Introduction: Navigating the Global Market for metal casting services

In an increasingly interconnected world, sourcing reliable metal casting services can pose significant challenges for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. The complexities of navigating diverse supplier capabilities, varying production techniques, and fluctuating material costs can create uncertainty in the procurement process. This comprehensive guide aims to demystify the global market for metal casting services by providing valuable insights into the various types of casting processes, including sand, die, and investment casting.

We will delve into critical applications across industries, supplier vetting strategies, and cost considerations to help buyers make informed decisions tailored to their specific needs. By understanding the nuances of metal casting services—from material selection to quality assurance procedures—B2B buyers can enhance their purchasing strategies and mitigate risks associated with international sourcing.

This guide not only equips decision-makers with the necessary knowledge to identify high-quality suppliers but also offers actionable insights to streamline procurement processes. As you navigate the complexities of sourcing metal castings, let this resource empower you to achieve optimal results, ensuring the success of your projects and the longevity of your partnerships.

Understanding metal casting services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sand Casting | Utilizes sand molds; versatile for large parts; cost-effective. | Automotive, aerospace, and art industries. | Pros: Low cost; adaptable for various sizes. Cons: Lower precision compared to other methods. |

| Investment Casting | Uses wax patterns; high precision; excellent surface finish. | Medical devices, aerospace components. | Pros: High detail; minimal waste. Cons: Higher initial costs; longer lead times. |

| Die Casting | Injects molten metal into molds; ideal for mass production. | Electronics, automotive, and consumer goods. | Pros: High volume efficiency; tight tolerances. Cons: Limited material options; high tooling costs. |

| Permanent Mold Casting | Metal molds used; good dimensional stability; repeatable. | Heavy machinery, automotive parts. | Pros: High durability; better surface quality. Cons: Higher setup costs; less flexibility in design. |

| Lost Foam Casting | Uses foam patterns; allows complex shapes; minimal finishing needed. | Aerospace, military applications. | Pros: Complex geometries; reduced finishing work. Cons: Not suitable for all materials; higher costs. |

What Are the Characteristics of Sand Casting Services?

Sand casting is a widely used method where a sand mold is created to form metal parts. This technique is highly adaptable, allowing for the production of both large and small components. It is particularly cost-effective for low to medium production volumes. B2B buyers should consider the desired part size and complexity, as well as the trade-off between cost and precision when choosing sand casting.

How Does Investment Casting Stand Out in Metal Casting Services?

Investment casting is characterized by its ability to produce intricate shapes and high-precision parts using a wax pattern that is melted away. This method is ideal for applications requiring detailed features, such as in the medical and aerospace industries. B2B purchasers should weigh the benefits of high detail and low waste against the higher initial costs and longer lead times associated with this casting technique.

Why Choose Die Casting for High-Volume Production?

Die casting is a process where molten metal is injected into a mold, making it suitable for high-volume production of complex parts. This method is often favored in industries such as electronics and automotive due to its efficiency and ability to produce tight tolerances. Buyers should consider the upfront tooling costs, as well as the limitations in material selection when opting for die casting services.

What Are the Advantages of Permanent Mold Casting?

Permanent mold casting utilizes reusable metal molds, providing excellent dimensional stability and surface quality. This method is commonly employed for producing durable parts in heavy machinery and automotive applications. B2B buyers should consider the trade-off between higher setup costs and the long-term benefits of reduced waste and improved part quality.

How Does Lost Foam Casting Facilitate Complex Designs?

Lost foam casting employs foam patterns that vaporize during the pouring of molten metal, allowing for the creation of complex shapes with minimal finishing required. This method is particularly useful in aerospace and military applications. Buyers should evaluate the complexity of the desired parts and the material requirements, as this method may not be suitable for all casting materials and can involve higher costs.

Key Industrial Applications of metal casting services

| Industry/Sector | Specific Application of Metal Casting Services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine blocks and transmission housings | High strength-to-weight ratio, improved fuel efficiency | Material specifications, quality standards, lead times |

| Aerospace | Structural components for aircraft | Lightweight materials, enhanced performance | Certification requirements, precision tolerances, sourcing reliability |

| Construction & Heavy Machinery | Custom parts for machinery and equipment | Durability, cost-effectiveness, reduced downtime | Material selection, production volume, secondary processing needs |

| Oil & Gas | Pipeline fittings and valves | Corrosion resistance, safety compliance | Regulatory compliance, material durability, logistics |

| Electronics | Housings and heat sinks for electronic devices | Thermal management, design flexibility | Precision machining, design specifications, lead times |

How is Metal Casting Used in the Automotive Industry?

In the automotive sector, metal casting services are essential for producing complex components such as engine blocks and transmission housings. These parts require high strength-to-weight ratios to enhance fuel efficiency and performance. B2B buyers should consider material specifications, such as ductile iron or aluminum, alongside quality standards to ensure durability and reliability. Additionally, lead times are critical, as automotive production schedules are tightly regulated, necessitating timely delivery of cast components.

What Role Does Metal Casting Play in Aerospace Applications?

Aerospace applications demand components that are not only lightweight but also robust and capable of withstanding extreme conditions. Metal casting services are utilized to manufacture structural components that meet stringent performance standards. Buyers in this sector must prioritize certification requirements, as parts must comply with aviation regulations. Precision tolerances are also vital, given the safety implications involved in aerospace manufacturing. Sourcing reliability is crucial for international buyers who require consistent quality and timely delivery.

