Introduction: Navigating the Global Market for metal cut design

Navigating the complexities of sourcing metal cut design services can present a significant challenge for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. With the increasing demand for precision-engineered components in industries like automotive, aerospace, and manufacturing, understanding the nuances of metal cut design—from material selection to fabrication techniques—is critical. This guide aims to illuminate the multifaceted landscape of metal cut design, addressing key considerations such as supplier vetting, cost structures, and various application scenarios.

Within these pages, you will find comprehensive insights into different types of metal cutting techniques, including laser cutting, waterjet cutting, and CNC machining. Each method comes with its own set of advantages and limitations, making it essential for buyers to choose wisely based on their project requirements. Additionally, we delve into best practices for evaluating potential suppliers, ensuring quality assurance, and negotiating pricing structures that align with your budget.

By empowering B2B buyers with actionable knowledge and industry-specific strategies, this guide serves as a valuable resource for informed purchasing decisions. Whether you are based in Brazil or Saudi Arabia, understanding the global market for metal cut design will enable you to leverage competitive advantages and streamline your procurement processes effectively.

Understanding metal cut design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laser Cutting | High precision, clean edges, and minimal material waste. | Aerospace, automotive, and electronics. | Pros: Excellent detail and complexity; Cons: Higher initial costs. |

| Waterjet Cutting | Uses high-pressure water mixed with abrasives for cutting. | Architecture, art, and thick materials. | Pros: No heat-affected zone; Cons: Slower than laser cutting. |

| CNC Routing | Computer-controlled cutting for various materials. | Furniture, signage, and prototypes. | Pros: Versatile for multiple materials; Cons: Limited to sheet sizes. |

| Plasma Cutting | Uses plasma to cut through electrically conductive materials. | Heavy manufacturing and metal fabrication. | Pros: Fast for thick metals; Cons: Rough edges requiring additional finishing. |

| Shearing | Straight-line cutting method for sheets and plates. | Metal fabrication and construction. | Pros: Cost-effective for large volumes; Cons: Limited to simple shapes. |

What Are the Characteristics of Laser Cutting and Its Suitability for B2B Buyers?

Laser cutting is a highly precise method that utilizes focused laser beams to cut materials, resulting in clean edges and minimal kerf. This technique is particularly suitable for intricate designs and thin materials, making it ideal for industries such as aerospace and electronics. B2B buyers should consider the initial investment, as while laser cutting can be more expensive upfront, the quality and precision can lead to reduced waste and lower overall costs in the long run.

How Does Waterjet Cutting Differ from Other Methods and What Are Its Key Applications?

Waterjet cutting employs a high-pressure stream of water, often mixed with abrasives, to cut through a variety of materials, including metals and stone. This method is unique as it does not introduce heat, preventing warping or thermal damage. It is well-suited for architectural designs and artistic applications where detail is paramount. Buyers should weigh the slower cutting speed against the benefit of preserving material integrity, especially for sensitive projects.

What Are the Key Features of CNC Routing and Its Ideal Use Cases?

CNC routing involves a computer-controlled router that can cut, engrave, or shape materials, making it highly versatile. It is commonly used for wood, plastics, and softer metals, ideal for applications in furniture manufacturing and signage. B2B buyers should consider the limitations of material thickness and sheet size, but appreciate the flexibility it offers for prototyping and custom designs.

Why is Plasma Cutting a Preferred Choice for Heavy Manufacturing?

Plasma cutting is favored in heavy manufacturing due to its speed and ability to cut through thick conductive materials like steel and aluminum. This method uses an ionized gas to create a plasma arc, enabling rapid cuts. B2B buyers should be aware that while plasma cutting is efficient, it often results in rougher edges that may require additional finishing processes, impacting overall project timelines and budgets.

What Benefits and Limitations Should Buyers Consider When Using Shearing?

Shearing is a straightforward cutting method that slices through sheet metal in straight lines, making it cost-effective for high-volume production. It is widely used in metal fabrication and construction projects. However, its simplicity means it is limited to basic shapes and cannot accommodate intricate designs. B2B buyers should evaluate their specific needs for complexity versus cost-effectiveness when considering shearing as an option.

Key Industrial Applications of metal cut design

| Industry/Sector | Specific Application of metal cut design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom brackets and mounts for vehicle assembly | Enhanced efficiency in assembly processes | Need for precision, rapid prototyping, and material quality |

| Aerospace | Structural components for aircraft | Lightweight and durable parts that meet strict regulations | Compliance with aerospace standards and certifications |

| Construction | Fabricated metal parts for building frameworks | Cost-effective solutions for large-scale projects | Local sourcing to reduce shipping costs and lead times |

| Electronics | Enclosures and chassis for electronic devices | Improved product durability and aesthetic appeal | Consideration of thermal management and electromagnetic interference |

| Renewable Energy | Components for wind turbines and solar panels | Support for sustainable practices and energy efficiency | Material selection for corrosion resistance and durability |

How is Metal Cut Design Used in the Automotive Industry?

