Contents

Manufacturing Insight: Melting Point Of Stainless Steel Fahrenheit

Understanding Stainless Steel Melting Points for Precision CNC Manufacturing

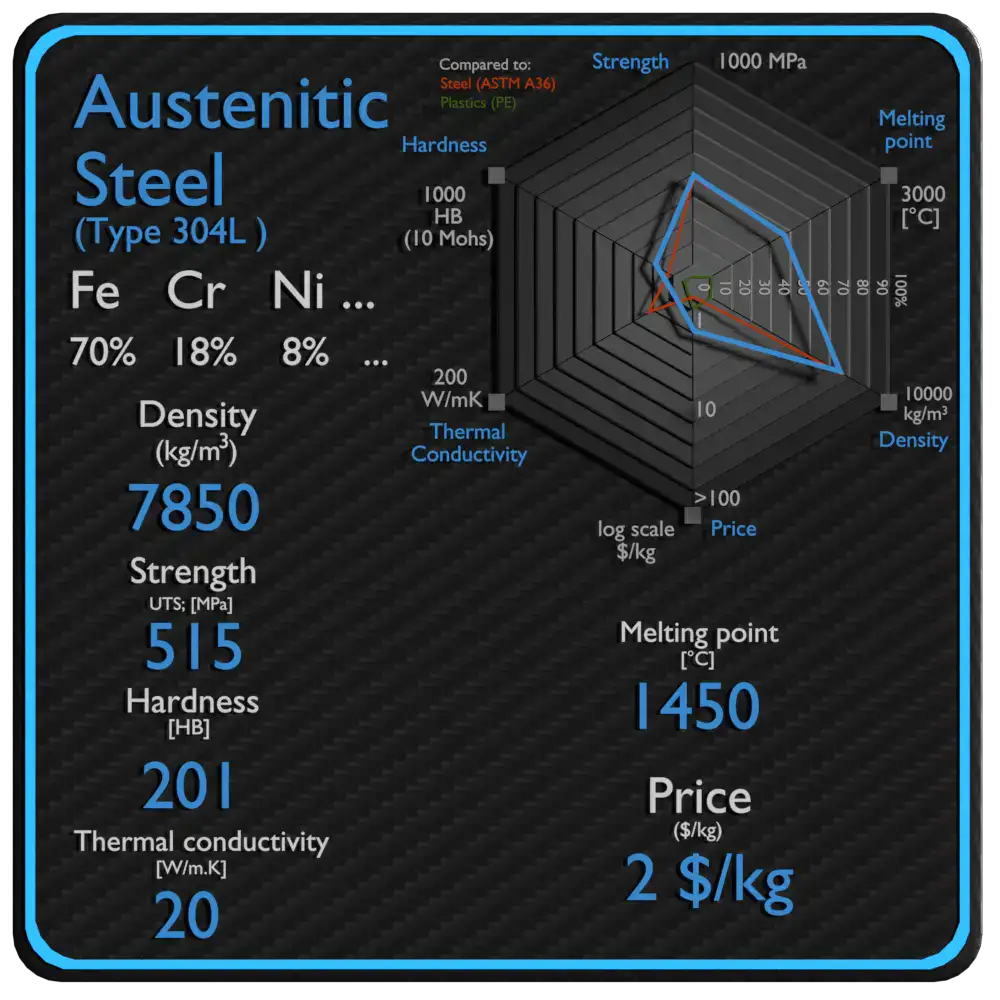

The melting point of stainless steel varies significantly by alloy composition, with common grades like 304 melting between 2550°F and 2650°F. This critical thermal property directly impacts CNC machining parameters, as excessive heat generation during cutting can approach material softening thresholds, risking dimensional inaccuracies, tool wear, and compromised part integrity. At Honyo Prototype, our engineering team leverages deep material science expertise to optimize CNC processes for stainless steel alloys, ensuring thermal management strategies maintain strict tolerances even under high-stress operations.