How is Metal Casting Beneficial in Construction and Heavy Machinery?

In the construction and heavy machinery industry, metal casting services are leveraged to create custom parts that enhance durability and reduce downtime. Components such as gears, brackets, and housings are often produced through casting methods, providing cost-effective solutions for manufacturers. Buyers should focus on material selection to ensure the right balance of strength and weight, as well as assess production volume requirements to optimize costs. Secondary processing needs, such as machining or coating, should also be discussed to ensure comprehensive service delivery.

Why is Metal Casting Important for the Oil & Gas Sector?

The oil and gas industry relies on metal casting services for producing critical components like pipeline fittings and valves. These parts must exhibit exceptional corrosion resistance and comply with safety regulations to ensure operational integrity. B2B buyers should consider regulatory compliance in their sourcing strategies, as the consequences of substandard materials can be severe. Additionally, the durability of cast components is paramount, necessitating careful material selection and logistics planning to facilitate timely delivery to remote locations.

How Does Metal Casting Enhance Electronics Manufacturing?

In electronics, metal casting services are used to create housings and heat sinks that manage thermal performance and protect sensitive components. The flexibility in design offered by casting allows for innovative solutions that meet the unique requirements of electronic devices. Buyers must prioritize precision machining to achieve the necessary tolerances and consider design specifications that align with their product needs. Lead times are also essential, especially for companies operating in fast-paced tech markets, to ensure timely product launches.

3 Common User Pain Points for ‘metal casting services’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Metal Casting

The Problem: One of the most pressing challenges faced by B2B buyers in the metal casting industry is ensuring consistent quality in the final products. Fluctuations in quality can arise from various factors, including material inconsistencies, manufacturing processes, and quality assurance practices. For instance, a buyer may receive a batch of cast parts that do not meet the required specifications, leading to costly delays, rework, and even damage to their reputation. Such discrepancies can be particularly detrimental for industries like aerospace and automotive, where precision and reliability are non-negotiable.

The Solution: To mitigate quality control issues, buyers should establish clear communication and expectations with their metal casting suppliers. It is crucial to request detailed documentation of the supplier’s quality assurance processes, including any certifications they hold, such as ISO 9001. Additionally, implementing a robust vendor qualification process can help ensure that the chosen supplier has a proven track record in producing high-quality castings. Buyers should also consider incorporating regular quality audits and on-site inspections to monitor production standards. Utilizing non-destructive testing (NDT) methods to evaluate the integrity of the cast parts before they are shipped can further enhance quality assurance, allowing buyers to catch potential issues before they escalate.

Scenario 2: Managing Costs and Budget Constraints in Metal Casting Projects

The Problem: Budget overruns can significantly impact a company’s bottom line, especially for B2B buyers who are often operating under tight financial constraints. Metal casting projects can become unexpectedly expensive due to factors such as material price fluctuations, unanticipated manufacturing complexities, or delays in production timelines. For example, a buyer might plan for a specific budget only to find that the chosen materials or processes exceed initial estimates, resulting in a scramble to find additional funds or compromising on quality.

The Solution: To effectively manage costs, buyers should engage in thorough upfront planning and detailed project specifications. This involves providing suppliers with comprehensive information, including drawings, specifications, and expected production volumes, which can help suppliers offer more accurate quotes. Buyers should also explore alternative materials or processes that can achieve the desired results at a lower cost. For instance, switching from a more expensive alloy to a cost-effective composite material might yield similar performance results. Additionally, forming long-term partnerships with suppliers can lead to better pricing agreements and reduced costs over time. Finally, incorporating flexible payment terms or volume discounts into contracts can help in managing cash flow more effectively.

Scenario 3: Overcoming Lead Time Issues in Metal Casting Services

The Problem: Extended lead times are a common pain point in the metal casting industry, often causing supply chain disruptions and affecting production schedules. Buyers may face delays due to factors such as inadequate inventory management, inefficient production processes, or unexpected spikes in demand. For instance, a manufacturer may need to expedite a critical project but find that their supplier has a backlog of orders, leading to missed deadlines and lost business opportunities.

The Solution: To address lead time challenges, B2B buyers should prioritize working with suppliers who have proven capabilities in efficient production and logistics management. Establishing a clear timeline at the outset, including milestones for each stage of the project, can help both parties stay on track. Buyers should also consider implementing a just-in-time (JIT) inventory system, which allows for better synchronization of production schedules with supply chain logistics. Additionally, maintaining a buffer stock of critical components can provide a safety net against delays. Engaging suppliers in regular forecasting discussions can help them anticipate demand and allocate resources more effectively, ultimately reducing lead times.

Strategic Material Selection Guide for metal casting services

What Are the Key Properties of Common Materials Used in Metal Casting Services?

In the realm of metal casting, selecting the appropriate material is pivotal for achieving the desired performance and longevity of the final product. Below, we analyze four commonly used materials in metal casting, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Ductile Iron Perform in Metal Casting Applications?

Ductile iron, known for its exceptional ductility and strength, is a popular choice in various applications. It exhibits excellent resistance to wear and impact, making it suitable for heavy-duty components. Ductile iron can withstand high temperatures and pressures, which is vital for industries like automotive and heavy machinery.

Pros: Ductile iron’s high tensile strength and ability to absorb shock make it ideal for critical applications. Its cost-effectiveness compared to steel also enhances its appeal.

Cons: While ductile iron is durable, it can be more brittle than other materials under specific conditions. Additionally, its manufacturing process can be complex, requiring precise control over the casting environment.

