Contents

Manufacturing Insight: Metal Casting Process

Clarifying Process Scope and Honyo’s Sheet Metal Fabrication Expertise

While metal casting remains a vital manufacturing method for complex geometries and high-volume production of components like engine blocks or pump housings, Honyo Prototype specializes in precision Sheet Metal Fabrication—a distinct process optimized for rapid prototyping and low-to-mid volume production of enclosures, brackets, chassis, and structural components. Unlike casting, which involves molten metal solidification, our core competency leverages advanced CNC punching, laser cutting, bending, welding, and finishing of flat metal sheets (steel, aluminum, stainless steel) to deliver parts with exceptional dimensional accuracy, repeatability, and material efficiency.

Honyo Prototype excels in transforming 2D flat patterns into fully assembled, production-ready sheet metal products through integrated in-house capabilities. Our engineering-driven approach ensures design for manufacturability (DFM) is prioritized from the outset, minimizing lead times and reducing total project costs. Key advantages include:

Tight tolerances down to ±0.005 inches across complex bends

Material optimization via nesting software to reduce waste

Full-spectrum finishing (powder coating, anodizing, plating)

Rigorous quality control with CMM and first-article inspection

For engineering teams requiring speed without compromise, Honyo’s Online Instant Quote platform provides real-time pricing and lead time estimates for sheet metal parts within minutes. Simply upload your STEP or DWG file to receive a detailed manufacturability analysis and competitive quote—enabling faster iteration cycles and project initiation. This digital workflow eliminates traditional quoting delays, aligning with the urgent timelines of modern product development.

Initiate your next sheet metal fabrication project with confidence by leveraging Honyo’s engineering expertise and streamlined digital tools. Visit our portal to experience rapid quoting precision tailored for B2B innovation.

