Introduction: Navigating the Global Market for metal bending service

In an increasingly interconnected world, international B2B buyers face the formidable challenge of sourcing reliable metal bending services that meet their specific needs. Whether you are in Africa, South America, the Middle East, or Europe, the quest for high-quality, cost-effective metal bending solutions can be daunting. This guide serves as a comprehensive resource, delving into the nuances of metal bending services, including various types of bending techniques, material specifications, and applications across different industries.

Moreover, we will explore essential factors such as supplier vetting processes, cost considerations, and lead times that can significantly impact your purchasing decisions. By equipping you with actionable insights and practical tools, this guide empowers you to make informed choices that align with your operational goals.

Understanding the intricacies of metal bending services not only helps in mitigating risks associated with production delays and subpar quality but also enhances your competitive edge in a global market. As you navigate this complex landscape, our aim is to provide clarity and confidence, ensuring that you can source metal bending services that fulfill your project requirements efficiently and effectively.

Understanding metal bending service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Metal Bending | High precision, automated processes, supports complex designs | Aerospace, automotive, electronics | Pros: Accuracy, repeatability; Cons: Higher initial setup cost. |

| Manual Metal Bending | Traditional methods, skilled labor, lower setup costs | Art, custom projects, prototypes | Pros: Flexibility, lower cost; Cons: Less precision, longer lead times. |

| Hydraulic Press Bending | Utilizes hydraulic force, suitable for thick materials | Heavy machinery, construction | Pros: Power for thick materials; Cons: Limited design complexity. |

| Air Bending | Uses air pressure to create bends, ideal for lightweight metals | HVAC, consumer products | Pros: Faster production; Cons: Limited to specific materials and thicknesses. |

| Rotary Bending | Employs rotary motion for continuous bending | Tube fabrication, automotive parts | Pros: Continuous, high-volume production; Cons: Requires specialized machinery. |

What are the Characteristics of CNC Metal Bending Services?

CNC metal bending services leverage advanced computer-controlled machinery to achieve high precision and repeatability. This method is particularly suitable for complex designs and tight tolerances, making it a preferred choice in industries such as aerospace and automotive. When considering CNC bending, B2B buyers should assess the technology capabilities of the service provider, including their ability to handle various materials and thicknesses, as well as the availability of instant pricing and design feedback tools.

How Does Manual Metal Bending Differ from Other Methods?

Manual metal bending relies on skilled labor and traditional techniques, which can be advantageous for custom projects or artistic endeavors. This method allows for greater flexibility in design adjustments but may result in longer lead times and less precision compared to automated processes. B2B buyers should consider their project requirements, including volume and complexity, when deciding if manual bending aligns with their needs.

What Are the Benefits of Hydraulic Press Bending?

Hydraulic press bending is a powerful technique ideal for working with thicker materials, offering significant force and capability. This service is commonly used in heavy machinery and construction applications where strength and durability are paramount. Buyers should evaluate the service provider’s capacity to handle their specific material requirements and the potential trade-offs in design complexity.

Why Choose Air Bending for Lightweight Metals?

Air bending is a fast and efficient method suitable for lightweight metals, making it popular in industries like HVAC and consumer products. This technique allows for rapid production cycles but is limited to specific materials and thicknesses. When considering air bending services, B2B buyers should assess the material compatibility and the potential impact on the final product’s strength and durability.

What is Rotary Bending and Its Applications?

Rotary bending utilizes rotary motion to create continuous bends, making it ideal for high-volume production of tube fabrications and automotive parts. This method can significantly enhance efficiency and reduce lead times for large orders. Buyers should confirm that the service provider has the necessary equipment and expertise to meet their production needs while ensuring the desired quality and precision.

Key Industrial Applications of metal bending service

| Industry/Sector | Specific Application of metal bending service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of vehicle frames and components | Enhanced structural integrity and lightweight designs | Certification standards (ISO, IATF), material specifications |

| Construction | Creation of structural supports and frameworks | Improved load-bearing capabilities and safety | Compliance with local building codes, material durability |

| Aerospace | Fabrication of aircraft components and parts | High precision and weight reduction for efficiency | Strict tolerances, aerospace-grade materials, certification |

| Electronics | Production of enclosures and chassis for devices | Protection of sensitive components and aesthetics | Customization capabilities, rapid prototyping, scalability |

| Energy (Renewable) | Development of solar panel frames and wind turbine components | Increased efficiency and durability in harsh conditions | Material sourcing for corrosion resistance, sustainability focus |

How is Metal Bending Service Utilized in the Automotive Industry?

In the automotive sector, metal bending services are crucial for producing vehicle frames and various components. The bending process allows for the creation of complex shapes that enhance structural integrity while reducing weight, contributing to fuel efficiency. Buyers in this sector must consider certification standards, such as ISO and IATF, and ensure that the materials used meet specific performance criteria to withstand rigorous testing and safety regulations.

What Role Does Metal Bending Play in Construction?

Metal bending services are integral to the construction industry, particularly in the fabrication of structural supports and frameworks. These services enable the creation of custom shapes that improve load-bearing capabilities and overall safety. For international buyers, compliance with local building codes is essential, as is the selection of durable materials that can withstand environmental factors. Buyers should also prioritize suppliers with a proven track record in delivering high-quality, precise bends.

How is Metal Bending Applied in Aerospace Manufacturing?

