Contents

Manufacturing Insight: Metal Bracket Fabrication

Precision Metal Bracket Fabrication Solutions from Honyo Prototype

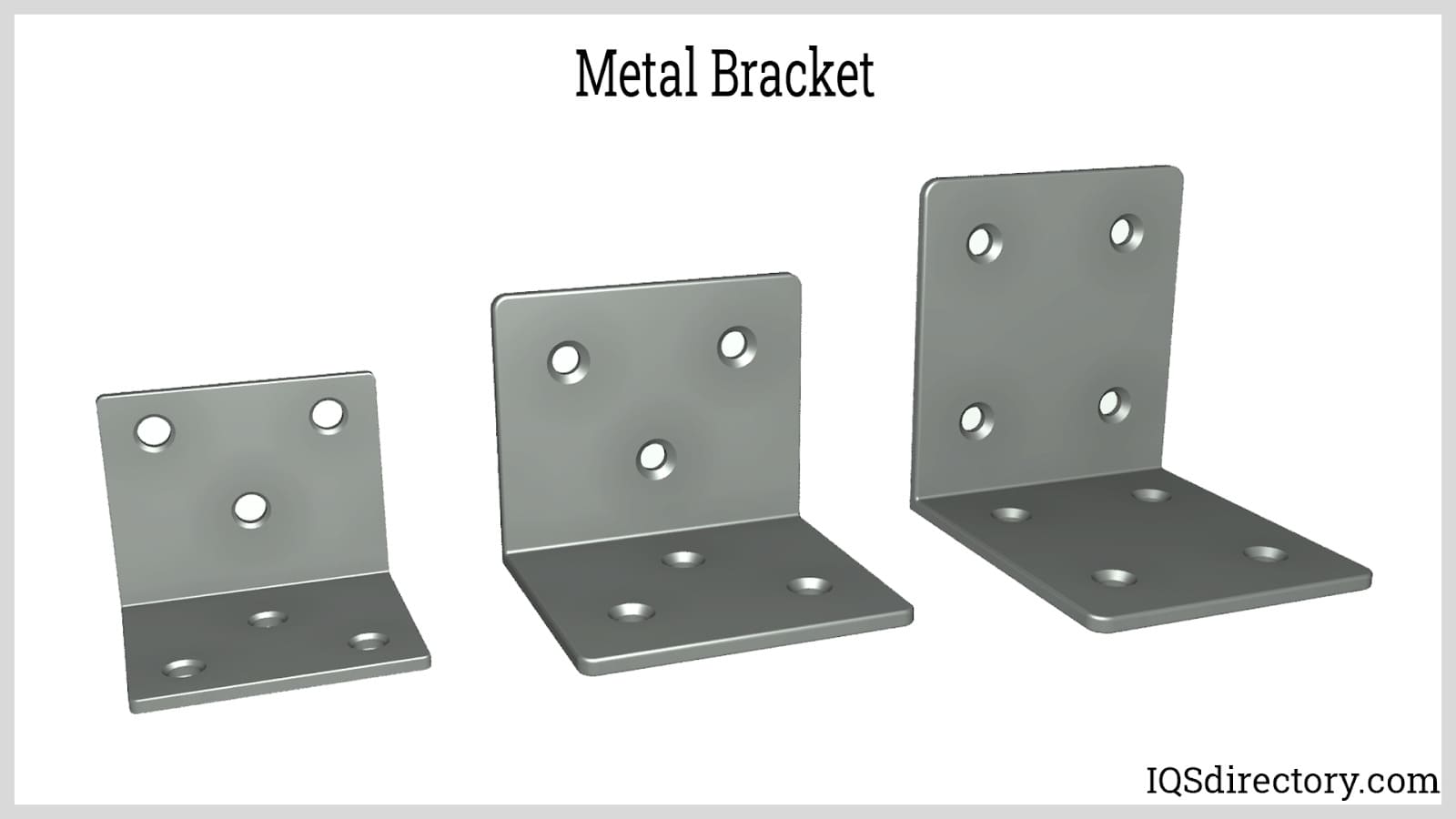

Metal brackets serve as critical structural and functional components across aerospace, medical, automotive, and industrial equipment applications. Their performance hinges on exacting dimensional accuracy, material integrity, and robust assembly compatibility. At Honyo Prototype, we specialize in high-integrity sheet metal fabrication engineered specifically for demanding bracket requirements. Our end-to-end capabilities integrate precision laser cutting, CNC bending, welding, and finishing processes under stringent ISO 9001-certified quality controls. This ensures consistent repeatability for complex geometries, tight tolerances down to ±0.005 inches, and optimal material utilization across aluminum, stainless steel, and mild steel alloys.

We eliminate traditional quoting bottlenecks through our Online Instant Quote platform. Upload your bracket CAD file in STEP, DWG, or DXF format to receive a detailed, no-obligation manufacturing assessment and cost estimate within hours—not days. This transparency accelerates your prototyping and low-to-mid volume production timelines while reducing engineering overhead. Partner with Honyo to transform bracket designs into mission-ready components with uncompromised quality and speed. Request your quote today to experience streamlined fabrication from concept to certified shipment.

Technical Capabilities

Technical specifications for metal bracket fabrication involve a combination of precision manufacturing processes including laser cutting, bending, and welding. These processes are selected based on material type, part geometry, mechanical requirements, and production volume. While aluminum and steel are standard for structural brackets, thermoplastics like ABS and nylon are generally not suitable for laser cutting and welding in the same context as metals due to their thermal properties and are typically processed via machining or molding instead.