In the automotive sector, metal cut design plays a crucial role in creating custom brackets and mounts that facilitate vehicle assembly. These components must be lightweight yet robust, ensuring that they contribute to overall vehicle performance without compromising safety. Buyers in this industry often seek rapid prototyping capabilities to iterate designs quickly. Additionally, precision is paramount, as even minor deviations can lead to assembly issues, impacting production timelines and costs.

What Role Does Metal Cut Design Play in Aerospace Applications?

Aerospace applications require metal cut design for the fabrication of structural components that must adhere to stringent safety and performance standards. These parts often need to be lightweight, which is critical for fuel efficiency, while also maintaining exceptional strength. International buyers must consider suppliers that possess the necessary certifications and quality assurance processes, as compliance with regulations like AS9100 is essential for aerospace manufacturing.

How is Metal Cut Design Utilized in the Construction Industry?

In construction, metal cut design is vital for fabricating metal parts used in building frameworks, such as beams, columns, and supports. This application allows construction firms to achieve cost-effective solutions for large-scale projects, significantly reducing lead times and labor costs. Buyers should prioritize local sourcing to minimize shipping expenses and ensure timely delivery, especially in regions with developing infrastructure, such as parts of Africa and South America.

What Benefits Does Metal Cut Design Offer Electronics Manufacturers?

For electronics manufacturers, metal cut design is essential for producing enclosures and chassis that protect sensitive components. These parts not only need to be durable but also must address thermal management and electromagnetic interference. International buyers should seek suppliers who offer materials with specific properties tailored to their device requirements, ensuring that the final products meet performance standards while maintaining aesthetic appeal.

How Does Metal Cut Design Contribute to Renewable Energy Projects?

In the renewable energy sector, metal cut design is employed to create components for wind turbines and solar panels, supporting sustainable energy solutions. These components must be designed for durability and corrosion resistance, given the environmental challenges they face. Buyers should focus on sourcing materials that align with their sustainability goals while ensuring that the manufacturing processes are efficient and environmentally friendly, which is increasingly important in markets across Europe and the Middle East.

3 Common User Pain Points for ‘metal cut design’ & Their Solutions

Scenario 1: Long Lead Times for Custom Metal Parts

The Problem: One of the most common frustrations for B2B buyers in the metal cut design industry is dealing with long lead times. When companies require custom metal parts for production, delays can lead to missed deadlines and increased costs. For instance, a manufacturer in Brazil may need specific metal components for machinery but faces a six-week wait due to their supplier’s production backlog. This not only hampers operational efficiency but can also jeopardize client relationships and project timelines.

The Solution: To mitigate long lead times, B2B buyers should prioritize suppliers that offer instant pricing and rapid turnaround times. By utilizing platforms that allow for the uploading of CAD files (such as DXF or STEP formats), companies can receive immediate quotes and production timelines. Additionally, opting for suppliers that maintain a wide range of materials in stock can expedite the order process. For example, choosing a service that promises standard production in 2-4 days, like SendCutSend, can significantly reduce wait times. Establishing a relationship with such suppliers and regularly communicating project needs can further streamline the ordering process.

Scenario 2: Inaccurate Specifications Leading to Errors

The Problem: Inaccurate specifications can lead to costly errors in metal cut designs. A company in Saudi Arabia may submit a design with unclear dimensions or improper tolerances, resulting in parts that don’t fit or function correctly. This not only wastes resources but also requires additional time and money to rectify the mistakes, which can be particularly damaging in a competitive market.

The Solution: To avoid specification errors, it is essential for buyers to leverage Design for Manufacturing (DFM) feedback tools offered by many modern metal cutting services. These tools provide instant feedback on design issues, helping to identify potential problems before production begins. For instance, platforms like OSH Cut offer comprehensive DFM analysis that highlights critical issues such as flange support and press brake collisions. Buyers should also conduct thorough reviews of their designs with engineers or utilize 3D modeling software to visualize components before submission. Establishing a checklist that includes all necessary specifications and tolerances can further enhance accuracy and minimize mistakes.

Scenario 3: Limited Material Options and Customization

The Problem: B2B buyers often face challenges with limited material options and insufficient customization capabilities. For instance, a manufacturer in Europe may require specialized materials for a project but find that their local supplier only offers standard steel and aluminum options. This limitation can restrict innovation and lead to suboptimal product performance.

The Solution: To overcome material limitations, buyers should seek out suppliers that offer a diverse range of materials and customization options. Suppliers with extensive inventories, such as those that stock various alloys, plastics, and composites, can provide the necessary flexibility to meet unique project demands. It is also beneficial to inquire about bespoke services, such as specific finishing processes or custom dimensions. Establishing partnerships with manufacturers that use advanced cutting technologies, like laser or waterjet cutting, can further enhance customization capabilities. Regularly reviewing and updating project requirements with suppliers can ensure that material selections align with both performance needs and budget constraints, fostering a more innovative approach to metal cut design.

Strategic Material Selection Guide for metal cut design

When selecting materials for metal cut design, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. This guide examines four common materials—carbon steel, stainless steel, aluminum, and brass—highlighting their suitability for various applications, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Carbon Steel for Metal Cut Design?