In aerospace manufacturing, precision is paramount, making metal bending services vital for fabricating aircraft components. The ability to produce parts with strict tolerances ensures that every component fits perfectly, which is crucial for safety and performance. Buyers must focus on sourcing aerospace-grade materials and work with suppliers that hold the necessary certifications to meet industry standards. Additionally, understanding the specific bending requirements for each part can streamline production and enhance efficiency.

What Benefits Does Metal Bending Offer to the Electronics Sector?

In the electronics industry, metal bending services are employed to create enclosures and chassis that protect sensitive components while providing an aesthetic appeal. The ability to customize designs quickly through bending services allows manufacturers to adapt to changing market demands. Buyers should seek suppliers capable of rapid prototyping and scalability, ensuring that they can meet fluctuating production needs without compromising quality.

How Does Metal Bending Contribute to the Renewable Energy Sector?

Metal bending services are increasingly important in the renewable energy sector, particularly for developing solar panel frames and wind turbine components. These applications require materials that can withstand harsh environmental conditions while maintaining efficiency. Buyers should prioritize sourcing materials with corrosion resistance and consider the sustainability of their suppliers. Additionally, understanding the specific bending requirements for renewable energy components can lead to improved performance and longevity of the products.

3 Common User Pain Points for ‘metal bending service’ & Their Solutions

Scenario 1: Navigating Complex Design Specifications

The Problem: B2B buyers often face challenges when their design specifications for metal bending are too complex or not well-defined. This can lead to miscommunication with service providers, resulting in parts that do not meet the desired specifications or functionality. For example, a buyer may design a component with intricate bends and specific tolerances, only to find that the metal bending service does not have the capability to execute such requirements. This misalignment can lead to increased costs and extended lead times, ultimately affecting project timelines and budgets.

The Solution: To mitigate this issue, buyers should invest time in thoroughly understanding the bending capabilities and limitations of their chosen service provider before submitting designs. This involves familiarizing themselves with key parameters such as bend radius, K-factor, and material tolerances. It is advisable to utilize online tools, such as bending calculators provided by many services, to simulate how their designs will be processed. Clear communication is essential; buyers should provide detailed drawings, including necessary specifications and tolerances. Engaging in a preliminary consultation with the service provider can also help clarify any potential issues before production begins, thus streamlining the entire process.

Scenario 2: Overcoming Material Compatibility Issues

The Problem: Another common challenge faced by B2B buyers is ensuring that the materials selected for bending are compatible with the specific bending process and intended application. For instance, a buyer may choose a material that is too brittle or thick for the desired bends, which can lead to cracking or failure during the bending process. This compatibility issue can result in wasted materials, increased production costs, and delays as replacements are sourced.

The Solution: To avoid material compatibility issues, buyers should conduct thorough research on material properties and their suitability for bending operations. This includes understanding the tensile strength, ductility, and thickness limits of the materials they intend to use. Buyers should consult with their metal bending service to gain insights into which materials have been successfully processed in the past, as well as the best practices for selecting materials for their specific projects. Additionally, requesting samples or conducting small test runs can help verify that the chosen material performs as expected in the bending process, ensuring a smoother production experience.

Scenario 3: Managing Expectations on Lead Times and Costs

The Problem: B2B buyers often grapple with unexpected lead times and costs associated with metal bending services. For example, after placing an order, they may find that the turnaround time is much longer than anticipated, or that additional costs were incurred due to complexity or additional services. This unpredictability can disrupt supply chains and impact the overall project timeline.

The Solution: To manage expectations effectively, buyers should seek out metal bending services that provide transparent pricing structures and clear timelines upfront. This includes understanding how factors such as order complexity, material choice, and additional services (like powder coating or hardware installation) affect both lead times and costs. Buyers should also take advantage of online quoting tools that offer instant pricing based on their specific requirements. Establishing a good relationship with the service provider can also facilitate better communication regarding potential delays or changes in costs, allowing for proactive adjustments to project timelines. Finally, building in buffer time for production and delivery can help mitigate the impact of unforeseen delays.

Strategic Material Selection Guide for metal bending service

What Are the Key Properties of Common Materials Used in Metal Bending Services?

When selecting materials for metal bending services, several factors play a crucial role in determining the suitability of each option. Here, we analyze four common materials: Aluminum, Steel, Stainless Steel, and Copper. Each material has unique properties, advantages, and limitations that can significantly impact product performance and application.

Aluminum: Lightweight and Versatile

Aluminum is renowned for its lightweight nature and excellent corrosion resistance. It has a relatively low density, making it ideal for applications where weight reduction is critical. Aluminum can withstand moderate temperatures and pressures, making it suitable for various environments.

Pros: Aluminum’s lightweight nature allows for easier handling and transportation. It is also highly malleable, which simplifies the bending process. Additionally, aluminum is often more cost-effective than other metals, particularly for large-scale production.

Cons: While aluminum is durable, it is not as strong as steel, making it less suitable for high-stress applications. It also has a lower temperature resistance, which may limit its use in extreme environments.

Impact on Application: Aluminum is commonly used in automotive, aerospace, and consumer goods. Its corrosion resistance makes it ideal for outdoor applications, but it may not be suitable for environments with high mechanical stress.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM B221 for aluminum extrusions. Countries like Germany and Brazil have specific regulations regarding aluminum usage in construction and automotive sectors.

Steel: Strength and Durability

Steel is one of the most widely used materials in metal bending due to its exceptional strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: Steel’s high tensile strength allows for the production of robust components. It is cost-effective for large-scale manufacturing, and various grades (like mild steel) offer flexibility in application.

