Introduction: Navigating the Global Market for met fab solutions

In today’s rapidly evolving global market, sourcing reliable metal fabrication solutions can pose significant challenges for international B2B buyers. Whether you are seeking bespoke aluminium pressings or advanced welding equipment, the need for quality, efficiency, and cost-effectiveness is paramount. This guide aims to demystify the landscape of metal fabrication solutions, providing insights into various types of products, their applications across industries, and essential supplier vetting criteria.

Our comprehensive exploration includes practical considerations around pricing structures, lead times, and the importance of certifications, all tailored to assist buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Vietnam and Saudi Arabia. By leveraging this guide, you will gain the knowledge necessary to make informed purchasing decisions, ensuring that your projects not only meet but exceed your operational standards.

Understanding the intricacies of metal fabrication will empower you to navigate supplier relationships with confidence, ultimately leading to successful project outcomes. As we delve into the nuances of the market, you will discover strategies to optimize your sourcing efforts, ensuring that you find the right partners for your metal fabrication needs.

Understanding met fab solutions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminium Pressings | Custom fabrication, lightweight, corrosion-resistant | Architectural cladding, industrial designs | Pros: Versatile, durable; Cons: Higher initial cost compared to steel. |

| Powder Coated Panels | Aesthetic finish, enhanced durability, color customization | Retail facades, commercial buildings | Pros: Extensive color options; Cons: Requires careful maintenance to avoid scratches. |

| Welding Equipment | Range of machines (MIG, TIG, etc.), welding consumables | Heavy construction, automotive, shipbuilding | Pros: Versatile applications; Cons: Initial equipment investment can be high. |

| Laser Cutting Services | Precision cutting, ability to handle various materials | Custom parts manufacturing, prototyping | Pros: High accuracy; Cons: Longer setup times for complex designs. |

| Vacuum Bonded Insulated Panels | Thermal efficiency, lightweight, fire-rated options | Energy-efficient buildings, refrigeration | Pros: Excellent insulation; Cons: May have limitations on size and shape. |

What Are Aluminium Pressings and Their Applications in B2B?

Aluminium pressings are formed metal products tailored to meet specific project requirements, often used in architectural cladding and industrial designs. Their lightweight nature and corrosion resistance make them suitable for diverse applications, especially in environments exposed to harsh conditions. When considering aluminium pressings, B2B buyers should evaluate customization options, production timelines, and potential cost implications, as the initial investment may be higher than traditional materials like steel.

How Do Powder Coated Panels Enhance Business Projects?

Powder coated panels offer an aesthetic finish alongside robust durability, making them ideal for retail facades and commercial buildings. The ability to customize colors enhances brand visibility and project appeal. However, B2B buyers should consider the maintenance requirements of these panels, as scratches can detract from their visual impact. Additionally, understanding the supplier’s capabilities in terms of color matching and lead times is crucial for successful project execution.

What Should Buyers Know About Welding Equipment?

Welding equipment encompasses a variety of machines and consumables essential for industries such as heavy construction, automotive, and shipbuilding. The versatility of MIG, TIG, and other welding technologies allows for a broad range of applications. Buyers should assess their specific needs, including the type of welding processes required and the potential for future scalability. While the upfront investment in high-quality welding equipment can be significant, the long-term benefits in productivity and quality often justify the cost.

Why Choose Laser Cutting Services for Precision Manufacturing?

Laser cutting services provide high precision in cutting various materials, making them suitable for custom parts manufacturing and prototyping. This method is particularly advantageous for complex designs that require intricate detailing. B2B buyers should consider the accuracy and quality of cuts when selecting a service provider, as well as the lead times associated with laser cutting, which can be longer for more complex projects. The investment in laser cutting technology can lead to significant efficiencies in production.

What Advantages Do Vacuum Bonded Insulated Panels Offer?

Vacuum bonded insulated panels are designed for optimal thermal efficiency, making them ideal for energy-efficient buildings and refrigeration applications. Their lightweight and fire-rated options further enhance their appeal for construction projects focused on sustainability. Buyers should evaluate the specifications of these panels, including size and shape limitations, as well as the overall cost-effectiveness compared to traditional insulation methods. The long-term energy savings can often offset the initial investment, making them a smart choice for forward-thinking businesses.

Key Industrial Applications of met fab solutions

| Industry/Sector | Specific Application of met fab solutions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Aluminium cladding and curtain walling for buildings | Enhances aesthetic appeal while ensuring durability | Quality certifications, lead times, and customization options |

| Automotive | Production of bespoke aluminium pressings for vehicle parts | Reduces weight and improves fuel efficiency | Material specifications, compliance with automotive standards |

| Energy & Utilities | Fabrication of components for renewable energy installations | Supports sustainability goals and operational efficiency | Environmental certifications, material sourcing, and durability |

| Shipbuilding | Manufacturing of structural components for ships | Increases structural integrity and longevity | Compliance with maritime regulations, weight considerations |

| Retail | Custom aluminium fixtures and fittings for store displays | Enhances brand visibility and customer experience | Design flexibility, quick turnaround, and cost-effectiveness |

How is Met Fab Solutions Applied in the Construction and Architecture Sector?