Carbon steel is renowned for its strength and versatility. It typically exhibits excellent tensile strength and hardness, making it suitable for structural applications. However, it has moderate corrosion resistance, which can be a limitation in certain environments. Carbon steel is often used in construction, automotive, and manufacturing sectors due to its ability to withstand high stress and pressure.

Pros: It is cost-effective and widely available, making it an attractive option for bulk orders. Its high strength-to-weight ratio allows for lightweight designs without compromising durability.

Cons: The primary drawback is its susceptibility to rust if not properly treated or coated. Additionally, the manufacturing complexity increases with the need for additional finishing processes to enhance corrosion resistance.

Impact on Application: Carbon steel is compatible with various media, but its use in corrosive environments requires protective coatings. International buyers should be aware of compliance with standards such as ASTM A36 for structural steel.

How Does Stainless Steel Compare in Terms of Performance and Application?

Stainless steel is celebrated for its corrosion resistance, making it ideal for applications exposed to moisture or chemicals. It also maintains structural integrity at high temperatures, which is vital for industries like food processing and pharmaceuticals.

Pros: Its durability and aesthetic appeal make it suitable for both functional and decorative applications. Stainless steel also requires minimal maintenance, contributing to lower long-term costs.

Cons: The initial cost is higher compared to carbon steel, which may deter some buyers. Additionally, its machining can be more complex, requiring specialized tools and techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including food and pharmaceuticals. International buyers should consider compliance with standards such as ASTM A240 for stainless steel sheets.

What Are the Advantages of Using Aluminum in Metal Cut Design?

Aluminum is lightweight yet strong, offering excellent corrosion resistance. It is highly malleable, making it suitable for intricate designs and applications in aerospace, automotive, and consumer products.

Pros: The low weight of aluminum can lead to reduced shipping costs and improved energy efficiency in applications like transportation. Its recyclability also appeals to environmentally conscious buyers.

Cons: Aluminum is generally more expensive than carbon steel and can be less durable under high-stress conditions. It may require additional treatments to enhance strength and wear resistance.

Impact on Application: Aluminum is compatible with various media, including water and chemicals. Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions.

Why Is Brass a Suitable Choice for Specific Applications?

Brass, an alloy of copper and zinc, is known for its excellent machinability and corrosion resistance. It is often used in applications requiring electrical conductivity, such as electrical connectors and plumbing fittings.

Pros: Brass has a pleasing appearance and is resistant to tarnishing, making it ideal for decorative applications. Its antimicrobial properties also make it suitable for medical applications.

Cons: The cost of brass can be significantly higher than that of carbon steel, and it may not be suitable for high-stress applications due to lower tensile strength.

Impact on Application: Brass is compatible with water and various chemicals but should be avoided in environments with high chloride levels. International buyers should consider compliance with standards such as ASTM B36 for brass sheet and plate.

Summary Table of Material Selection for Metal Cut Design

| Material | Typical Use Case for metal cut design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components in construction | Cost-effective and strong | Susceptible to rust | Low |

| Stainless Steel | Food processing and pharmaceuticals | Corrosion resistant and durable | Higher initial cost | High |

| Aluminum | Aerospace and automotive applications | Lightweight and recyclable | More expensive and less durable | Med |

| Brass | Electrical connectors and plumbing | Excellent machinability and appeal | Higher cost and lower strength | High |

This guide provides B2B buyers with essential insights into material selection for metal cut design, ensuring informed decisions that align with their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal cut design

What Are the Main Stages of Manufacturing Processes in Metal Cut Design?

The manufacturing process for metal cut design typically encompasses several key stages: material preparation, forming, assembly, and finishing. Each of these stages is critical in ensuring that the final product meets the required specifications and quality standards.

How Is Material Prepared for Metal Cutting?

Material preparation is the first stage in the manufacturing process. It involves selecting the appropriate metal type based on the application, whether it’s carbon steel, stainless steel, aluminum, or other alloys. Once the material is chosen, it is cut to size, deburred, and inspected for defects. This stage may also include pre-treatment processes such as cleaning or surface treatments to enhance adhesion for subsequent finishing processes.

What Forming Techniques Are Commonly Used?

Forming is the next stage, where the prepared metal undergoes various processes such as laser cutting, waterjet cutting, or CNC routing. These techniques allow for precise cuts and intricate designs, which are essential for applications ranging from automotive parts to decorative elements. Laser cutting is particularly favored for its speed and accuracy, while waterjet cutting is utilized for thicker materials or more complex geometries that require a non-thermal cutting process.

After cutting, the parts may undergo additional forming processes like bending or punching, depending on the design requirements. The integration of automated machinery in this stage enhances efficiency and reduces human error.

How Is Assembly Managed in Metal Fabrication?

The assembly stage involves joining different components together to form the final product. This can include welding, riveting, or using fasteners depending on the application and design. Quality assurance is critical during this stage to ensure that the assembled parts meet structural integrity and functionality requirements. For instance, in industries such as aerospace and automotive, even minor defects can lead to significant safety issues.

