Introduction: Navigating the Global Market for metal bracket fabrication

Navigating the complex landscape of metal bracket fabrication can be a daunting challenge for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Sourcing high-quality metal brackets that meet specific application needs while ensuring competitive pricing and timely delivery is critical for maintaining operational efficiency. This guide aims to demystify the global market for metal bracket fabrication by providing insights into various types of brackets, their applications across industries, and strategies for effective supplier vetting.

From understanding the nuances of materials like steel, stainless steel, and aluminum to exploring the latest fabrication techniques, this comprehensive resource empowers decision-makers with the knowledge needed to make informed purchasing choices. Buyers will gain valuable insights into cost considerations, production capabilities, and the importance of quick turnaround times, which are particularly relevant for dynamic markets like Brazil and Nigeria. Furthermore, we will delve into best practices for establishing partnerships with reliable manufacturers, ensuring that your sourcing process is not only efficient but also aligns with your business objectives.

By equipping B2B buyers with actionable insights and strategies, this guide serves as a vital tool for navigating the intricacies of metal bracket fabrication, ultimately supporting the growth and success of businesses across continents.

Understanding metal bracket fabrication Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laser Cut and Folded | Precision cutting and bending from flat metal sheets | Aerospace, Telecommunications, Industrial Equipment | Pros: High accuracy; customizable shapes. Cons: Potentially higher costs for low volumes. |

| Laser Cut and Welded | Combines cutting and welding for complex structures | Automotive, Heavy Machinery, Construction | Pros: Stronger joints; suitable for heavy loads. Cons: Longer lead times; requires more skilled labor. |

| Mechanically Fastened | Utilizes bolts or screws for assembly, allowing easy disassembly | Furniture, Racking Systems, Electrical Equipment | Pros: Easy to install and replace; versatile. Cons: May require additional hardware; less aesthetic finish. |

| Powder Coated Brackets | Coated with a durable finish for aesthetics and corrosion resistance | Retail Displays, Architectural Features, Marine | Pros: Enhanced appearance; weather-resistant. Cons: Additional cost for coating; potential for chipping. |

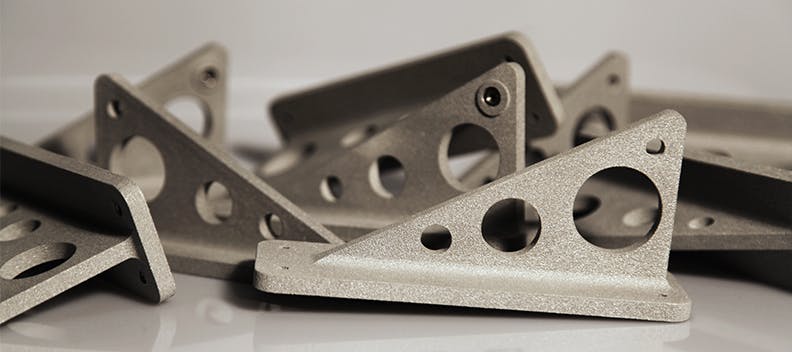

| Custom Fabricated Brackets | Tailored designs based on specific client requirements | Specialty Equipment, Medical Devices, Custom Furniture | Pros: Perfect fit for unique applications; high flexibility. Cons: Longer production time; may require detailed specifications. |

