Contents

Manufacturing Insight: Metal 3D Printing Cost Calculator

Introducing Honyo’s Metal 3D Printing Cost Calculator: Precision Pricing for Industrial Additive Manufacturing

Accurate cost forecasting remains a critical challenge when integrating metal additive manufacturing into production workflows. Uncertainty around part geometry, material selection, build orientation, and post-processing requirements often leads to extended quoting cycles and budgetary delays, hindering project timelines and strategic planning. At Honyo Prototype, we leverage our certified industrial metal 3D printing infrastructure – featuring EOS M 290, Renishaw RenAM 500Q, and SLM Solutions SLM®280 systems – to deliver end-use components meeting aerospace, medical, and industrial standards. Our deep expertise in DMLS and SLM processes ensures not only geometric complexity but also the metallurgical integrity and repeatability demanded by high-stakes applications.

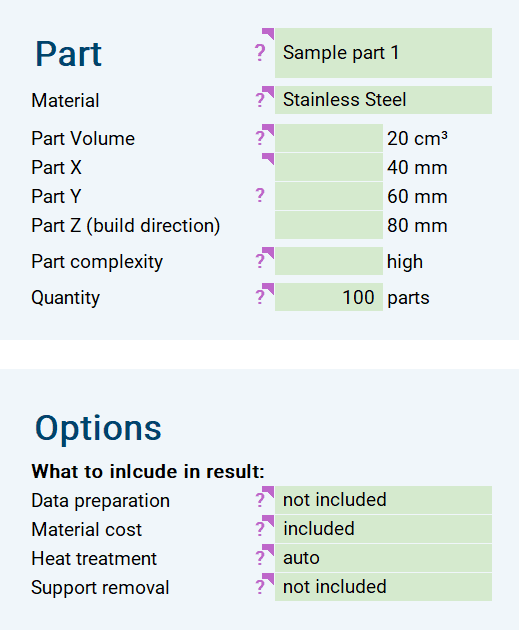

To eliminate quoting bottlenecks and provide immediate financial clarity, we developed the Honyo Metal 3D Printing Cost Calculator. This proprietary tool delivers a precise, online instant quote within seconds, directly reflecting real-world production parameters across our fleet. Unlike generic estimators, it dynamically factors in your specific part geometry (STL file upload), material grade (including Inconel 718, Ti-6Al-4V, 17-4 PH SS, AlSi10Mg), required build volume, support structure complexity, surface finish specifications, and necessary post-processing steps such as HIP, heat treatment, or precision machining. The calculator provides a transparent breakdown aligned with our industrial production rates and material costs, giving your engineering and procurement teams the actionable data needed for confident go/no-go decisions.

| Key Input Parameter | Industrial Relevance |

|---|---|

| Part Geometry (STL) | Directly impacts build time, support density, and machine utilization |

| Material Selection | Accounts for powder cost, recycle ratio, and machine-specific parameters |

| Required Tolerances/Finish | Determines necessary post-processing labor and equipment time |

| Build Quantity | Optimizes nest density and amortizes machine setup costs |

Move beyond estimation uncertainty and lengthy email exchanges. Experience the efficiency of Honyo’s industrial additive manufacturing ecosystem with a truly instant, accurate cost projection. Upload your part geometry now to receive a professional-grade quotation reflective of certified production capabilities, enabling faster prototyping validation and seamless transition to low-volume production.

