Contents

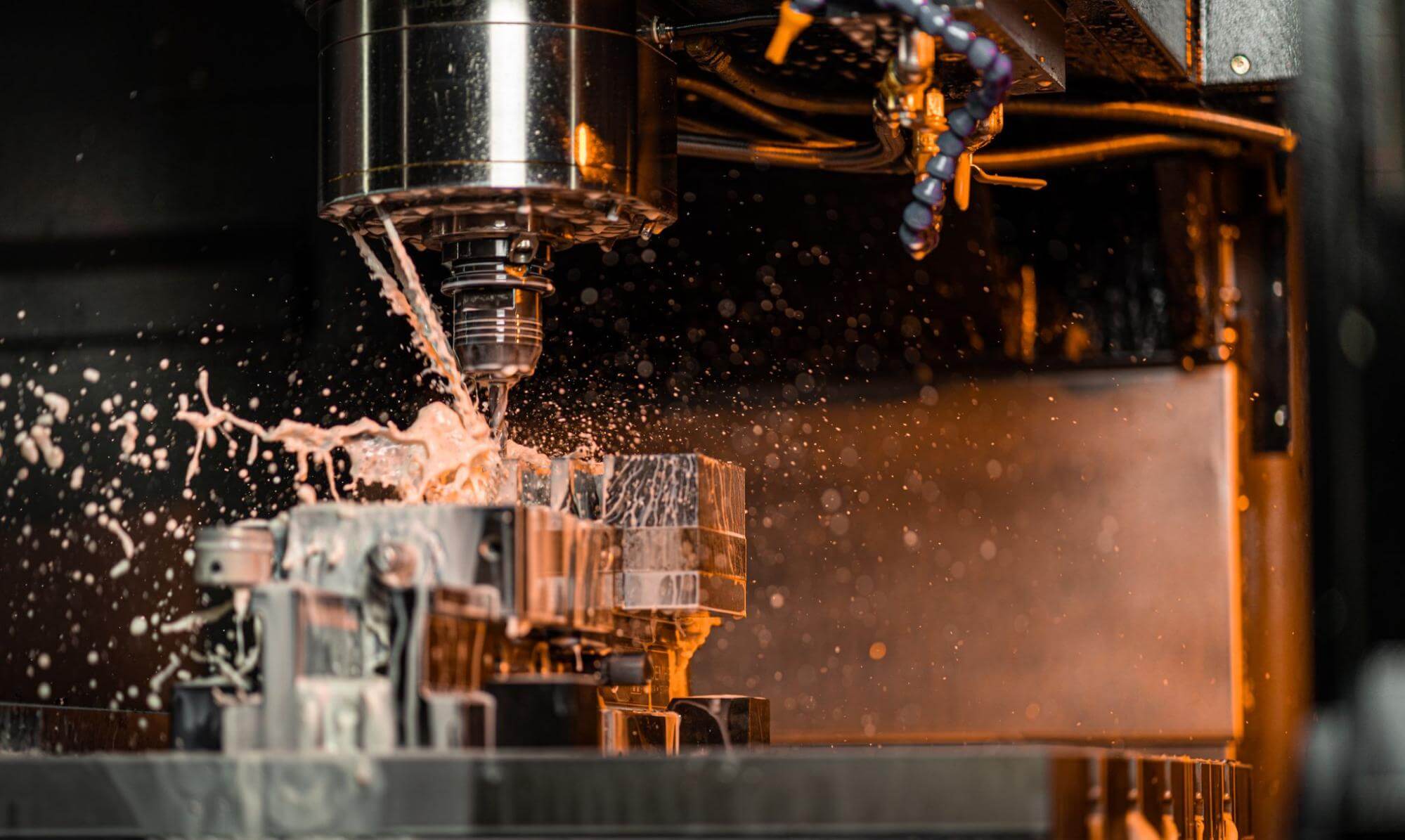

Manufacturing Insight: Metal Casting Services

Clarifying Manufacturing Capabilities for Precision Metal Solutions

Honyo Prototype delivers advanced metal manufacturing solutions, though it is critical to distinguish between distinct processes to ensure optimal project outcomes. Metal casting involves pouring molten material into molds to create complex geometries, while our core expertise lies in precision Sheet Metal Fabrication—a subtractive and formative process ideal for components requiring tight tolerances, structural integrity, and rapid iteration. Confusing these methodologies can lead to suboptimal material selection, extended lead times, or cost inefficiencies. At Honyo, we specialize exclusively in sheet metal fabrication, leveraging cutting-edge CNC punching, laser cutting, bending, welding, and finishing to transform flat metal stock into high-performance assemblies for aerospace, medical, and industrial applications.

Why Partner with Honyo for Sheet Metal Fabrication?

Our end-to-end sheet metal capabilities support low-to-mid volume prototyping and production runs with exceptional speed and accuracy. Utilizing state-of-the-art Amada and Bystronic equipment, we achieve tolerances down to ±0.05mm while handling materials from aluminum and stainless steel to copper and specialty alloys up to 6mm thickness. Every project benefits from integrated DFM analysis during quoting, ensuring manufacturability and cost control without compromising design intent. Crucially, our Online Instant Quote System provides real-time pricing and lead time estimates within 60 seconds—simply upload your STEP or DXF file to receive a transparent, no-obligation quotation validated by our engineering team. This digital workflow eliminates traditional quoting delays, accelerating your path from concept to certified, ready-to-assemble components.

Operational Excellence Backed by Data

Honyo maintains rigorous quality protocols across all fabrication stages, with ISO 9001:2015 certification and in-process inspections at critical control points. Below is a summary of our standard sheet metal fabrication performance metrics:

| Capability | Standard Specification | Max Capacity |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm | 8.0mm (select alloys) |

| Tolerance Accuracy | ±0.05mm | ±0.1mm (complex forms) |

| Lead Time (Prototype) | 5–7 business days | 10 business days |