Impact on Application: Ductile iron is often used in automotive parts, pipes, and fittings, where both strength and flexibility are essential.

Considerations for International Buyers: Compliance with international standards such as ASTM A536 is crucial. Buyers should also consider local sourcing capabilities and the availability of ductile iron foundries in their region.

What Are the Benefits of Using Aluminum in Metal Casting?

Aluminum is widely recognized for its lightweight and corrosion-resistant properties, making it a favored choice in industries such as aerospace, automotive, and consumer goods. Its low density and excellent thermal conductivity enhance its suitability for various applications.

Pros: The recyclability of aluminum and its favorable strength-to-weight ratio are significant advantages. Additionally, aluminum castings can be produced with intricate designs, allowing for greater flexibility in product development.

Cons: Aluminum can be more expensive than other materials, particularly when high-performance alloys are required. The casting process can also require more energy, impacting overall production costs.

Impact on Application: Aluminum is ideal for applications that require lightweight components, such as automotive parts and electronic housings, where weight reduction is critical.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ASTM B108 for aluminum castings. Understanding local regulations regarding aluminum recycling and sustainability practices can also be beneficial.

Why Choose Stainless Steel for Metal Casting Services?

Stainless steel is renowned for its corrosion resistance and durability, making it suitable for applications in harsh environments, including chemical processing and marine industries. Its ability to withstand high temperatures further enhances its versatility.

Pros: The longevity and low maintenance requirements of stainless steel products make them a cost-effective choice over time. Its aesthetic appeal is also a plus for consumer-facing products.

Cons: The initial cost of stainless steel can be higher than other materials, and the casting process can be more complex due to its high melting point.

Impact on Application: Stainless steel is commonly used in food processing equipment, medical devices, and architectural applications, where hygiene and appearance are paramount.

Considerations for International Buyers: Compliance with standards such as ASTM A351 is essential. Buyers should also consider the availability of stainless steel foundries in their region and the implications of tariffs or trade agreements affecting stainless steel imports.

What Are the Advantages of Using Grey Iron in Metal Casting?

Grey iron is characterized by its excellent castability and machinability, making it a popular choice for various applications, particularly in automotive and machinery components. Its ability to dampen vibrations is another significant benefit.

Pros: Grey iron is relatively inexpensive and easy to cast, allowing for efficient production processes. Its thermal conductivity is also beneficial in applications requiring heat dissipation.

Cons: While grey iron is strong, it is more brittle than ductile iron and can fail under high-stress conditions. Its corrosion resistance is also inferior compared to stainless steel.

Impact on Application: Common applications include engine blocks, machine bases, and other components where vibration dampening is crucial.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A48. Understanding the local market for grey iron products can also influence sourcing decisions.

Summary Table of Material Selection for Metal Casting Services

| Material | Typical Use Case for metal casting services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ductile Iron | Automotive parts, pipes, fittings | High tensile strength and ductility | Brittle under specific conditions | Medium |

| Aluminum | Aerospace components, consumer goods | Lightweight and recyclable | Higher initial cost | High |

| Stainless Steel | Food processing, medical devices | Corrosion resistance and durability | Higher initial cost and complexity | High |

| Grey Iron | Engine blocks, machine bases | Cost-effective and easy to cast | Brittle and lower corrosion resistance | Low |

This strategic material selection guide provides insights into the properties and considerations of various materials used in metal casting services, helping international B2B buyers make informed decisions tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for metal casting services

What Are the Key Stages in Metal Casting Manufacturing Processes?

Metal casting is a complex process that involves several critical stages to transform raw materials into finished products. Understanding these stages is essential for B2B buyers to make informed decisions regarding their suppliers and the quality of the products they intend to procure.

1. Material Preparation: How Is Raw Material Processed for Metal Casting?

The first stage in the metal casting process involves preparing the raw materials, which typically include various metals like aluminum, iron, or steel. This preparation can include melting the metal in a furnace and refining it to remove impurities. The choice of material affects not only the properties of the final product but also the selection of casting techniques.

For instance, aluminum is often used in die casting due to its lightweight and corrosion-resistant properties, while iron may be preferred for applications requiring high strength. B2B buyers should ensure that suppliers utilize high-grade materials and have robust material sourcing strategies to maintain quality.

2. Forming: What Techniques Are Used in Metal Casting?

The forming stage encompasses various casting techniques, each suited for different applications and production volumes. The most common methods include:

- Sand Casting: This method uses sand molds to shape the molten metal. It is versatile and cost-effective for low to medium production runs.

- Die Casting: Ideal for high-volume production, die casting involves forcing molten metal into a mold under pressure, which allows for intricate designs and tight tolerances.

- Investment Casting: This precision method involves creating a wax pattern, coating it with a ceramic shell, and then melting away the wax. It is often used for complex shapes and high-value components.

- Permanent Mold Casting: This method uses metal molds for repeated use, providing better surface finishes and dimensional accuracy compared to sand casting.

Understanding these techniques allows B2B buyers to choose the right process based on their specific needs, whether it’s for prototyping or mass production.

3. Assembly: How Are Components Joined After Casting?

Once the casting is completed, the next phase is assembly. This step may involve machining operations to achieve desired tolerances, followed by joining processes such as welding, riveting, or adhesive bonding. The need for assembly can vary based on the product’s complexity and application.

B2B buyers should inquire about a supplier’s capabilities in secondary operations and assembly processes, as these can significantly influence the overall quality and performance of the final product.