We recognize that material behavior under thermal load is non-negotiable in aerospace, medical, and energy applications where performance hinges on precision. Our CNC machining services integrate real-time thermal monitoring, specialized toolpath algorithms, and coolant protocols calibrated to stainless steel’s unique properties, delivering components that meet exacting industry standards.

For immediate project assessment, utilize Honyo’s Online Instant Quote system. Input your stainless steel part specifications—including grade, geometry, and tolerance requirements—to receive a detailed manufacturability analysis and competitive pricing within hours, backed by our engineering validation.

Key Stainless Steel Melting Ranges (Fahrenheit)

| Alloy Grade | Typical Melting Range (°F) | Common Applications |

|————-|—————————-|—————————|

| 304 | 2550–2650 | Food processing, aerospace|

| 316 | 2500–2650 | Marine, chemical systems |

| 17-4 PH | 2460–2550 | Medical implants, valves |

| 410 | 2500–2700 | Cutlery, fasteners |

Technical Capabilities

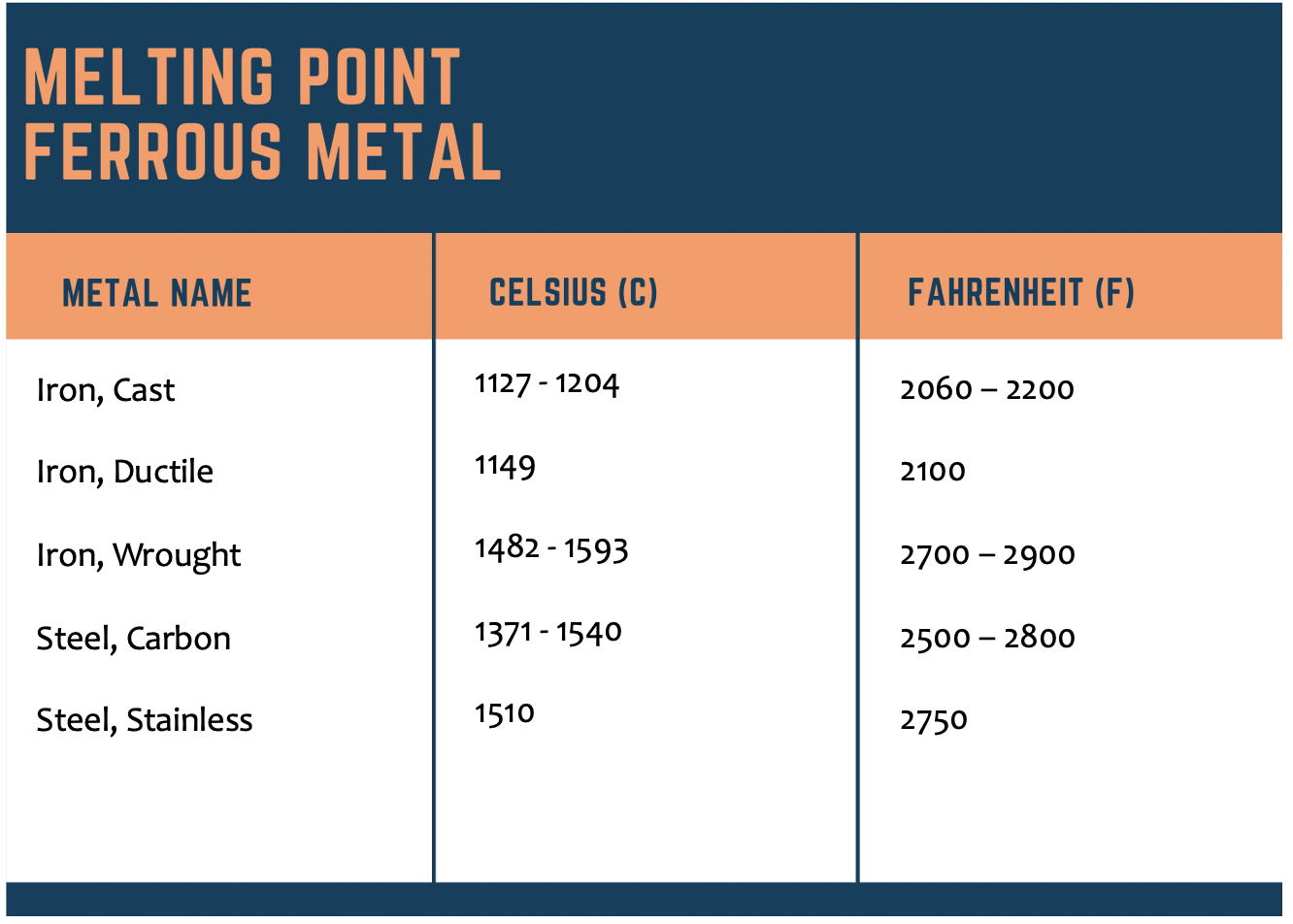

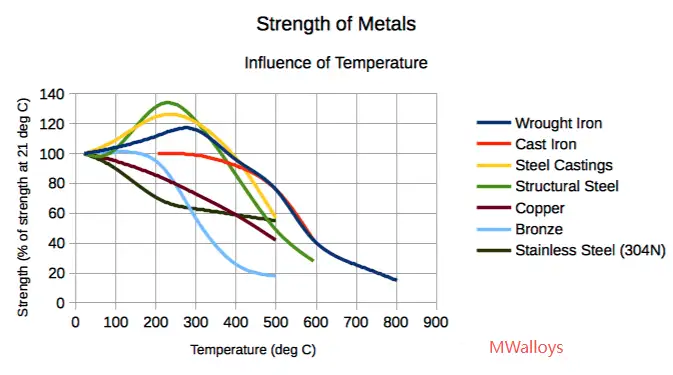

The melting point of stainless steel is a critical parameter in high-precision machining processes such as 3/4/5-axis milling and turning, especially when working with tight tolerances. While the melting point itself does not directly govern machining parameters, it influences thermal management, tool selection, and coolant strategies during operations. Stainless steel typically melts between 2,500°F and 2,750°F depending on the alloy composition. This high thermal resistance necessitates robust tooling and controlled machining environments to prevent heat buildup that can affect dimensional accuracy.

In multi-axis milling and turning applications requiring tight tolerances (±0.0005″ or better), thermal expansion due to frictional heat must be carefully managed. Materials such as aluminum, steel (including stainless), ABS, and nylon exhibit vastly different melting or softening behaviors, which influence machining strategies.

