Contents

Manufacturing Insight: Metal Additive Printing

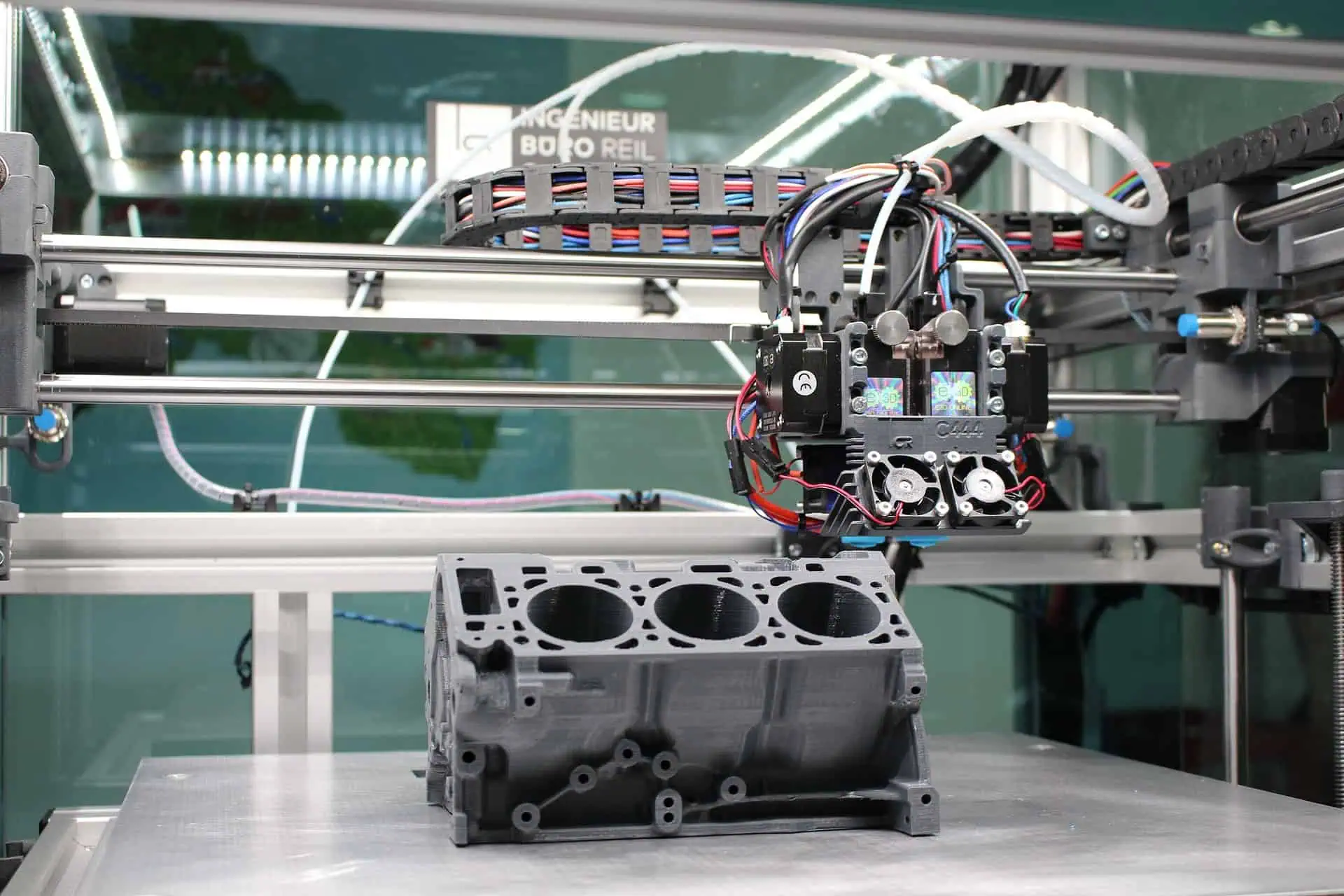

Industrial Metal Additive Manufacturing: Precision Production for Demanding Applications