In the construction and architecture sector, Met Fab Solutions provides high-quality aluminium cladding and curtain walling systems. These products are essential for modern buildings, offering both aesthetic appeal and structural integrity. They help solve issues related to weather resistance and insulation while meeting specific architectural designs. For international buyers, especially from regions with diverse climates, the ability to customize designs and ensure quick delivery times are crucial factors when sourcing these materials.

What Role Does Met Fab Solutions Play in the Automotive Industry?

In the automotive industry, bespoke aluminium pressings manufactured by Met Fab Solutions are pivotal for creating lightweight vehicle components. This application not only reduces the overall weight of vehicles but also enhances fuel efficiency and performance. Buyers need to consider compliance with stringent automotive standards and the ability to meet specific material requirements. Sourcing partners must provide transparency in their manufacturing processes to ensure quality and reliability.

How Does Met Fab Solutions Support the Energy and Utilities Sector?

Met Fab Solutions plays a significant role in the energy and utilities sector by fabricating components for renewable energy installations, such as solar panel frames and wind turbine parts. These products contribute to sustainability goals while ensuring operational efficiency. Buyers should prioritize suppliers that have environmental certifications and can demonstrate the durability of their products, particularly in harsh operational environments.

In What Ways is Met Fab Solutions Beneficial to the Shipbuilding Industry?

The shipbuilding industry benefits from Met Fab Solutions’ expertise in manufacturing structural components that enhance the integrity and longevity of marine vessels. The use of aluminium helps in reducing the weight of ships, improving fuel efficiency and performance. Buyers in this sector must ensure that their suppliers comply with maritime regulations and can provide materials that withstand corrosive marine environments.

How Does Met Fab Solutions Enhance Retail Environments?

In the retail sector, Met Fab Solutions offers custom aluminium fixtures and fittings that significantly enhance store displays and customer experiences. The ability to create bespoke solutions allows retailers to improve brand visibility and create inviting shopping environments. Buyers should consider the design flexibility offered by suppliers, as well as their capacity for rapid prototyping and cost-effectiveness, to meet the fast-paced demands of the retail industry.

3 Common User Pain Points for ‘met fab solutions’ & Their Solutions

Scenario 1: Long Lead Times Affecting Project Timelines

The Problem: B2B buyers in the construction and architectural sectors often face the challenge of long lead times when sourcing custom aluminium pressings and panels. Delays can stem from outsourcing manufacturing processes, leading to uncertainty in delivery schedules. For international buyers, particularly in regions like Africa and South America, such delays can disrupt project timelines, resulting in financial penalties and reputational damage.

The Solution: To mitigate this issue, buyers should prioritize suppliers like Met-Fab Solutions, which offers complete in-house production capabilities. By sourcing from a manufacturer that controls all aspects of the fabrication process, including cutting, bending, welding, and powder coating, buyers can ensure faster turnaround times. It is advisable to communicate specific project deadlines upfront and inquire about the supplier’s production capacity. Establishing a strong partnership with the manufacturer can also facilitate expedited processes, such as priority production for urgent projects, ensuring that deadlines are met consistently.

Scenario 2: Quality Assurance and Compliance Concerns

The Problem: Quality assurance is a significant concern for B2B buyers, particularly in industries where safety and compliance standards are stringent, such as construction and manufacturing. Buyers often worry about the consistency of product quality and the potential for defects in aluminium pressings and panels. This is particularly critical for international projects, where compliance with local regulations is mandatory, and any discrepancies can lead to costly rework or project shutdowns.

The Solution: Buyers can alleviate quality concerns by selecting suppliers that adhere to recognized standards, such as ISO 9001 and Qualicoat certifications, which signify rigorous quality management systems and superior product finishes. Met-Fab Solutions, for instance, has a proven track record of maintaining high-quality standards throughout its manufacturing processes. Buyers should conduct thorough due diligence by requesting samples, reviewing quality assurance documentation, and discussing the manufacturer’s quality control protocols. Establishing clear quality expectations and compliance requirements during the initial discussions can also set the stage for a successful partnership.

Scenario 3: Difficulty in Customization and Specification

The Problem: Many B2B buyers struggle with the challenge of obtaining customized solutions that meet their specific project requirements. This is particularly relevant in sectors like architecture and construction, where unique designs are often necessary to achieve aesthetic and functional goals. The inability to specify exact dimensions, finishes, and other critical details can lead to a mismatch between the buyer’s needs and the final product, causing delays and additional costs.