Below is a comparison of relevant thermal and material properties for common machining materials:

| Material | Melting Point (°F) | Typical Use in Precision Machining | Thermal Conductivity (BTU/hr·ft·°F) | Considerations for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|

| Stainless Steel | 2,500 – 2,750 | High-strength components, medical, aerospace | 16 – 18 (304 SS) | High work hardening rate; requires rigid setups, sharp tooling, and consistent coolant flow to manage heat. Tight tolerances demand thermal stability in environment and machine. |

| Carbon Steel | 2,500 – 2,800 | Industrial machinery, tooling | 25 – 30 | Easier to machine than stainless but still generates significant heat. Preheating not required, but thermal expansion must be monitored in precision work. |

| Aluminum (6061) | 1,200 – 1,220 | Aerospace, automotive, enclosures | 100 – 130 | Low melting point requires lower cutting temps. High thermal conductivity helps dissipate heat. Ideal for high-speed 5-axis milling with tight tolerances. Minimal thermal lag. |

| ABS | 1,650 – 2,210 (softens ~220°F) | Prototypes, housings, jigs | ~0.1 | Low heat resistance; prone to melting or deformation at low temperatures. Requires sharp tools, low RPM, and minimal pressure in turning/milling. Not suitable for high-temp environments. |

| Nylon (PA6) | 428 – 473 (melts) | Bearings, insulators, lightweight parts | ~0.15 | Begins to soften well below steel’s melting range. Sensitive to heat buildup during machining. Use cryogenic cooling or air blasting for tight tolerance work. |

Note: While stainless steel has a high melting point, the actual cutting zone temperature during milling or turning rarely exceeds 1,200°F with proper coolant use. However, in high-speed 5-axis operations, localized heat accumulation can approach levels that affect tool life and part integrity. For tight tolerance work, material stability, coefficient of thermal expansion, and machining-induced stresses are more critical than melting point alone.

