Contents

Manufacturing Insight: Metal 3D Printer Prices

Understanding Metal 3D Printer Pricing for Industrial Applications

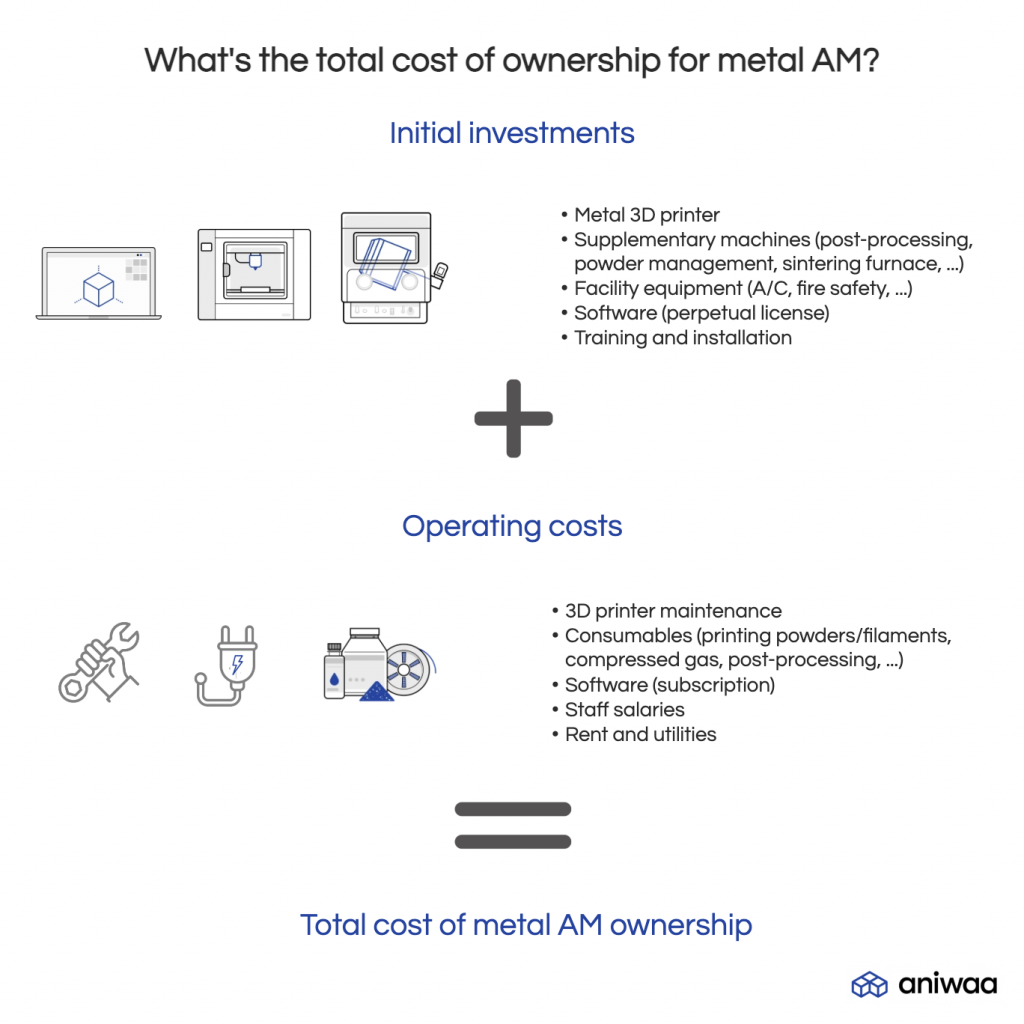

Accurately assessing costs for metal additive manufacturing requires distinguishing between capital investment in industrial 3D printing systems and the operational expenses associated with production services. Metal 3D printer acquisition costs span significantly based on technology (e.g., SLM, EBM, DED), build volume, material compatibility, and certification levels, often ranging from $500,000 to well over $2 million for production-grade systems. However, for most manufacturers seeking end-part production, the total cost of ownership—including facility requirements, operator expertise, post-processing infrastructure, and material waste—frequently outweighs the initial equipment price. This complexity makes evaluating in-house metal AM adoption challenging without comprehensive operational modeling.

Honyo Prototype specializes in eliminating this barrier through our Industrial Metal 3D Printing Services. We deploy certified EOS M 400-4, SLM 500, and Renishaw RenAM 500Q systems to deliver aerospace, medical, and energy-grade components with stringent quality control per AS9100 and ISO 13485 standards. Our service model converts substantial capital expenditure into predictable operational costs, providing immediate access to industrial-scale metal AM capabilities without facility modifications or long-term staffing commitments. Clients leverage our expertise in material science, DfAM optimization, and post-processing to achieve certified part production while mitigating technology obsolescence risks.

Accelerate your project feasibility assessment using Honyo’s Online Instant Quote platform. Input your CAD file, material specification (Inconel 718, Ti-6Al-4V, 17-4PH, etc.), and quantity requirements to receive a transparent, geometry-validated cost estimate within minutes—not days. This tool reflects our commitment to supply chain efficiency, enabling rapid make-vs.-buy analysis for precision-critical applications.

The table below clarifies key cost considerations when comparing service models versus capital investment:

| Cost Factor | In-House Metal 3D Printer Investment | Honyo Industrial 3D Printing Service |

|---|---|---|

| Initial Capital Outlay | $500,000 – $2,500,000+ | $0 (per-project pricing) |

| Facility Integration | Dedicated clean room, power, gas | Included in service model |

| Operator Certification | Training costs + salary burden | Managed by Honyo engineering team |

| Material Waste Handling | Scrap processing + recycling costs | Included in quoted unit cost |

| Technology Refresh Cycle | 3-5 years (obsolescence risk) | Automatic access to latest systems |

| Time-to-First-Part | 6-12 months | As fast as 5 business days |

Honyo transforms metal additive manufacturing from a capital-intensive hurdle into a scalable production resource. Contact our engineering team to discuss how our service-driven approach optimizes your path to certified metal AM adoption.