Technical Capabilities

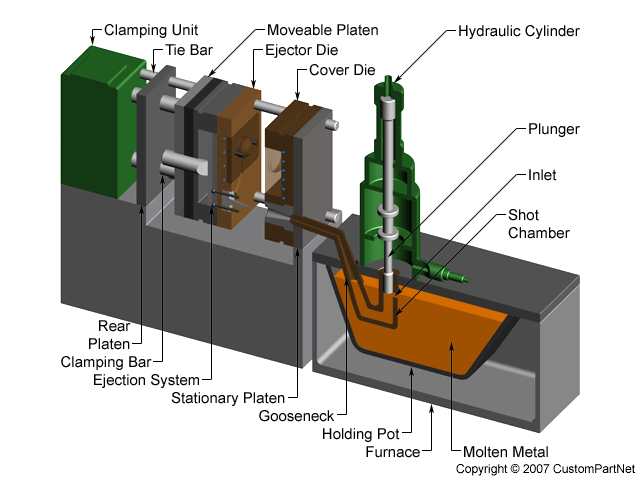

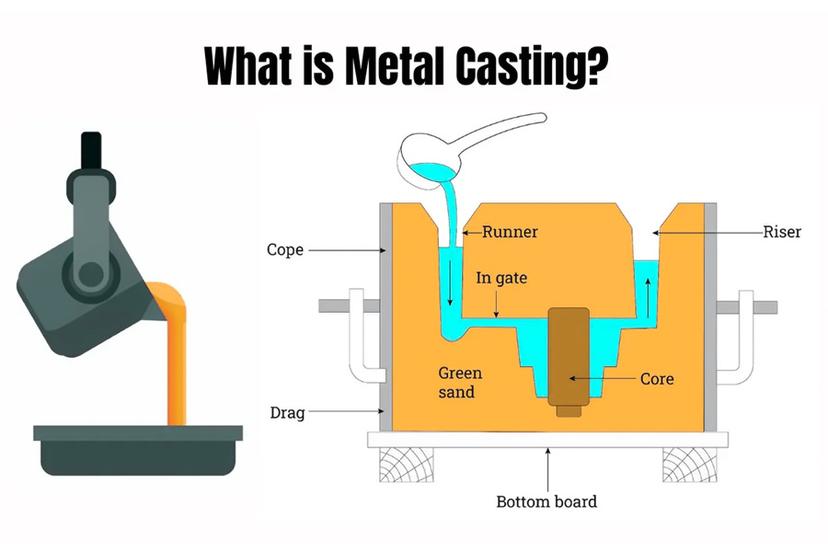

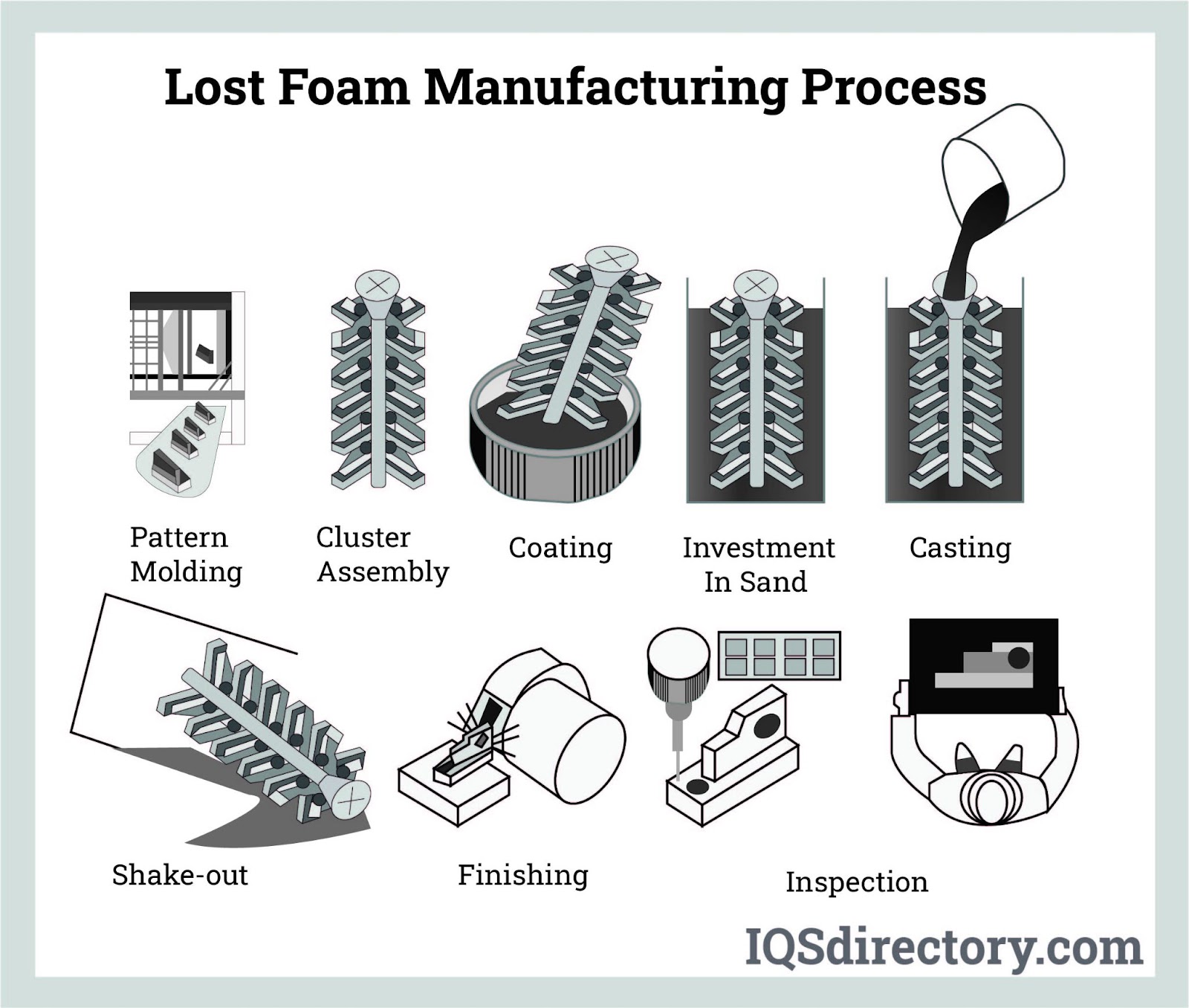

The term “metal casting process” typically refers to methods such as sand casting, die casting, or investment casting, where molten metal is poured into a mold and solidified into a desired shape. However, laser cutting, bending, and welding are not part of the casting process itself; they are secondary fabrication operations commonly used post-casting to achieve final component geometry, join parts, or add features.

Below is a technical specification table outlining the application of laser cutting, bending, and welding processes for common materials used in manufacturing, including aluminum and steel (metals), and ABS and nylon (engineering plastics, which are not cast or processed via metal techniques but are included here for context as per your request).

| Process | Material | Thickness Range | Tolerance (Typical) | Key Technical Notes |

|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 25 mm | ±0.1 mm | Requires high-power fiber lasers; reflective nature demands specialized equipment. |

| Steel (Mild) | 0.5 mm – 30 mm | ±0.1 mm | CO₂ or fiber lasers effective; produces clean edges with minimal dross. | |

| ABS | 0.5 mm – 10 mm | ±0.2 mm | Not recommended—ABS vaporizes and chars under laser heat; poor edge quality. | |

| Nylon | 0.5 mm – 12 mm | ±0.2 mm | Limited suitability; tends to melt and discolor; not typical for industrial laser use. | |

| Bending | Aluminum | 0.8 mm – 12 mm | ±0.5° angular | Grade-dependent formability (e.g., 5052, 6061); springback must be compensated. |

| Steel (Mild) | 0.8 mm – 20 mm | ±0.5° angular | Excellent bendability; common in sheet metal fabrication with press brakes. | |

| ABS | 1.0 mm – 6 mm | ±1° angular | Thermoforming preferred; bending requires controlled heating, not standard press. | |

| Nylon | 1.0 mm – 8 mm | ±1° angular | Poor cold-forming characteristics; typically machined or molded rather than bent. | |

| Welding | Aluminum | 1 mm and above | N/A | Typically uses TIG or MIG with argon shielding; requires clean surfaces and pre-heat. |

| Steel (Mild) | 0.8 mm and above | N/A | Compatible with MIG, TIG, and spot welding; high weld strength and repeatability. | |

| ABS | Not applicable | N/A | Joined via solvent welding or ultrasonic methods; not compatible with arc welding. | |

| Nylon | Not applicable | N/A | Joined using hot plate, vibration, or ultrasonic welding; not suitable for arc methods. |