What Quality Assurance Measures Are Implemented in Metal Cut Design?

Quality assurance is a vital component of the manufacturing process, ensuring that the final product adheres to both international and industry-specific standards. Common quality standards include ISO 9001:2015, which emphasizes a quality management system, and CE marking, which signifies compliance with European safety standards.

How Are International Quality Standards Applied?

In metal cut design, compliance with ISO 9001 ensures that suppliers maintain consistent quality in their processes. This involves a systematic approach to managing quality through documentation, process control, and continuous improvement. For international B2B buyers, understanding these standards can provide assurance of a supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints typically include:

- Incoming Quality Control (IQC): This is the initial inspection of raw materials to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this involves monitoring and testing to catch defects early. Techniques such as visual inspections and measurements are commonly employed.

- Final Quality Control (FQC): At this stage, finished products undergo thorough inspections and testing to verify they meet the required specifications before shipment.

These checkpoints help mitigate risks and enhance product reliability.

What Testing Methods Are Commonly Used in Metal Fabrication?

Common testing methods include non-destructive testing (NDT) techniques like ultrasonic testing, magnetic particle testing, and dye penetrant testing. These methods allow for the detection of internal and surface flaws without damaging the parts. Other testing methods may include tensile strength tests, hardness tests, and dimensional checks to ensure that the products meet design specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify a supplier’s quality control processes:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing practices and quality control measures. This direct engagement allows buyers to assess compliance with international standards and evaluate the overall production environment.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history, including metrics on defect rates and customer complaints.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes and product integrity. This is especially important for buyers in regions with specific regulatory requirements.

What Are the Nuances of Quality Control for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding local regulations and compliance requirements is crucial. Each region may have different standards, and suppliers should be able to demonstrate their ability to meet these varying requirements.

Additionally, language barriers and cultural differences can impact communication and quality expectations. Establishing clear lines of communication and utilizing technology for real-time updates can help mitigate these challenges.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures in metal cut design is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and robust quality control measures, buyers can ensure they are partnering with reliable suppliers that uphold high standards. This approach not only enhances product quality but also fosters long-term business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal cut design’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure metal cut design services. As a critical component in various industries, understanding the nuances of sourcing metal cut design can significantly impact your production efficiency, cost, and overall project success. This guide outlines essential steps to ensure a smooth procurement process.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements of your metal cut design project. This includes dimensions, tolerances, material types, and specific finishing processes needed. Having precise specifications minimizes misunderstandings and ensures that suppliers can provide accurate quotes and timelines.

- Considerations:

- Specify the material (e.g., steel, aluminum) and its grade for optimal performance.

- Include tolerances to ensure parts fit seamlessly into your final product.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in metal cut design. Look for companies with a strong reputation and experience in your industry. Supplier reliability can directly affect your production timelines and quality.

- Action Items:

- Search for online reviews and testimonials from previous clients.

- Utilize platforms like LinkedIn to gauge their industry presence.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and quality standards. Look for ISO certifications or specific industry-related qualifications that demonstrate adherence to quality and safety standards. This step is vital for ensuring that the supplier meets your quality expectations.

- Key Certifications:

- ISO 9001:2015 for quality management systems.

- Industry-specific certifications relevant to your project.

Step 4: Request Detailed Quotes

Once you’ve shortlisted potential suppliers, request detailed quotes that outline pricing, lead times, and terms. A well-structured quote should include all costs associated with the project, allowing you to compare suppliers effectively.

- What to Look For:

- Breakdown of costs, including material, labor, and any additional services.

- Estimated lead times for production and delivery.

Step 5: Assess Production Capabilities

Evaluate the production capabilities of each supplier to ensure they can meet your project’s scale and complexity. This includes their machinery, technology, and workforce expertise. Understanding their capabilities will help you assess if they can handle your specific requirements.

- Considerations:

- Inquire about the types of cutting methods used (e.g., laser, waterjet).

- Ensure they can accommodate any special requirements, such as complex geometries.

Step 6: Check for Post-Processing Services

Post-processing can significantly affect the final product’s quality and functionality. Confirm whether the supplier offers additional services such as bending, plating, or powder coating. These services can save you time and ensure a single-source solution for your project.

- Benefits:

- Streamlined logistics by working with one supplier for multiple processes.

- Enhanced quality control by maintaining consistency throughout production.

Step 7: Establish Clear Communication Channels

Finally, establish effective communication channels with your chosen supplier. Open lines of communication can help address any issues quickly and facilitate smoother collaboration throughout the project lifecycle.

- Tips for Effective Communication:

- Set regular check-ins during the project to discuss progress and any potential adjustments.

- Utilize project management tools to keep track of timelines and deliverables.

By following this checklist, B2B buyers can navigate the complexities of sourcing metal cut design services with confidence, ultimately leading to successful project outcomes.

Comprehensive Cost and Pricing Analysis for metal cut design Sourcing

What Are the Key Cost Components in Metal Cut Design Sourcing?

When sourcing metal cut designs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of material significantly impacts pricing. Common options include various grades of steel, aluminum, and composite materials, each with differing costs. For instance, while cold-rolled steel may be priced lower than aluminum, the latter often provides superior durability for specific applications.

