASERPRO (2) – LVD STRIPPIT (2) – TROTEC (2) – BODOR (1) – CINCINNATI (1) – COHERENT (1) – HK LASER & SYSTEMS (1) – HYPERUSA (1) – IPG PHOTONICS (1) – NUKON (1) – ROBO…

4. Kern – Metal Cutting Laser System

Domain: kernlasers.com

Registered: 1998 (27 years)

Introduction: Kern’s metal cutting laser system allows for accurate cutting of sheet metal including stainless steel, mild steel, aluminum, copper, and brass. Key features include: 1. Automatic Focusing Height Follower for optimal cutting; 2. Cutting nozzle controlled by a capacitance sensor and z-axis motor; 3. Protective cover lens (K-Lens for CO2, F-Lens for fiber) to protect focusing lenses; 4. Durable stee…

5. StyleCNC – Metal Laser Cutting Machine

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: A metal laser cutting machine is an industrial equipment that uses high-energy CO2/fiber laser beams to accurately cut metal materials into various shapes and contours. It operates as a high-speed computer numerical controlled (CNC) system, utilizing CAM software to guide the laser for 2D/3D cuts in materials such as stainless steel, galvanized steel, carbon steel, mild steel, cold & hot rolled st…

Strategic Sourcing Conclusion and Outlook for metal cutting laser for sale

In navigating the dynamic landscape of metal cutting lasers, strategic sourcing emerges as a critical factor for success. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must consider the diverse range of laser technologies available, including fiber, gas, and crystal lasers. Each type offers unique advantages in precision, efficiency, and cost-effectiveness, allowing businesses to tailor their investments to specific operational needs.

A key takeaway is the importance of evaluating suppliers based on technological advancements, service support, and total cost of ownership. This approach not only ensures the acquisition of high-quality equipment but also fosters long-term partnerships that enhance operational capabilities. As the demand for laser cutting technology continues to rise, driven by trends such as automation and customization, companies that prioritize strategic sourcing will be well-positioned to capitalize on these opportunities.

Looking ahead, the metal cutting laser market is poised for significant growth, with advancements in technology promising even greater efficiency and affordability. International buyers should act now to explore options, engage with reputable suppliers, and invest in the right technology to ensure they remain competitive in their respective industries.