The Solution: To overcome customization challenges, buyers should work closely with suppliers that offer bespoke manufacturing capabilities. Met-Fab Solutions specializes in producing custom aluminium pressings and panels tailored to the unique specifications of each project. Buyers should provide detailed design documents, including CAD files and specifications for finishes and dimensions, to facilitate the customization process. Regular communication during the design and production phases can help ensure alignment and address any potential issues early on. Additionally, leveraging the supplier’s design expertise can enhance the final product, ensuring that it meets both aesthetic and functional requirements.

Strategic Material Selection Guide for met fab solutions

What Are the Key Properties of Common Materials Used in Met Fab Solutions?

In the realm of metal fabrication, particularly for products like aluminium panels and pressings, the selection of materials is crucial. This guide will analyze four common materials—aluminium, stainless steel, carbon steel, and brass—focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminium Perform in Metal Fabrication Applications?

Aluminium is renowned for its lightweight and corrosion-resistant properties, making it an ideal choice for architectural applications. It typically has a temperature rating of up to 600°C and excellent resistance to atmospheric corrosion. The advantages of aluminium include its durability, ease of fabrication, and aesthetic appeal, especially when powder-coated. However, it can be more expensive than other metals and may not be suitable for high-stress applications due to its lower tensile strength compared to steel.

For international buyers, especially in regions like Africa and the Middle East, compliance with standards such as ASTM B241 and EN 573 is essential. The availability of aluminium in various forms, such as extrusions and sheets, makes it adaptable for different project needs.

What Are the Benefits and Limitations of Stainless Steel?

Stainless steel offers superior corrosion resistance and strength, making it suitable for a variety of industrial applications. With a temperature rating that can exceed 800°C, it is ideal for environments that experience high temperatures and corrosive elements. The primary advantages include its longevity and low maintenance requirements. However, stainless steel can be more challenging to fabricate and is generally more expensive than aluminium.

For B2B buyers in Europe and South America, understanding the different grades of stainless steel (like 304 and 316) is vital, as they have varying corrosion resistance and strength properties. Compliance with standards such as ASTM A240 and EN 10088 is also crucial for ensuring product quality.

Why Choose Carbon Steel for Metal Fabrication Projects?

Carbon steel is widely used due to its high strength and versatility. It typically has a temperature rating of up to 500°C and is suitable for a variety of structural applications. The advantages of carbon steel include its cost-effectiveness and ease of fabrication. However, it is susceptible to corrosion, which may require additional surface treatments like galvanization.

International buyers, particularly in regions with high humidity or saline environments, should consider the need for protective coatings to enhance durability. Compliance with standards such as ASTM A36 and EN 10025 is essential for ensuring that the material meets local regulations.

What Role Does Brass Play in Metal Fabrication?

Brass is known for its excellent machinability and corrosion resistance, especially in marine environments. It has a temperature rating of around 300°C and is often used for fittings and decorative applications. The key advantages of brass include its aesthetic appeal and resistance to tarnishing. However, it is generally more expensive than carbon steel and may not be suitable for high-load applications.

For international buyers, particularly in the Middle East, understanding the specific grades of brass (like C36000) is essential, as they have different mechanical properties. Compliance with standards such as ASTM B16 and EN 12164 is crucial for ensuring quality and compatibility.

Summary Table of Material Selection for Met Fab Solutions

| Material | Typical Use Case for met fab solutions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminium | Architectural cladding, panels | Lightweight, corrosion-resistant | Higher cost, lower tensile strength | Medium |

| Stainless Steel | Industrial equipment, structural parts | High strength, excellent corrosion resistance | More challenging to fabricate, expensive | High |

| Carbon Steel | Structural beams, frames | Cost-effective, high strength | Susceptible to corrosion | Low |

| Brass | Decorative fittings, marine applications | Excellent machinability, corrosion-resistant | Generally more expensive, not for high-load | Medium |

This strategic material selection guide equips international B2B buyers with the insights needed to make informed decisions regarding material choices in metal fabrication projects. Understanding the properties, advantages, and limitations of these materials is essential for optimizing performance and ensuring compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for met fab solutions

What Are the Key Stages in the Manufacturing Processes of Met Fab Solutions?

Met Fab Solutions employs a comprehensive manufacturing process that ensures high-quality aluminium products tailored to meet the needs of various industries. The main stages of this process include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves sourcing high-grade aluminium sheets and other materials. The company emphasizes the use of environmentally friendly materials, aligning with global sustainability trends. Materials are inspected for quality upon arrival (Incoming Quality Control – IQC) to ensure they meet specified standards before proceeding to fabrication.

-

Forming: This stage utilizes state-of-the-art machinery for cutting, bending, and welding. Advanced CNC (Computer Numerical Control) technology ensures precision in forming the aluminium into desired shapes and sizes. Techniques such as laser cutting and punching are employed to achieve complex designs with high accuracy, which is crucial for architectural applications.