Cons: Steel is heavier than aluminum, which may pose challenges in applications where weight is a concern. It is also susceptible to corrosion unless treated or coated, which can increase manufacturing complexity.

Impact on Application: Steel is widely used in construction, machinery, and automotive industries. Its strength makes it suitable for load-bearing applications, but its weight can be a drawback in portable designs.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is essential. Buyers in regions like the Middle East may need to consider the impact of humidity on steel corrosion.

Stainless Steel: Corrosion Resistance with Strength

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it ideal for a variety of applications, especially in harsh environments.

Pros: Its resistance to rust and staining makes stainless steel suitable for food processing, medical equipment, and marine applications. It also maintains structural integrity at high temperatures.

Cons: Stainless steel is generally more expensive than both aluminum and regular steel. Its increased hardness can complicate the bending process, requiring specialized equipment.

Impact on Application: Stainless steel is often used in industries where hygiene and corrosion resistance are critical. Its durability makes it ideal for long-lasting products, but its cost may limit its use in budget-sensitive projects.

Considerations for International Buyers: Buyers should be familiar with standards such as ASTM A240 for stainless steel sheets. Countries like Germany have stringent regulations regarding food-grade materials, making compliance crucial.

Copper: Excellent Conductivity

Copper is known for its excellent electrical and thermal conductivity, making it a preferred choice for electrical applications. It is also malleable and ductile, allowing for intricate designs.

Pros: Copper’s conductivity makes it ideal for electrical components and heat exchangers. Its antimicrobial properties also make it suitable for healthcare applications.

Cons: Copper is heavier and more expensive than aluminum and steel. It can also tarnish over time, which may affect aesthetic appeal.

Impact on Application: Copper is primarily used in electrical wiring, plumbing, and roofing. Its unique properties make it suitable for specialized applications, but its cost can be prohibitive for large-scale production.

Considerations for International Buyers: Compliance with standards like ASTM B152 for copper sheets is important. Buyers in regions like South America should be aware of the availability and sourcing of copper due to fluctuating market prices.

Summary Table of Material Selection for Metal Bending Services

| Material | Typical Use Case for metal bending service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, consumer goods | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Steel | Construction, machinery | High tensile strength | Heavier and prone to corrosion | Low |

| Stainless Steel | Food processing, medical equipment | Corrosion-resistant and durable | Higher cost and harder to bend | High |

| Copper | Electrical components, plumbing | Excellent conductivity | Heavier and expensive | High |

This guide aims to equip international B2B buyers with essential insights into material selection for metal bending services, ensuring informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal bending service

What Are the Key Stages in the Metal Bending Manufacturing Process?

The metal bending manufacturing process is a multi-stage operation that transforms raw materials into finished components. Understanding these stages is crucial for B2B buyers to ensure they partner with suppliers who uphold high standards of quality and efficiency.

Material Preparation: How Is Raw Material Selected and Processed?