Below is a detailed comparison of fabrication parameters by material and process:

| Process | Material | Thickness Range | Tolerances | Equipment Type | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 12 mm | ±0.1 mm | Fiber laser cutter | High reflectivity requires proper beam delivery; nitrogen assist recommended |

| Laser Cutting | Steel (Mild) | 0.8 mm – 20 mm | ±0.1 mm | CO₂ or fiber laser cutter | Oxygen assist for thicker sections; burr-free edges with proper settings |

| Laser Cutting | ABS | Not recommended | N/A | Not applicable | ABS emits toxic fumes when laser-cut; poor edge quality; not used structurally |

| Laser Cutting | Nylon | Not recommended | N/A | Not applicable | High melting point and thermal deformation; unsuitable for laser cutting |

| Bending | Aluminum | 0.8 mm – 6 mm | ±0.2° angular, ±0.2 mm | CNC press brake with V-dies | Use larger bend radii to avoid cracking; annealed grades preferred |

| Bending | Steel (Mild) | 1.0 mm – 10 mm | ±0.2° angular, ±0.2 mm | CNC press brake with hardened tooling | Springback compensation required; lubrication may be needed |

| Bending | ABS | 1.5 mm – 5 mm | ±0.5° angular, ±0.5 mm | Heated bending or manual jig | Requires controlled heating; not compatible with standard metal brakes |

| Bending | Nylon | 2 mm – 6 mm | ±0.5° angular, ±0.5 mm | Thermal forming or jig-based | High elasticity; prone to springback; not typically bent like metal |

| Welding | Aluminum | ≥2 mm | ±1 mm positional | TIG or MIG with argon shield | Requires clean surface; pre-weld cleaning essential; distortion control needed |

| Welding | Steel (Mild) | ≥1.5 mm | ±0.8 mm positional | MIG, TIG, or spot welding | Robust weldability; post-weld grinding often required for smooth finish |

| Welding | ABS | Not applicable | N/A | Ultrasonic or hot-plate | Not welded in metal sense; limited structural joining; not load-bearing |

| Welding | Nylon | Not applicable | N/A | Vibration or hot-gas welding | Used for sealing or assembly; low strength compared to metal welds |

Note: ABS and nylon are included for comparative purposes only. They are not typically used in structural bracket fabrication involving laser cutting, bending, and welding as these are metal-centric processes. For plastic brackets, alternative methods such as CNC machining, 3D printing, or injection molding are more appropriate.

From CAD to Part: The Process

Honyo Prototype Metal Bracket Fabrication Process Overview

Honyo Prototype employs a streamlined, technology-driven workflow for metal bracket fabrication designed to ensure precision, cost efficiency, and rapid turnaround. The process begins when a client uploads a CAD file to our secure online portal. This triggers an immediate automated analysis by our proprietary AI quoting engine, which evaluates geometric complexity, material requirements, tolerances, and surface finish specifications. The AI generates a detailed quotation within hours, including cost breakdowns, lead time estimates, and material sourcing options, eliminating manual quote delays while maintaining accuracy through machine learning trained on decades of manufacturing data.

Following quote acceptance, the CAD file enters our Digital Manufacturing (DFM) review phase. Unlike automated-only systems, Honyo combines AI-driven preliminary analysis with direct engineer oversight. Our senior manufacturing engineers conduct a rigorous manual DFM assessment to identify potential manufacturability risks, such as non-optimal wall thicknesses, tool access constraints, or weld seam conflicts. Key DFM checks include:

| DFM Parameter | Action Taken | Outcome |

|---|---|---|

| Material Utilization | Nesting optimization for laser/plasma cutting | Minimized scrap, reduced material cost |

| Tolerance Feasibility | Verification against ISO 2768-mK standards; adjustment suggestions | Elimination of unachievable tolerances |

| Secondary Operations | Assessment of deburring, tapping, or coating requirements | Integrated process planning |

| Assembly Compatibility | Interference checks for mating components | Prevention of downstream assembly issues |

Upon DFM approval and client sign-off, the bracket moves to production. Honyo utilizes in-house multi-axis CNC machining centers, fiber laser cutters, and robotic welding cells for critical operations. All metal brackets undergo rigorous in-process inspections at defined checkpoints using calibrated CMMs and optical comparators. For structural brackets, we implement first-article inspection (FAI) per AS9102 standards, including material certification traceability and hardness testing. Final assemblies receive passivation or anodizing as specified, with full documentation of coating thickness and adhesion results.

The completed brackets enter our integrated logistics stage, where they are packaged with anti-corrosion protection and serialized tracking labels. Honyo provides real-time shipment visibility via client portal integration, supported by our global freight partnerships. Every delivery includes a comprehensive quality dossier: dimensional reports, material certs, process validation records, and third-party test results if applicable. This closed-loop system ensures brackets arrive certified-ready for integration, typically reducing time-to-installation by 30% compared to industry benchmarks.

Start Your Project

For precision metal bracket fabrication, contact Susan Leo at [email protected]. Our dedicated manufacturing facility in Shenzhen ensures high-quality production with fast turnaround times. Partner with Honyo Prototype for reliable, cost-effective solutions tailored to your engineering requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.