4. Finishing: What Are the Final Touches Applied to Cast Metal Products?

The finishing stage is crucial in enhancing the aesthetic and functional properties of the cast products. Common finishing processes include:

- Machining: This involves removing excess material to achieve precise dimensions and surface finishes.

- Coating: Protective coatings can be applied to prevent corrosion and wear, extending the product’s lifespan.

- Heat Treatment: This process alters the physical and sometimes chemical properties of the material to improve strength and durability.

Buyers should ensure that their suppliers offer comprehensive finishing services to meet specific performance requirements.

What Quality Assurance Standards Should B2B Buyers Expect in Metal Casting?

Quality assurance is critical in metal casting, ensuring that the products meet specified standards and perform reliably in their intended applications. Buyers should be familiar with the relevant international and industry-specific standards.

1. What Are the International Quality Standards for Metal Casting?

ISO 9001 is a widely recognized international standard that specifies requirements for quality management systems. Suppliers should be certified to this standard to demonstrate their commitment to quality and continuous improvement.

Additionally, industry-specific certifications such as CE marking for products sold in Europe or API standards for oil and gas applications may be relevant depending on the intended use of the cast components.

2. What Are the Key Quality Control Checkpoints in Metal Casting?

Quality control (QC) in metal casting typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This ensures that raw materials meet required specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): At this stage, finished products are rigorously tested to ensure they meet all specifications before delivery.

B2B buyers should discuss the QC processes with their suppliers to understand how they monitor quality at each stage.

3. What Testing Methods Are Commonly Used in Metal Casting Quality Assurance?

Several testing methods are employed to validate the quality of cast products, including:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing help detect internal flaws without damaging the product.

- Destructive Testing: This includes tensile tests, impact tests, and hardness tests to evaluate the mechanical properties of the materials.

- Dimensional Inspection: Ensuring that the final products meet the specified dimensions and tolerances is crucial.

B2B buyers should confirm that their suppliers have robust testing protocols in place and can provide documentation of results.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control measures of potential suppliers is essential for B2B buyers to mitigate risks associated with poor quality products. Here are some strategies:

1. What Should Buyers Look for in Supplier Audits?

Conducting supplier audits can help buyers assess the effectiveness of a supplier’s quality management system. During an audit, buyers should evaluate:

- Compliance with international standards (e.g., ISO 9001).

- The effectiveness of the supplier’s quality control processes.

- The qualifications and training of staff involved in quality assurance.

2. How Can Buyers Utilize Quality Reports and Certifications?

Requesting quality reports and certifications from suppliers provides insight into their operational capabilities. These documents should demonstrate compliance with relevant industry standards and illustrate a commitment to quality.

3. What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These inspections can be particularly valuable for international buyers who may face challenges in assessing suppliers remotely.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Essential for B2B Buyers?

In the dynamic landscape of global trade, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of metal casting manufacturing processes and quality assurance is vital. By familiarizing themselves with these aspects, B2B buyers can make informed decisions that enhance their supply chain, reduce risks, and ensure the delivery of high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal casting services’

To effectively procure metal casting services, B2B buyers must approach the process with a strategic mindset. This guide provides a comprehensive checklist to streamline your sourcing efforts, ensuring you select the right supplier for your specific needs.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is crucial. This includes dimensions, tolerances, and material properties. Providing detailed specifications helps suppliers understand your expectations and enables them to offer accurate quotes.

- Dimension Details: Include all necessary measurements and tolerances.

- Material Requirements: Specify the type of metal and any relevant standards.

Step 2: Research Potential Suppliers

A thorough research phase is essential to identify potential suppliers who align with your project needs. Look for companies that specialize in the type of casting you require, such as sand casting, die casting, or investment casting.

- Industry Experience: Evaluate their experience in your specific industry.

- Technology and Capabilities: Ensure they have the necessary technology and equipment to meet your specifications.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or AS9100. These certifications indicate adherence to quality management standards, which is vital for ensuring consistent product quality.

- Quality Assurance Processes: Ask about their quality control measures and testing procedures.

- Compliance with Regulations: Ensure they comply with any industry-specific regulations.

Step 4: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to compare pricing structures. Provide all necessary details in your Request for Quotation (RFQ) to ensure you receive comparable estimates.

- Cost Breakdown: Look for transparency in pricing, including material costs, labor, and shipping.

- Volume Discounts: Inquire about pricing for bulk orders or long-term contracts.

Step 5: Assess Production Capabilities and Lead Times

Understanding a supplier’s production capacity and lead times is critical to ensure they can meet your project deadlines. Ask for detailed timelines from order placement to delivery.

- Production Flexibility: Assess their ability to handle fluctuations in order volume.

- Past Performance: Request information on their track record for meeting deadlines.

Step 6: Conduct Site Visits or Virtual Tours

Whenever possible, visit the supplier’s facility or request a virtual tour. This allows you to assess their operations, equipment, and work environment firsthand, which can be telling of their capabilities and quality standards.

- Cleanliness and Organization: A well-maintained facility often reflects the quality of their work.

- Employee Expertise: Observe the skill level and professionalism of their staff.

Step 7: Review Contracts and Terms of Service

Before finalizing your supplier choice, thoroughly review the contract terms. Pay close attention to payment terms, warranties, and conditions for returns or defects.

- Clear Terms: Ensure all agreements are clearly outlined to avoid misunderstandings.

- Dispute Resolution: Understand the procedures in place for resolving potential disputes.