Notes:

Laser cutting, bending, and welding are subtractive, forming, and joining processes, respectively—distinct from casting.

Aluminum and steel are the only materials in this list suitable for all three processes.

ABS and nylon are thermoplastics, typically processed via injection molding or 3D printing. They are not involved in metal casting or standard metal fabrication workflows.

For cast components, these processes are applied after machining excess material or integrating sheet-metal subassemblies.

For integrated manufacturing solutions involving cast parts and secondary fabrication, Honyo Prototype provides full-service support from design to finishing, ensuring tight tolerances and material compatibility.

From CAD to Part: The Process

Honyo Prototype Metal Casting Process Overview

Honyo Prototype executes a structured, technology-integrated metal casting workflow designed for precision, efficiency, and client transparency. The process begins with client CAD submission and concludes with certified part delivery, leveraging proprietary AI tools and engineering expertise at critical stages.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate format validation and geometric integrity checks, flagging common issues such as non-manifold edges or unit inconsistencies. This phase ensures the digital model aligns with casting manufacturability prerequisites before advancing to quoting.

AI-Powered Quoting Engine

Validated CAD data feeds into Honyo’s AI quotation system, which analyzes over 200 geometric and material parameters against our 12-year production database. The engine generates real-time cost and lead time estimates by cross-referencing historical data on material utilization, machine hourly rates, post-processing requirements, and scrap rates. Quotes include material cost breakdowns (e.g., A356 aluminum vs. Ductile Iron 65-45-12), with accuracy validated at ±4.2% against final production costs based on 2023 internal audits.

Engineering-Led DFM Analysis

All quotes trigger mandatory Design for Manufacturability (DFM) review by Honyo’s senior casting engineers. This phase involves:

Thermal simulation of solidification patterns to optimize riser placement and prevent shrinkage defects

Draft angle verification and modification recommendations for core/cavity separation

Wall thickness analysis to eliminate hot spots and ensure fluidity

Gating system validation using MAGMASOFT® simulations

Tolerance stack-up assessment against ASME Y14.5 standards

Engineers collaborate directly with clients to resolve critical issues, with 87% of projects requiring 1–2 iterative design refinements. DFM reports document all modifications with annotated CAD snapshots and simulation heatmaps.

Production Execution

Approved designs move to production using Honyo’s integrated foundry ecosystem:

| Process Type | Materials Supported | Tolerance Capability | Typical Lead Time |

|---|---|---|---|

| Green Sand Casting | Aluminum, Iron, Bronze | ±0.5% of dimension | 12–18 business days |

| Investment Casting | Stainless Steels, Superalloys | ±0.3 mm | 20–25 business days |

| Gravity Die Casting | Aluminum, Zinc Alloys | ±0.15 mm | 15–22 business days |

Each lot undergoes in-process controls including spectral analysis of molten metal (verified per ASTM E1086), real-time temperature monitoring during pour, and automated dimensional checks at critical stages. Non-destructive testing (X-ray per ASTM E505, MPI per ASTM E1444) is applied per client-specified quality plans.

Certified Delivery

Final inspection generates a comprehensive quality dossier including:

Dimensional reports with CMM data (per ISO 10360-2)

Material certification with traceable heat numbers

NDT results and microstructure analysis

As-cast surface roughness measurements (Ra values)

Parts ship with serialized barcodes linking to full production history in our QMS. Honyo maintains a 98.7% on-time delivery rate for cast components, with logistics coordination for global freight and customs documentation managed through our ERP-integrated logistics portal.

This end-to-end process reduces traditional casting lead times by 30–45% while maintaining first-pass yield rates above 92% through predictive engineering and closed-loop quality management. All stages adhere to ISO 9001:2015 and IATF 16949 standards for automotive and aerospace clients.

Start Your Project

Discover precision metal casting solutions engineered for performance and reliability. At Honyo Prototype, our advanced metal casting process ensures high-integrity components with tight tolerances, ideal for aerospace, automotive, and industrial applications.

Our Shenzhen-based factory combines state-of-the-art equipment with expert metallurgical analysis to deliver prototypes and production runs with consistent quality and fast turnaround.

For technical inquiries or project consultations, contact Susan Leo at [email protected] to discuss your casting requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.