At Honyo Prototype, we leverage this data to optimize tool paths, spindle speeds, and cooling strategies across materials, ensuring micron-level accuracy in complex geometries.

From CAD to Part: The Process

Honyo Prototype does not determine or alter the melting point of stainless steel as part of its manufacturing process, as this is an inherent material property defined by metallurgical composition. The melting point range for common stainless steel alloys is a fixed scientific parameter. Our process instead leverages this known data to ensure manufacturability and part integrity. Below is an accurate explanation of how thermal properties like melting point inform our standard workflow, with emphasis on material science integration:

Upload CAD

Upon receiving a CAD file, our system immediately cross-references the specified stainless steel grade (e.g., 304, 316, 410) against validated material databases. Critical thermal properties—including the alloy’s precise melting point range in Fahrenheit—are extracted for downstream analysis. This step prevents material misapplication; for instance, if a design requires high-temperature exposure near 2500°F, we flag 410 stainless (melting point 2500–2650°F) as unsuitable versus 304 (2550–2650°F).

AI Quote

The quotation engine incorporates melting point data to assess process feasibility. For example:

Laser cutting or welding operations must operate significantly below the melting threshold to avoid material degradation.

Casting or sintering parameters are pre-validated against the alloy’s thermal limits.

The AI checks whether requested tolerances or geometries could induce thermal stress failures during production, using melting point as a boundary condition in thermal simulations.

DFM (Design for Manufacturability)

This phase critically applies melting point knowledge:

Thermal distortion risks are modeled using finite element analysis (FEA), with melting point as the absolute failure threshold.

For welding/joining operations, we verify that localized heat input remains ≤70% of the melting point to prevent liquation cracking.

Machining parameters (e.g., coolant flow, RPM) are optimized to avoid heat buildup exceeding 50% of the melting point, which could alter microstructure.

DFM feedback explicitly references melting point constraints when suggesting design modifications for thermal stability.

Production

During fabrication, melting point data directly governs process controls:

| Process | Stainless Steel Grade | Melting Point (°F) | Production Constraint |

|---|---|---|---|

| TIG Welding | 304 | 2550–2650 | Interpass temp maintained < 300°F to prevent sensitization |

| Laser Cutting | 316 | 2540–2630 | Power settings calibrated to keep HAZ < 2200°F |

| Investment Casting | 17-4 PH | 2560–2625 | Mold preheat temp held at 1800°F max |

Real-time thermal monitoring ensures no process step approaches the melting threshold, with automated shutdowns triggered at 85% of the alloy’s melting point.

Delivery

All certified material test reports (MTRs) included with shipments validate the stainless steel grade’s compliance with ASTM/AMS standards, which reference melting point ranges. We provide thermal property documentation upon request, including:

Verified melting point for the specific heat lot used

Heat treatment records confirming no exposure beyond 50% of melting point during processing

Residual stress analysis tied to thermal limits

Honyo treats melting point as a non-negotiable design constraint—not a variable output. Our process ensures every prototype operates safely within thermal margins defined by the material’s fundamental properties, with all deliverables traceable to certified material science data. For alloy-specific melting points, consult our material selector tool or request a thermal properties addendum with your quote.

Start Your Project

The melting point of stainless steel typically ranges between 2,500°F and 2,750°F, depending on the specific alloy composition. This high thermal resistance makes stainless steel ideal for demanding applications in aerospace, automotive, and industrial manufacturing.

For precise material specifications or custom prototyping needs, contact Susan Leo at [email protected]. Honyo Prototype offers advanced manufacturing solutions with a fully operational factory located in Shenzhen, China, ensuring fast turnaround and strict quality control for your engineering projects.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.