Contents

Manufacturing Insight: Medical Sheet Metal Fabrication

Precision Medical Sheet Metal Fabrication: Engineered for Compliance and Critical Performance

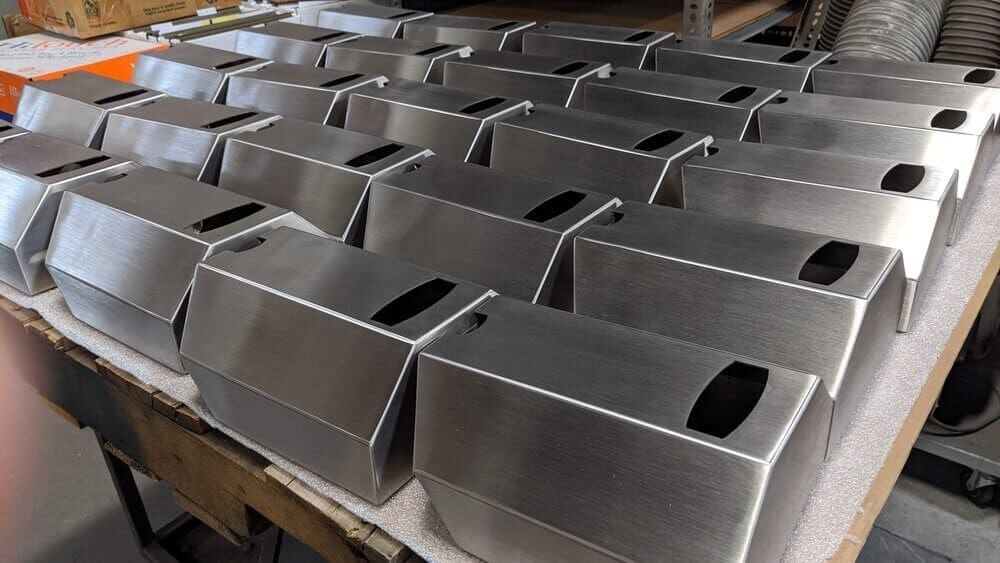

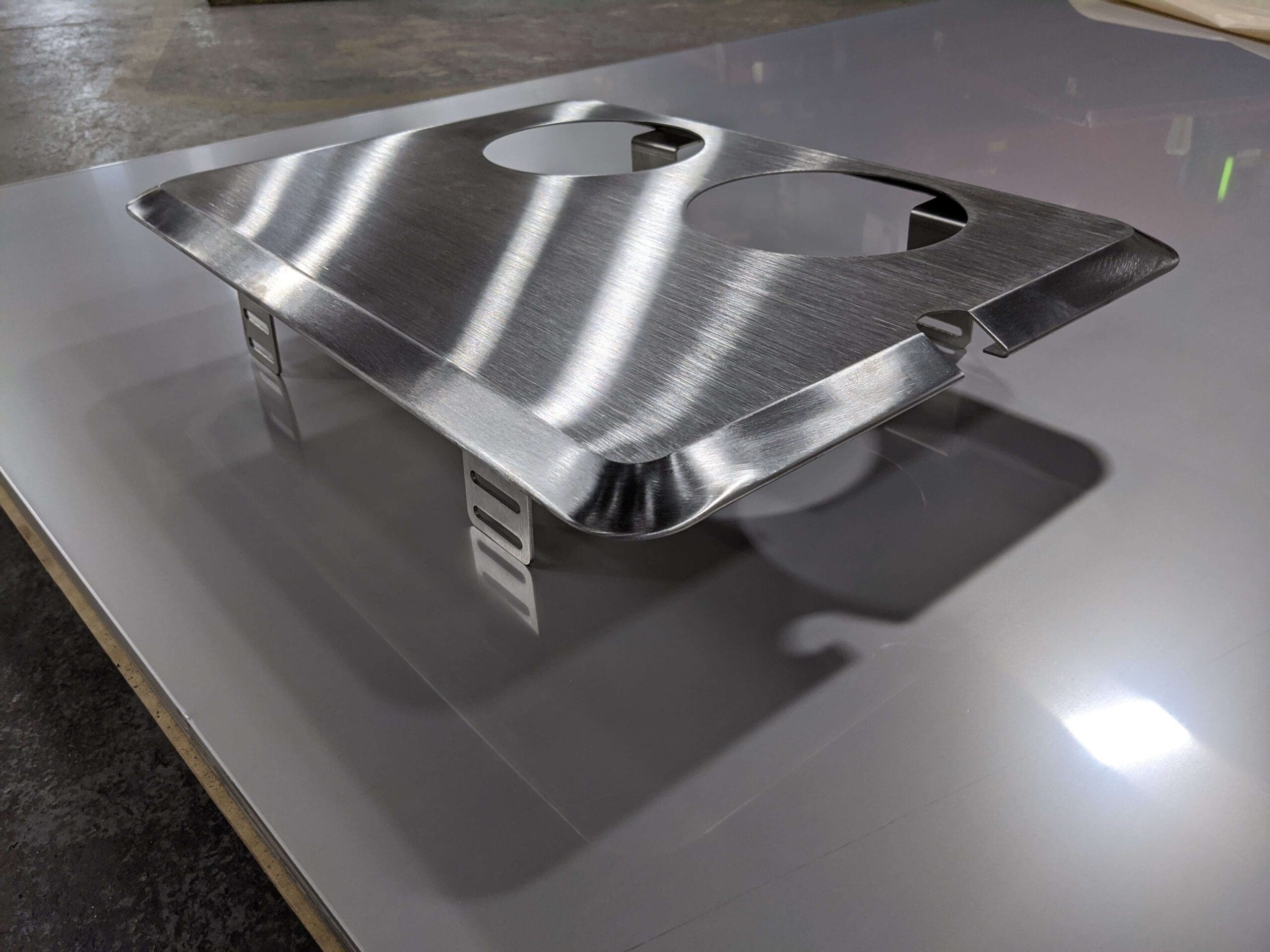

Medical device manufacturers demand uncompromising precision, material integrity, and regulatory adherence in every component. Honyo Prototype specializes in high-accuracy sheet metal fabrication tailored explicitly for the medical industry, where tolerances of ±0.005 mm and biocompatible material processing are non-negotiable. Our ISO 13485-certified facility leverages state-of-the-art fiber laser cutting, precision bending, and cleanroom assembly to produce critical elements such as surgical instrument housings, diagnostic equipment frames, and implantable device subassemblies. We rigorously process materials including 316L stainless steel, titanium, and medical-grade aluminum, with secondary operations like electropolishing, passivation, and laser welding to ensure surface finishes meet ASTM F86 standards for biocompatibility and corrosion resistance.

Every project integrates full documentation traceability, from raw material certs to first-article inspection reports, streamlining your FDA 510(k) or CE submissions. Accelerate your development timeline with Honyo’s Online Instant Quote platform, which delivers validated pricing and manufacturability feedback within hours—no manual RFQ delays. Simply upload your STEP or DXF file to receive a detailed cost breakdown, lead time estimate, and DFM suggestions optimized for medical-grade production. For mission-critical components where failure is not an option, Honyo delivers engineering rigor from prototype to volume manufacturing.

Technical Capabilities

Medical sheet metal fabrication involves precision manufacturing processes that meet stringent regulatory and hygiene standards required in medical device and equipment production. Key processes include laser cutting, bending, and welding, each performed with high accuracy to ensure biocompatibility, cleanability, and structural integrity. Below are the technical specifications for these processes, including compatible materials such as aluminum, stainless steel, and engineering plastics like ABS and nylon—though note that ABS and nylon are not metals and are typically processed via machining or molding rather than sheet metal techniques.