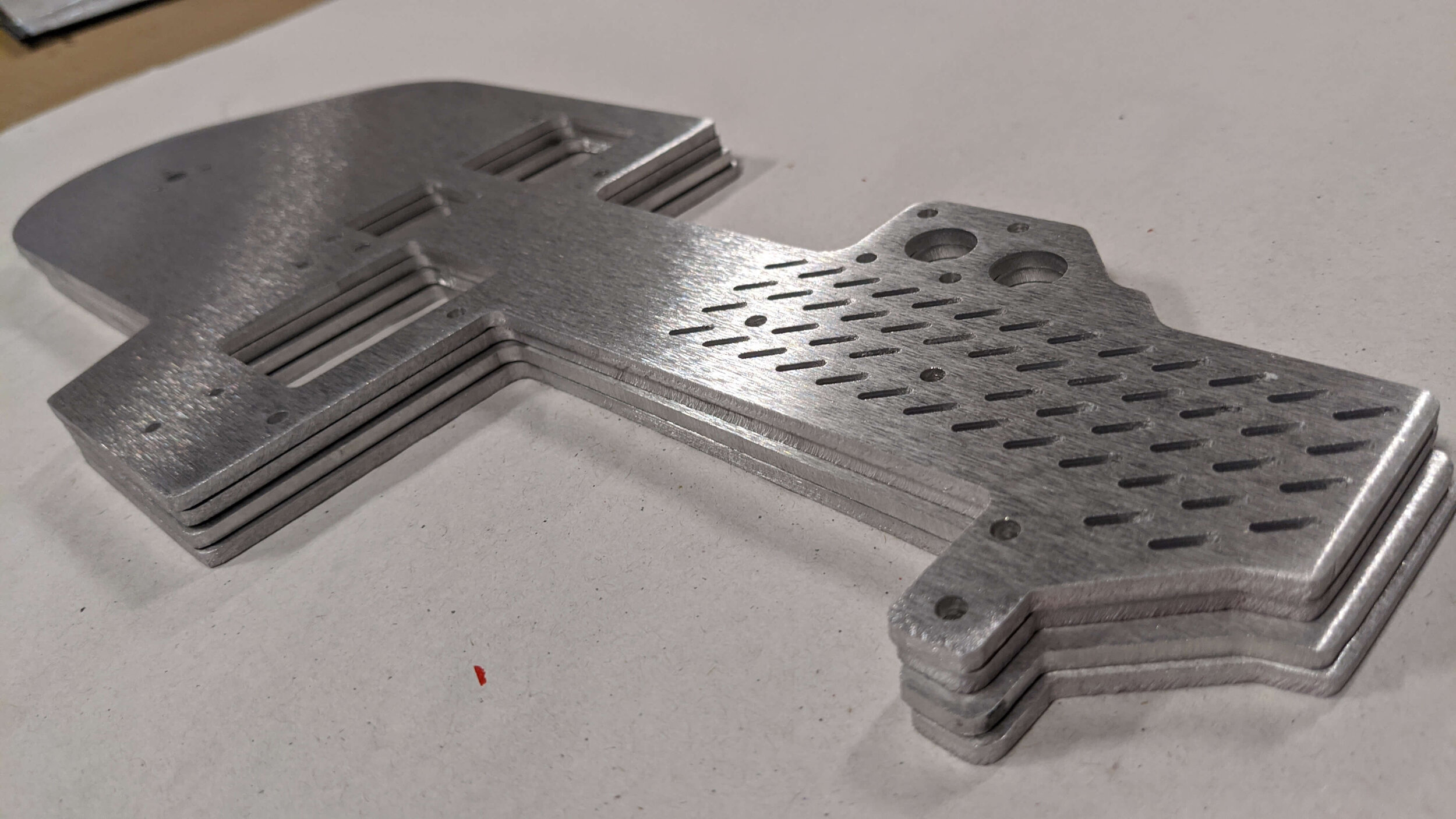

What Are the Characteristics of Laser Cut and Folded Brackets?

Laser cut and folded brackets are fabricated from flat metal sheets using high-precision laser cutting technology. This method allows for intricate designs and tight tolerances, making it ideal for applications in sectors like aerospace and telecommunications where precision is paramount. When considering this type, B2B buyers should evaluate their volume needs, as costs can escalate for lower production runs.

How Do Laser Cut and Welded Brackets Stand Out?

Laser cut and welded brackets are known for their robustness, combining the accuracy of laser cutting with the strength of welding. This fabrication method is particularly suited for industries such as automotive and heavy machinery, where durability is critical. Buyers should consider the required lead time and the complexity of their designs, as these factors can influence the overall cost and timeline.

What Are the Benefits of Mechanically Fastened Brackets?

Mechanically fastened brackets are designed for ease of assembly and disassembly, using bolts or screws. This versatility makes them popular in furniture and racking systems. When purchasing, B2B buyers should assess their installation needs and whether the ability to disassemble is a priority, as this could affect the choice between different fastening methods.

Why Choose Powder Coated Brackets for Your Projects?

Powder coated brackets offer both aesthetic appeal and enhanced durability, making them suitable for retail displays and architectural applications. The powder coating process provides a weather-resistant finish, which is essential for outdoor use. Buyers must weigh the additional costs associated with powder coating against the benefits of improved appearance and longevity.

What Makes Custom Fabricated Brackets a Smart Investment?

Custom fabricated brackets are tailored to meet the specific requirements of a project, offering unparalleled flexibility in design. This type of fabrication is beneficial in niche markets such as specialty equipment and medical devices. B2B buyers should be prepared to provide detailed specifications and understand that the customization process may extend lead times, impacting project timelines.

Key Industrial Applications of metal bracket fabrication

| Industry/Sector | Specific Application of metal bracket fabrication | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Mounting brackets for aircraft components | Enhances safety and performance of aircraft systems | Compliance with aviation standards and certifications |

| Telecommunications | Brackets for antenna and tower installations | Ensures stability and longevity of communication systems | Materials that withstand environmental conditions |

| Automotive | Hanger brackets for exhaust systems | Improves vehicle durability and performance | Customization for specific vehicle models and specs |

| Food Processing | Brackets for equipment support in processing plants | Ensures hygiene and efficiency in food production | Compliance with food safety regulations |

| Construction | Structural brackets for framing and support | Provides essential support for building integrity | Local sourcing for quicker delivery and compliance with local codes |

How is Metal Bracket Fabrication Used in Aerospace Applications?

In the aerospace industry, metal bracket fabrication is crucial for mounting various aircraft components, including engines, control surfaces, and instrumentation. These brackets must meet stringent safety and performance standards, ensuring that they can withstand high stress and extreme environmental conditions. International buyers in this sector should prioritize suppliers with proven experience in aerospace applications and the ability to provide documentation for compliance with aviation regulations.

What Role Do Metal Brackets Play in Telecommunications?

Telecommunications relies on robust metal brackets for supporting antennas and towers. These brackets must be designed to endure harsh weather conditions while maintaining signal integrity. Buyers should consider sourcing brackets made from corrosion-resistant materials, such as stainless steel, to ensure long-term performance. Additionally, suppliers should demonstrate expertise in custom designs that accommodate specific installation requirements.

How are Metal Brackets Utilized in the Automotive Sector?

In the automotive industry, metal bracket fabrication is essential for creating hanger brackets that support exhaust systems and other components. These brackets are designed to enhance vehicle durability and performance by minimizing vibrations and ensuring secure placements. International buyers should look for manufacturers that can provide custom solutions tailored to specific vehicle models, as well as materials that comply with automotive industry standards.

What is the Importance of Metal Bracket Fabrication in Food Processing?

Metal brackets are vital in food processing facilities, where they support equipment such as conveyors and mixers. These brackets must comply with food safety regulations, ensuring that they are easy to clean and resistant to corrosion. Buyers in this sector should prioritize suppliers that understand the unique challenges of food processing environments and can deliver solutions that enhance operational efficiency while maintaining hygiene standards.