-

Assembly: Once the components are formed, they are assembled according to project specifications. This may include the integration of additional elements like brackets and accessories. The assembly process is closely monitored to maintain quality, with In-Process Quality Control (IPQC) checkpoints ensuring that every component meets the required standards before moving to the next stage.

-

Finishing: The final stage involves surface treatment, primarily through powder coating. This process not only enhances the aesthetic appeal but also provides durable protection against environmental factors. Met Fab Solutions is one of the few manufacturers that offer in-house powder coating, which allows for tighter quality control and quicker turnaround times. Each product is subjected to Final Quality Control (FQC) checks to verify that it meets all specifications before dispatch.

How Does Met Fab Solutions Ensure Quality Assurance in Manufacturing?

Quality assurance is integral to Met Fab Solutions’ operations, with adherence to internationally recognized standards and rigorous internal protocols.

-

International Standards Compliance: Met Fab Solutions is committed to maintaining compliance with ISO 9001, a globally recognized standard for quality management systems. This certification underscores the company’s dedication to continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE mark and API standards ensure that products meet the necessary safety and performance criteria.

-

Quality Checkpoints: Throughout the manufacturing process, several quality checkpoints are implemented:

– Incoming Quality Control (IQC): Verification of materials upon receipt to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the fabrication process to catch any deviations early.

– Final Quality Control (FQC): Comprehensive inspections of finished products before shipment, ensuring they meet the promised quality standards. -

Testing Methods: Common testing methods include dimensional checks, surface finish assessments, and performance testing of finished products. These tests help identify any defects that could affect the product’s functionality or appearance.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with local regulations.

-

Conducting Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, quality control systems, and overall operational capabilities firsthand. An audit can reveal much about a supplier’s commitment to quality and adherence to standards.

-

Requesting Quality Reports: Suppliers should be willing to provide quality assurance documentation, including inspection reports, test results, and certifications. These documents serve as evidence of compliance with international standards and the effectiveness of their quality control measures.

-

Engaging Third-party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of production, offering buyers peace of mind regarding the quality of the products they are sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances can be complex for international buyers. Here are key considerations:

-

Understanding Local Standards: Different regions may have specific regulatory requirements. Buyers should familiarize themselves with the local standards in their target markets, ensuring that the products meet these requirements.

-

Cultural Differences in Business Practices: Cultural attitudes towards quality assurance can vary significantly. Buyers from regions with stringent quality expectations may need to communicate these standards clearly to suppliers in regions where practices may differ.

-

Supply Chain Transparency: Buyers should seek suppliers that offer transparency in their supply chains. Understanding where materials are sourced and how products are manufactured can help mitigate risks associated with quality issues.

-

Building Long-term Relationships: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations. Long-term partnerships often result in a greater commitment to meeting quality standards and addressing any issues proactively.

Conclusion

For B2B buyers, understanding the manufacturing processes and quality assurance measures at Met Fab Solutions is crucial for making informed purchasing decisions. By focusing on the detailed stages of production, adherence to international standards, and the ability to verify quality control practices, buyers can ensure that they receive high-quality aluminium products that meet their specific needs. Engaging with suppliers who prioritize quality assurance not only enhances product reliability but also builds a foundation for successful business relationships across global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘met fab solutions’

To assist B2B buyers in successfully sourcing metal fabrication solutions, this guide provides a structured checklist. Each step aims to streamline the procurement process and ensure that you partner with a reliable supplier capable of meeting your project specifications.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements of your project. This includes dimensions, material types, tolerances, and finishes. Precise specifications help suppliers understand your needs and prevent costly miscommunications during production.

- Identify material requirements: Specify whether you need aluminum, stainless steel, or other materials.

- Consider environmental factors: Mention any fire ratings or sustainability standards that must be met.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in metal fabrication solutions relevant to your industry. Look for companies with a strong reputation and proven track records.

- Use industry-specific directories: These can lead you to experienced suppliers.

- Check online reviews and testimonials: They provide insights into customer satisfaction and product quality.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications and quality assurance processes of potential suppliers. This is crucial for ensuring compliance with industry standards.

- Look for ISO certifications: Such as ISO 9001, which indicates a commitment to quality management.

- Check for specific industry certifications: Relevant to your project, such as Qualicoat for powder coating.

Step 4: Request Samples and Prototypes

Ask suppliers for samples or prototypes of their work. This step allows you to assess the quality of materials, finishes, and craftsmanship firsthand before making a larger commitment.

- Evaluate the samples: Check for adherence to your specifications.

- Test durability and functionality: Ensure that the samples meet your project’s operational requirements.

Step 5: Inquire About Production Capabilities

Discuss the supplier’s production capabilities, including their technology and equipment. Understanding their capacity will help you gauge whether they can meet your project timelines and volume needs.