By following these steps, B2B buyers can effectively navigate the metal casting procurement process, ensuring they partner with a supplier that meets their technical and business needs.

Comprehensive Cost and Pricing Analysis for metal casting services Sourcing

What Are the Key Cost Components in Metal Casting Services?

When sourcing metal casting services, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of metal significantly impacts costs. Common materials such as ductile iron, aluminum, and stainless steel vary in price based on market conditions and specific supplier agreements. For instance, aluminum die casting is popular due to its lightweight properties but may require higher initial investment due to its processing demands.

-

Labor: Labor costs are influenced by the complexity of the casting process, such as sand casting or die casting. Skilled labor is essential for precision work, especially for custom parts, and this can drive up costs. Suppliers often have varying labor rates based on their geographic location, which is an important consideration for international buyers.

-

Manufacturing Overhead: This includes utilities, maintenance, and facility costs. Efficient suppliers will often have optimized processes that minimize overhead, which can lead to more competitive pricing.

-

Tooling: Tooling costs can be substantial, especially for custom projects requiring unique molds. The investment in tooling often depends on the complexity and volume of the parts being produced. Buyers should consider the long-term benefits of investing in high-quality tooling that can withstand repeated use.

-

Quality Control (QC): Ensuring the quality of cast parts can incur additional costs. Suppliers may implement various quality assurance measures, including non-destructive testing (NDT) and other certification processes. These costs should be factored into the overall pricing structure.

-

Logistics: Shipping and handling costs can vary widely, particularly for international shipments. Factors such as distance, shipping method, and customs duties can all impact the final cost. Buyers should clarify logistics arrangements early in the negotiation process.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. Understanding the market and typical margins in the region can help buyers negotiate more effectively.

How Do Price Influencers Affect Metal Casting Services?

Several factors can influence the pricing of metal casting services, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to reduced per-unit costs due to economies of scale. Suppliers are more willing to negotiate pricing for larger orders, so buyers should assess their long-term needs.

-

Specifications and Customization: Custom specifications can significantly raise costs. Detailed drawings and specifications help suppliers provide accurate quotes and avoid unexpected costs later in the process.

-

Material Selection: The choice of materials can impact both cost and quality. Certain alloys may be more expensive but offer better performance, which can be a crucial factor in industries like aerospace or automotive.

-

Quality and Certifications: Buyers looking for certified products may face higher prices due to the additional processes involved. Certifications can also affect lead times, as suppliers may need to conduct more extensive testing.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can affect pricing. Established suppliers with a track record of quality may command higher prices, but they can also provide greater reliability.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate who is responsible for shipping costs, insurance, and risk during transport, which can affect the overall cost structure.

What Buyer Tips Can Help in Negotiating Metal Casting Prices?

To navigate the complexities of pricing in metal casting services, consider the following tips:

-

Negotiate Based on Total Cost of Ownership: Instead of focusing solely on upfront costs, evaluate the total cost of ownership, including maintenance, durability, and potential rework. This approach can reveal the true value of a supplier’s offering.

-

Clarify Expectations Early: Provide detailed project specifications and anticipated volumes early in the negotiation process. This transparency can lead to more accurate quotes and better pricing.

-

Understand Pricing Nuances for International Sourcing: For buyers in Africa, South America, the Middle East, and Europe, be aware of potential additional costs related to tariffs, import duties, and local regulations. Engaging a supplier familiar with these nuances can mitigate unexpected expenses.

-

Request Multiple Quotes: Always seek quotes from multiple suppliers to compare pricing and services. This competitive approach can provide leverage during negotiations.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and favorable terms in future transactions.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing metal casting services, ensuring they receive quality products at competitive prices.

Alternatives Analysis: Comparing metal casting services With Other Solutions

Understanding Alternatives to Metal Casting Services

In the pursuit of manufacturing high-quality metal components, businesses often explore various methodologies beyond traditional metal casting services. While metal casting is a popular choice due to its versatility and cost-effectiveness, alternative solutions like 3D printing and forging can also meet specific manufacturing needs. This section provides a comparative analysis of metal casting services against these alternatives, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Metal Casting Services | 3D Printing | Forging |

|---|---|---|---|

| Performance | High precision and complex geometries possible | Good for prototyping, limited for large runs | Exceptional strength, excellent for high volumes |

| Cost | Economical for large volumes; tooling costs | Higher per unit for small runs; no tooling cost | Moderate initial investment; cost-effective for bulk |

| Ease of Implementation | Established processes, requires setup time | Rapid setup, requires design adjustments | Requires specialized equipment and skilled labor |

| Maintenance | Regular quality checks needed | Minimal maintenance required | Equipment maintenance is essential |

| Best Use Case | High volume, complex shapes | Prototyping, custom designs | High-strength applications, large production runs |

What Are the Advantages and Disadvantages of 3D Printing as an Alternative?

3D printing, or additive manufacturing, is increasingly being adopted for creating intricate designs and prototypes. The key advantage of 3D printing is its ability to quickly produce complex geometries without the need for expensive molds or tooling. This makes it ideal for rapid prototyping or small batch production. However, the cost per unit can be significantly higher than traditional casting methods, particularly for larger volumes. Additionally, while 3D printing materials have improved, they may not always match the mechanical properties of cast metals, limiting their use in high-strength applications.

How Does Forging Compare to Metal Casting Services?