| Process | Material | Thickness Range | Tolerance | Surface Finish (Ra) | Key Process Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum (e.g., 5052, 6061) | 0.5 – 6.0 mm | ±0.1 mm | 3.2 – 6.3 µm | High-precision cutting with minimal heat-affected zone; nitrogen assist for clean edges |

| Stainless Steel (e.g., 304, 316L) | 0.5 – 8.0 mm | ±0.1 mm | 3.2 – 6.3 µm | 316L preferred for biocompatibility; fiber laser recommended for corrosion resistance | |

| ABS | Not applicable (thermoplastic) | N/A | Varies | Typically not laser-cut in sheet metal context; CNC machining or routing preferred | |

| Nylon | Not applicable (thermoplastic) | N/A | Varies | Poor laser absorption; not suitable for standard sheet metal laser processing | |

| Bending | Aluminum (5052, 6061) | 0.8 – 6.0 mm | ±0.2° angular tolerance | As-formed, no added finish | Use wiping or air bending with polished tooling to avoid surface marring |

| Stainless Steel (304, 316L) | 0.8 – 8.0 mm | ±0.2° angular tolerance | As-formed, passivated post-process | Tooling must be dedicated to stainless to avoid cross-contamination | |

| ABS | Not applicable | N/A | N/A | Thermoforming used instead; not compatible with standard sheet metal bending | |

| Nylon | Not applicable | N/A | N/A | Not suitable for press braking; limited formability in thin sheet configurations | |

| Welding | Aluminum (5052, 6061) | 1.0 – 6.0 mm | ±0.5 mm joint fit-up | 6.3 – 12.5 µm | TIG or pulsed MIG with high-purity argon; post-weld clean to remove oxidation |

| Stainless Steel (304, 316L) | 0.8 – 8.0 mm | ±0.5 mm joint fit-up | 3.2 – 6.3 µm | Orbital or pulsed TIG preferred; full documentation for traceability and passivation | |

| ABS | Not applicable | N/A | Varies | Ultrasonic or solvent welding used; not applicable to metal fabrication workflows | |

| Nylon | Not applicable | N/A | Varies | Hot plate or vibration welding; not compatible with arc or resistance methods |

Notes:

Aluminum and stainless steel are the primary materials used in medical sheet metal fabrication due to their strength, corrosion resistance, and sterilizability.