How are Metal Brackets Applied in Construction Projects?

In construction, metal bracket fabrication is key for providing structural support in framing and other applications. These brackets ensure the stability and integrity of buildings, making them essential for safe construction practices. Buyers should consider local sourcing to facilitate faster delivery times and ensure compliance with regional building codes. Additionally, understanding the specific load requirements for different construction projects can help in selecting the right type of brackets.

3 Common User Pain Points for ‘metal bracket fabrication’ & Their Solutions

Scenario 1: Inconsistent Quality of Metal Brackets

The Problem: B2B buyers often face challenges with the inconsistency in quality when sourcing metal brackets. Variability in dimensions, strength, and finish can lead to significant issues in assembly and functionality, ultimately affecting the overall performance of the end product. For companies in sectors such as construction or manufacturing, these inconsistencies can result in costly delays and rework, damaging client relationships and reputations.

The Solution: To mitigate quality issues, buyers should prioritize sourcing from manufacturers that provide detailed specifications and quality assurance processes. Requesting samples before bulk orders can help assess the quality of the brackets. Additionally, establishing a robust communication channel with suppliers about specific requirements, such as material grades and tolerances, is crucial. Engaging with manufacturers that utilize advanced fabrication techniques—like laser cutting and precision welding—can ensure high-quality outputs. Regular audits and quality checks throughout the production process can further help maintain the standard.

Scenario 2: Long Lead Times in Metal Bracket Production

The Problem: Long lead times can be a significant pain point for B2B buyers, especially when they require custom metal brackets for urgent projects. Delays in receiving essential components can stall production lines or project timelines, leading to missed deadlines and increased costs. This is particularly problematic for businesses in fast-paced industries like automotive or aerospace, where time-to-market is critical.

The Solution: To address lead time concerns, buyers should seek manufacturers who offer rapid prototyping and have streamlined production processes. Inquire about the manufacturer’s capabilities for quick-turnaround projects and their average lead times for various order volumes. Establishing relationships with multiple suppliers can also provide backup options in case of unforeseen delays. Additionally, investing in planning and forecasting tools can help anticipate bracket needs, allowing companies to place orders well in advance. Suppliers who can ship custom orders the same day or within a few days should be prioritized to ensure timely delivery.

Scenario 3: Difficulty in Customization and Design Adaptability

The Problem: Customization is often a necessity for B2B buyers seeking metal brackets tailored to specific applications. However, many suppliers have rigid designs and limited options, making it difficult for buyers to find the right fit for their unique requirements. This limitation can stifle innovation and compromise the functionality of the final product, particularly in specialized industries like telecommunications or medical equipment.

The Solution: To overcome challenges in customization, buyers should engage with manufacturers that have a flexible approach to design and fabrication. Clearly communicate your specifications, including dimensions, materials, and finishes, to ensure the supplier understands your needs. Look for companies that offer CAD design services, allowing buyers to visualize the product before fabrication begins. This can also facilitate adjustments in design, ensuring the final product meets expectations. Additionally, consider suppliers that have experience across various industries, as their diverse knowledge can lead to innovative solutions and ideas for unique bracket designs. Regular feedback loops with the supplier during the design process can ensure alignment and satisfaction with the final product.

Strategic Material Selection Guide for metal bracket fabrication

What Are the Key Properties of Common Materials Used in Metal Bracket Fabrication?

When selecting materials for metal bracket fabrication, it’s essential to consider their properties, performance, and suitability for specific applications. Below is an analysis of four common materials used in the industry: steel, stainless steel, aluminum, and brass.

Steel: A Versatile Choice for Structural Applications

Steel is renowned for its high tensile strength and durability, making it an ideal choice for heavy-duty applications. It can withstand significant loads and is suitable for environments where high pressure and temperature variations are common. However, steel is prone to corrosion, which may necessitate additional protective coatings or treatments.

Pros: Steel brackets are cost-effective and readily available. They can be fabricated easily and are suitable for a wide range of applications, from construction to automotive.

Cons: The main drawback of steel is its susceptibility to rust if not properly treated. This can limit its use in outdoor or humid environments.

Impact on Application: Steel brackets are often used in structural applications, such as supporting beams or heavy machinery, where strength is paramount.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local standards for steel grades (e.g., ASTM A36) and corrosion resistance requirements.

Stainless Steel: Corrosion-Resistant and Durable

Stainless steel is known for its excellent corrosion resistance, making it suitable for applications exposed to moisture or chemicals. It maintains its strength at elevated temperatures and is often used in food processing and medical applications.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, which enhances its longevity. It also offers a polished finish that is aesthetically pleasing.

Cons: Stainless steel is generally more expensive than regular steel and can be more challenging to machine due to its hardness.

Impact on Application: Ideal for environments requiring hygiene and corrosion resistance, stainless steel brackets are commonly used in the food and beverage industry, as well as in medical equipment.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel grades is crucial, especially in regions with strict health regulations.

Aluminum: Lightweight and Versatile

Aluminum is favored for its lightweight properties, making it an excellent choice for applications where weight reduction is critical. It offers good corrosion resistance and can be easily machined and formed.

Pros: Aluminum brackets are easy to transport and install due to their light weight. They also have a good strength-to-weight ratio, which is beneficial in many applications.

Cons: While aluminum is resistant to corrosion, it is not as strong as steel or stainless steel, which may limit its use in heavy-duty applications.