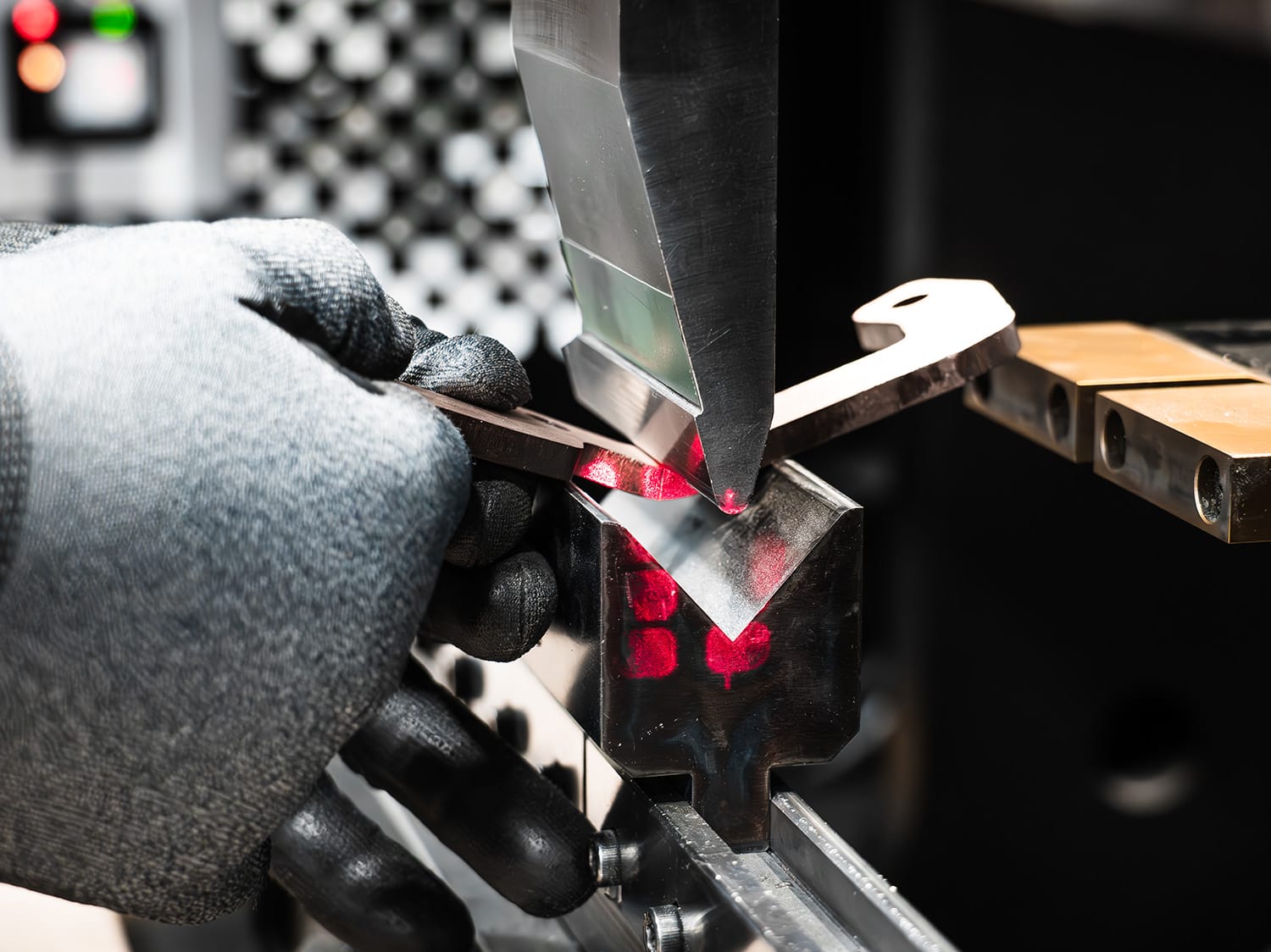

The first step in metal bending involves selecting the appropriate raw material, typically sheet metal made from steel, aluminum, or stainless steel. Factors such as thickness, tensile strength, and material properties play a significant role in this selection. Once the material is chosen, it undergoes a preparation phase where it is cut to the required dimensions using techniques like laser cutting or shearing. This stage is vital for ensuring that the material can be bent without defects.

Forming: What Techniques Are Used for Metal Bending?

The forming stage employs various techniques, with CNC (Computer Numerical Control) bending being the most prevalent due to its precision and efficiency. In this process, the prepared sheet metal is placed into a bending machine equipped with specialized dies. The machine applies force to create bends at specified angles, with tolerances often within ±1 degree. Advanced CNC systems can perform complex bends and even handle odd flange shapes, allowing for greater design flexibility.

Assembly: How Are Bended Parts Joined Together?

After bending, components may require assembly, particularly in creating larger structures. This may involve welding, riveting, or using mechanical fasteners to join parts securely. Quality during assembly is crucial, as improper joining can compromise the structural integrity of the final product.

Finishing: What Post-Bending Treatments Are Commonly Applied?

The finishing stage may include processes such as deburring, polishing, or applying protective coatings like powder coating. These treatments enhance the aesthetic appeal and durability of the parts, making them suitable for various applications. Buyers should inquire about the finishing capabilities of their suppliers to ensure that the final products meet their specifications.

What Quality Assurance Practices Are Essential in Metal Bending Services?

Quality assurance (QA) is a critical aspect of the metal bending service, ensuring that products meet both customer expectations and regulatory standards. For international B2B buyers, understanding the QA processes can significantly impact their supplier selection.

What International Standards Should B2B Buyers Look For?

Many metal bending suppliers adhere to internationally recognized standards, such as ISO 9001:2015, which focuses on quality management systems. This certification indicates that a company has established processes for maintaining quality across its operations. Other industry-specific certifications, such as CE marking for European markets or API standards for the oil and gas sector, may also be relevant depending on the application.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that defects are identified and addressed promptly. Common QC checkpoints include:

- Incoming Quality Control (IQC): This initial phase inspects raw materials for compliance with specifications before they enter production.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this stage ensures that bending operations are executed correctly and that tolerances are maintained.

- Final Quality Control (FQC): This final inspection assesses the completed products against design specifications, ensuring that they meet all required standards before shipment.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers should actively verify the quality assurance practices of their suppliers. This can be done through:

- Audits: Conducting on-site audits to evaluate the supplier’s processes, equipment, and adherence to quality standards can provide insights into their operational capabilities.

- Quality Reports: Requesting regular quality reports can help buyers monitor the performance of their suppliers over time.

- Third-Party Inspections: Engaging independent third-party inspectors to assess the quality of products before shipment can provide an additional layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from diverse regions, such as Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific QC nuances that may affect their procurement process.

How Do Regional Standards Impact Quality Control?

Different regions may have varying standards and regulations governing metal fabrication and quality assurance. For instance, European buyers may require CE marking, while buyers from other regions might prioritize compliance with local standards. Understanding these regional nuances is essential for ensuring that the products meet local requirements.

What Are the Implications of Language and Cultural Differences?

Language barriers and cultural differences can complicate communication between buyers and suppliers. Clear documentation, including specifications, quality standards, and expectations, is vital to mitigate misunderstandings. Establishing a single point of contact within the supplier’s organization can also facilitate smoother communication.

How Can Buyers Leverage Technology to Enhance Quality Control?

Advancements in technology, such as digital platforms for real-time tracking and communication, can greatly enhance quality control processes. Buyers can use online portals to monitor production timelines, access quality reports, and communicate directly with suppliers, ensuring that any issues are addressed promptly.

Conclusion

Navigating the manufacturing processes and quality assurance practices for metal bending services requires a deep understanding of both the technical aspects and the standards in play. By focusing on material preparation, forming, assembly, and finishing, as well as implementing rigorous quality control measures, B2B buyers can ensure that they select the right suppliers for their needs. Engaging suppliers who prioritize quality assurance and adhere to international standards will facilitate smoother transactions and better product outcomes, ultimately supporting the success of their business initiatives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal bending service’

To ensure an efficient procurement process for metal bending services, this checklist provides a structured approach for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. Each step is designed to help you make informed decisions that align with your project requirements and budget.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications of your metal bending project, including material types, thickness, bend angles, and tolerances. This is crucial as it influences the choice of supplier and the bending techniques they can employ. Be specific about the requirements to avoid any misunderstandings later on.