Forging is a manufacturing process that shapes metal using compressive forces, resulting in products that possess superior strength and durability. This method is particularly effective for high-stress applications such as aerospace and automotive components. The main advantages of forging include enhanced mechanical properties and a high production rate for large batches. However, forging requires significant upfront investment in specialized machinery and tooling. Additionally, it is less flexible than casting for producing complex shapes, as it is primarily suited for simpler geometries.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate manufacturing solution, B2B buyers should evaluate their specific requirements, including production volume, material properties, and budget constraints. Metal casting services excel in producing complex geometries at scale, making them ideal for high-volume applications. In contrast, 3D printing offers agility for prototyping and small batches, while forging is best for high-strength, large-scale production. By thoroughly assessing these factors, businesses can align their manufacturing strategy with their operational goals and ensure optimal outcomes in their supply chain management.

Essential Technical Properties and Trade Terminology for metal casting services

What Are the Key Technical Properties for Metal Casting Services?

Understanding the technical properties of metal casting services is crucial for B2B buyers aiming to make informed procurement decisions. Below are several critical specifications that should be considered:

1. Material Grade

The material grade indicates the specific composition and mechanical properties of the metal used in casting, such as ductile iron, stainless steel, or aluminum alloys. Each grade has its unique characteristics that affect strength, durability, and corrosion resistance. For buyers, selecting the appropriate material grade is essential for ensuring that the final product meets industry standards and performance requirements.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. High precision tolerances are vital in applications where parts must fit together perfectly, such as in machinery or automotive components. Establishing the required tolerances upfront helps suppliers deliver products that meet the exact specifications, reducing the need for costly rework or delays.

3. Surface Finish

The surface finish defines the texture and quality of the product’s exterior. It can range from rough to highly polished, influencing not only aesthetics but also functional aspects like wear resistance and corrosion protection. Buyers must communicate their surface finish requirements clearly, as this can affect lead times and costs associated with secondary processing.

4. Mechanical Properties

Mechanical properties include strength, hardness, ductility, and impact resistance. These characteristics determine how a material will perform under various loads and conditions. Understanding the mechanical properties of the casting materials helps buyers select parts that can withstand operational demands, thereby ensuring reliability and longevity in their applications.

5. Heat Treatment

Heat treatment processes are employed to enhance the mechanical properties of cast metals, such as increasing hardness or improving ductility. Different heat treatment methods, such as annealing or quenching, can significantly impact the performance of the final product. Buyers should be aware of the heat treatment options available and specify them based on the intended use of the parts.

What Are Common Trade Terms in Metal Casting Services?

Familiarity with industry jargon can streamline communication and ensure clarity in negotiations. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier operates as an OEM is crucial for buyers looking for specific components that fit into larger systems or products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to produce or sell in a single order. Knowing the MOQ is essential for buyers to plan their budgets and inventory effectively, as it may influence overall purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for specific products or services. Providing detailed information in an RFQ can lead to more accurate quotes and better alignment with project requirements, helping buyers avoid unexpected costs.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for buyers to manage shipping costs, risk, and delivery timelines effectively.

5. NDT (Non-Destructive Testing)

NDT refers to a variety of testing methods used to evaluate the properties of a material, component, or assembly without causing damage. It is an essential part of quality assurance in metal casting, as it helps ensure that the products meet safety and performance standards.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies and foster more effective partnerships with metal casting service providers.

Navigating Market Dynamics and Sourcing Trends in the metal casting services Sector

What Are the Current Market Dynamics and Key Trends in Metal Casting Services?

The global metal casting services market is witnessing significant transformation driven by technological advancements, changing consumer demands, and evolving industry standards. Key drivers include the growing demand for lightweight and durable materials, particularly in the automotive and aerospace sectors. Countries in Africa, South America, the Middle East, and Europe are increasingly focusing on local manufacturing capabilities to reduce dependency on imports, thus boosting regional foundries.

Emerging B2B technologies such as additive manufacturing (3D printing) and advanced automation are reshaping traditional casting processes. These technologies enable faster prototyping, reduced material waste, and increased precision, appealing to international buyers looking for cost-effective and high-quality solutions. Additionally, the integration of Industry 4.0 principles, such as IoT and data analytics, is enhancing supply chain transparency and operational efficiency, allowing companies to respond swiftly to market fluctuations.

International buyers are also increasingly concerned about lead times and logistics. As a result, many casting companies are investing in streamlining their supply chains through strategic partnerships and localized production to ensure timely delivery. For instance, foundries in Brazil and Saudi Arabia are optimizing their production schedules to cater to their specific regional markets, thus gaining a competitive edge.

How Is Sustainability and Ethical Sourcing Impacting the Metal Casting Services Sector?

In the contemporary B2B landscape, sustainability and ethical sourcing have emerged as paramount considerations for metal casting services. The environmental impact of metal casting—characterized by energy consumption and emissions—has prompted buyers to seek suppliers committed to sustainable practices. This shift is particularly relevant for companies in Africa and South America, where regulatory frameworks are evolving to address environmental concerns.

Ethical supply chains are essential for fostering trust and transparency between buyers and suppliers. Companies are increasingly prioritizing partnerships with foundries that utilize recycled materials and environmentally-friendly processes. Certifications such as ISO 14001 for environmental management systems and the use of “green” materials are becoming critical factors in supplier selection. These certifications not only assure buyers of compliance with international standards but also enhance their brand reputation.

Moreover, as global consumers demand more sustainable products, international buyers are encouraged to evaluate the entire lifecycle of their casting materials, from sourcing to end-of-life disposal. This approach not only mitigates environmental risks but also positions companies favorably in a competitive market that values corporate social responsibility.