- Ask about lead times: Determine how quickly they can deliver based on your schedule.

- Assess their ability to handle large orders: Ensure they can scale production if necessary.

Step 6: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Ensure that the supplier has a dedicated team for your project and that you have direct access to them.

- Set up regular check-ins: This helps track progress and address any issues promptly.

- Utilize project management tools: These can facilitate smoother communication and updates.

Step 7: Negotiate Terms and Conditions

Finally, discuss pricing, payment terms, and delivery conditions. Clear agreements on these aspects can prevent misunderstandings later on.

- Review pricing structures: Ensure they are competitive and transparent.

- Agree on delivery schedules: Establish penalties for late deliveries to protect your interests.

By following this checklist, B2B buyers can enhance their sourcing process for metal fabrication solutions, ensuring they select a supplier that aligns with their project needs and standards.

Comprehensive Cost and Pricing Analysis for met fab solutions Sourcing

What Are the Key Cost Components in Sourcing from Met-Fab Solutions?

When considering sourcing from Met-Fab Solutions, it is essential to understand the various cost components involved. These generally include:

-

Materials: The choice of materials, particularly aluminium, significantly impacts pricing. High-quality, certified materials may command higher prices but result in superior end products.

-

Labor: Labor costs can vary based on location and the expertise required for specialized tasks such as welding or custom fabrication. Met-Fab Solutions benefits from competitive labor rates in regions like the UK and Serbia, allowing for cost-effective manufacturing.

-

Manufacturing Overhead: This encompasses expenses related to running the manufacturing facility, including utilities, equipment maintenance, and administrative costs. Efficient operations and in-house production reduce overhead, enabling competitive pricing.

-

Tooling: The cost of tooling can be substantial, especially for custom projects. Buyers should consider whether the tooling costs are included in the quoted price or if they will incur additional expenses.

-

Quality Control (QC): Met-Fab Solutions emphasizes quality assurance, which can add to the overall cost but ensures reliability and compliance with international standards.

-

Logistics: Shipping costs can fluctuate based on distance, shipping methods, and Incoterms. Understanding these factors is vital for calculating the total cost.

-

Margin: This is the profit margin added by Met-Fab Solutions. While competitive, margins will vary depending on the complexity of the order and the level of customization required.

How Do Pricing Influencers Affect Your Purchase Decision?

Several factors influence pricing, which international buyers must consider:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger volumes often leads to better pricing per unit. Understanding Met-Fab’s MOQ policy can help buyers optimize their orders for cost savings.

-

Specifications and Customization: Custom projects may incur additional costs. Clear communication regarding specifications can help avoid unexpected expenses.

-

Materials and Quality Certifications: Products that meet high-quality standards or certifications (such as Qualicoat) may have higher upfront costs but offer long-term value through durability and lower maintenance needs.

-

Supplier Factors: The reputation and reliability of Met-Fab Solutions can influence pricing. Established suppliers with a track record of quality may command a premium.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Buyers should clarify these terms to understand their total financial commitment.

What Buyer Tips Can Help You Negotiate Better Prices?

To ensure a favorable sourcing experience, consider the following tips:

-

Negotiate Terms: Engage in discussions regarding pricing, payment terms, and delivery schedules. Don’t hesitate to ask for discounts on larger orders or repeat business.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial pricing and assess the long-term costs associated with maintenance, repairs, and potential product lifespan.

-

Research Market Rates: Familiarize yourself with market prices for similar products. This knowledge can empower you during negotiations and help you identify fair pricing.

-

Understand Pricing Nuances for International Buyers: Different regions may have unique pricing structures due to factors like labor costs, material availability, and shipping logistics. Tailor your approach based on your geographic market.

-

Request Detailed Quotes: Ask for itemized quotes that break down costs into components. This transparency can help you identify areas for potential savings.

Disclaimer Regarding Indicative Prices

It is important to note that prices can vary widely based on project specifications, market conditions, and other dynamic factors. Always request updated quotes from Met-Fab Solutions to ensure accurate pricing for your specific needs.

Alternatives Analysis: Comparing met fab solutions With Other Solutions

Understanding Alternatives in Metal Fabrication Solutions

In the competitive landscape of metal fabrication, businesses often seek alternatives to optimize their production processes, cost-efficiency, and product quality. With a variety of solutions available, it is essential for international B2B buyers to understand how different options stack up against each other. This analysis focuses on comparing Met Fab Solutions with two notable alternatives in the market: traditional metal fabrication services and automated robotic fabrication systems.