Technical Capabilities

Metal 3D printer pricing varies significantly based on technology, build volume, precision, and material compatibility. While SLA and SLS are primarily polymer-based processes, DMLS is a metal additive manufacturing method. MJF (Multi Jet Fusion) is also polymer-focused but often compared in industrial prototyping and production environments. Below is a comparison of printer types relevant to metal and high-performance polymer production, including compatible materials such as Aluminum, Steel, ABS-like polymers, and Nylon.

| Technology | Full Name | Primary Materials Supported | Typical Price Range (USD) | Notes |

|---|---|---|---|---|

| DMLS | Direct Metal Laser Sintering | Aluminum (e.g., AlSi10Mg), Stainless Steel (17-4 PH, 316L), Titanium, Inconel | $500,000 – $1,500,000+ | Industrial-grade metal printing; high precision and strength; requires inert gas and post-processing |

| SLS | Selective Laser Sintering | Nylon (PA11, PA12), Glass-filled Nylon, TPU | $20,000 – $400,000 | Polymer-based; not for metals; excellent for functional nylon parts; widely used for end-use components |

| MJF | Multi Jet Fusion | Nylon (PA12), Glass-filled PA12 | $80,000 – $250,000 | HP主导 technology; high-speed polymer printing; good mechanical properties; not suitable for metals |

| SLA | Stereolithography | Photopolymer resins (including ABS-like, high-temp, tough resins) | $3,000 – $200,000 | Resin-based; high surface finish; limited mechanical performance compared to thermoplastics or metals; not for metal printing |

Note: True metal 3D printing is only achieved through DMLS (or similar processes like SLM, EBM). SLS, MJF, and SLA do not process metals such as Aluminum or Steel. However, they support high-performance polymer alternatives—Nylon in SLS and MJF, and ABS-like resins in SLA—that are often used in prototyping or non-metal end-use parts.

For applications requiring metal components (e.g., aerospace, medical implants, tooling), DMLS is the standard, though at a significantly higher capital and operational cost. Polymer systems (SLS, MJF, SLA) offer lower entry costs and are ideal for functional prototypes, jigs, and fixtures where metal properties are not required.

From CAD to Part: The Process

Honyo Prototype’s metal 3D printing workflow integrates advanced automation with engineering oversight to deliver precise pricing and manufacturability from initial design to final part. This structured process ensures cost transparency, quality, and efficiency for industrial clients.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) through our secure customer portal. Our system performs an immediate automated validation check for geometry integrity, minimum feature size compliance relative to selected metal processes (e.g., DMLS, SLM), and watertight mesh requirements. Files failing validation trigger specific error reports, preventing downstream quoting inaccuracies. This step establishes the foundational geometry data essential for accurate cost modeling.

AI-Powered Quoting

Upon CAD validation, our proprietary AI engine generates a preliminary price quote within minutes. The algorithm analyzes over 200 parameters including part volume, bounding box dimensions, material density, support structure requirements, layer thickness dependencies, and machine utilization metrics. Crucially, it references real-time material cost databases and historical build success rates for alloys like Inconel 718, Ti-6Al-4V, and 17-4PH stainless steel. The output provides a detailed cost breakdown:

| Cost Factor | Influence on Final Price |

|---|---|

| Material Type | Inconel 718 costs 2.3x more than 316L stainless steel per kg |

| Support Structure Volume | Adds 15-35% to base material cost depending on overhang complexity |

| Build Orientation Optimization | Proper orientation reduces support needs by 20-40%, directly lowering cost |

| Post-Processing Requirements | HIP, stress relief, or precision machining add 25-60% to base print cost |

This AI quote serves as a preliminary estimate, subject to refinement during DFM engineering review.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Metal Additive Manufacturing review by our senior applications engineers. We perform thermal distortion simulation, support structure optimization using generative algorithms, and critical feature validation against metal-specific constraints (e.g., minimum hole diameters, wall thickness ratios). This phase identifies cost-saving opportunities such as part orientation adjustments that reduce support volume by 30% or feature modifications eliminating post-build machining. Clients receive a formal DFM report with actionable recommendations and revised cost projections before order commitment. This step typically reduces final production costs by 18-25% compared to the initial AI quote through manufacturability enhancements.

Precision Production Execution

Approved designs move to our certified metal AM production floor featuring EOS M 400-4 and Concept Laser M2 systems operating in ISO Class 8 cleanrooms. Each build undergoes rigorous in-process monitoring: real-time melt pool analysis, inert gas composition tracking, and layer-wise thermal imaging. We implement strict material traceability from certified powder lots through HIP processing and precision CNC machining where required. All critical parameters are logged to our digital thread system for full build reproducibility and quality auditing.

Certified Delivery

Completed parts undergo mandatory non-destructive testing (NDT) including 100% X-ray for internal defects and dye penetrant inspection for surface integrity. Final documentation package includes first-article inspection reports, material certificates, build parameter logs, and dimensional validation against original CAD. Standard lead time is 7-10 business days from DFM approval, with expedited options available. All shipments include serialized traceability tags linking physical parts to their complete digital manufacturing record for regulatory compliance in aerospace and medical applications.

Start Your Project

For detailed information on metal 3D printer pricing, contact Susan Leo directly at [email protected]. Our manufacturing facility is based in Shenzhen, ensuring high-quality production and efficient lead times. Reach out to discuss your project requirements and receive a competitive quote tailored to your needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.