- Material Selection: Identify the metals you need (e.g., aluminum, stainless steel) and their respective thicknesses.

- Bend Radius and Tolerances: Specify the required bend radius and tolerances, as these can vary significantly depending on the material and bending process.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential metal bending service providers. Look for companies with proven expertise in the specific materials and techniques relevant to your project.

- Industry Experience: Focus on suppliers who have worked with businesses in your sector, as they will better understand your needs.

- Geographical Considerations: Evaluate suppliers based on their location and ability to ship to your region efficiently.

Step 3: Verify Supplier Certifications and Standards

Ensure that your chosen suppliers adhere to industry standards and certifications, such as ISO 9001:2015. This compliance indicates a commitment to quality and process improvement.

- Quality Assurance Processes: Inquire about their quality control measures and how they ensure precision in bending operations.

- Safety Standards: Confirm that they follow safety regulations that protect both workers and products.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes for your project. Ensure that the quotes include all associated costs, such as tooling, labor, and shipping.

- Transparent Pricing: Look for suppliers who provide clear breakdowns of costs, enabling you to compare pricing effectively.

- Value vs. Cost: Consider not just the price but the value offered, including turnaround time, customer service, and additional services like finishing or assembly.

Step 5: Evaluate Production Capabilities and Lead Times

Assess the production capabilities of your potential suppliers, particularly their ability to handle your project’s scale and complexity.

- Technology and Equipment: Inquire about the technology they use for bending, such as CNC machines, which can provide higher precision.

- Lead Time Estimates: Confirm their lead times and ensure they align with your project schedule.

Step 6: Request Samples or Prototypes

Before finalizing your decision, ask for samples or prototypes of similar work they have completed. This step allows you to evaluate the quality of their work firsthand.

- Quality Assessment: Check for accuracy in bends, finishes, and overall craftsmanship.

- Feedback from Previous Clients: If possible, obtain references or testimonials from past clients to gauge their satisfaction with the supplier’s work.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the procurement process. Ensure that your chosen supplier is responsive and open to collaboration.

- Design Feedback: Choose suppliers who provide feedback on design feasibility and can assist in optimizing your designs for bending.

- Point of Contact: Establish a primary contact at the supplier’s organization for streamlined communication and updates throughout the project.

By following this checklist, you will enhance your sourcing strategy for metal bending services, ensuring a successful collaboration with your chosen supplier while minimizing potential risks and inefficiencies.

Comprehensive Cost and Pricing Analysis for metal bending service Sourcing

What Are the Key Cost Components in Metal Bending Services?

When sourcing metal bending services, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of metal used significantly influences pricing. Common materials such as aluminum, stainless steel, and carbon steel have varying costs based on market demand and availability. Specialty metals or those with specific certifications can further increase expenses.

-

Labor: Skilled labor is essential for precision metal bending. The labor cost encompasses both direct wages and any associated benefits. Expertise in handling complex designs or specialized machinery can lead to higher labor costs but is often necessary for high-quality outcomes.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Overhead can vary based on the location of the supplier and the scale of operations. Efficient facilities may pass savings onto customers.

-

Tooling: Tooling costs depend on the complexity of the bending process. Custom dies or specialized equipment for unique designs will incur additional costs. Suppliers may also charge setup fees for small batch sizes, impacting overall pricing.

-

Quality Control (QC): Ensuring that parts meet specifications requires investment in quality control processes. This includes inspection tools and processes to verify that the bends are within tolerances. Comprehensive QC measures can increase upfront costs but reduce long-term risks associated with defects.

-

Logistics: Shipping costs can vary significantly depending on distance, weight, and chosen Incoterms. International shipments may also involve customs duties and tariffs, adding to the total cost.

-

Margin: Suppliers typically add a margin to cover their risks and desired profits. Understanding the competitive landscape can provide insight into reasonable margins for different suppliers.

How Do Price Influencers Impact Metal Bending Service Costs?

Several factors can influence the pricing structure of metal bending services:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, reducing the per-unit cost. Conversely, small orders may incur higher prices due to the fixed costs associated with setup and production.

-

Specifications and Customization: Complex designs requiring unique specifications can lead to increased costs. Buyers should provide detailed drawings and specifications to avoid unexpected charges.

-

Material Choices: The choice of material not only affects the base cost but also influences machining and bending capabilities. Some materials may require specialized processes that can drive up costs.

-

Quality Certifications: Suppliers with ISO certifications or other quality assurances may charge more due to their commitment to maintaining high standards. However, this can provide peace of mind regarding the quality of the final product.

-

Supplier Factors: The supplier’s location, reputation, and operational efficiency can impact pricing. Established suppliers may command higher prices due to their experience and reliability, while newer entrants may offer competitive rates to build their client base.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they dictate shipping responsibilities and costs. This can significantly affect the total landed cost of products.

What Are Effective Buyer Tips for Cost-Efficiency in Metal Bending Services?

To maximize cost-efficiency when sourcing metal bending services, buyers should consider the following strategies:

-

Negotiate Terms: Engage in discussions about pricing, especially for larger orders. Suppliers may offer discounts or better terms for bulk purchases.