Comparison Table

| Comparison Aspect | ‘Met Fab Solutions’ | Traditional Metal Fabrication Services | Automated Robotic Fabrication Systems |

|---|---|---|---|

| Performance | High-quality, bespoke production with rapid turnaround | Moderate quality; turnaround varies widely | High precision and consistency |

| Cost | Competitive pricing with guaranteed quality | Generally lower initial costs, but variable | Higher initial investment, but lower long-term costs |

| Ease of Implementation | Streamlined process with in-house capabilities | Requires coordination between multiple suppliers | Requires specialized training for operation |

| Maintenance | Minimal due to in-house quality controls | Regular maintenance required; quality varies | High maintenance costs but consistent output |

| Best Use Case | Custom architectural projects, quick delivery | General construction and repair | High-volume production with uniform requirements |

Detailed Breakdown of Alternatives

Traditional Metal Fabrication Services

Traditional metal fabrication services often provide a wide array of options for businesses looking for general metal work. These services can be cost-effective, particularly for projects that do not require high customization. However, they may involve delays due to the need for sourcing materials from multiple suppliers, which can affect turnaround times and overall product quality. While these services are suitable for straightforward projects, they may not meet the stringent demands of architectural and bespoke fabrication that require precision and rapid delivery.

Automated Robotic Fabrication Systems

Automated robotic fabrication systems represent a cutting-edge approach to metal fabrication, offering high levels of precision and consistency. These systems are ideal for large-scale production where uniformity is critical, such as in automotive or aerospace manufacturing. However, they come with a higher initial investment and the need for specialized training for staff to operate the machinery. Maintenance can also be costly, and any downtime can significantly impact production schedules. While they excel in large volume outputs, they may not be suitable for smaller, customized projects where flexibility is necessary.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a metal fabrication solution, B2B buyers must carefully consider their specific project requirements, budget constraints, and the desired quality of the final product. Met Fab Solutions stands out for its high-quality, bespoke offerings with rapid turnaround times, making it an excellent choice for architectural projects. In contrast, traditional services may be more appropriate for less complex needs, while automated systems cater to high-volume production. By evaluating these aspects, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for met fab solutions

What Are the Key Technical Properties in Metal Fabrication Solutions?

In the context of metal fabrication, understanding critical technical properties is vital for ensuring product quality and performance. Here are several essential specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the classification of materials based on their mechanical and chemical properties. For instance, aluminum grades such as 6061 and 5052 have distinct strengths, corrosion resistance, and weldability. Selecting the appropriate material grade impacts durability and functionality, particularly in demanding environments like construction and industrial applications.

2. Tolerance

Tolerance indicates the permissible limit or limits of variation in a physical dimension. It is crucial in metal fabrication, as precise tolerances ensure that components fit together correctly and function as intended. Inaccurate tolerances can lead to costly reworks and project delays, making it essential for buyers to specify their tolerance requirements upfront.

3. Surface Finish

The surface finish of fabricated metal products affects both aesthetics and functionality. For example, powder coating provides a durable, weather-resistant finish, while anodizing enhances corrosion resistance. Understanding the desired surface finish is critical for meeting client specifications and ensuring long-lasting performance, especially in architectural applications.

4. Weight and Load-Bearing Capacity

Weight specifications and load-bearing capacities are vital for structural integrity in construction projects. Buyers must understand the weight of the materials being used and their ability to support intended loads. This is particularly important in industries like construction and automotive manufacturing, where safety and compliance with regulations are paramount.

5. Insulation Properties

In projects involving aluminum panels, insulation properties such as thermal resistance and sound insulation become significant. These properties impact energy efficiency and comfort in buildings. Buyers should evaluate insulation specifications to ensure that products meet environmental standards and client expectations.

What Common Trade Terms Should B2B Buyers Be Aware Of?

Familiarity with industry jargon can enhance communication and negotiation in B2B transactions. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In metal fabrication, understanding whether a supplier is an OEM can influence pricing and customization options. Buyers should consider OEM relationships when seeking specialized products or services.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly important in metal fabrication, where production setups may require significant investment. Knowing the MOQ helps buyers budget effectively and plan for inventory levels, especially in large-scale projects.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. It typically includes detailed specifications and quantities. Buyers should prepare RFQs meticulously to ensure they receive accurate quotes, facilitating better comparison and decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers engaged in cross-border trade, as they clarify shipping responsibilities, risk management, and cost allocation.

5. CAD (Computer-Aided Design)

CAD refers to the use of computer software to facilitate the creation, modification, analysis, or optimization of a design. In metal fabrication, CAD files are essential for precision manufacturing and prototyping. Buyers should ensure that their suppliers are capable of working with CAD files to streamline the design and fabrication process.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of metal fabrication more effectively, ensuring that they make informed decisions that align with their project requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the met fab solutions Sector

What Are the Current Market Dynamics and Key Trends in the Met Fab Solutions Sector?

The global metal fabrication industry is witnessing significant transformations, driven by various factors such as technological advancements, increasing demand for customized solutions, and a growing emphasis on sustainability. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focused on suppliers who can deliver high-quality, tailored products efficiently. The rise of automation and smart manufacturing technologies, such as CNC machining and laser cutting, is streamlining operations and reducing lead times, enabling suppliers to meet specific client requirements more effectively.