-

Labor: Labor costs vary based on the complexity of the cutting process and the skill level required. Automated systems can reduce labor costs, but high-precision jobs may still necessitate skilled workers, thereby increasing overall expenses.

-

Manufacturing Overhead: This encompasses the costs of facilities, utilities, and equipment maintenance. Efficient operations can help minimize these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: Tooling costs relate to the creation and maintenance of the dies and fixtures used in the cutting process. High-quality tooling can lead to better precision and reduced scrap rates, ultimately influencing the final price.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the final products meet specifications and standards, which can incur additional costs. However, these costs often pay off by reducing rework and enhancing customer satisfaction.

-

Logistics: Shipping and handling costs can add a significant layer to the total cost, especially for international transactions. Factors such as distance, shipping method, and handling requirements can influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. This margin can vary widely based on the supplier’s business model and market competition.

How Do Price Influencers Affect Metal Cut Design Costs?

Several factors can influence the pricing of metal cut designs, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts. Suppliers may offer lower per-unit costs for larger quantities, allowing buyers to achieve economies of scale.

-

Specifications and Customization: Custom designs or specific tolerances can lead to higher costs. Buyers should provide detailed specifications to avoid unexpected price hikes.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, ASTM) can increase costs. However, they often provide assurance of quality and durability, which may justify the higher price.

-

Supplier Factors: The supplier’s operational efficiency, reputation, and location can affect pricing. Suppliers with advanced technologies and efficient processes may offer better rates.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can impact shipping costs and responsibilities. Understanding these terms is essential for managing logistics expenses effectively.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers can enhance their cost-efficiency through strategic negotiation and planning:

-

Conduct Thorough Market Research: Familiarize yourself with market prices and supplier capabilities. Understanding the landscape enables you to negotiate more effectively.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ thresholds. This can result in significant savings.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial costs but also maintenance, logistics, and potential rework expenses. A lower upfront cost may not always equate to better value.

-

Build Long-Term Relationships: Establishing a rapport with suppliers can lead to preferential pricing, improved service, and flexibility in negotiations.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when assessing quotes.

Conclusion

While indicative prices can provide a baseline, international B2B buyers should approach metal cut design sourcing with a comprehensive understanding of the cost structure and influencing factors. By leveraging effective negotiation strategies and focusing on the total cost of ownership, businesses can secure favorable pricing and maintain a competitive edge in their respective markets.

Alternatives Analysis: Comparing metal cut design With Other Solutions

Introduction to Alternative Solutions in Metal Cutting

When evaluating manufacturing processes for metal parts, it’s essential to consider various methods that can achieve similar outcomes to metal cut design. This analysis will compare metal cut design against laser cutting and CNC machining—two popular alternatives in the industry. Each method offers unique benefits and challenges, making them suitable for different applications depending on the specific needs of the buyer.

Comparison Table

| Comparison Aspect | Metal Cut Design | Laser Cutting | CNC Machining |

|---|---|---|---|

| Performance | High precision and speed | Excellent for intricate designs | Versatile for complex shapes |

| Cost | Moderate cost for custom parts | Generally lower for high volume | Higher initial setup costs |

| Ease of Implementation | User-friendly design interface | Requires CAD files, some complexity | More complex setup and programming |

| Maintenance | Low, minimal upkeep | Medium, requires regular maintenance | High, frequent calibration needed |

| Best Use Case | Custom parts in low to medium volume | Prototyping and intricate designs | High-precision parts in large volumes |

Detailed Breakdown of Alternatives

Laser Cutting

Laser cutting is a process that uses focused light to cut through materials, making it an excellent choice for intricate designs. One of the main advantages is its speed and ability to produce clean cuts with high precision, which is ideal for prototyping. Additionally, laser cutting can handle various materials, including metals and plastics. However, it typically requires CAD files for operation, which can complicate the implementation process for companies without in-house design capabilities. Cost-wise, laser cutting can be more economical for high-volume orders but may not be as competitive for low-volume custom parts.

CNC Machining

CNC machining employs computer-controlled cutting tools to create parts from solid blocks of material. This method is highly versatile and can produce complex shapes with tight tolerances, making it suitable for applications in industries such as aerospace and automotive. However, CNC machining has a higher initial setup cost and requires skilled operators to program the machinery effectively. Maintenance is also a significant consideration, as CNC machines need regular calibration to ensure precision. Despite these challenges, the ability to produce high-precision parts in large quantities makes CNC machining a preferred choice for mass production.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the decision between metal cut design, laser cutting, and CNC machining should be guided by specific project requirements, including volume, complexity, and cost considerations. If your needs revolve around custom parts with moderate quantities and a straightforward design process, metal cut design may be the best fit. Conversely, for intricate designs or high-volume production, laser cutting or CNC machining could be more advantageous. Ultimately, understanding the strengths and limitations of each method will empower buyers to make informed choices that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for metal cut design

What Are the Key Technical Properties for Metal Cut Design?

