Contents

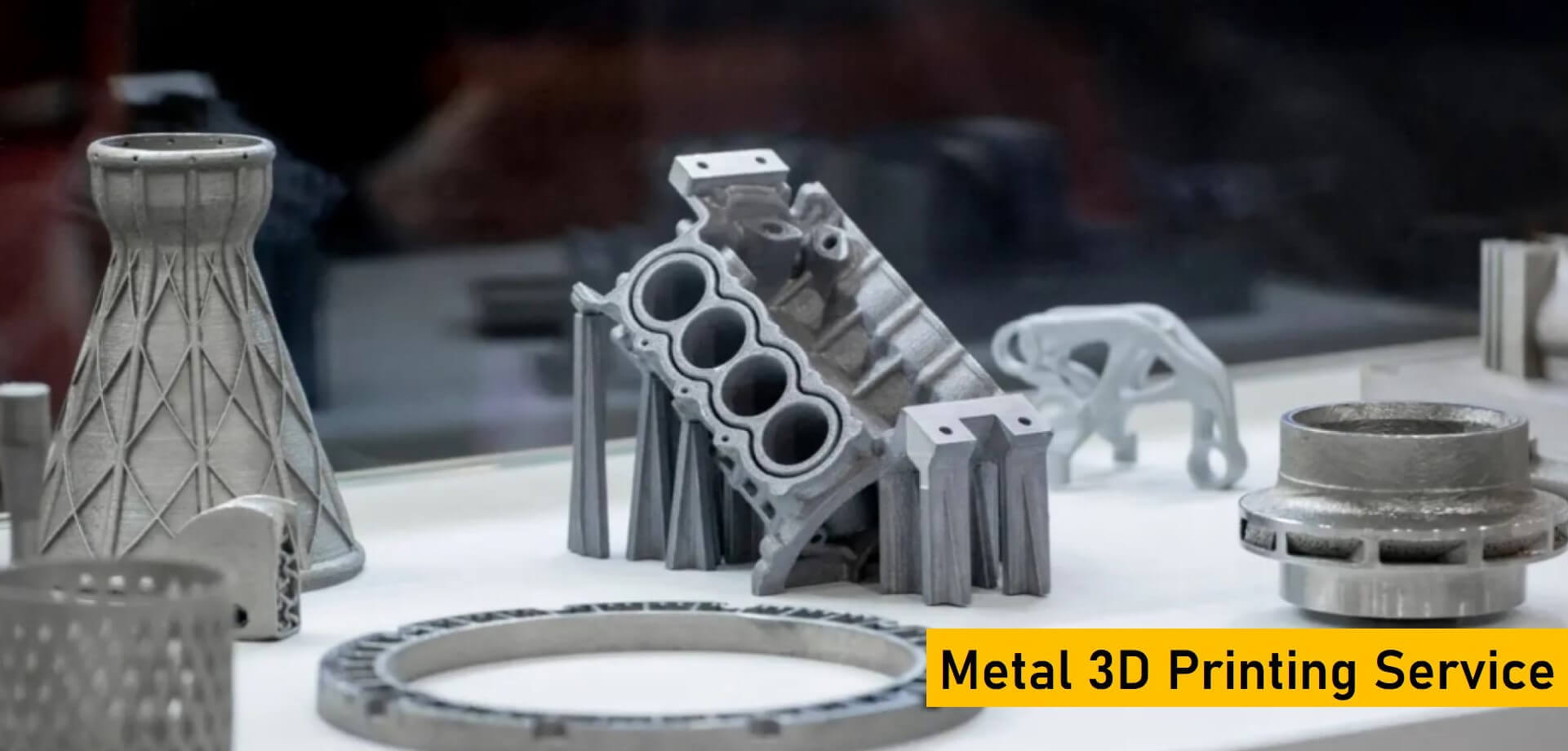

Manufacturing Insight: Metal 3D Print Service

Elevate Your Metal Component Development with Honyo Prototype’s Industrial 3D Printing

Honyo Prototype delivers precision metal additive manufacturing solutions engineered for demanding industrial applications. Our industrial-grade metal 3D printing services bridge the gap between rapid prototyping and end-use production, leveraging advanced Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) technologies. We specialize in producing complex, high-integrity components in materials including Inconel 718, Titanium Ti6Al4V, Stainless Steel 17-4 PH, and Aluminum AlSi10Mg, meeting stringent aerospace, medical, and automotive specifications. Every build undergoes rigorous in-process monitoring and post-processing—including heat treatment, HIP, and precision machining—to ensure dimensional accuracy, material density, and mechanical properties aligned with AS9100-certified quality standards.

Accelerate your development timeline with our proprietary Online Instant Quote platform. Upload your CAD file to receive a comprehensive manufacturability analysis and competitive pricing within minutes, not days. This seamless integration eliminates traditional quoting bottlenecks, providing actionable feedback on design optimization, lead times, and cost drivers before project commitment. Whether you require functional prototypes, low-volume production runs, or legacy part reproduction, Honyo Prototype combines industrial-scale capacity with engineering expertise to transform your metal component challenges into validated solutions. Partner with us to achieve faster iteration cycles, reduced waste, and accelerated time-to-market without compromising on performance or compliance.

