Contents

Manufacturing Insight: Meaning Of Cnc

Computer Numerical Control (CNC) Defined

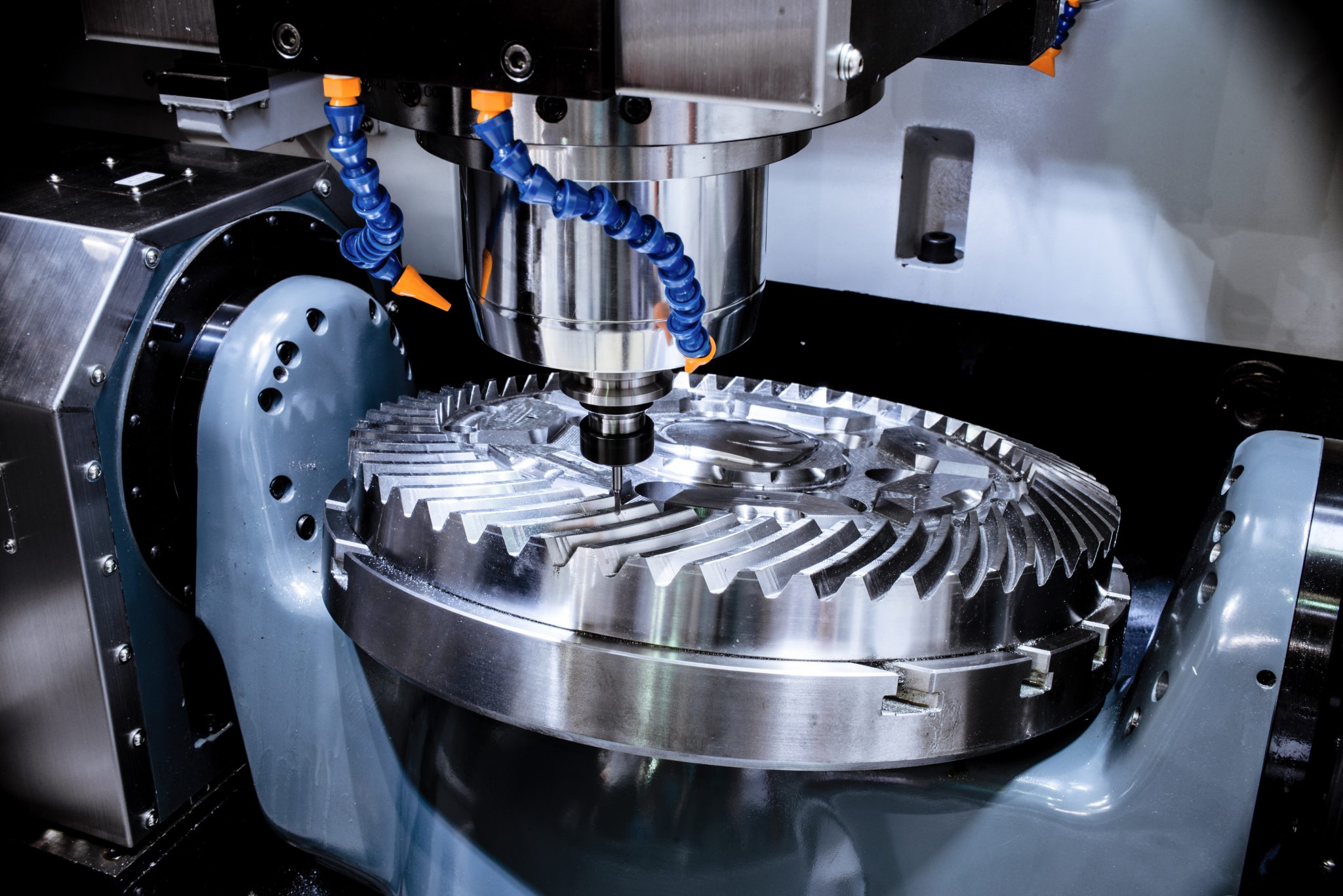

Computer Numerical Control (CNC) represents the foundational automation technology driving modern precision manufacturing. At its core, CNC utilizes pre-programmed software to dictate the exact movement of factory tools and machinery, translating digital design data into physical components with exceptional accuracy, repeatability, and efficiency. This process eliminates manual intervention, minimizes human error, and enables the production of complex geometries across diverse materials—from aerospace-grade alloys to medical polymers—that would be impractical or impossible with conventional machining methods.