Impact on Application: Commonly used in aerospace and automotive applications, aluminum brackets are ideal for mounting equipment where weight savings are essential.

Considerations for International Buyers: Buyers should ensure that the aluminum grades meet regional standards, such as the European EN 573 or American ASTM B221.

Brass: Aesthetic Appeal with Moderate Strength

Brass is often used for decorative applications due to its attractive appearance and good machinability. It offers moderate strength and corrosion resistance, making it suitable for various indoor applications.

Pros: Brass brackets provide a unique aesthetic appeal and are resistant to corrosion, particularly in dry environments.

Cons: Brass is generally more expensive than steel and aluminum, and its strength is lower, which can limit its use in load-bearing applications.

Impact on Application: Brass brackets are commonly used in architectural applications and decorative fixtures.

Considerations for International Buyers: Understanding the specific brass grades and their properties is essential, especially for buyers in regions with varying aesthetic preferences.

Summary of Material Selection for Metal Bracket Fabrication

| Material | Typical Use Case for metal bracket fabrication | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty structural applications | High strength and durability | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Aluminum | Aerospace, automotive applications | Lightweight and easy to fabricate | Lower strength compared to steel | Medium |

| Brass | Decorative fixtures, architectural applications | Aesthetic appeal and good machinability | Moderate strength and higher cost | Medium |

This guide serves as a strategic overview for international B2B buyers, enabling informed decisions on material selection for metal bracket fabrication based on specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metal bracket fabrication

What Are the Main Stages of Metal Bracket Fabrication?

Metal bracket fabrication involves a series of precise manufacturing stages that ensure the final product meets the specifications required by B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Metal Bracket Fabrication?

Material preparation is crucial as it sets the foundation for quality output. Manufacturers typically start by sourcing high-grade metals such as stainless steel, aluminum, and carbon steel, which are chosen based on the application requirements. The materials are then cut to size using methods like shearing or laser cutting, ensuring minimal waste and high accuracy. Additionally, the preparation stage may include surface cleaning to remove any contaminants that could affect subsequent processes.

What Forming Techniques Are Commonly Used in Metal Bracket Fabrication?

The forming stage is where the flat metal sheets are transformed into the desired bracket shapes. Common techniques include:

- Bending: This is often achieved using press brakes, which apply force to bend the metal at specific angles, creating the necessary structure for the brackets.

- Stamping: This technique involves pressing a die onto the metal sheet to cut or shape it. Stamping is efficient for high-volume production and provides consistent results.

- Welding: For brackets requiring multiple components, welding is employed to join parts securely. Techniques such as MIG or TIG welding are commonly used depending on the metal type and thickness.

These forming techniques ensure that the brackets are not only functional but also meet aesthetic requirements when applicable.

How Are Metal Brackets Assembled and Finished?

Once the individual components are formed, assembly begins. This may involve mechanical fastening, such as using screws or bolts, or welding, depending on the design. After assembly, finishing processes enhance the bracket’s durability and appearance. Common finishing techniques include:

- Powder Coating: This process involves applying a dry powder that is then cured under heat, creating a hard finish that is resistant to chipping and scratching.

- Polishing: For applications requiring a more aesthetic appeal, polishing can provide a mirror-like finish, particularly for stainless steel brackets.

- Painting: Traditional painting methods may also be used, allowing for a variety of colors and finishes.

What Quality Assurance Measures Are Essential in Metal Bracket Fabrication?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final products meet international standards and specific industry requirements.

Which International Standards Should B2B Buyers Consider?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding international standards is vital. ISO 9001 is the most recognized standard for quality management systems, emphasizing a process-oriented approach. Compliance with this standard indicates that a manufacturer has robust processes in place to ensure quality.

Industry-specific standards may also apply, such as:

- CE Marking: Required for products sold in the European Economic Area, it signifies compliance with health, safety, and environmental protection standards.

- API Standards: For those in the oil and gas sector, adherence to American Petroleum Institute (API) standards ensures that products meet rigorous safety and quality benchmarks.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage checks the materials received for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing inspections ensure that processes are adhered to and that any deviations are corrected immediately.

- Final Quality Control (FQC): Once production is complete, the finished products undergo rigorous testing against the set specifications, including dimensional checks, visual inspections, and functional tests.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

Verification of a supplier’s quality assurance processes is crucial for mitigating risks associated with product quality. Buyers can take several steps to ensure compliance:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality assurance practices. Buyers should:

- Request access to the supplier’s quality management system documentation.

- Review their compliance with relevant standards such as ISO 9001 or industry-specific certifications.

- Evaluate their QC processes, including how they handle non-conformances and their corrective actions.

How Can Third-Party Inspections Enhance Quality Assurance?

Utilizing third-party inspection services can further enhance confidence in the supplier’s quality assurance processes. Independent inspectors can conduct thorough evaluations of manufacturing practices, ensuring that the products meet all necessary specifications before shipment. This is particularly beneficial for international buyers who may face challenges verifying compliance from afar.

What Nuances Should International Buyers Consider Regarding Quality Certification?

International buyers must also be aware of the nuances surrounding quality certifications. For instance, certificates may vary in recognition depending on the region, and local regulations can affect compliance requirements. Buyers in Africa, South America, and the Middle East should familiarize themselves with both international standards and local regulations to ensure that their suppliers can meet all necessary compliance measures.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures in metal bracket fabrication is essential for B2B buyers. By focusing on the main stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions that ensure they receive high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal bracket fabrication’

Introduction

Navigating the procurement of metal bracket fabrication requires careful planning and a clear understanding of your specific needs. This guide provides a practical checklist for B2B buyers, ensuring you secure high-quality metal brackets that meet your technical specifications while optimizing costs and delivery times. Follow these steps to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Clearly articulate the requirements for your metal brackets, including dimensions, materials, load-bearing capacity, and finish. This step is crucial as it sets the foundation for your entire project and ensures suppliers can meet your expectations. Consider the specific applications of the brackets and any industry standards that may apply.