Emerging trends include the integration of Industry 4.0 principles, where data analytics and IoT technologies are utilized to enhance operational efficiency and product quality. Additionally, the demand for lightweight materials, particularly aluminum, is on the rise due to its advantages in energy efficiency and cost-effectiveness. International buyers are also prioritizing suppliers that can provide rapid prototyping and just-in-time production, which are essential for maintaining competitive advantages in fast-paced markets.

Moreover, geopolitical factors and supply chain disruptions have made sourcing strategies more critical than ever. Buyers are seeking reliable partners who can ensure consistent quality and timely delivery, thus favoring manufacturers with in-house capabilities and proven track records. In summary, understanding these market dynamics and sourcing trends is crucial for international B2B buyers to make informed decisions in the met fab solutions sector.

How Is Sustainability and Ethical Sourcing Shaping the Met Fab Solutions Sector?

Sustainability has become a pivotal concern for B2B buyers in the metal fabrication sector. The environmental impact of manufacturing processes, particularly in terms of waste generation and energy consumption, is under scrutiny. As a result, companies are increasingly adopting sustainable practices, such as using recycled materials and implementing energy-efficient technologies, to minimize their ecological footprint. Suppliers who can demonstrate their commitment to sustainability are more likely to attract buyers who prioritize environmentally responsible sourcing.

Ethical supply chains are equally important, as buyers seek transparency and accountability in their sourcing decisions. This shift is prompting suppliers to obtain green certifications and adhere to standards that ensure responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and Qualicoat for powder coating quality are becoming essential credentials for manufacturers aiming to appeal to international markets.

In addition, the trend towards circular economy practices is gaining traction, with companies exploring ways to recycle and repurpose materials throughout the production cycle. By adopting these sustainable and ethical sourcing strategies, businesses not only contribute to environmental preservation but also enhance their brand reputation, which is increasingly valued by consumers and stakeholders alike.

What Is the Historical Context of the Met Fab Solutions Sector?

The met fab solutions sector has evolved significantly over the past few decades, transitioning from traditional manual fabrication techniques to advanced automated processes. Initially dominated by small-scale workshops, the industry has seen a consolidation of capabilities, with larger manufacturers investing in state-of-the-art technology to meet growing demands for precision and efficiency.

The introduction of computer-aided design (CAD) and computer numerical control (CNC) machining in the late 20th century marked a turning point, allowing for higher accuracy and the ability to produce complex components at scale. Furthermore, the globalization of supply chains has facilitated access to diverse materials and technologies, enabling manufacturers to enhance their offerings.

As the industry moves into the 21st century, the focus has shifted towards sustainability and ethical practices, reflecting broader societal trends and consumer expectations. This evolution underscores the importance of adaptability in the met fab solutions sector, as businesses must continuously innovate to remain competitive in an increasingly complex marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of met fab solutions

-

How do I ensure the quality of met fab solutions products?

To ensure the quality of products from Met Fab Solutions, it is essential to verify their certifications and quality management systems. Look for ISO 9001 certification, which indicates adherence to international quality standards. Additionally, request samples or conduct a factory visit to assess the manufacturing processes and quality control measures in place. Establishing clear quality expectations in your contract will also help maintain the desired standards throughout the production and delivery phases. -

What customization options are available for aluminium panels and pressings?

Met Fab Solutions offers extensive customization options for aluminium panels and pressings, allowing you to tailor products to your specific project requirements. You can specify dimensions, finishes, and other design elements. It’s advisable to communicate your exact needs during the initial discussions, including any architectural specifications or aesthetic preferences. Collaborating closely with the design team can lead to optimal results that meet your functional and visual criteria. -

What is the minimum order quantity (MOQ) for aluminium pressings?

The minimum order quantity (MOQ) for aluminium pressings can vary based on the specific product and complexity of the design. Typically, Met Fab Solutions is flexible with MOQs, accommodating both small and large orders. It is best to discuss your project’s scale with their sales team, who can provide guidance on the MOQ that would be most suitable for your needs while ensuring cost-effectiveness. -

What payment terms can I expect when ordering from Met Fab Solutions?

Payment terms for orders from Met Fab Solutions will generally depend on the size of the order and your relationship with the supplier. Common arrangements include a deposit upfront, followed by the balance due upon delivery or net payment terms (e.g., 30 or 60 days). It’s crucial to clarify these terms during negotiations to ensure smooth transactions and avoid any misunderstandings. -

How does Met Fab Solutions handle international shipping and logistics?

Met Fab Solutions has experience in managing international shipping logistics, ensuring that products reach their destinations efficiently. They typically work with reliable freight forwarders to handle customs clearance and transportation. As a buyer, you should confirm shipping options, estimated delivery times, and associated costs during the order process. Providing accurate shipping details can help facilitate a seamless delivery experience. -

What should I consider when vetting suppliers for met fab solutions?