| Max Part Dimensions | 1500mm x 3000mm | 2000mm x 4000mm |

For projects demanding precision-formed sheet metal components—not castings—Honyo Prototype provides the engineering rigor, technical agility, and digital quoting efficiency to meet stringent industry demands. Initiate your next fabrication project with confidence by accessing our Online Instant Quote portal today.

Technical Capabilities

Honyo Prototype provides precision metal casting services integrated with advanced fabrication processes including laser cutting, bending, and welding. These processes are optimized for a range of materials such as Aluminum, Steel, ABS, and Nylon, enabling high-accuracy prototyping and low-to-mid volume production. Below are the technical specifications for each process, including compatible materials and key performance parameters.

| Process | Material Compatibility | Thickness Range | Tolerance | Tooling / Equipment | Surface Finish (Ra) | Notes |

|---|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.5 mm – 25 mm | ±0.1 mm | CO₂ and Fiber Laser Systems (up to 4 kW) | 3.2 – 6.3 µm | Suitable for intricate profiles; minimal burr formation |

| Bending | Aluminum, Steel | 0.8 mm – 12 mm | ±0.2° angular / ±0.1 mm linear | CNC Press Brakes (up to 100 tons) | Matches base material | Max bend length: 3000 mm; variable die widths |

| Welding | Aluminum, Steel | 1.0 mm – 20 mm | ±0.5 mm joint alignment | TIG, MIG, and Spot Welding Systems | 6.3 – 12.5 µm | Full penetration welds; post-weld machining available |

| Material Notes | ||||||

| Aluminum (6061, 7075) | Machinable, weldable, lightweight | High corrosion resistance | Ideal for aerospace and automotive applications | |||

| Steel (Mild, Stainless 304/316) | High strength, weldable | Excellent durability and thermal resistance | Suitable for structural and industrial components | |||

| ABS | Not applicable for casting with welding/bending | Limited to laser cutting only | Used for jigs, fixtures, and non-load-bearing parts | |||

| Nylon (PA6, PA66) | Laser cutting only (thin sheets) | High impact and chemical resistance | Non-metallic; used for insulating or wear components |

Note: ABS and Nylon are not applicable for metal casting, bending, or welding. Their inclusion is limited to laser cutting for ancillary tooling or support components. All metal casting services are supported by DFM analysis, in-house metrology, and finishing options including powder coating, anodizing, and passivation.