Honyo Prototype’s Precision CNC Machining Capabilities

Honyo Prototype leverages advanced CNC machining centers to deliver end-to-end prototyping and low-volume production solutions engineered for demanding industrial applications. Our facility integrates multi-axis milling, turning, and mill-turn systems capable of achieving tight tolerances down to ±0.0002 inches while maintaining rigorous quality control through in-process inspection and CMM validation. Material versatility spans aluminum, titanium, stainless steel, brass, and engineering plastics like PEEK and Delrin, supported by secondary operations including anodizing, plating, and precision grinding to meet stringent industry specifications. Every component undergoes engineer-approved process planning to optimize speed without compromising structural integrity or surface finish requirements.

Accelerate your development timeline with Honyo’s Online Instant Quote platform, designed specifically for engineering teams. Upload your CAD file to receive a detailed manufacturability analysis and competitive pricing within hours—no sales calls required. This seamless digital workflow ensures rapid validation of design feasibility and cost transparency, empowering faster decision-making for your next project. Submit your CAD file today to experience precision CNC machining engineered for innovation.

Technical Capabilities

Technical Specifications for CNC Machining at Honyo Prototype

CNC (Computer Numerical Control) machining refers to a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. At Honyo Prototype, we specialize in high-precision CNC machining across 3-axis, 4-axis, and 5-axis milling platforms, as well as CNC turning operations. Our capabilities support tight tolerance requirements and a broad range of engineering-grade materials, including aluminum, steel, ABS, and nylon.

The following table outlines the technical specifications for our CNC machining services:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, + Rotary (A-axis) | X, Y, Z, + Two Rotary Axes (A/B or A/C) | X, Z, + C-axis (optional) | Supported across all platforms |

| Typical Applications | Flat surfaces, prismatic parts, slots, pockets | Indexing features, angled details, mid-complexity geometries | Complex contours, organic shapes, aerospace components | Cylindrical parts, shafts, bushings, threaded components | Critical-fit components, medical devices, aerospace fittings |

| Tolerance Range | ±0.005 mm to ±0.025 mm | ±0.005 mm to ±0.025 mm | ±0.005 mm to ±0.025 mm | ±0.005 mm to ±0.025 mm | Down to ±0.005 mm (tight-tolerance focus) |

| Surface Finish (Typical) | Ra 1.6 µm | Ra 1.6 µm | Ra 0.8 – 1.6 µm | Ra 1.6 µm | Ra 0.4 – 1.6 µm (controlled finish options) |

| Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon | Aluminum, Steel, ABS, Nylon (in bar stock form) | Full material range with precision process control |

| Max Work Envelope (Typical) | 700 x 400 x 350 mm | 700 x 400 x 350 mm (with indexing) | 500 x 400 x 300 mm (full continuous 5-axis) | Ø300 mm x 500 mm length | Depends on platform; tight tolerances maintained within mid-range envelopes |

| Tooling & Control | High-speed spindle (up to 24,000 RPM), rigid tapping | Same as 3-axis + rotary indexing | Simultaneous 5-axis interpolation, high dynamic accuracy | Live tooling, sub-spindle options | Closed-loop feedback, thermal compensation, in-process probing |

Material Notes:

Aluminum (6061, 7075): Lightweight, excellent machinability, ideal for aerospace and automotive prototypes.

Steel (1018, 4140): High strength and wear resistance; used in structural and load-bearing components.

ABS: Impact-resistant thermoplastic; suitable for functional prototypes and non-load-bearing parts.