Understanding the essential technical properties of metal cut design is crucial for B2B buyers involved in manufacturing and engineering processes. Here are some critical specifications:

1. Material Grade

Material grade indicates the quality and type of metal used in production. Common grades include stainless steel (e.g., 304, 316), aluminum (e.g., 6061, 7075), and carbon steel. The choice of material affects durability, corrosion resistance, and overall performance. For international buyers, selecting the right grade can ensure compliance with regional standards and improve product longevity.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a part. It is vital for ensuring that components fit together correctly in assemblies. In industries such as aerospace or automotive, where precision is paramount, tight tolerances are essential to maintain functionality and safety. Buyers should communicate their tolerance requirements clearly to avoid costly rework or delays.

3. Thickness

The thickness of the metal sheet impacts both strength and weight. Thicker materials may provide increased durability but can be more challenging to cut and form. Understanding the required thickness helps in selecting the appropriate cutting method and machinery, which can optimize production costs and lead times.

4. Surface Finish

Surface finish describes the texture and quality of the metal’s surface after machining. Options range from raw cuts to polished or coated finishes (e.g., anodizing, powder coating). The desired finish can influence not only aesthetics but also corrosion resistance and adhesion properties in subsequent processes. Buyers should specify surface finish requirements to align with their product standards.

5. Mechanical Properties

Mechanical properties include tensile strength, yield strength, and ductility. These properties determine how the material behaves under stress and strain. For applications that require high strength and flexibility, understanding these properties is essential for selecting the right material and ensuring product reliability.

6. Heat Treatment

Heat treatment processes alter the physical and sometimes chemical properties of a material, enhancing characteristics such as hardness and strength. Common methods include annealing and quenching. Buyers should be aware of how heat treatment can impact the final product’s performance and lifecycle.

What Are Common Trade Terms in Metal Cut Design?

Navigating the metal cut design industry also requires familiarity with key trade terminology. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source components for assembly in larger systems. This term often denotes quality assurance and industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it impacts inventory levels and cash flow. Being aware of MOQs can help in planning procurement strategies, especially for startups or small businesses.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. It is an essential tool for B2B buyers to obtain competitive pricing and ensure that all suppliers are evaluated on the same criteria. Providing detailed specifications in an RFQ can lead to better quotes and faster turnaround times.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. They dictate who is responsible for shipping, insurance, and tariffs. Understanding Incoterms can help buyers mitigate risks and avoid unexpected costs during international transactions.

5. DFM (Design for Manufacturing)

DFM refers to the practice of designing products to optimize their manufacturability. By considering manufacturing processes early in the design phase, companies can reduce costs and improve efficiency. Incorporating DFM principles can lead to faster production cycles and higher-quality outcomes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions in the metal cut design industry, enhancing their procurement processes and product quality.

Navigating Market Dynamics and Sourcing Trends in the metal cut design Sector

What Are the Current Market Dynamics and Key Trends in Metal Cut Design?

The global metal cut design market is experiencing a transformative phase, driven by several factors that influence B2B purchasing decisions. Key drivers include technological advancements in manufacturing processes such as laser cutting, CNC machining, and waterjet cutting, which significantly enhance precision and reduce lead times. These innovations allow companies to produce custom parts quickly and efficiently, catering to the growing demand for bespoke solutions from industries such as automotive, aerospace, and construction.

Emerging trends indicate a shift towards digital manufacturing platforms that provide instant pricing and rapid prototyping capabilities. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly leveraging online services that allow for the upload of design files, instant quotes, and streamlined ordering processes. This trend not only enhances the speed of production but also reduces costs associated with traditional sourcing methods, making it easier for companies to iterate on designs and meet market demands.

Moreover, the focus on supply chain transparency is intensifying. B2B buyers are looking for suppliers who can provide traceable certifications and quality guarantees, ensuring that the materials used meet industry standards. This is especially pertinent for regions with stringent regulatory requirements, making it essential for suppliers to adapt to these market dynamics to remain competitive.

How Is Sustainability and Ethical Sourcing Impacting Metal Cut Design?

Sustainability is becoming a critical consideration in the metal cut design sector, as environmental concerns gain prominence among B2B buyers. The manufacturing process of metal components can have significant environmental impacts, including high energy consumption and waste generation. As such, there is an increasing demand for suppliers who implement sustainable practices and utilize eco-friendly materials.

Ethical sourcing is also paramount. Companies are seeking suppliers who prioritize responsible sourcing of metals, including those with certifications like ISO 14001, which signifies a commitment to environmental management. The use of recycled materials is gaining traction, as it not only reduces the carbon footprint but also appeals to environmentally conscious buyers.

Furthermore, the integration of ‘green’ certifications into supply chains is becoming a selling point for many suppliers. Buyers are increasingly interested in knowing the lifecycle of the materials they procure, which includes the extraction, processing, and disposal phases. This heightened awareness compels suppliers to adopt more sustainable practices, ensuring that their offerings align with the values of their clients.

How Has the Metal Cut Design Sector Evolved Over Time?