When vetting suppliers for met fab solutions, consider their industry experience, certifications, and reputation in the market. Look for customer testimonials and case studies that highlight their capabilities and reliability. Additionally, assess their manufacturing processes, lead times, and after-sales support. Engaging in direct communication can also reveal their responsiveness and willingness to address your concerns, which is vital for long-term partnerships. -

How can I stay informed about the latest trends in metal fabrication?

To stay informed about the latest trends in metal fabrication, subscribe to industry publications, join relevant trade associations, and participate in webinars or conferences. Following leading manufacturers like Met Fab Solutions on social media can provide insights into new products and innovations. Networking with industry professionals can also facilitate knowledge sharing and keep you updated on market developments and emerging technologies. -

What are the environmental considerations of working with Met Fab Solutions?

Met Fab Solutions emphasizes environmentally friendly practices, including energy-efficient manufacturing processes and the use of recyclable materials. They adhere to regulations regarding waste management and emissions, contributing to sustainable building practices. As a buyer, inquire about their specific sustainability initiatives, such as certifications related to environmental management (e.g., ISO 14001), to align your procurement strategies with your environmental goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Met Fab Solutions Manufacturers & Suppliers List

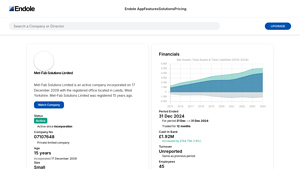

1. Met-Fab Solutions – Aluminium Panels and Pressings

Domain: met-fab.co.uk

Registered: 2010 (15 years)

Introduction: Met-Fab Solutions specializes in the manufacture of aluminium panels, aluminium pressings, and brackets for the aluminium curtain walling industry. Key product details include:

– Complete in-house panel production with no outsourcing, ensuring high quality and timely delivery.

– Aluminium pressings and panels made to order for new build and refurbishment projects.

– Capabilities include in-hous…

2. Company Information – Fabricated Metal Products

Domain: find-and-update.company-information.service.gov.uk

Introduction: Manufacture of other fabricated metal products not elsewhere classified

3. LinkedIn – Dedicated API

Domain: uk.linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

4. Linde Gas – Metal Fabrication Solutions

Domain: lindedirect.com

Registered: 2020 (5 years)

Introduction: Metal Fabrication Solutions offered by Linde Gas & Equipment Inc. include a wide range of products categorized into several sections: Gases (Oxygen, Nitrogen, Argon, Helium, etc.), Welding Wire & Electrodes (TIG, MIG, Stick, Flux-Cored, etc.), Welding & Cutting Equipment (Oxy Acetylene, Plasma Cutting, Multi-Process Welding, etc.), Abrasives (Grinding, Cutting, Sanding, etc.), Safety & PPE (Protec…

5. Met-Fab Solutions – Architectural Aluminium Fabrications

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Met-Fab Solutions – Architectural Aluminium Fabrications, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Met-Fab – Aluminium Fabrication Solutions

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: This company, Met-Fab – Aluminium Fabrication Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. MetFab Solutions – Precision Metal Fabrication Services

Domain: metfab.rs

Registered: 2018 (7 years)

Introduction: MetFab Solutions offers a variety of services including Laser Cutting, Sheet Metal Punching, Waterjet Cutting, Sheet Metal Folding, Mig & Tig Welding, Tube Bending, and CNC Machined & Milled Parts. They provide surface treatments such as Powder Coating, Wet Painting, Zinc Plating, and Hot Dip Galvanising. The company focuses on custom solutions tailored to unique project needs, emphasizing lean ma…

8. Met-Fab Solutions – Manufacturing Excellence

Domain: open.endole.co.uk

Registered: 2014 (11 years)

Introduction: This company, Met-Fab Solutions – Manufacturing Excellence, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for met fab solutions

In the evolving landscape of metal fabrication, strategic sourcing has emerged as a critical component for international B2B buyers seeking high-quality solutions. Met-Fab Solutions stands out for its comprehensive in-house capabilities, which enable rapid production and precise customization of aluminium panels and pressings. With over 30 years of industry expertise, their commitment to quality and efficiency ensures that buyers receive not only superior products but also reliable service that meets tight deadlines.

Investing in strategic sourcing with Met-Fab Solutions allows businesses across Africa, South America, the Middle East, and Europe to leverage competitive pricing, reduced lead times, and high-quality standards backed by internationally recognized certifications. This positions them favorably in a market that increasingly prioritizes sustainability and innovation.

As you consider your sourcing strategies, remember that aligning with a trusted partner like Met-Fab Solutions can significantly enhance your operational efficiency and product offerings. The future of metal fabrication holds exciting opportunities; seize them by reaching out to Met-Fab Solutions today to explore how they can meet your unique project needs.