- Materials: Decide whether you need aluminum, stainless steel, or another metal based on strength, corrosion resistance, and weight.

- Dimensions: Specify exact measurements, including thickness, width, and length.

Step 2: Conduct Market Research

Before selecting a supplier, conduct thorough market research to identify potential manufacturers. Look for companies with a strong reputation in the metal fabrication industry, especially those experienced in your sector. Understanding market trends and pricing can also help you negotiate better terms.

- Industry Reviews: Consult industry-specific forums and publications for insights on supplier performance.

- Competitive Analysis: Compare offerings from different suppliers to gauge quality and pricing.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence helps you assess their capabilities and reliability, ensuring you choose a supplier that aligns with your project needs.

- Certifications: Verify if the supplier holds relevant quality certifications, such as ISO 9001, which reflects their commitment to quality standards.

- Experience: Look for suppliers with a proven track record in custom metal fabrication, especially for the types of brackets you require.

Step 4: Request Samples and Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of their metal brackets. This step allows you to evaluate the quality and craftsmanship firsthand, ensuring they meet your specifications before making a larger commitment.

- Testing: Assess the samples for durability, finish quality, and adherence to your specifications.

- Feedback: Involve your engineering team in the evaluation process to get technical insights.

Step 5: Discuss Lead Times and Production Capabilities

Understanding the supplier’s lead times and production capabilities is critical for planning your project timeline. Ensure they can meet your deadlines, especially if you have tight schedules or high-volume needs.

- Flexibility: Inquire about their ability to handle rush orders or adjustments to production schedules.

- Capacity: Confirm whether they can scale production to accommodate future orders.

Step 6: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms and pricing that align with your budget. Transparency in pricing structures, including material costs and potential additional fees, is essential to avoid unexpected expenses later.

- Volume Discounts: Ask about pricing tiers based on order quantities to maximize savings.

- Payment Terms: Discuss payment options, including potential deposit requirements and payment schedules.

Step 7: Finalize Contracts and Agreements

Once you’ve selected a supplier, finalize contracts that outline all agreed-upon terms, including specifications, pricing, lead times, and quality assurance measures. Having a solid contract in place protects both parties and ensures accountability throughout the fabrication process.

- Legal Review: Consider having a legal expert review the contract to ensure all terms are clear and enforceable.

- Change Management: Include provisions for managing changes to specifications or timelines, should the need arise.

By following these steps, B2B buyers can effectively navigate the sourcing of metal bracket fabrication, ensuring they make informed decisions that align with their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for metal bracket fabrication Sourcing

What Are the Key Cost Components in Metal Bracket Fabrication?

When sourcing metal bracket fabrication, understanding the cost structure is essential for making informed decisions. The primary cost components include:

-

Materials: The choice of metal significantly impacts costs. Common materials such as steel, stainless steel, and aluminum have varying prices. For instance, stainless steel tends to be more expensive than carbon steel due to its corrosion resistance and durability. Buyers should request current material prices from suppliers to gauge market trends.

-

Labor: Labor costs vary depending on the complexity of the fabrication process. Skilled labor is required for custom designs, which can increase hourly rates. Moreover, regions with higher labor costs will reflect this in their pricing.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and other operational costs associated with running a fabrication facility. Efficient manufacturers often have lower overhead costs, which can translate into better pricing for buyers.

-

Tooling: If custom tooling is required for specific designs, this adds to the initial costs. Buyers should consider whether the tooling costs can be amortized over larger production runs to minimize the impact on unit price.

-

Quality Control (QC): Ensuring that products meet specified standards can incur additional costs. Effective QC processes are essential for maintaining quality, especially for industries like aerospace or automotive, where compliance with regulations is critical.

-

Logistics: Shipping costs can vary widely based on the destination, size, and weight of the brackets. International buyers should account for potential tariffs and customs duties, which can add to the overall cost.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding standard margins within the industry can help buyers gauge if a quote is competitive.

How Do Price Influencers Impact Metal Bracket Costs?

Several factors influence the final price of metal brackets:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ is crucial, as it can impact total costs, especially for smaller businesses.

-

Specifications and Customization: Custom designs typically incur higher costs due to the additional labor and tooling required. Buyers should balance their need for customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) often come at a premium. However, these can be essential for specific applications where safety and durability are paramount.

-

Supplier Factors: The reliability and reputation of the supplier can also affect pricing. Established suppliers may charge more, but they often provide better quality assurance and customer service.

-

Incoterms: Understanding shipping terms is vital. Different Incoterms can alter the cost structure significantly, with some placing the responsibility for shipping and insurance on the buyer and others on the seller.

What Tips Can International Buyers Use to Navigate Pricing Nuances?

International buyers should consider several strategies to optimize their sourcing process:

-

Negotiate Wisely: Engage in negotiations with suppliers to explore volume discounts or flexible payment terms. Having multiple quotes can strengthen your negotiating position.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes not only the purchase price but also shipping, handling, and long-term durability of the brackets.

-

Consider Local Regulations: Different regions have varying regulations and standards, which can affect costs. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local compliance requirements to avoid unexpected expenses.

-

Leverage Technology: Utilize online platforms for sourcing and comparing suppliers. This can aid in identifying competitive pricing and gaining insights into supplier reliability.