316L stainless steel is especially favored in surgical and implantable device housings due to superior biocompatibility and resistance to chloride corrosion.

ABS and nylon are engineering thermoplastics commonly used in medical enclosures or components but are not processed using traditional sheet metal techniques. Their inclusion here is for comparative context.

All metal parts intended for medical use must undergo passivation (for stainless steel), deburring, and electropolishing where applicable to meet ISO 13485 and FDA guidelines.

Laser cutting and welding must be performed in controlled environments with traceable process parameters to meet medical device quality standards.

From CAD to Part: The Process

Honyo Prototype implements a rigorously controlled sheet metal fabrication process specifically designed for medical device components, adhering to ISO 13485 standards and FDA Class II requirements. Our workflow ensures precision, traceability, and compliance from initial design to final delivery.

CAD Upload

Customers submit detailed 3D CAD models and technical specifications via our secure online portal. All files undergo immediate validation for format compatibility (STEP, IGES, native formats) and completeness, including critical annotations for material grade (e.g., ASTM F899 stainless steel 316L), surface finish (Ra ≤ 0.8 µm), and biocompatibility requirements. File integrity checks prevent downstream errors, with automated notifications for missing critical data.

AI-Powered Quoting

Our proprietary AI engine analyzes the validated CAD data against real-time parameters: material availability from certified medical-grade suppliers, machine capacity, secondary operation requirements (e.g., electropolishing, passivation), and regulatory constraints. The system cross-references historical production data and current shop floor loads to generate an accurate cost and lead time estimate within 2 hours. This quote includes explicit compliance statements for ISO 13485 documentation and material traceability, with engineering flags for potential regulatory risks.

Regulatory-Driven DFM Analysis

Engineered DFM review occurs in parallel with quoting, led by senior manufacturing engineers specializing in medical devices. This phase focuses on manufacturability while ensuring adherence to medical standards:

Assessment of bend radii for sterilization compatibility

Verification of tolerances against ISO 2768-mK

Evaluation of feature geometries to eliminate bacterial harborage points

Confirmation of material suitability for intended biological contact

Review of surface finish specifications for cleanability

Customers receive a formal DFM report with actionable recommendations, requiring explicit approval before production release. All suggestions document compliance implications.

Controlled Production Execution

Approved designs move to dedicated medical production cells operating under ISO Class 8 cleanroom conditions for critical components. Key protocols include:

Material traceability via laser-etched batch numbers logged in our QMS

In-process inspections at defined checkpoints using calibrated CMMs

Mandatory first-article inspection (FAI) per AS9102 standards

Process validation for secondary operations (e.g., passivation per ASTM A967)

Real-time SPC monitoring of critical dimensions

Cleanroom classification requirements vary by component criticality:

| Component Criticality | Cleanroom Class | Particle Count per m³ (≥0.5µm) | Documentation Level |

|---|---|---|---|

| Critical Contact | ISO 5 | ≤ 3,520 | Full DHR with FAI |

| Non-Critical Contact | ISO 7 | ≤ 352,000 | Batch Records |

| External Housing | ISO 8 | ≤ 3,520,000 | Standard Inspection |

Regulatory-Compliant Delivery

Final inspection generates a Device History Record (DHR) containing material certificates of conformance, process validation records, FAI reports, and dimensional inspection data. All components ship in validated sterile barrier systems where required, with serialized labels meeting UDI requirements. Shipping documentation includes:

Certificate of Conformance with ISO 13485 registration

Full traceability documentation (material lot, operator, equipment IDs)

Sterilization validation summary (if applicable)

Compliance statement for relevant FDA 21 CFR parts

We provide electronic DHR access via our customer portal, ensuring complete audit readiness for regulatory submissions. Standard lead time from approved DFM to delivery is 10-15 business days for first-article production.

Start Your Project

Looking for precision medical sheet metal fabrication? Honyo Prototype delivers high-quality, compliant solutions tailored to the demanding standards of the medical device industry. With our advanced manufacturing capabilities and strict quality control, we ensure reliability and repeatability for your critical applications.

Our state-of-the-art factory is located in Shenzhen, China—strategically positioned for efficient production and global logistics.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.