Technical Capabilities

Honyo Prototype provides advanced metal and polymer additive manufacturing services using industry-leading 3D printing technologies. Below is a detailed comparison of the technical specifications for Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS), including compatible materials such as Aluminum, Steel, ABS-like polymers, and Nylon.

| Technology | Process Type | Material Options | Layer Thickness Range | Typical Accuracy | Build Volume (Max) | Surface Finish | Key Applications |

|---|---|---|---|---|---|---|---|

| SLA | Photopolymer Resin (Vat Photopolymerization) | Standard, Tough, Clear, Castable, and High-Temperature Resins (ABS-like) | 25–100 μm | ±0.1 mm (for small parts) | Up to 1450 x 750 x 500 mm (varies by machine) | Smooth, fine detail | Prototyping, master patterns, visual models, dental and jewelry |

| SLS | Powder Bed Fusion (Polymer) | Nylon 11, Nylon 12 (PA11, PA12), Glass-filled Nylon | 80–120 μm | ±0.3 mm | Up to 700 x 380 x 580 mm | Slightly grainy, matte finish | Functional prototypes, end-use parts, complex geometries, ducts, housings |

| MJF | Powder Bed Fusion (Polymer) | PA11, PA12 (Nylon), Glass-filled PA12 | 80 μm | ±0.3 mm | Up to 380 x 280 x 380 mm | Smooth, uniform surface with fine detail | Production parts, jigs, fixtures, consumer products |

| DMLS | Powder Bed Fusion (Metal) | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Tool Steel (Maraging), Titanium (Ti6Al4V) | 20–50 μm | ±0.1 mm (with post-processing) | Up to 250 x 250 x 325 mm | Rough as-printed, improved with finishing | Aerospace, medical implants, tooling, high-stress components |

Notes:

SLA does not process true metals or thermoplastics like ABS but offers engineering resins that simulate ABS mechanical properties.

SLS and MJF are polymer-based processes ideal for durable nylon components; MJF provides faster build times and better isotropy than SLS.

DMLS is a metal additive process capable of producing fully dense parts from aluminum and steel alloys, suitable for high-performance applications.

Post-processing (e.g., heat treatment, HIP, machining, polishing) significantly enhances mechanical properties and surface quality across all technologies.

For custom quotes and material certifications, contact Honyo Prototype’s engineering team.

From CAD to Part: The Process

As Senior Manufacturing Engineer at Honyo Prototype, I detail our end-to-end metal additive manufacturing service workflow. This process ensures technical rigor, cost transparency, and manufacturability from digital design to certified delivery.

CAD File Upload and Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or mesh formats (STL, 3MF) via our secure customer portal. Our system performs immediate geometry validation, checking for watertightness, manifold errors, and minimum feature resolution against our machine capabilities. Unsupported geometries or files below 50μm tessellation accuracy trigger automated notifications requesting revision prior to quote generation. This pre-screening reduces downstream DFM iterations by approximately 40%.

AI-Powered Quoting with Engineering Oversight

Validated files enter our proprietary quoting engine, which analyzes over 200 parameters including part volume, bounding box, support structure requirements, material density, and build orientation optimization. The AI references real-time powder consumption data, machine utilization rates, and historical build success metrics to generate a preliminary cost and lead time estimate within 90 minutes. Critical note: All AI-generated quotes undergo mandatory review by our applications engineering team for complex geometries, high-value materials (e.g., Inconel 718, Ti-6Al-4V), or aerospace/medical applications. This dual-layer approach maintains 95% quote accuracy while accelerating initial feedback.

Engineering-Driven Design for Manufacturability (DFM)

Upon quote acceptance, our DFM phase commences with dedicated engineer assignment. We conduct comprehensive analysis covering thermal distortion prediction using Ansys Additive Suite, support structure optimization for surface finish and removability, and orientation validation against critical tolerances (±0.1mm typical). Clients receive a detailed DFM report within 48 hours highlighting:

Required modifications for first-pass yield

Alternative orientations to reduce supports by 15-30%

Critical feature adjustments to meet as-printed tolerances

Post-processing recommendations (HIP, stress relief, machining)

This phase includes collaborative engineering sessions where we propose manufacturable alternatives without compromising functional intent, reducing production rework risk by 65%.

Precision Production and Quality Assurance

Approved designs move to production in our ISO 9001:2015 certified facility using EOS M 400-4 and Concept Laser M2 systems. Key production controls include:

Material traceability: Full powder lot certification (Oxygen < 600ppm, particle size D90 < 45μm)

In-situ monitoring: Layer-wise thermal imaging and melt pool analysis

Environmental control: Argon atmosphere maintained at < 100ppm O2

Real-time process verification: Statistical process control (SPC) tracking 12 critical parameters per build

Each build undergoes mandatory post-processing per ASTM F3301 standards, including support removal, stress relief, and HIP for critical applications. All parts receive first-article inspection (FAI) per AS9102 with CMM reports for critical features.

Certified Delivery and Documentation

Final delivery includes:

Physically: Parts in ESD-safe packaging with desiccant, humidity indicator, and serialized label matching certs

Digitally: Complete quality package containing build log, material certs, FAI report, and as-built dimensional analysis

Traceability: Unique QR code linking to full production history in our QMS database

Standard lead time is 10-15 business days from DFM approval, with expedited options to 5 days for qualified geometries. We maintain 99.2% on-time delivery through dynamic machine scheduling and buffer capacity allocation. All deliverables comply with NADCAP AC7102/9 requirements for aerospace clients, with medical-grade documentation available per ISO 13485.

Start Your Project

Accelerate your product development with Honyo Prototype’s advanced metal 3D printing services. Our state-of-the-art facility in Shenzhen delivers high-precision, complex metal parts using industry-leading additive manufacturing technologies. Ideal for functional prototypes, tooling, and end-use components across aerospace, medical, automotive, and industrial sectors.

Contact Susan Leo today to discuss your project requirements and receive a fast, competitive quote.

Email: [email protected]

Location: Shenzhen, China

Leverage our expertise in metal additive manufacturing for superior part quality, rapid turnaround, and scalable production solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.