-

Be Aware of Pricing Fluctuations: Metal prices can be volatile due to market conditions. Keeping abreast of market trends and being flexible with timing can lead to better purchasing decisions.

Disclaimer on Indicative Prices

Pricing for metal bracket fabrication can fluctuate based on a multitude of factors, including market conditions, material availability, and supplier capabilities. It is advisable for buyers to request updated quotes directly from suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing metal bracket fabrication With Other Solutions

When evaluating solutions for structural support and mounting applications, businesses often consider a variety of methods beyond traditional metal bracket fabrication. This section explores alternative solutions, focusing on their performance, cost-effectiveness, implementation ease, maintenance needs, and best use cases. Understanding these alternatives is crucial for B2B buyers looking to make informed decisions that align with their specific operational requirements.

Comparison Table

| Comparison Aspect | Metal Bracket Fabrication | 3D Printing | Injection Molding |

|---|---|---|---|

| Performance | High strength and durability | Variable strength; depends on material | High precision and consistency |

| Cost | Moderate for low to medium volumes | High setup costs, low for large runs | High initial investment, low per unit at scale |

| Ease of Implementation | Requires skilled labor and equipment | Requires design software and knowledge | Requires molds and setup time |

| Maintenance | Low; generally long-lasting | Medium; depends on material properties | Low; durable parts but requires quality checks |

| Best Use Case | Custom applications across industries | Prototyping and complex geometries | High-volume production runs |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of 3D Printing?

3D printing, or additive manufacturing, offers unique advantages, particularly in rapid prototyping and complex design capabilities. It allows for the creation of intricate shapes that would be challenging or impossible to fabricate using traditional methods. The initial costs can be high due to the need for specialized equipment and software, but the cost per unit decreases significantly for larger production runs. However, the strength of 3D-printed parts can vary widely depending on the materials used, which may not always match the robustness of metal brackets. This method is best suited for industries requiring customization and rapid iteration, such as aerospace and medical devices.

How Does Injection Molding Compare to Metal Bracket Fabrication?

Injection molding is a highly efficient manufacturing process for producing large quantities of identical parts, making it ideal for high-volume applications. The initial setup cost is substantial due to the need for custom molds, but once established, the cost per unit drops significantly. Injection molded parts are typically very consistent in quality and can be made from a variety of materials, including plastics and metals. However, this method lacks the flexibility of metal bracket fabrication, as it is not suitable for small runs or custom designs. It is best utilized in consumer goods and automotive industries where large quantities are required.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right fabrication method depends on multiple factors, including production volume, material requirements, and the intended application. Metal bracket fabrication is an excellent choice for custom, low to medium volume needs where strength and durability are paramount. In contrast, 3D printing is advantageous for intricate designs and rapid prototyping, while injection molding excels in high-volume production scenarios. B2B buyers should evaluate their specific needs, including budget constraints and project timelines, to determine the most suitable solution that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for metal bracket fabrication

What Are the Key Technical Properties in Metal Bracket Fabrication?

Understanding the technical properties of metal brackets is crucial for B2B buyers to ensure they select the right components for their applications. Here are some essential specifications to consider:

-

Material Grade

– The material grade refers to the specific type of metal used in fabrication, such as stainless steel (e.g., 304, 316), aluminum (e.g., 5052, 6061), or carbon steel. Different grades offer varying levels of strength, corrosion resistance, and weight. For instance, 316 stainless steel is often preferred in marine environments due to its superior corrosion resistance, while 6061 aluminum is favored for its lightweight properties. Selecting the right material grade is essential for meeting performance requirements and ensuring longevity in various applications. -

Tolerance

– Tolerance is the allowable deviation from specified dimensions in the fabrication process. It is vital for ensuring that parts fit together correctly and function as intended. For example, tighter tolerances may be required in applications involving high-precision equipment. Understanding tolerance levels helps buyers determine whether the manufacturer can meet their specific needs and ensures compatibility with other components. -

Thickness

– The thickness of the metal bracket impacts its strength and durability. Common thicknesses for metal brackets range from 0.024 inches to 1.000 inches, depending on the material and intended use. Thicker brackets provide greater support and can withstand heavier loads, making it essential for buyers to specify their load-bearing requirements to avoid premature failure. -

Finish

– The finish of a metal bracket affects both aesthetics and functionality. Options include brushed, polished, or powder-coated surfaces. A powder-coated finish can enhance corrosion resistance and provide a visually appealing look, which is particularly important in consumer-facing applications. Buyers should consider the environmental conditions the bracket will face and choose an appropriate finish to maximize performance and lifespan. -

Load Capacity

– Load capacity indicates the maximum weight a bracket can support safely. It is a critical consideration for applications such as shelving, automotive parts, and structural supports. Buyers must ensure that the selected bracket can handle the expected loads to prevent accidents and failures, which can be costly.

What Are the Common Trade Terms in Metal Bracket Fabrication?

Familiarity with industry jargon can facilitate smoother transactions and better communication between buyers and manufacturers. Here are some common terms to know:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In metal bracket fabrication, OEMs often provide custom brackets tailored to specific product requirements. Understanding the OEM relationship can help buyers navigate their sourcing strategies effectively. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for buyers to understand, as it can impact inventory management and costs. For businesses looking to purchase metal brackets, knowing the MOQ can help in budgeting and planning production schedules. -

RFQ (Request for Quote)

– An RFQ is a formal process where buyers request pricing information from suppliers for specific products or services. Submitting an RFQ allows buyers to compare prices, lead times, and capabilities, enabling informed decision-making. This process is especially important for custom fabrication projects. -

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. These terms clarify who bears the costs and risks associated with shipping and delivery. Familiarity with Incoterms can help B2B buyers ensure smooth logistics and minimize disputes. -

Lead Time

– Lead time is the duration from the placement of an order to the delivery of the product. Understanding lead times is essential for buyers to effectively plan their projects, especially in industries where timing is critical, such as construction or manufacturing.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in metal bracket fabrication, ensuring they select the right components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the metal bracket fabrication Sector

What Are the Key Market Dynamics and Trends Influencing Metal Bracket Fabrication?