Nylon: High toughness, low friction; used in wear pads, gears, and insulating components.

Our CNC processes are supported by ISO-compliant quality control, CMM inspection, and GD&T analysis to ensure adherence to tight tolerance requirements. Honyo Prototype delivers precision-machined components across industries including aerospace, medical, robotics, and industrial automation.

From CAD to Part: The Process

CNC Definition and Honyo Prototype Process Flow

CNC refers to Computer Numerical Control machining, a subtractive manufacturing process where pre-programmed software dictates the movement of industrial machine tools to precisely cut, shape, or fabricate parts from raw materials like metals, plastics, or composites. At Honyo Prototype, this process is streamlined through an integrated digital workflow designed for speed, accuracy, and manufacturability.

Upload CAD

Clients initiate the process by uploading native 3D CAD files (STEP, IGES, or native formats like SolidWorks) via our secure portal. Our system automatically validates file integrity, identifies critical datums, tolerances, and material specifications, and flags potential ambiguities before proceeding. This stage ensures geometric accuracy and reduces manual intake errors, typically completing within minutes.

AI Quote Generation

Leveraging proprietary AI algorithms, Honyo analyzes the validated CAD model to generate instant, data-driven quotes within 30 seconds. The AI evaluates part complexity, material utilization, machine time, tooling requirements, and secondary operations while referencing real-time shop floor capacity and material costs. Quotes include detailed cost breakdowns, lead time estimates, and preliminary feasibility insights, eliminating traditional quoting delays.

DFM Analysis

Following quote acceptance, our engineering team conducts a rigorous Design for Manufacturability review. This phase focuses on optimizing the design for CNC production without compromising functionality. Key checks include wall thickness validation, tolerance stack-up analysis, tool access verification, fixture strategy planning, and material waste reduction. We provide actionable feedback with suggested modifications—such as adjusting radii or simplifying undercuts—to enhance producibility, reduce costs, and prevent post-production failures. This collaborative step typically resolves 95% of design issues before machining begins.

Production Execution

Approved designs move to our climate-controlled production floor, where multi-axis CNC mills (3-axis to 5-axis) and lathes execute machining. Each part undergoes in-process inspections using calibrated CMMs and optical comparators to verify critical dimensions against GD&T callouts. We employ high-speed machining strategies, adaptive toolpaths, and live tool monitoring to maintain ±0.005 mm tolerances. Secondary operations like deburring, anodizing, or tapping are managed in-house with full traceability via IoT-enabled work orders.

Delivery and Documentation

Completed parts undergo final QA sign-off, including first-article inspection reports (FAIR) and material certifications. Honyo ships globally via tracked logistics partners, with standard lead times of 5–7 business days for prototypes and 10–12 days for low-volume production. Every delivery includes digital as-built documentation, dimensional reports, and a DFM summary for future iterations. Our on-time delivery rate exceeds 98.5%, supported by real-time shipment tracking accessible through the client portal.

Process Performance Metrics

| Stage | Avg. Duration | Key Output |

|—————-|—————|——————————–|

| Upload CAD | < 5 min | Validated geometry file |

| AI Quote | < 30 sec | Cost breakdown + lead time |

| DFM | 4–8 hours | Optimized design feedback |

| Production | 5–12 days | FAIR-certified parts |

| Delivery | 1–3 days | Traceable shipment + docs |

This closed-loop process ensures manufacturability is prioritized from the earliest design phase, minimizing rework and accelerating time-to-market while maintaining aerospace and medical-grade quality standards. Honyo’s integration of AI-driven quoting with engineer-led DFM delivers unmatched efficiency for rapid CNC prototyping and production.

Start Your Project

Learn more about the meaning of CNC and how precision manufacturing can elevate your next project. Contact Susan Leo at [email protected] to discuss your requirements. Our state-of-the-art factory in Shenzhen supports high-accuracy CNC machining for rapid prototyping and low-volume production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.