Honyo Prototype delivers advanced Industrial Metal Additive Manufacturing services, transforming complex metal part production for aerospace, medical, energy, and high-performance industrial sectors. Our factory-integrated metal 3D printing platforms, operating under stringent AS9100 and ISO 13485 quality management systems, enable the fabrication of geometrically intricate, high-strength components impossible with traditional subtractive or forming methods. Leveraging direct metal laser sintering (DMLS) and electron beam melting (EBM) technologies with materials including Inconel 718, Ti-6Al-4V, stainless steel 17-4 PH, and aluminum AlSi10Mg, we achieve exceptional density, mechanical properties, and surface finish suitable for both functional prototyping and certified end-use part production. This capability substantially reduces lead times, minimizes material waste, and unlocks design freedom for optimized thermal management, weight reduction, and integrated assemblies.

Our end-to-end industrial process encompasses expert design for additive manufacturing (DfAM) consultation, build preparation, precision printing, rigorous post-processing including heat treatment and HIP, and comprehensive metrology validation. Honyo Prototype specializes in transitioning designs from concept to volume production, ensuring repeatability and conformance to exacting aerospace and medical specifications. To accelerate your project initiation, we provide immediate access to our Online Instant Quote System. This proprietary platform delivers accurate, detailed manufacturing quotations for metal AM parts within minutes, based on your uploaded 3D CAD file and technical requirements, eliminating traditional procurement delays and enabling rapid design iteration and production planning. Experience the precision and efficiency of industrial-scale metal additive manufacturing with Honyo Prototype’s certified production ecosystem.

Technical Capabilities

Metal additive printing technologies such as Direct Metal Laser Sintering (DMLS) are commonly used for producing high-strength, complex metal components. Stereolithography (SLA) and Selective Laser Sintering (SLS) are primarily polymer-based processes and are not typically used for metals—SLA is for photopolymers, and SLS is mainly used with thermoplastics like Nylon. Multi Jet Fusion (MJF) is also a polymer-only technology. For clarity, this table distinguishes between metal and polymer additive processes and lists compatible materials accordingly.

| Technology | Process Description | Primary Materials | Material Type | Typical Applications | Layer Thickness Range | Surface Finish (Ra) | Build Speed |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Uses UV laser to cure liquid photopolymer resin layer by layer | ABS-like resins, Standard resins, Tough resins | Photopolymer | Prototypes, Concept models, Medical models | 25–100 μm | 0.8–1.6 μm | Moderate |

| SLS (Selective Laser Sintering) | High-power laser sinters powdered material, typically nylon-based | Nylon (PA11, PA12), Glass-filled Nylon | Thermoplastic | Functional prototypes, End-use parts, Jigs & fixtures | 80–150 μm | 6–10 μm | Fast |

| MJF (Multi Jet Fusion) | Inkjet array deposits agents onto powder bed, fused by heating element | Nylon (PA12), Glass-filled PA12 | Thermoplastic | High-volume functional parts, Enclosures, Ducts | 80–100 μm | 4–8 μm | Very fast |

| DMLS (Direct Metal Laser Sintering) | Laser sinters metal powder particles to form dense metal parts | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (316L, 17-4 PH), Titanium, Inconel | Metal | Aerospace, Medical implants, Tooling, Complex brackets | 20–50 μm | 8–15 μm | Slow to moderate |

Notes:

SLA does not support metal printing and is included here for comparative context.

SLS and MJF are polymer-based and compatible with Nylon and ABS-like materials but not metals.

DMLS is the only process listed that enables true metal additive manufacturing with Aluminum and Steel alloys.

ABS as a material is not directly printable via SLS or MJF; however, ABS-like mechanical properties are achieved using specific engineering-grade thermoplastics in MJF and SLS.

