Contents

Manufacturing Insight: Metal Composition Of Stainless Steel

At Honyo Prototype, every sheet-metal part starts with the right alloy—and nobody knows stainless steel like we do. From 301’s spring-hardened resilience to 316L’s salt-spray-defying molybdenum, our engineers specify the exact metal composition your design demands, then laser-cut, bend, weld, and finish it in the same ISO-certified cell. Need proof? Upload your STEP file today and get an Online Instant Quote that locks in material grade, thickness, and lead time in under 60 seconds. That’s precision sheet-metal fabrication, composition to completion, powered by Honyo.

Technical Capabilities

Important Clarification: Your query contains a critical misunderstanding. “Metal composition” applies only to metals and alloys (like stainless steel or aluminum). ABS and Nylon are plastics (polymers) – they have no metal composition and are fundamentally different material categories. As a Senior Manufacturing Engineer at Honyo Prototype, I must correct this upfront to prevent dangerous or costly errors in your fabrication process.

Below is a technically accurate breakdown of material specifications and fabrication behavior for each category separately, with focus on Laser Cutting, Bending, and Welding. I’ve structured this to clarify the confusion and provide actionable specs for actual materials used in prototyping.

🔧 1. STAINLESS STEEL (Metal Alloy)

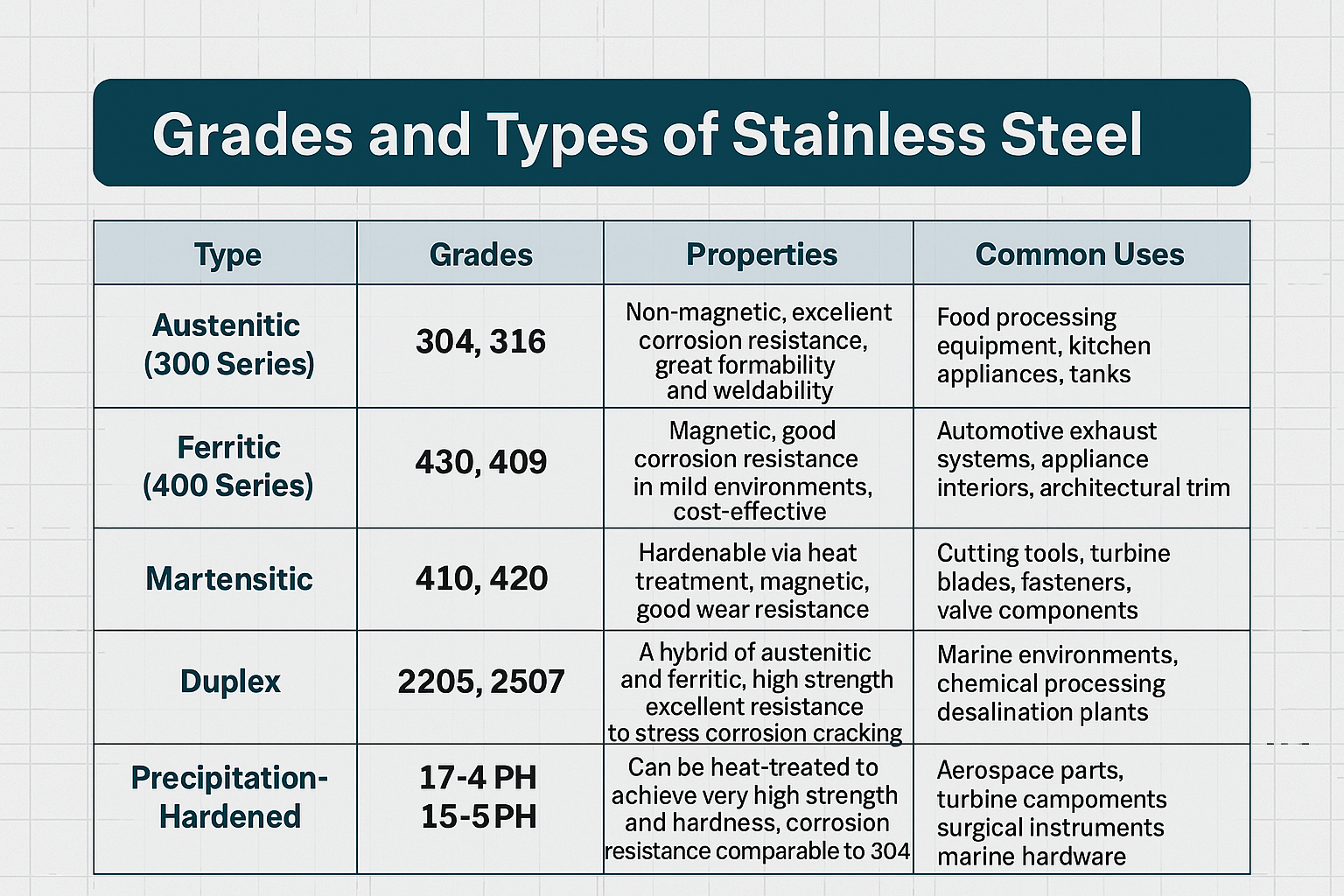

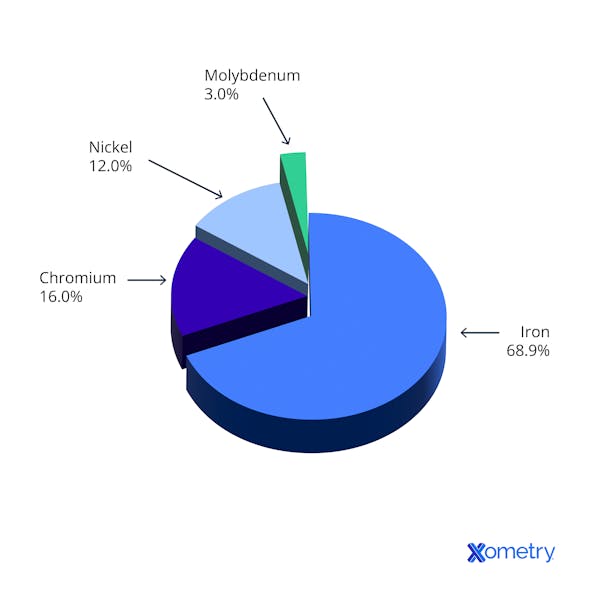

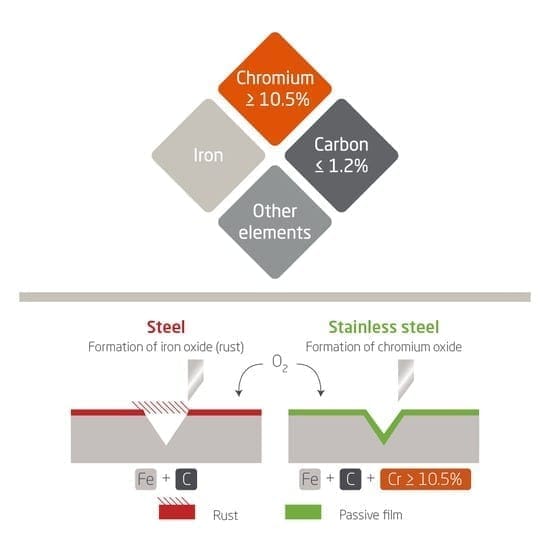

Core Composition: Iron (Fe) + Chromium (Cr, min. 10.5%) + Nickel (Ni, typically 8-12% for austenitic grades) + Carbon (C, low for weldability) + Molybdenum (Mo, in some grades).

Key Standards: ASTM A240, EN 10088-2.

| Process | Critical Technical Specs & Considerations | Common Grades Used at Honyo |

|—————|———————————————————————————————————-|—————————–|

| Laser Cutting | – Oxygen vs. Nitrogen Assist Gas:

– 304/316 (Austenitic): Use high-purity N₂ (99.999%) for clean cuts (prevents oxidation/scaling).

