Contents

Manufacturing Insight: Melting Temp Of Steel

Understanding Steel Thermal Properties in Precision CNC Machining

While the melting temperature of steel (typically 1370°C–1510°C depending on alloy composition) is a fundamental material property, it is rarely a direct concern in CNC machining operations where temperatures remain significantly lower. However, the thermal behavior of steel—including its thermal conductivity, expansion coefficient, and resistance to localized heat buildup—critically impacts machining precision, tool life, and final part integrity. At Honyo Prototype, our engineering team leverages deep material science expertise to optimize CNC machining parameters for diverse steel grades, from low-carbon 1018 to tool steels like D2 or stainless variants such as 304 and 17-4 PH. We meticulously control cutting speeds, coolant strategies, and toolpath geometries to mitigate thermal deformation, ensuring tight tolerances (±0.005mm achievable) and superior surface finishes even in complex geometries.

This precision-driven approach eliminates costly rework and accelerates time-to-market for mission-critical components in aerospace, medical, and industrial applications. When material properties intersect with machining dynamics, Honyo’s process-specific knowledge becomes your competitive advantage. Ready to transform your steel component designs into high-accuracy prototypes or production runs?

Access Honyo’s Online Instant Quote System

Submit your STEP/IGS file and technical requirements today for a detailed manufacturability assessment and competitive pricing within hours—not days. Our platform integrates material-specific machining intelligence to deliver accurate quotes reflective of real-world production constraints.

| Service Feature | Benefit for Steel Machining |

|---|---|

| Material-Optimized Toolpaths | Minimizes heat-induced warpage in thin-walled steel parts |

| In-Process Metrology | Validates dimensional stability despite thermal cycling |

| Alloy-Specific Coolant Systems | Extends tool life for abrasive stainless/tool steels |

Technical Capabilities

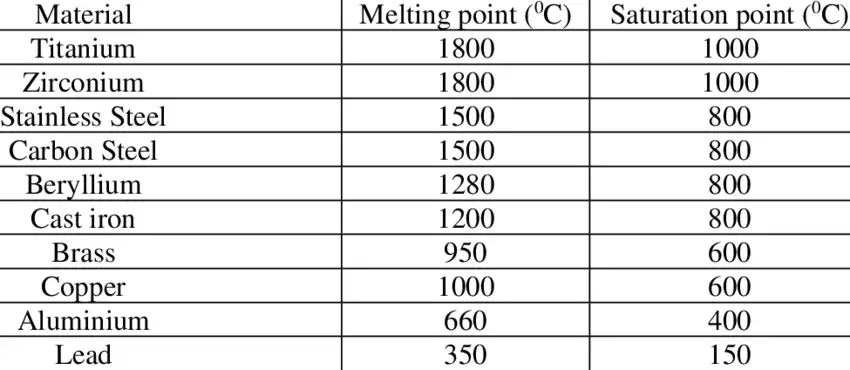

The melting temperature of a material is a fundamental thermal property that influences machining parameters such as cutting speed, tool selection, coolant requirements, and thermal management during precision manufacturing processes like 3/4/5-axis milling and turning. While melting temperature itself does not directly define machinability, it correlates with thermal conductivity, hardness at elevated temperatures, and tool wear behavior—critical factors when holding tight tolerances (±0.0005″ or tighter).

Below is a comparison of key engineering materials commonly machined at Honyo Prototype, with emphasis on their melting temperatures and relevance to high-precision CNC operations.

| Material | Melting Temperature (°C) | Melting Temperature (°F) | Typical Use in 3/4/5-Axis Machining | Considerations for Tight Tolerance Machining |

|---|---|---|---|---|

| Aluminum (e.g., 6061-T6) | 582–652 | 1080–1205 | High-speed milling and complex 5-axis contours; lightweight structural components | Low melting point and high thermal conductivity require controlled cutting speeds and effective chip evacuation to prevent built-up edge and thermal deformation |

| Steel (e.g., 4140, 1045) | 1370–1510 | 2500–2750 | Precision turning and multi-axis milling for durable tooling, shafts, and fixtures | High melting point allows for aggressive machining but generates significant heat; carbide tools and high-pressure coolant recommended for maintaining dimensional stability |

| ABS (Acrylonitrile Butadiene Styrene) | 105 (softens) | 221 (softens) | Prototyping and low-stress functional parts via precision CNC | Low thermal resistance; minimal cutting forces required; tooling must avoid friction-induced melting; fixturing critical due to thermal expansion |

| Nylon (Polyamide, e.g., PA6) | 215–225 | 420–440 | Precision-machined components for wear and chemical resistance | Tends to absorb moisture; pre-drying recommended; machined slightly above room temperature to avoid brittle fracture and maintain tight tolerances |

Notes on Machining Strategy:

For tight tolerance work in steel and aluminum, thermal management is critical due to the heat generated during high-speed 3/4/5-axis milling. Although steel has a significantly higher melting temperature than aluminum, its lower thermal conductivity means heat concentrates at the cutting edge, accelerating tool wear and risking workpiece distortion. In contrast, aluminum’s high thermal conductivity spreads heat quickly but can lead to rapid tool adhesion without proper coatings (e.g., TiAlN) and lubrication.