Technical Capabilities

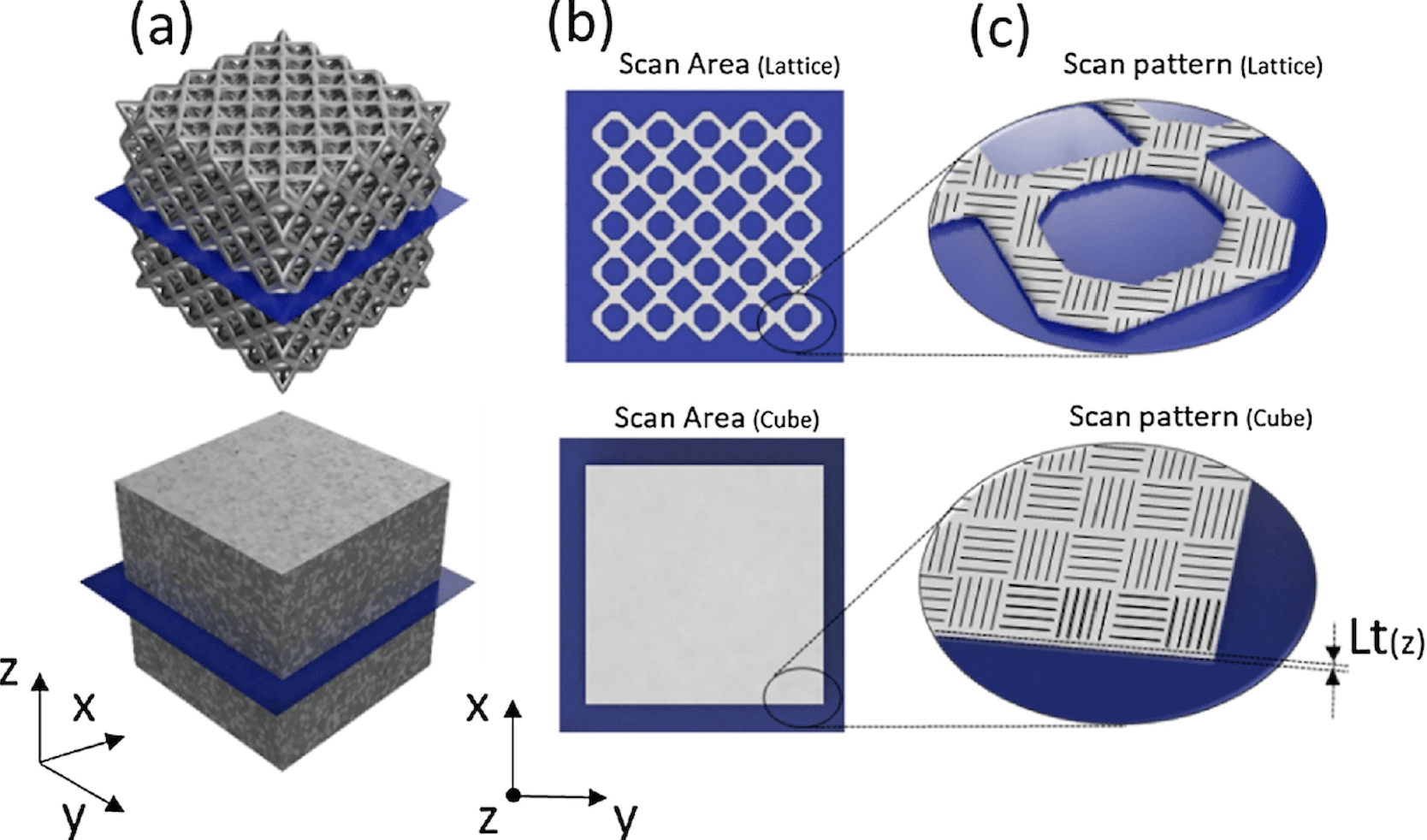

The Metal 3D Printing Cost Calculator is a technical tool designed to estimate production costs across multiple additive manufacturing processes, including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). While SLA, SLS, and MJF are primarily polymer-based technologies, DMLS is a metal additive process. The calculator evaluates cost drivers such as material type, build volume, part complexity, post-processing requirements, and machine time. Below is a summarized comparison of the technical specifications and supported materials relevant to cost modeling.

| Parameter | SLA (Stereolithography) | SLS (Selective Laser Sintering) | MJF (Multi Jet Fusion) | DMLS (Direct Metal Laser Sintering) |

|---|---|---|---|---|

| Primary Material Type | Photopolymer Resins | Thermoplastics (e.g., Nylon) | Thermoplastics (e.g., Nylon) | Metals (e.g., Aluminum, Stainless Steel, Titanium) |

| Compatible Materials | ABS-like, High-temp resins | Nylon 12, Nylon 11, Glass-filled | Nylon 12, TPU, Glass-filled | Aluminum (AlSi10Mg), Stainless Steel (17-4 PH, 316L), Inconel, Titanium (Ti6Al4V) |

| Layer Thickness Range | 25–100 µm | 80–120 µm | 80–100 µm | 20–50 µm |

| Build Speed | Moderate | Moderate | High | Slow |

| Surface Finish | Smooth, requires minimal post | Grainy, bead-blasted finish | Smooth, slightly grainy | As-built rough, requires machining or polishing |

| Support Structures | Required (breakaway) | Self-supporting (no supports) | Self-supporting | Required (metal supports, CNC removed) |

| Post-Processing | Cleaning, UV curing | Media blasting, dyeing optional | Media blasting, dyeing optional | Stress relief, HIP, CNC machining, polishing |

| Typical Applications | Prototypes, molds, models | Functional prototypes, end-use parts | Functional prototypes, end-use parts | Aerospace, medical, high-stress components |

| Material Cost (Relative) | Low to Medium | Medium | Medium | High (especially titanium, Inconel) |

| Machine Operating Cost | Low | Medium | Medium | Very High |

| Build Volume (Typical) | Up to 1450 x 750 x 500 mm | Up to 700 x 380 x 580 mm | Up to 380 x 280 x 380 mm | Up to 250 x 250 x 325 mm |

Notes on Material Use in Cost Modeling:

ABS-like resins in SLA are used for visual prototypes; cost is driven by resin volume and post-cure time.