– 430 (Ferritic): Can use O₂ for faster cutting but increases roughness.

– Power Requirements: 1-4 kW (fiber lasers preferred).

– Risk: Chromium carbide precipitation at cut edges if cooled too slowly → corrosion risk. Post-cut passivation often needed. | 304L (most common), 316L, 430 |

| Bending | – Work Hardening: Austenitic grades (304/316) harden rapidly during bending → higher springback than carbon steel.

– Minimum Bend Radius: ≤ 1.5x material thickness for 304 (vs. 0.5x for mild steel).

– Tooling: Use hardened steel dies; avoid carbon steel tools (contamination risk).

– Post-Bend: Annealing may be needed for severe bends to restore corrosion resistance. | 304L, 316L |

| Welding | – Welding Methods: TIG (best for thin sections), MIG (thicker), or laser welding.

– Critical Risk: Sensitization (Cr carbide precipitation at grain boundaries) if welded at 425–850°C → intergranular corrosion.

– Solution: Use low-carbon grades (304L/316L) or post-weld annealing (1050°C + quench).

– Filler Metal: ER308L for 304, ER316L for 316.

– Shielding Gas: 98% Ar + 2% CO₂ or pure Ar for TIG. | 304L, 316L |

⚡ 2. ALUMINUM (Metal Alloy)

Core Composition: Aluminum (Al) + Copper (Cu), Magnesium (Mg), Silicon (Si), or Manganese (Mn). No iron-based alloy.

Key Standards: ASTM B209, EN 573.

| Process | Critical Technical Specs & Considerations | Common Grades Used at Honyo |

|—————|———————————————————————————————————-|—————————–|

| Laser Cutting | – Reflectivity: Aluminum reflects 95% of CO₂ laser energy → fiber lasers (1μm wavelength) are mandatory.

– Assist Gas: N₂ (for clean cuts) or O₂ (for thicker sections, but oxidizes surface).

– Power: 2–6 kW (high power needed due to reflectivity/thermal conductivity).

– Risk: Molten aluminum can splash and damage optics. Requires optimized focus position. | 6061-T6, 5052-H32 |

| Bending | – Springback: Higher than steel → bend allowance calculations differ (use 1.5–2x steel springback factors).

– Minimum Bend Radius: ≤ 1.0x material thickness for 6061-T6.

– Tooling: Aluminum-specific dies (no steel contamination); avoid excessive force (cracking risk). | 6061-T6, 5052-H32 |

| Welding | – Welding Methods: TIG (best for precision), MIG (thicker sections).

– Critical Risk: Hydrogen cracking (from moisture/humidity) and hot cracking.

– Solution: Preheat (100–150°C), use pure argon shielding gas, and clean surfaces thoroughly (remove oxide layer with stainless steel brush).

– Filler Metal: ER4043 or ER5356. | 6061-T6, 5052 |

⚙️ 3. STEEL (Carbon Steel / Mild Steel)

Core Composition: Iron (Fe) + Carbon (C, 0.05–0.25%) + Manganese (Mn). Not stainless – no significant Cr/Ni.

Key Standards: ASTM A1011, EN 10025.

| Process | Critical Technical Specs & Considerations | Common Grades Used at Honyo |

|—————|———————————————————————————————————-|—————————–|

| Laser Cutting | – Assist Gas: O₂ (for faster cuts, but oxidizes edge) or N₂ (for cleaner cuts on thinner sheets).

– Power: 1–3 kW (lower than stainless/aluminum due to lower reflectivity).

– Risk: Rust on cut edges if not treated; may require passivation. | A36, 1018 |

| Bending | – Springback: Low (predictable) → easier to control than stainless/aluminum.

– Minimum Bend Radius: ≤ 0.5x material thickness for mild steel.