What Is the Historical Evolution of Metal Casting Services Relevant to Today’s B2B Market?

The history of metal casting dates back thousands of years, evolving from primitive techniques to highly sophisticated manufacturing processes. Initially, casting was a labor-intensive craft, with artisans using sand and clay molds. The Industrial Revolution marked a significant turning point, introducing mechanization and mass production techniques that increased efficiency and scale.

In the late 20th century, advancements in materials science and computer-aided design (CAD) revolutionized the metal casting sector. The introduction of precision casting methods, such as investment and die casting, allowed for the production of complex geometries and tighter tolerances, meeting the demands of modern industries.

Today, as the market continues to evolve, the focus has shifted towards integrating advanced technologies and sustainable practices, ensuring that metal casting services remain relevant in an increasingly competitive global landscape. This historical context is crucial for B2B buyers to understand the capabilities and innovations available in the sector, enabling informed sourcing decisions that align with their strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of metal casting services

-

1. How do I solve issues related to quality assurance in metal casting?

To address quality assurance concerns, start by clearly defining your quality standards and specifications. Engage with potential suppliers to discuss their quality control processes, including testing methods like non-destructive testing (NDT) and material certifications. Request samples or prototypes before placing larger orders to assess their capabilities. Additionally, establishing a clear communication channel throughout the production process can help you monitor quality and address any issues promptly. -

2. What is the best metal casting method for my specific project?

The optimal metal casting method depends on your project’s requirements such as complexity, volume, and material type. For high-volume production of complex parts, die casting may be ideal due to its efficiency and precision. If you need flexibility with material types and part sizes, sand casting is a good choice. For intricate designs requiring tight tolerances, consider investment casting. Assess your project goals and consult with suppliers to identify the best method suited to your needs. -

3. How can I ensure timely delivery of my metal casting orders?

To ensure timely delivery, provide suppliers with detailed project specifications, including deadlines and shipping requirements. Discuss production timelines upfront, understanding that initial runs may take longer than subsequent orders. Use suppliers who offer robust logistics support and can manage cross-border shipping. Regular communication and updates throughout the production process will help mitigate any potential delays and allow for timely adjustments as needed. -

4. What are the minimum order quantities (MOQs) for metal casting services?

Minimum order quantities vary by supplier and the specific casting method used. Generally, die casting requires higher MOQs due to the investment in tooling, while sand and investment casting may accommodate smaller orders. Discuss your needs with potential suppliers and inquire about their flexibility on MOQs. If you anticipate future orders, some suppliers may offer reduced MOQs for initial runs, especially if a long-term partnership is established. -

5. How do I vet suppliers for metal casting services internationally?

To vet international suppliers, begin by researching their reputation and track record in the industry. Request references and case studies to assess their experience with similar projects. Verify their certifications, quality control processes, and production capabilities. Additionally, consider visiting their facilities if possible, or arrange for virtual tours. Engaging with suppliers who have a clear understanding of international trade regulations and logistics is also essential for smooth transactions. -

6. What payment terms should I negotiate with metal casting suppliers?

When negotiating payment terms, consider factors like order size, supplier relationships, and project risk. Common terms include a deposit upfront with the balance due upon delivery or after inspection. For larger orders, extended payment terms may be negotiated. Ensure that terms are clearly outlined in the contract to avoid disputes. Additionally, consider using secure payment methods that offer some level of buyer protection, especially in international transactions. -

7. How do I manage logistics for international shipping of metal castings?

Managing logistics for international shipping involves coordinating with your supplier to understand shipping options, costs, and timelines. Discuss who will handle import/export documentation and customs clearance to avoid delays. Utilize freight forwarders experienced in handling metal products to ensure compliance with regulations. Establish a clear shipping plan and consider warehousing options if needed to manage inventory effectively upon arrival. -

8. What are the common applications for metal castings across different industries?

Metal castings are widely used in various industries, including automotive, aerospace, construction, and consumer goods. In the automotive sector, castings are used for engine blocks and transmission housings due to their strength and durability. Aerospace applications often utilize lightweight aluminum castings for components requiring high strength-to-weight ratios. In construction, castings serve in fixtures and fittings. Understanding industry-specific requirements can guide you in selecting the right materials and methods for your casting needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Metal Casting Services Manufacturers & Suppliers List