-

Consider Total Cost of Ownership (TCO): Focus on the complete cost associated with sourcing, including shipping, handling, and potential rework costs. Sometimes, a higher upfront price may result in lower overall expenses due to superior quality.

-

Research and Compare Suppliers: Conduct thorough research to understand the landscape of available suppliers. Comparing quotes and service offerings can provide leverage in negotiations.

-

Communicate Clearly: Providing precise specifications and expectations can minimize misunderstandings and unexpected costs. This is particularly important for international transactions where language barriers may exist.

-

Understand International Pricing Nuances: Buyers from regions like Africa and South America should be aware of regional pricing dynamics and potential import duties. Familiarize yourself with local regulations and market conditions to avoid surprises.

Disclaimer on Indicative Prices

Prices for metal bending services can vary widely based on the factors discussed. The information provided is intended for guidance and should not be considered a fixed quote. Always request detailed quotes from multiple suppliers to obtain the most accurate pricing for your specific needs.

Alternatives Analysis: Comparing metal bending service With Other Solutions

Exploring Alternatives to Metal Bending Services

In the realm of metal fabrication, businesses often seek the most efficient and cost-effective methods for achieving desired shapes and structures. While metal bending services are widely recognized for their precision and versatility, there are several alternative approaches that can also meet specific project requirements. This analysis compares metal bending services against two viable alternatives: metal stamping and welding.

| Comparison Aspect | Metal Bending Service | Metal Stamping | Welding |

|---|---|---|---|

| Performance | High precision with tight tolerances (+/- 1°) | High speed for large volumes | Strong joints, versatile applications |

| Cost | Moderate to high, varies by complexity | Low per unit for large quantities | Moderate, depends on labor and materials |

| Ease of Implementation | Requires design adjustments for bends | Simple for standard shapes | Requires skilled labor and safety measures |

| Maintenance | Minimal, mostly software and tool upkeep | Low, with robust machinery | Moderate, equipment and safety gear required |

| Best Use Case | Custom parts with complex geometries | High-volume production of flat parts | Structural assemblies or repairs |

Understanding Metal Stamping: Pros and Cons

Metal stamping is a manufacturing process that uses dies to shape metal sheets into desired forms, making it particularly effective for high-volume production. The primary advantage of metal stamping is its cost-effectiveness; the more parts produced, the lower the cost per unit. It is ideal for projects requiring consistent, flat shapes, such as brackets or panels. However, metal stamping may not be suitable for complex designs or small batch sizes, as the setup costs for dies can be significant. Additionally, the initial investment in equipment can be high, making it less accessible for smaller companies or one-off projects.

Evaluating Welding: Advantages and Disadvantages

Welding is a versatile method used to join metal parts together, offering strong and durable joints. This process is particularly beneficial for structural applications, where load-bearing strength is crucial. Welding can accommodate a wide variety of materials and thicknesses, making it suitable for both small and large projects. However, it requires skilled labor, which can increase costs and lead times. Furthermore, welding may not provide the same aesthetic finish as bending, and the heat involved can affect the integrity of certain materials if not managed correctly.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right metal shaping solution depends on several factors, including project volume, complexity, and budget. For businesses focused on custom parts with intricate designs, metal bending services offer unparalleled precision. In contrast, if you are looking for a cost-effective solution for high-volume production of simple shapes, metal stamping may be the best choice. For projects requiring strong structural integrity, welding stands out as a versatile option. By carefully assessing your specific needs and constraints, you can make an informed decision that aligns with your operational goals and enhances your product offerings.

Essential Technical Properties and Trade Terminology for metal bending service

What Are the Key Technical Properties in Metal Bending Services?

Understanding the technical properties of metal bending is crucial for international B2B buyers to ensure optimal product quality and compliance with project specifications. Here are some essential properties to consider:

-

Material Grade

The material grade defines the type of metal used, such as aluminum, steel, or stainless steel. Different grades offer varying tensile strengths, corrosion resistance, and workability. For B2B buyers, selecting the correct material grade is vital for ensuring that the final product meets performance requirements and industry standards, particularly in sectors like automotive and aerospace. -

Bend Radius

The bend radius is the inside radius of the bend in a sheet metal part. It is crucial to specify the correct bend radius to avoid material failure or distortion during the bending process. A smaller bend radius can lead to cracking, especially in harder materials. For buyers, understanding the bend radius can help in designing parts that not only fit correctly but also maintain structural integrity. -

Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension. For metal bending, typical tolerances might be ±1 degree for angles and ±0.015 inches for lengths. Precise tolerances are critical for ensuring that parts fit together as intended. B2B buyers should prioritize suppliers who can meet stringent tolerance requirements, as this affects overall assembly and functionality. -

K-Factor

The K-factor is a ratio that helps determine the material’s stretch during bending. It is essential for calculating the flat pattern layout of the sheet metal before it is bent. A proper understanding of the K-factor aids in achieving accurate dimensions in the final bent part. For buyers, ensuring that the supplier can provide the correct K-factor for their chosen material is vital for accurate production. -

Minimum Flange Length

This specification indicates the shortest length a flange can have without compromising the part’s integrity during bending. Adequate flange length is necessary to prevent issues like flange collision, which can lead to production delays. B2B buyers should ensure that their designs adhere to minimum flange length requirements to avoid costly reworks.

What Are Common Terms Used in Metal Bending Services?