The evolution of the metal cut design sector has been marked by significant advancements in technology and shifts in market demand. Historically, metal fabrication relied heavily on manual processes, which were time-consuming and limited in precision. However, the advent of computer-aided design (CAD) and automated cutting technologies revolutionized the industry, allowing for greater accuracy and efficiency.

As industries evolved, so did the needs of B2B buyers. The demand for customization and rapid prototyping led to the rise of digital manufacturing platforms, enabling companies to obtain tailored solutions without the delays associated with traditional manufacturing. Today, the focus on sustainability and ethical sourcing reflects a broader societal shift towards responsible business practices, underscoring the ongoing transformation within the sector.

In conclusion, understanding these market dynamics and trends is essential for international B2B buyers looking to navigate the complexities of the metal cut design landscape effectively. By prioritizing technology, sustainability, and ethical sourcing, businesses can position themselves for success in an increasingly competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of metal cut design

-

How do I choose the right supplier for metal cut design?

Choosing the right supplier involves several key factors. First, evaluate their experience in the industry and the materials they specialize in. Check for certifications like ISO 9001 to ensure quality management. Review customer testimonials and case studies to gauge their reliability and service quality. Additionally, consider their ability to accommodate your specific design needs, including customization options and turnaround times. Finally, ensure they have transparent pricing structures to avoid unexpected costs. -

What are the typical lead times for metal cut design services?

Lead times can vary significantly based on the supplier, complexity of the design, and the materials used. Generally, most suppliers offer standard lead times ranging from 2 to 4 days for simple laser-cut parts. However, for more complex designs or additional services like bending or anodizing, lead times may extend to 1-2 weeks. It’s crucial to communicate your project deadlines upfront and confirm the supplier’s ability to meet them. -

What is the minimum order quantity (MOQ) for metal cut design?

Minimum order quantities can differ among suppliers and depend on the material and complexity of the design. Some suppliers offer no minimum order requirements, allowing you to order a single prototype. Others may require MOQs ranging from 10 to 100 pieces for bulk pricing benefits. It’s essential to clarify these terms during your initial discussions to align with your production needs. -

How do I ensure quality control in metal cut design?

Ensuring quality control involves several steps. First, establish clear specifications and tolerances for your designs. Request samples or prototypes to assess the supplier’s capabilities before placing a larger order. Many suppliers provide DFM (Design for Manufacturing) feedback, helping identify potential issues early in the process. Additionally, inquire about their quality assurance processes, including traceable mill certifications and inspections throughout production. -

What payment terms should I expect when ordering metal cut designs?

Payment terms can vary widely among suppliers. Typically, you may encounter options such as upfront payments, net 30 or 60-day terms, or payment upon delivery. International buyers should also consider currency fluctuations and potential fees associated with cross-border transactions. Always clarify payment methods accepted (credit card, bank transfer, etc.) and negotiate terms that align with your cash flow and project timelines. -

How can I customize my metal cut designs?

Customization options are often extensive, ranging from material choice to additional processing services like bending, powder coating, or hardware insertion. Most suppliers allow you to upload design files in various formats (e.g., DXF, STEP) and provide instant pricing based on your specifications. If you lack CAD designs, many suppliers offer templates or can work from sketches. Discuss your unique requirements with the supplier to explore all available options. -

What should I consider regarding logistics for international shipping?

When sourcing metal cut designs internationally, consider shipping methods, costs, and delivery times. Confirm whether the supplier has experience in exporting to your region and can handle customs documentation. Evaluate shipping options like express versus standard delivery to meet your timeline. Additionally, be aware of potential tariffs or duties that may apply to imported goods, which can affect your overall budget. -

How can I verify the supplier’s reliability before placing a large order?

To verify a supplier’s reliability, start by conducting thorough research, including checking online reviews and ratings. Request references from other clients, particularly those in your industry or region. Engaging in a small initial order or prototype can also provide insights into their service quality and adherence to specifications. Furthermore, ensure they have a transparent communication process and are responsive to your inquiries, as this is indicative of their commitment to customer service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Metal Cut Design Manufacturers & Suppliers List

1. SendCutSend – Custom Sheet Metal Fabrication Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom sheet metal parts with no minimum quantities and free US shipping on orders over $39. Standard orders ar…

2. Oshcut – Laser Cutting and Sheet Metal Services

Domain: oshcut.com

Registered: 2018 (7 years)

Introduction: Laser Cutting and Sheet Metal Services, 2-day delivery throughout the US, Online DFM/Ordering, Laser Metal Cutting, Laser Tube Cutting, Flat Finishing, Bending, Metal Tapping, Bead Blasting, Centrifugal Tumbling, Powder Coating, ISO 9001:2015 Certified, Supported Files: DXF, SVG, AI, STEP, SLDPRT, CATPART, IPT, IGS, PAR, IGES, NX, SolidEdge, JT, Rhino (3DM), Parasolid (x_t), ACIS (SAT, SAB), Insta…

3. Moz Designs – Laser Cut Metal Collection

Domain: mozdesigns.com

Registered: 1998 (27 years)

Introduction: Laser Cut Metal Collection includes over 40 standard patterns in solid-core 3/16″ (up to 1/4″) aluminum 5052 material, available in 4′ x 8′ standard sheet sizes. Dozens of standard powder coat colors are offered. Products are available by the sheet or as ready-to-install solutions for columns, dividers, walls, ceilings, and exterior applications.