– Tooling: Standard steel dies; no contamination concerns. | A36, 1018 |

| Welding | – Welding Methods: MIG, TIG, or Stick welding.

– Critical Risk: Hardenability increases with carbon content → cracking risk in high-carbon steels.

– Solution: Preheat (100–200°C) for thick sections; use low-hydrogen electrodes (e.g., E7018). | A36, 1018 |

🚫 4. ABS & NYLON (PLASTICS – NO METAL COMPOSITION)

CRITICAL NOTE: ABS and Nylon are thermoplastics. They have zero metal composition – they are carbon/hydrogen-based polymers. “Metal composition” is meaningless and incorrect for these materials.

| Process | Critical Technical Specs & Considerations | Key Hazards |

|—————|———————————————————————————————————-|————-|

| Laser Cutting | – ABS:

– Emits toxic fumes (hydrogen cyanide, carbon monoxide) → requires industrial-grade fume extraction and explosion-proof laser cutter.

– Melts/vaporizes easily; cut edges are smooth but require ventilation.

– Nylon:

– Not recommended for laser cutting – high flammability, releases toxic fumes (HCN, NOₓ), and can ignite. Use CNC milling or waterjet instead.

– Laser Type: CO₂ lasers only (fiber lasers ineffective on plastics). | ABS: HCN gas (lethal). Nylon: Fire risk + toxic fumes. |

| Bending | – Not applicable! Plastics cannot be “bent” like metal. They undergo heat forming (e.g., with a heat gun or mold).

– ABS: Softens at 100–120°C; form slowly to avoid warping.

– Nylon: Softens at 150–180°C; requires precise temp control (hygroscopic – must be dried first). | None – but improper heating → warping or degradation. |

| Welding | – Not arc welding! Plastics use ultrasonic welding, hot plate welding, or solvent welding.

– ABS: Solvent welding (e.g., acetone-based glue) or ultrasonic welding.

– Nylon: Hot plate welding (requires moisture control) – solvent welding causes cracking. | None – but incorrect method → weak joints. |

✅ Honyo Prototype Recommendations

- Never mix material categories: Stainless steel specs ≠ aluminum specs ≠ plastic specs.

- ABS/Nylon are NOT metals: They require completely different safety protocols (e.g., ABS laser cutting must have cyanide gas monitoring).

- For stainless steel: Always specify grade (e.g., 304L vs 316L) – composition directly impacts weldability and corrosion resistance.

- Always request material datasheets:

- Stainless steel: ASTM A240 or EN 10088-2

- Aluminum: ASTM B209

- ABS/Nylon: ISO 1043 or manufacturer-specific specs (e.g., BASF Ultradur® for ABS).

💡 Pro Tip: At Honyo, we use a material-specific process database to avoid these mistakes. For any project, share the exact material grade (e.g., “316L stainless steel” or “ABS 3D printing grade”) – not just “steel” or “plastic.” This ensures safe, accurate, and cost-effective fabrication.

Need clarification on a specific material or process? Share the exact grade/requirements, and I’ll provide detailed specs. 🔍

From CAD to Part: The Process

Honyo Prototype – Stainless-Steel Part Workflow

(what we do to turn your 3-D file into a finished, chemically-verified stainless component)

-

Upload CAD

• Any common neutral format (STEP, IGES, Parasolid, STL).

• Portal auto-checks for water-tightness, wall-thickness < 0.3 mm alerts, and hidden internal volumes.

• Stainless grade is pre-selected by you (303, 304L, 316L, 17-4 PH, 15-5 PH, 2205 Duplex, etc.). If you do not specify we default to 316L for general corrosion resistance. -

AI Quote (≤ 5 min)

• Geometry is parsed into machinable surfaces, mill-turn ops, 5-axis indexed faces, EDM cuts, and support structures for additive or casting routes.

• Alloy-specific cost multipliers are applied: 316L (+8 % vs 304L), 17-4 PH (+12 %), 2205 (+18 %).