Familiarity with industry terminology can enhance communication and streamline the procurement process. Here are some key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is crucial for buyers looking to source components that meet specific design criteria or industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers, as understanding MOQ can help in budgeting and inventory management. Suppliers with low MOQs can be advantageous for companies needing prototypes or small batch runs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific quantities and types of goods or services. Utilizing RFQs can streamline the procurement process, allowing buyers to compare offers from multiple suppliers and make informed decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations, ensuring smoother transactions. -

CNC (Computer Numerical Control)

CNC refers to the automation of machine tools through computer programming. In metal bending, CNC technology ensures high precision and repeatability, which is critical for producing complex parts. Buyers should seek suppliers that utilize CNC technology for enhanced accuracy and efficiency.

By understanding these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing metal bending services, ensuring that their projects meet quality standards and specifications.

Navigating Market Dynamics and Sourcing Trends in the metal bending service Sector

What Are the Key Trends Shaping the Metal Bending Service Market?

The metal bending service market is witnessing significant transformation driven by several global factors. Key among these is the increasing demand for customized metal components across various industries, including automotive, aerospace, and construction. Buyers from regions like Africa, South America, the Middle East, and Europe are particularly seeking flexible manufacturing solutions that can accommodate both small and large production runs without compromising quality. The rise of advanced manufacturing technologies, such as CNC bending and automated quoting systems, is streamlining operations, reducing lead times, and enhancing precision. These technologies enable instant pricing and real-time feedback, which are crucial for international buyers who require transparency and speed in their procurement processes.

Moreover, sustainability is becoming a pivotal concern, influencing purchasing decisions. B2B buyers are increasingly favoring suppliers who can demonstrate environmentally responsible practices and materials. This trend is particularly pronounced in Europe, where stringent regulations regarding emissions and waste management are in place. Additionally, the global supply chain disruptions caused by recent geopolitical events have prompted companies to rethink their sourcing strategies, favoring local suppliers or those with robust contingency plans to mitigate risks.

How Is Sustainability Influencing Metal Bending Services and Ethical Sourcing?

Sustainability and ethical sourcing are no longer optional considerations in the metal bending service sector; they are essential to competitive advantage. The environmental impact of metal fabrication processes, including energy consumption and waste generation, is driving companies to adopt greener practices. For instance, many suppliers are now utilizing recycled materials or environmentally friendly coatings, appealing to eco-conscious buyers.

Ethical supply chains are also gaining traction, as businesses are held accountable for their sourcing decisions. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming increasingly important, as they assure buyers of a supplier’s commitment to sustainable practices. Additionally, the demand for transparency in sourcing—where materials are sourced from ethically responsible suppliers—has become a significant factor influencing purchasing decisions, particularly among buyers from regions with strong regulatory frameworks.

What Is the Evolution of Metal Bending Services in the B2B Landscape?

The evolution of metal bending services can be traced back to traditional manual processes, which have significantly transformed with the advent of technology. Initially, metal bending relied heavily on labor-intensive methods, limiting design complexity and production speed. However, the introduction of CNC technology in the late 20th century revolutionized the industry by enabling precise bends and complex geometries that were previously unattainable.

As the market has evolved, so too have buyer expectations. Today’s B2B buyers demand quick turnaround times, custom solutions, and transparency in pricing and processes. The integration of digital tools, such as automated quoting systems and 3D modeling software, has streamlined operations and made it easier for buyers to collaborate with manufacturers. This shift towards a tech-driven approach not only enhances efficiency but also supports the growing trend of just-in-time manufacturing, allowing companies to reduce inventory costs and respond swiftly to market changes.

In summary, understanding the dynamics and trends of the metal bending service sector is crucial for international B2B buyers. By focusing on technological advancements, sustainability, and the historical context of the industry, buyers can make informed decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of metal bending service

-

How do I ensure my metal bending designs avoid common issues?

To prevent issues like flange collisions or improper bend radii, it’s crucial to incorporate adequate clearances and follow the bending guidelines provided by your supplier. Use CAD software to simulate the bending process and verify the design against the supplier’s specifications, including material thickness and bend radius. Providing detailed drawings and notes on your designs can also help ensure your requirements are clearly understood, minimizing the risk of errors during production. -

What materials are typically used in metal bending services?

Common materials for metal bending include aluminum, steel, stainless steel, and copper. The choice of material often depends on the application’s requirements, such as strength, weight, corrosion resistance, and cost. Each material has specific bending characteristics, such as the required bend radius and K-factor, which can affect the overall design and production process. Always consult with your supplier about the best material options for your specific project needs. -

What customization options are available for metal bending services?

Most metal bending service providers offer a range of customization options, including bend angles, lengths, and finishes. You can specify unique requirements in your design files, including complex shapes or additional features like holes or notches. Some companies also provide services like powder coating or hardware installation alongside bending, allowing for a more comprehensive solution. Be sure to communicate your specific needs clearly when submitting your designs to ensure the final product meets your expectations. -

Are there minimum order quantities (MOQs) for metal bending services?

Many metal bending service providers have no minimum order quantities, allowing you to place orders for single prototypes or large production runs. This flexibility is particularly advantageous for businesses looking to test designs without committing to large quantities. However, it’s essential to verify this with your supplier, as some may have different policies based on the complexity of the project or the materials used. -

What are the payment terms typically offered for metal bending services?

Payment terms can vary significantly among suppliers, but common arrangements include upfront payments, net 30 days, or payment upon delivery. International buyers should inquire about any additional fees, such as currency conversion or wire transfer charges. Establishing clear payment terms upfront can help avoid misunderstandings and ensure a smooth transaction process. Always request a detailed invoice outlining all costs before making payments. -

How do I vet a metal bending supplier for international trade?