4. Metal Cut Design – Custom Wall Art & Accessories

Domain: metalcutdesign.com

Registered: 2021 (4 years)

Introduction: MYWAY Greights Puzzle Holder, Wall Mount Medal Holder, Detroit Born & Raised Decorative Wall Art, Military Tumbler, Flask & Coasters, Table Top Items, Fire Pits, Custom Projects for Ford, GM, Chrysler, Adidas.

5. Krench(TM) – Keychain Wrench

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Metal Fruit Bowl DXF SVG Files, Laser Plasma Cut Pattern, Serving Tray Vector Plans Kitchen Decor; Krench(TM) – Keychain Wrench ***Metric & SAE*** Pocket Wrench; Screwpop Stainless Steel Metric Multi-tool Pocket & Key Chain Wrench Screwdriver; CLEMATIS – Wall-mounted decorative panel by Logical Space design; DiY series for garden hose holder or extension cord holder from HiTSAD.

6. Etsy – Custom CNC & Laser Cutting Services

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Custom CNC & Laser Cutting Services – Stainless Steel, Brass, Aluminum, Wood, and More! Precision Metal and Material Cutting. Custom laser Metal cutting up to 3/16″ thick- FAST- ACCURATE. Sale Price $20.00 (Original Price $25.00, 20% off). Laser cutting up to 3/4″ thick, Fast, Accurate. Custom Sign / Your Custom Text Metal Sign / Your Logo Here Sign / Metal Sign Custom / Your Text Here Sign / Cust…

7. Steel Supply LP – Barrel Racer

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”BARREL RACER”,”material”:”10GA”,”price”:”$28.00″},{“name”:”BRONC BUSTER”,”material”:”10GA”,”price”:”$25.50″},{“name”:”BOY FISHING”,”material”:”10GA”,”price”:”$40.60″},{“name”:”CALF ROPER”,”material”:”10GA”,”price”:”$37.04″},{“name”:”12″ CIRCLE/STAR”,”material”:”10GA”,”price”:”$26.52″},{“name”:”20″ CIRCLE/STAR”,”material”:”10GA”,”price”:”$40.34″},{“name”:”24″ CIRCLE/STAR”,”mat…

8. Langmuir Systems – Plasma Table Design & Software

Domain: forum.langmuirsystems.com

Registered: 2017 (8 years)

Introduction: The discussion revolves around designing and cutting metal signs/art using plasma tables. Key software mentioned includes Inkscape, Fusion 360, Affinity Designer, and SheetCam. Users emphasize the importance of vector drawing programs for CNC design, as they work with paths rather than pixels. The workflow typically involves designing in a vector or CAD program, generating a file compatible with p…

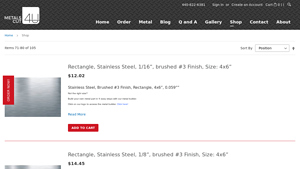

9. Metals Cut 4U – Stainless Steel Rectangles

Domain: metalscut4u.com

Registered: 2015 (10 years)

Introduction: [{‘name’: ‘Rectangle, Stainless Steel, 1/16”, brushed #3 Finish, Size: 4×6”’, ‘price’: ‘$12.02’, ‘material’: ‘Stainless Steel’, ‘finish’: ‘Brushed #3 Finish’, ‘size’: ‘4×6”’, ‘thickness’: ‘0.059”’}, {‘name’: ‘Rectangle, Stainless Steel, 1/8”, brushed #3 Finish, Size: 4×6”’, ‘price’: ‘$14.45’, ‘material’: ‘Stainless Steel’, ‘finish’: ‘Brushed #3 Finish’, ‘size’: ‘4×6”’, ‘thickness’: ‘0.118”’}, {‘na…

Strategic Sourcing Conclusion and Outlook for metal cut design

In the ever-evolving landscape of metal cut design, strategic sourcing emerges as a critical driver for international B2B buyers seeking efficiency and innovation. By leveraging advanced technologies such as instant pricing and rapid prototyping, businesses can significantly reduce lead times while ensuring high-quality outputs. Companies like SendCutSend and OSH Cut exemplify how streamlined processes and customer-centric approaches can enhance the sourcing experience, enabling firms to scale operations and respond agilely to market demands.

For buyers in Africa, South America, the Middle East, and Europe, embracing these advancements not only fosters cost savings but also opens doors to new partnerships and growth opportunities. The ability to customize materials and services on-demand empowers companies to meet diverse client needs, thereby enhancing competitiveness in a global market.

As we look to the future, the integration of digital manufacturing technologies will continue to reshape the metal cut design industry. International buyers are encouraged to engage with innovative suppliers and explore the potential of strategic sourcing as a means to elevate their production capabilities. Seize the opportunity to transform your sourcing strategies today and stay ahead in this dynamic field.