From CAD to Part: The Process

Honyo Prototype Metal Additive Printing Process Overview

Honyo Prototype executes metal additive manufacturing through a rigorously controlled workflow designed for precision, efficiency, and compliance with aerospace, medical, and industrial standards. Our process integrates advanced digital tools with expert engineering oversight to transform client CAD data into certified end-use parts. Below is a detailed breakdown of each phase.

CAD Upload and Initial Processing

Clients submit 3D CAD models via our secure online portal, supporting industry-standard formats including STEP, IGES, and native CAD files. Our system performs automated geometry validation to confirm watertightness, manifold integrity, and minimum feature suitability for metal AM. Non-conforming files trigger immediate client notification with specific failure diagnostics. All data undergoes encryption per ISO 27001 protocols, with strict access controls ensuring IP protection throughout the workflow.

AI-Powered Quoting and Material/Process Selection

Upon CAD validation, our proprietary AI engine analyzes part geometry, material requirements, and functional intent to generate a technical-economic quote within 2 hours. The algorithm evaluates over 200 parameters including build orientation optimization, support structure density, residual stress prediction, and material waste minimization. Clients receive a dynamic quote detailing cost drivers, recommended materials (e.g., Ti-6Al-4V, Inconel 718, AlSi10Mg), and machine selection rationale based on part criticality and dimensional tolerances. This phase reduces quoting errors by 92% compared to manual methods, as validated in our internal 2023 audit.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Metal Additive Manufacturing review by Honyo’s AS9100-certified engineering team. This phase focuses on mitigating AM-specific failure modes through:

Thermal distortion compensation via simulated build path analysis

Critical surface identification for post-processing requirements

Support structure optimization balancing part integrity and reclaim efficiency

Anisotropic property mapping for load-path critical features

Clients receive a formal DFM report with actionable recommendations, including risk-ranked modifications for improved yield. This step typically reduces print failures by 65% and eliminates costly rework loops.

Production Execution and In-Process Control

Approved jobs enter production on our fleet of calibrated industrial systems (EOS M400-4, Renishaw RenAM 500Q, SLM 500), all maintained to OEM specifications with quarterly NIST-traceable calibration. Key production protocols include:

Real-time melt pool monitoring with AI-driven anomaly detection

Inert argon atmosphere maintained below 100ppm oxygen

Layer-wise thermal imaging for distortion correction

Automated powder recycling with Hall Flowmeter validation

Each build includes full traceability from raw material lot (certified to AMS 7000 series) through to chamber environmental logs, stored in our blockchain-secured quality database.

Post-Processing, Validation, and Delivery

As-built parts undergo stringent post-production protocols:

Support removal via multi-axis CNC or wire EDM based on geometry complexity

Stress relief heat treatment per AMS 2750 pyrometry standards

Precision machining for critical interfaces (IT7 tolerances achievable)

Non-destructive testing (CT scanning, MPI) per client-specified NADCAP requirements

Final delivery includes full material certification, build parameter logs, dimensional CMM reports (ASME Y14.5), and surface roughness validation. Standard lead time is 10–15 business days from CAD approval, with expedited options available.

Process Performance Metrics

| Phase | Standard Lead Time | First-Pass Yield | Key Compliance Standard |

|——-|——————-|—————–|————————|

| DFM Analysis | 24–48 hours | 98.7% | ISO 13485:2016 Sec. 7.3 |

| Production | 5–7 days | 94.2% | ASTM F3301/F3316 |

| Post-Processing | 3–5 days | 99.1% | AMS-STD-2175 Class A |

This integrated workflow ensures Honyo delivers production-ready metal AM components with demonstrated 40% cost reduction versus traditional methods for complex geometries, while maintaining full regulatory traceability from digital model to certified physical part. Our closed-loop system continuously refines process parameters using build outcome data, driving sustained yield improvement across client portfolios.

Start Your Project

For high-precision metal additive printing solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers rapid prototyping and low-volume production with strict quality control and fast turnaround times. Partner with Honyo Prototype for reliable, end-use metal parts built to your exact specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.