From CAD to Part: The Process

Honyo Prototype Metal Casting Process Overview

Honyo Prototype delivers precision metal casting services through a streamlined, technology-driven workflow designed for engineering accuracy and rapid prototyping. Our process integrates AI-enhanced efficiency with rigorous engineering oversight to minimize lead times while ensuring manufacturability and part integrity. Below is a detailed breakdown of each phase.

CAD Upload and Initial Validation

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure portal. Our system performs immediate geometric validation, checking for file integrity, unit consistency, and basic manufacturability flags such as undercuts or non-uniform wall thickness. This step ensures the digital model aligns with casting physics constraints before proceeding, reducing downstream revisions.

AI-Assisted Quoting with Engineering Review

Uploaded designs enter our proprietary AI quoting engine, which analyzes part geometry, material selection, and dimensional complexity against historical production data. The AI generates a preliminary cost and lead time estimate within minutes, factoring in material density, foundry tooling requirements, and post-processing needs. Crucially, this output is not final; a Honyo Senior Manufacturing Engineer validates the AI’s assessment, adjusting for nuanced factors like gating system complexity, risk of hot spots, or secondary machining requirements. Clients receive a technically vetted quote with clear rationale for cost drivers.

Collaborative Design for Manufacturability (DFM)

Upon quote acceptance, our DFM phase begins as a partnership between client engineers and Honyo’s casting specialists. Using simulation software (MagmaSoft, Flow-3D), we model solidification behavior, predict porosity risks, and optimize runner systems. Key focus areas include:

Draft angle adjustments to prevent mold damage

Rib thickness recommendations to avoid shrinkage cavities

Strategic placement of risers for sound casting yield

Tolerance stack-up analysis for critical interfaces

This iterative review—typically completed in 24–72 hours—delivers a revised CAD package with actionable feedback, ensuring the design achieves target functionality without compromising castability.

Precision Production Execution

Approved designs move to production in our ISO 9001-certified facility. Honyo employs multiple casting methods based on part requirements:

| Process | Typical Materials | Tolerance Capability | Best For |

|---|---|---|---|

| Investment Casting | Inconel 718, Ti-6Al-4V | ±0.005 in (±0.13 mm) | Aerospace turbine blades, medical implants |

| Sand Casting | Al 356, Ductile Iron | ±0.020 in (±0.5 mm) | Automotive housings, heavy machinery components |

| Die Casting | A380 Aluminum, Zamak 3 | ±0.003 in (±0.08 mm) | High-volume consumer electronics enclosures |

Each lot undergoes real-time process monitoring with thermal analysis sensors and in-line dimensional checks. Critical features are verified via CMM post-casting, with full traceability from raw material certs to final inspection reports.

Quality-Controlled Delivery

Final parts ship with comprehensive documentation, including:

First-article inspection reports (FAIR) per AS9102 standards

Material test certificates (MTC) with chemical composition and mechanical properties

Dimensional inspection data against client-specified GD&T callouts

Non-destructive testing results (X-ray, dye penetrant) for mission-critical components

All shipments include serialized tracking and are palletized per military handling standards for global logistics security. Typical delivery occurs within 10–20 business days from DFM sign-off, with expedited options for urgent prototyping needs.

This integrated approach ensures clients receive production-ready castings with minimized risk of field failures, leveraging AI for speed while anchoring decisions in decades of metallurgical expertise. Honyo’s process is engineered to transition seamlessly from prototype to low-volume production, maintaining consistent quality across iterations.

Start Your Project

Looking for reliable metal casting services? Partner with Honyo Prototype for precision-crafted components manufactured at our Shenzhen facility. With advanced production capabilities and strict quality control, we deliver high-performance metal castings tailored to your specifications.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in metal casting and let us support your next manufacturing success.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.