• A real-time LME (London Metal Exchange) scrap-surcharge index is pulled so the stainless surcharge is current to the hour.

• You receive an itemised line: material, machine time, heat-treat, passivation, inspection, freight. -

DFM (Design-for-Manufacture) – 24 h engineering review

• Chemical compliance check: if your part will be welded we restrict sulphur to ≤ 0.005 % (304L) to avoid hot-cracking; if it will be vacuum brazed we specify low-carbon 316L to prevent carbide precipitation.

• Corrosion environment mapping: marine splash zone automatically triggers 2205 duplex + super-finish Ra ≤ 0.4 µm; food-contact surfaces trigger 316L + electropolish to Ra ≤ 0.25 µm.

• Machinability tweaks: 303 free-machining grade is offered if > 75 % of volume will be removed; we add a 0.2 mm corner relief to reduce tool chatter.

• Tolerance freeze: standard ±0.05 mm, down to ±0.01 mm on mating features; we flag grind or lapping operations if tighter.

• A PDF report + revised 3-D is returned; you click “Accept” to lock the grade and routing. -

Production – certified stainless route

a. Raw material

– Mill test certificates (EN 10204 3.1) verify Cr, Ni, Mo, Cu, C, N, Mn, Si, P, S within ASTM/AMS windows.

– Each plate/bar is laser-etched with a heat number that follows the part to delivery.

b. Programming & set-up

– CAM generates neutral turning, 3- to 5-axis milling, and wire-EDM paths; tooling library already knows 316L speeds ≈ 80 m/min HSM, feeds 0.08 mm/tooth Ø6 mm end-mill.

– First-article cut on redundant machine to validate cutter compensation and avoid scrap on the primary line.

c. Machining / forming / additive

– Coolant is 8 % water-soluble oil with < 0.5 % Cl to eliminate pitting.

– Chip evacuation monitored by spindle-load sensor; load spike > 15 % triggers automatic tool change.

– For thin-wall (< 0.5 mm) 316L brackets we switch to trochoidal paths + compressed-air coolant to avoid work-hardening.

d. Heat treatment (when specified)

– 17-4 PH: solution 1040 °C / 30 min → H900 age 482 °C 1 h, argon atmosphere, hardness 40-44 HRC.

– 316L stress-relief: 450 °C 2 h, slow cool to prevent sensitisation.

e. Surface finishing

– Passivation per ASTM A967 (citric acid, 20 min, 60 °C) → free-Fe < 0.1 µg/cm².

– Electropolish optional: 30 µm stock removal, mirror finish ≤ 0.1 µm Ra, Cr/Fe ratio > 1.5 by XPS.

– Laser marking (heat-number + part-number) done after passivation to avoid ink contamination.

f. Dimensional & alloy verification

– CMM ±0.003 mm accuracy on critical datums.

– Positive Material Identification (PMI) with XRF gun—30 s test confirms Cr 16-18 %, Ni 10-14 %, Mo 2-3 % for 316L.

– Ferrite check on 2205 duplex: ferrite 35-55 % by Fischer Feritscope.

- Delivery

• Parts vacuum-sealed with VCI paper, silica-gel pack, RoHS label; heat-number barcode on outer bag.

• Digital shipment file (link) contains:

– original MTR, passivation certificate, CMM report, PMI spectrum, photos of packed parts.

• Typical lead-time: 3 days (CNC) to 10 days (heat-treated 17-4 PH) ex-works Shenzhen; DHL/UPS 2-day express to most regions.

In short, every stainless part we make is traceable from CAD upload to your dock, with alloy chemistry locked at the DFM stage and verified again before it leaves the building.

Start Your Project

Expert stainless steel composition solutions tailored to your project needs. Contact Susan Leo at [email protected] for precision manufacturing from our Shenzhen facility.

Honyo Prototype: Where precision meets performance.

🚀 Rapid Prototyping Estimator