In non-metallic materials like ABS and Nylon, the softening or melting point is close to ambient machining temperatures, so sharp tools, low RPM, and high feed rates are used to minimize dwell and friction. These materials are typically machined dry or with air blast cooling to avoid moisture-related issues.

Successful tight tolerance production across these materials depends on material-specific toolpaths, thermal compensation in CNC programs, and rigorous in-process inspection using CMM or laser probing.

From CAD to Part: The Process

Honyo Prototype does not determine or process the melting temperature of steel as part of our standard manufacturing workflow. The melting point of steel is a fixed material property defined by its composition and established through metallurgical science, not a variable derived during prototyping. Our process focuses on leveraging known material properties to ensure manufacturability and quality. Below is an accurate explanation of where material specifications like melting temperature are applied within our workflow, followed by the correct sequence for steel-based prototyping.

Material properties such as melting temperature are referenced from authoritative sources (e.g., ASM Handbooks, ISO 4948 standards) during the Design for Manufacturability (DFM) phase. Engineers cross-verify client-specified materials against these benchmarks to confirm feasibility. For example, common steel grades have well-documented melting ranges:

| Steel Grade Category | Typical Melting Range (°C) | Primary Use Case at Honyo |

|---|---|---|

| Low-Carbon Steel (e.g., 1018) | 1425–1540 | Structural prototypes, fixtures |

| Stainless Steel 304 | 1400–1450 | Medical/aerospace components |

| Tool Steel (e.g., D2) | 1370–1425 | High-wear tooling prototypes |

The actual workflow for steel prototyping at Honyo follows this sequence:

Upload CAD

Clients submit CAD files specifying material requirements. Our system flags missing or ambiguous material callouts for clarification before proceeding. Critical parameters like grade (e.g., ASTM A36) must be defined; we do not infer thermal properties from geometry.

AI Quote

Our AI engine analyzes the CAD model against Honyo’s production capabilities. Material specifications provided by the client are validated against our material database. If melting point or thermal properties are relevant to the process (e.g., casting, welding), the system checks for consistency with industry standards. Quotes include material cost based on verified grade specifications.

DFM Analysis

Senior engineers conduct rigorous Design for Manufacturability review. For steel components, this includes:

Confirming material grade aligns with thermal requirements (e.g., ensuring 4140 steel is used for high-heat applications instead of low-carbon steel)

Validating that proposed processes (e.g., laser cutting, CNC machining) are compatible with the steel’s thermal behavior

Flagging designs where thermal expansion or heat treatment could cause distortion

Material properties are treated as inputs, not outputs, of this phase.

Production

Manufacturing executes using pre-qualified steel stock with certified material test reports (MTRs). For processes involving heat (e.g., welding, heat treating), parameters are set based on the steel’s documented thermal properties. In-process thermal monitoring ensures adherence to specifications, but melting temperature itself is never measured or altered.

Delivery

Final parts ship with full material traceability documentation, including MTRs verifying chemical composition and mechanical properties. Thermal characteristics are referenced from original material certifications, not derived during production.

Honyo’s value lies in applying established material science to prototype manufacturing, not redefining fundamental properties. We ensure your steel selection is optimal for both design intent and production realities through systematic verification against metallurgical standards. For thermal-critical applications, we recommend specifying exact steel grades during CAD submission to enable precise DFM analysis.

Start Your Project

For precise information regarding the melting temperature of steel and material-specific properties, contact Susan Leo at [email protected]. As a Senior Manufacturing Engineer at Honyo Prototype, I recommend consulting directly with our engineering team to ensure material suitability for your application.

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, capable of handling prototyping and production runs with strict thermal and mechanical specifications. Our Shenzhen factory supports advanced metallurgical processing and material testing, ensuring compliance with international standards.

For technical inquiries or to request material data sheets, reach out to Susan Leo via email. We provide detailed support for OEMs and design engineers working with carbon steels, stainless steels, and specialty alloys.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.