The global metal bracket fabrication market is currently experiencing a transformative phase driven by various factors. Rapid industrialization in emerging markets, particularly in Africa, South America, and the Middle East, is creating a surge in demand for custom metal brackets across multiple sectors, including automotive, aerospace, and construction. Additionally, the increasing adoption of advanced manufacturing technologies such as laser cutting and 3D printing is enhancing production capabilities, allowing for quicker turnaround times and greater customization options.

B2B buyers are increasingly focused on sourcing suppliers that can provide not just high-quality products, but also advanced technical support and short lead times. This trend is particularly significant for international buyers in regions like Brazil and Nigeria, where local production capabilities are still developing. Furthermore, the rise of e-commerce and digital platforms is facilitating easier access to suppliers, enabling buyers to compare offerings, request quotes, and manage orders online efficiently.

Another noteworthy trend is the growing emphasis on scalability. Buyers are looking for manufacturers who can accommodate both small-scale prototypes and large-volume orders without compromising quality. The flexibility to adapt to varying production needs is becoming a decisive factor in supplier selection.

How Is Sustainability and Ethical Sourcing Shaping Metal Bracket Fabrication?

Sustainability has become a critical consideration for international B2B buyers in the metal bracket fabrication sector. As environmental regulations tighten globally, companies are increasingly held accountable for their sourcing practices and the environmental impact of their operations. This scrutiny is leading to a rise in demand for ethically sourced materials and ‘green’ certifications, such as ISO 14001, which indicate a commitment to sustainable practices.

Buyers are actively seeking suppliers who utilize recyclable materials, minimize waste during production, and employ energy-efficient processes. The use of eco-friendly coatings and finishes, such as powder coating, is also gaining traction, providing both aesthetic appeal and a reduced environmental footprint.

Furthermore, ethical sourcing is not just about environmental impact; it also encompasses fair labor practices and supply chain transparency. B2B buyers are more inclined to partner with manufacturers who demonstrate ethical labor practices and a commitment to social responsibility, ensuring that their supply chains are not only sustainable but also ethically sound.

What Is the Historical Context of Metal Bracket Fabrication?

The evolution of metal bracket fabrication can be traced back to the industrial revolution when the demand for reliable fastening solutions surged alongside advancements in machinery and construction methods. Initially, brackets were simple metal components used primarily for structural support. Over the decades, advancements in materials science and manufacturing techniques have transformed the sector.

By the late 20th century, the introduction of computer-aided design (CAD) and manufacturing (CAM) technologies revolutionized the fabrication process, allowing for greater precision and customization. Today, the market features a diverse range of materials, including stainless steel, aluminum, and brass, catering to various applications from industrial to architectural needs. As the market continues to evolve, the focus remains on innovation, sustainability, and meeting the specific needs of a global clientele.

This historical perspective not only highlights the technological advancements in the sector but also underscores the increasing complexity and specialization required to meet the demands of contemporary B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of metal bracket fabrication

-

How do I ensure the metal brackets meet my specifications?

To guarantee that metal brackets meet your exact specifications, provide detailed drawings or CAD models to your supplier. Specify the materials, dimensions, tolerances, and any required finishes. Engage in open communication with the manufacturer throughout the design and fabrication process. Request prototypes or samples to evaluate the quality before placing larger orders. Establishing clear expectations upfront can significantly reduce discrepancies and ensure the final product aligns with your needs. -

What are the best materials for custom metal brackets?

The choice of material for custom metal brackets largely depends on the application. For high strength and durability, stainless steel is ideal, particularly grades 304 and 316 for corrosion resistance. Aluminum is lightweight and suitable for applications where weight savings are critical. For aesthetic purposes, consider powder-coated options for added protection and design flexibility. Consult with your fabricator to select the most appropriate material based on environmental conditions and load requirements. -

What is the typical lead time for custom metal bracket fabrication?

Lead times for custom metal bracket fabrication can vary based on factors such as complexity, order volume, and the manufacturer’s capacity. Typically, you can expect a turnaround of a few days for simple designs and up to several weeks for more complex projects or larger quantities. It is advisable to discuss timelines with your supplier upfront and consider building in extra time for unexpected delays, especially when shipping internationally. -

How can I vet a metal bracket fabrication supplier?

To vet a metal bracket fabrication supplier, evaluate their experience and expertise in your industry. Request references or case studies of similar projects they have completed. Assess their quality assurance processes, certifications, and production capabilities. Conduct site visits if feasible, or utilize virtual meetings to gauge their operational standards. Additionally, check their financial stability and customer service responsiveness to ensure a reliable partnership. -

What are the minimum order quantities (MOQs) for metal brackets?

Minimum order quantities (MOQs) for metal brackets can vary significantly among manufacturers. Some suppliers may offer MOQs as low as one piece for prototypes, while others may require larger quantities for cost-effectiveness. Discuss your needs with potential suppliers to find flexible options that accommodate both small and large orders. Understanding the MOQ will help you plan your budget and production schedule effectively. -

What payment terms should I expect when sourcing metal brackets internationally?