When sourcing metal bending services internationally, it’s crucial to assess the supplier’s credentials, including certifications (like ISO 9001), production capabilities, and customer reviews. Request samples of previous work and ask for references from other B2B clients. Additionally, consider the supplier’s experience with international shipping and customs, as this can impact lead times and costs. A reliable supplier should also have clear communication channels for addressing any concerns during the project. -

What quality assurance measures should I expect from a metal bending service?

A reputable metal bending service will have robust quality assurance processes in place, including inspections of raw materials and finished products. Look for suppliers that utilize advanced measurement tools to ensure accuracy in dimensions and angles, and those that provide documentation certifying that parts meet specified tolerances. Inquire about their return policies and how they handle defective products, as this can provide insight into their commitment to quality. -

What logistics considerations should I keep in mind when sourcing metal bending services?

When working with international suppliers, consider logistics factors such as shipping times, customs clearance, and potential tariffs. It’s vital to discuss the expected lead times with your supplier and plan accordingly, especially if you have tight project deadlines. Additionally, ensure that the supplier has experience in handling international shipments and can provide tracking information. Understanding these logistics will help you manage your project timelines effectively and avoid unexpected delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Metal Bending Service Manufacturers & Suppliers List

1. SendCutSend – CNC Sheet Metal Bending Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers CNC sheet metal bending services to transform flat designs into functional parts. Key features include:

– Tolerances of +/- 1 degree or better

– No minimum quantity required

– Pricing starting at $0.70 per bend in bulk

– Available materials: 9 metals and 1 plastic, including 5052 H32 Aluminum, Brass, 4130 Chromoly, Copper, G90 Galvanized Steel, Mild Steel, Polycarbonate, 304…

2. Fabworks – Precision Sheet Metal Bending Service

Domain: fabworks.com

Registered: 2000 (25 years)

Introduction: Sheet Metal Bending Service at Fabworks offers precision bending using advanced CNC technology. Key features include:

– Upload 3D STEP files for automatic bending configuration.

– No minimum quantity required for orders.

– Materials available: Aluminum, Steel, Stainless Steel.

– Bending capabilities: 1-135 degree bends with +/- 1 degree angle tolerance and +/- .015″ length tolerance.

– Fast turnar…

3. OSH Cut – On-Demand Custom Metal Bending Services

Domain: oshcut.com

Registered: 2018 (7 years)

Introduction: On-Demand Custom Metal Bending Services at OSH Cut offer bending in steel, stainless, aluminum, and copper with thicknesses up to 5/16″. The service includes precision bending with tolerances of +/- 1.0 degree and back-gauge positioning within +/- 0.0001″. Customers can upload flat patterns with bend lines or 3D sheet metal models for instant pricing and manufacturability feedback. The system supp…

4. LaserBoost – Custom Metal Fabrication

Domain: laserboost.com

Registered: 2012 (13 years)

Introduction: This company, LaserBoost – Custom Metal Fabrication, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. MiniFaber – Precision Metal Bending Services

Domain: minifaber.com

Registered: 2000 (25 years)

Introduction: MiniFaber specializes in metal bending services, offering precision bending for various materials including steel, aluminum, and brass. The company utilizes advanced machinery and techniques to achieve high-quality bends with tight tolerances. Their capabilities include both small and large production runs, catering to diverse industries such as automotive, construction, and furniture. MiniFaber e…

6. Laserfab – Custom Metal Forming & Bending Services

Domain: laserfab.net

Registered: 2000 (25 years)

Introduction: Metal Forming & Bending Services offered by Laserfab include custom metal bending using high-capacity CNC press brakes. Key details include:

– Materials: Mild Steel, Stainless Steel, Aluminum, Copper, Brass, Bronze

– Max Length: 174 inches

– Thickness: Up to 1 inch

– Optional Die Protection

– Machine Specs: 4 CNC Press Brakes, Max 359 Tons, 6-Axis Back Gauge

– Features: Precision CNC control…

7. eMachineShop – CNC Bending Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: eMachineShop offers CNC bending services for custom sheet metal parts, utilizing advanced CNC bending equipment alongside sheet metal cutting capabilities. Key features include: 50+ materials available, free shipping in the USA, and a 100% quality guarantee. The bending process involves using a pneumatic or hydraulic press brake to manipulate ductile metals such as aluminum, stainless steel, and b…

Strategic Sourcing Conclusion and Outlook for metal bending service

As the demand for precision and efficiency in metal bending services continues to rise, strategic sourcing becomes increasingly vital for international B2B buyers. Key takeaways emphasize the importance of understanding material specifications, tolerances, and the capabilities of suppliers. By collaborating with providers that utilize advanced CNC technology, businesses can ensure high-quality outcomes while maintaining cost-effectiveness.

Furthermore, leveraging instant pricing tools and transparent communication can significantly streamline the procurement process, reducing lead times and enhancing project management. Buyers should prioritize suppliers who offer flexibility in order sizes and comprehensive support for complex designs, allowing for successful prototyping and production runs.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe must remain proactive in seeking partnerships that foster innovation and adaptability in metal bending services. Embrace the opportunity to elevate your sourcing strategy—invest in relationships with suppliers who not only meet your immediate needs but also align with your long-term goals for growth and sustainability. Take the next step in your procurement journey and explore the vast possibilities that strategic sourcing in metal bending can offer.