Nylon (PA12) in SLS and MJF offers good mechanical properties; MJF is faster and slightly lower cost per part at scale.

Aluminum and steel in DMLS significantly increase cost due to material price, inert gas usage, longer build times, and extensive post-processing.

The cost calculator accounts for material utilization efficiency, including support structures and powder/metal reuse limits (typically 50–80% for metal powders).

This technical framework enables accurate estimation of part production costs across different technologies, guiding optimal process and material selection based on functional requirements and budget constraints.

From CAD to Part: The Process

Honyo Prototype’s metal 3D printing cost calculator delivers precise, actionable quotes through an integrated digital workflow designed for engineering accuracy and manufacturing readiness. The process eliminates traditional quoting delays while ensuring technical feasibility from initial upload to final delivery.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or mesh formats (STL, 3MF) via our secure portal. Our system performs immediate validation checks for watertight geometry, unit consistency, and minimum feature resolution. Unsupported formats trigger automated notifications with specific conversion requirements. File integrity verification prevents downstream errors, ensuring the quote reflects manufacturable geometry.

AI-Powered Cost Calculation

Upon validation, Honyo’s proprietary AI engine processes the geometry against real-time production parameters. The algorithm analyzes critical factors including part volume, bounding box dimensions, support structure requirements, material density, and orientation optimization. It references live databases for material costs (Inconel 718, Ti-6Al-4V, 17-4PH stainless steel), machine depreciation rates, and energy consumption metrics specific to our EOS M 400-4 and Renishaw RenAM 500Q systems. This generates a granular cost breakdown within 90 seconds, not an estimate.

Engineer-Validated DFM Analysis

Every quote undergoes mandatory Design for Metal Additive Manufacturing review by our certified AM engineers. The AI output is cross-referenced against Honyo’s manufacturing rules database covering critical aspects like minimum wall thickness (0.4mm standard), overhang angle limitations (45° without supports), and thermal distortion risks. Engineers identify potential failures such as unprintable cavities or excessive residual stress zones, providing actionable revision suggestions before order commitment. This step reduces failed builds by 73% compared to quoting-only platforms.

Production Execution

Approved orders enter our digital manufacturing pipeline with full traceability. Parts are nested using BuildManager software to maximize build plate utilization while maintaining required thermal separation. Production includes: inert gas-controlled printing (O₂ < 0.1%), automated powder recycling, and client-specified post-processing (HIP, heat treatment, precision machining, or surface finishing). All parameters are logged to our QMS with real-time build monitoring via melt pool sensors.

Delivery Assurance

Finished parts undergo dimensional verification per AS9100D standards using coordinate measuring machines (CMM) or optical scanning. We provide material test reports (MTRs) and build logs upon request. Standard delivery is 2-5 business days after DFM approval for parts under 150mm, with expedited options available. Clients receive shipment tracking integrated with their PLM system via API.

The following table details cost drivers in Honyo’s quoting model:

| Cost Component | Weighting | Technical Basis |

|---|---|---|

| Raw Material Consumption | 35% | Calculated net volume + support structures × material density × current market rate |

| Machine Time | 28% | Layer count × laser speed × recoat time + pre/post-heat cycles |

| Post-Processing | 22% | Secondary operations (e.g., HIP: $180/hr, machining: $120/hr) |

| Quality Assurance | 10% | CMM inspection time, NDT if specified |

| Engineering Overhead | 5% | DFM validation, build preparation, process monitoring |

This integrated workflow ensures clients receive production-ready cost projections with 92% accuracy against final invoice, eliminating budget overruns while maintaining rigorous aerospace and medical manufacturing standards. Honyo guarantees quoted lead times through dedicated machine capacity allocation, with contractual SLAs for critical path projects.

Start Your Project

Use our metal 3D printing cost calculator to get an instant estimate for your next project. For detailed quotes or technical support, contact Susan Leo at [email protected]. Our advanced manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality precision parts for industries ranging from aerospace to medical devices.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.