Payment terms for international metal bracket sourcing can vary by supplier and region. Common arrangements include advance payments, net 30/60 days, or letters of credit for larger orders. It’s essential to negotiate clear payment terms that protect both parties. Consider using secure payment methods and ensure that all terms are documented in your contract. Being aware of currency exchange rates and transaction fees is also important when dealing with international suppliers. -

What quality assurance practices should I look for in a metal bracket supplier?

When sourcing metal brackets, inquire about the supplier’s quality assurance practices, including certifications such as ISO 9001. Look for manufacturers that conduct regular inspections during production and offer testing reports for materials used. Ensure they have a system in place for handling defects and customer feedback. A robust quality assurance program is crucial for ensuring that the fabricated brackets meet your specifications and industry standards. -

How do I manage logistics for international shipping of metal brackets?

Managing logistics for international shipping of metal brackets involves planning for customs clearance, shipping methods, and delivery timelines. Work with your supplier to understand shipping options and choose reliable carriers. Prepare all necessary documentation, including invoices and packing lists, to facilitate smooth customs processing. Consider insurance for high-value shipments and stay informed about import regulations in your destination country to avoid delays. Regular communication with your supplier and freight forwarder can help streamline the process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Metal Bracket Fabrication Manufacturers & Suppliers List

1. Metal Stamper – Metal Brackets

Domain: metalstamper.net

Registered: 2001 (24 years)

Introduction: Metal brackets are intermediate metal components used for fixing one part to another, providing support. They consist of two or more planes connected along one edge and are commonly fabricated by bending a flat object. Metal brackets can be powder coated in various colors for aesthetic purposes. They are used in applications such as mounting shelves, countertops, and furniture. Common types includ…

2. SendCutSend – Custom Sheet Metal Fabrication

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom parts uploaded in STEP, DXF, or EPS formats, with no minimum quantities and free US shipping on orders o…

3. Reddit – Bracket Fabrication Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The bracket can be fabricated for approximately $5-$10 if laser cut and bent. Recommended material is standard 44W sheet metal, with options for painting or plating. The cost may increase if CAD drawing and DXF files are required for laser cutting. Stainless steel is preferred if not prohibitively expensive. The fabrication process may involve drilling holes and bending the metal, with suggestions…

4. Treehouse Brackets – Custom Fabrication of Supports

Domain: treehousebrackets.com

Registered: 2009 (16 years)

Introduction: Custom Fabrication of Brackets/Supports for $10.00. Custom styles available upon request. Contact for a quote before ordering. Shipping typically via USPS Priority mail (2-3 days) for shipments under 20 lbs.

5. PowrFab – Joist Hanger for Double 2×10 Dimensional Lumber

Domain: powrfab.com

Registered: 2000 (25 years)

Introduction: PowrFab offers a range of solid stainless steel brackets and custom brackets, specifically designed for demanding applications. Key products include:

1. Joist Hanger for double 2″x10″ dimensional lumber (JH210-2) – 16ga 316L Stainless, Price: $41.89

2. 3/16″ x 2″ 316L Stainless Steel Flat Bar Splice Plate (HSP2) – Price: $33.84

3. Stainless Steel Splice Plate 3″x8″ (SP4) – 16ga 316L Stainless, Pr…

6. Protocase – Custom Sheet Metal Brackets and Mounting Hardware

Domain: protocase.com

Registered: 2001 (24 years)

Introduction: Custom Sheet Metal Brackets and Mounting Hardware, built in 2-3 days. No minimum order required. Common bracket styles include L-Bracket, Z-Bracket, U-Bracket, Offset-Bracket, and Gusset Bracket. Available in a wide range of dimensions with various stocked fasteners and hardware. Materials include Cold Rolled Steel, Galvanneal, Stainless Steel, Aluminum, and Copper. Finishes available: Powdercoat,…

7. Woodward Fab – Sheet Metal Bracket Maker

Domain: woodwardfab.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Sheet Metal Bracket Maker”, “model”: “WFUB”, “price”: “$409.99”, “dimensions”: “15 x 11 x 10 inches”, “weight”: “70 lbs”, “compatible_materials”: [“cold rolled steel”, “hot rolled steel”, “galvanized steel”, “aluminum”, “stainless steel”], “features”: {“bending_capability”: “produces neat and clean metal bends”, “forming_flats”: “up to 2 3/4\” x 1/4\””, “forming_rounds”: “up to 3…

Strategic Sourcing Conclusion and Outlook for metal bracket fabrication

In the evolving landscape of metal bracket fabrication, strategic sourcing emerges as a vital component for international B2B buyers. By leveraging a diverse range of materials—including steel, stainless steel, and aluminum—companies can find custom solutions tailored to their specific needs, whether for single prototypes or larger production runs. The ability to collaborate closely with manufacturers not only ensures that products meet exact specifications but also enhances turnaround times, often reducing them to just a few days.

Moreover, as industries across Africa, South America, the Middle East, and Europe seek to optimize supply chains, prioritizing partnerships with experienced fabricators can lead to significant cost savings and improved product quality. Emphasizing the importance of versatility, manufacturers can adapt to varied applications across sectors such as aerospace, automotive, and construction, ensuring that buyers receive robust and reliable solutions.

Looking ahead, B2B buyers are encouraged to explore strategic sourcing opportunities that align with their growth objectives. By investing in strong manufacturer relationships and embracing innovative fabrication techniques, businesses can position themselves for success in an increasingly competitive market. Engage with top-tier suppliers today to elevate your sourcing strategy and drive operational excellence.