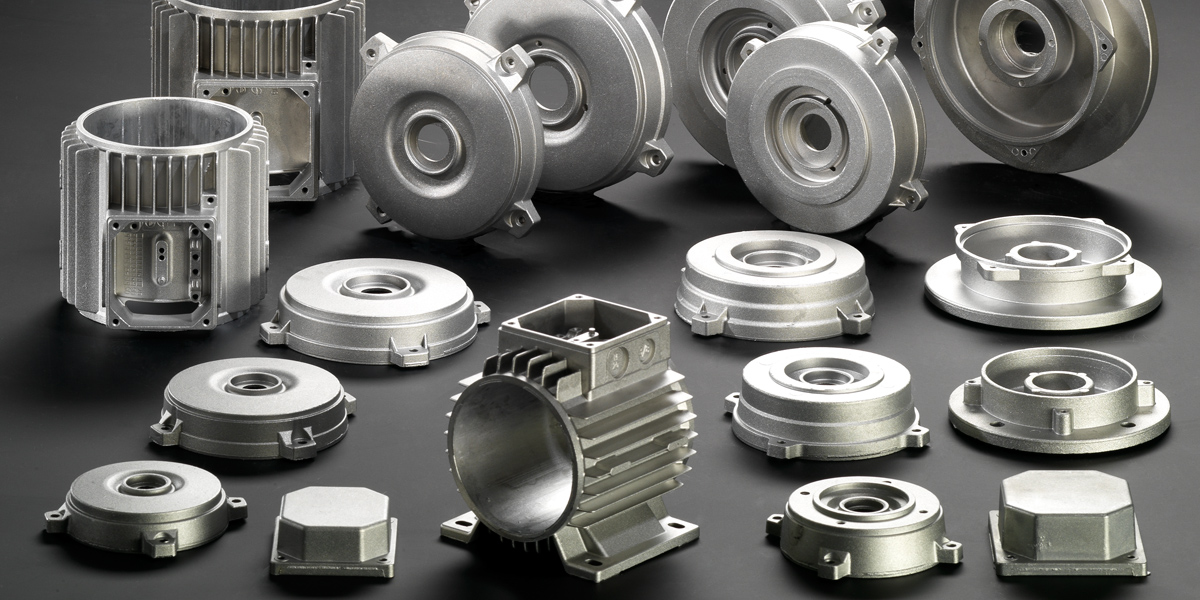

1. Reliance Foundry – Custom Metal Casting & Fabrication Services

Domain: reliance-foundry.com

Registered: 1997 (28 years)

Introduction: Reliance Foundry offers custom metal casting and fabrication services, including sand casting, investment casting, die casting, assembly, forging, fabrication, machining, and coating. They work with various metals such as ductile iron, grey iron, carbon steel, alloy steel, stainless steel, and aluminum. The company provides services like pattern development, production logistics, secondary process…

2. Compass & Anvil – Custom Metal Casting Services

Domain: compass-anvil.com

Registered: 2006 (19 years)

Introduction: Compass & Anvil offers a range of custom metal casting services including Die Casting, Investment Casting, Permanent Mold Casting, and Sand Casting. They work with various metals such as aluminum, steel, stainless steel, copper, zinc, magnesium, nickel, and alloys. The company has over 30 years of experience in global sourcing and provides hands-on facilitation throughout the product development p…

3. DeeCo Metals – Custom Metal Casting Services

Domain: deecometals.com

Registered: 2001 (24 years)

Introduction: Custom Metal Casting Services including Sand Castings, Die Castings, Green Sand Castings, Investment Castings, Architectural Metal Castings, and Gravity Casting. Specialization in custom metal cast parts such as Electric Motor Housings, Gear Boxes, Pump Housings, Valve Bodies, Fire Sprinkler Frames, Architectural parts, Marine parts, and Sporting equipment parts. Additional services include full o…

4. Buffalo Metal Casting – Non-Ferrous Castings & Machining Services

Domain: buffalometalcasting.com

Registered: 1999 (26 years)

Introduction: Buffalo Metal Casting is a single-source supplier of non-ferrous castings and finished parts, specializing in aluminum, brass, bronze, and copper sand metal castings. The company offers a range of services including sand casting (permanent mold, green sand, no-bake), CNC machining, and milling. They handle projects from prototype casting to high volume runs, ensuring quality assurance through in-h…

5. Casting House – Jewelry Casting Services

Domain: castinghouse.com

Registered: 1998 (27 years)

Introduction: Casting House offers jewelry casting services for both custom and mass production. The casting process includes several steps: wax model preparation, investment, burnout, melting, casting (using techniques like centrifugal, vacuum-assisted, pressure, and torch casting), and divesting. They provide access to over 40 precious metals, including variations of platinum, gold, white gold, and silver. Th…

6. Chicago White Metal Casting – High Pressure Die Casting Solutions

Domain: cwmdiecast.com

Registered: 1995 (30 years)

Introduction: Chicago White Metal Casting, Inc. specializes in high pressure die casting with a focus on Aluminum, Magnesium, and Zinc alloy castings. They offer full-service capabilities including engineering design services, tooling, machining, finishing, and contract assembly. Their applications span various industries such as industrial, medical and dental, transportation, recreational, alternative energy, …

7. Carrera Casting – Jewelry Casting Services

Domain: carreracasting.com

Registered: 2010 (15 years)

Introduction: Carrera Casting offers a variety of jewelry casting services including casting in white gold, yellow gold, pink gold, green gold, platinum, palladium, silver, brass, and bronze. Additional services include 3D scanning, 3D printing, and rubber mold services. They provide a free online pricing tool for instant pricing on all casting alloys and support custom design jewelry molds.

Strategic Sourcing Conclusion and Outlook for metal casting services

As the global demand for high-quality metal casting services continues to grow, strategic sourcing has become an essential practice for B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. By partnering with experienced suppliers who offer a range of services—from sand casting to die casting—companies can ensure they receive precision-engineered products that meet their specific requirements. Key considerations include material selection, production methods, and logistics management, which can significantly impact both cost and quality.

Investing time in a thorough sourcing strategy not only enhances product quality but also optimizes supply chain efficiency, allowing businesses to remain competitive in their respective markets. By leveraging advanced technologies and expertise offered by specialized foundries, buyers can access innovative solutions tailored to their unique challenges.

Looking ahead, the landscape of metal casting services is poised for transformation, driven by technological advancements and increasing collaboration across borders. International B2B buyers are encouraged to explore these opportunities and engage with suppliers who are committed to delivering exceptional value and performance. Embrace strategic sourcing today to secure a competitive edge in the dynamic global marketplace.