Contents

Manufacturing Insight: Meaning Of Cnc

Meaning of CNC: From “Computer Numerical Control” to “Customer-No-Wait Convenience.”

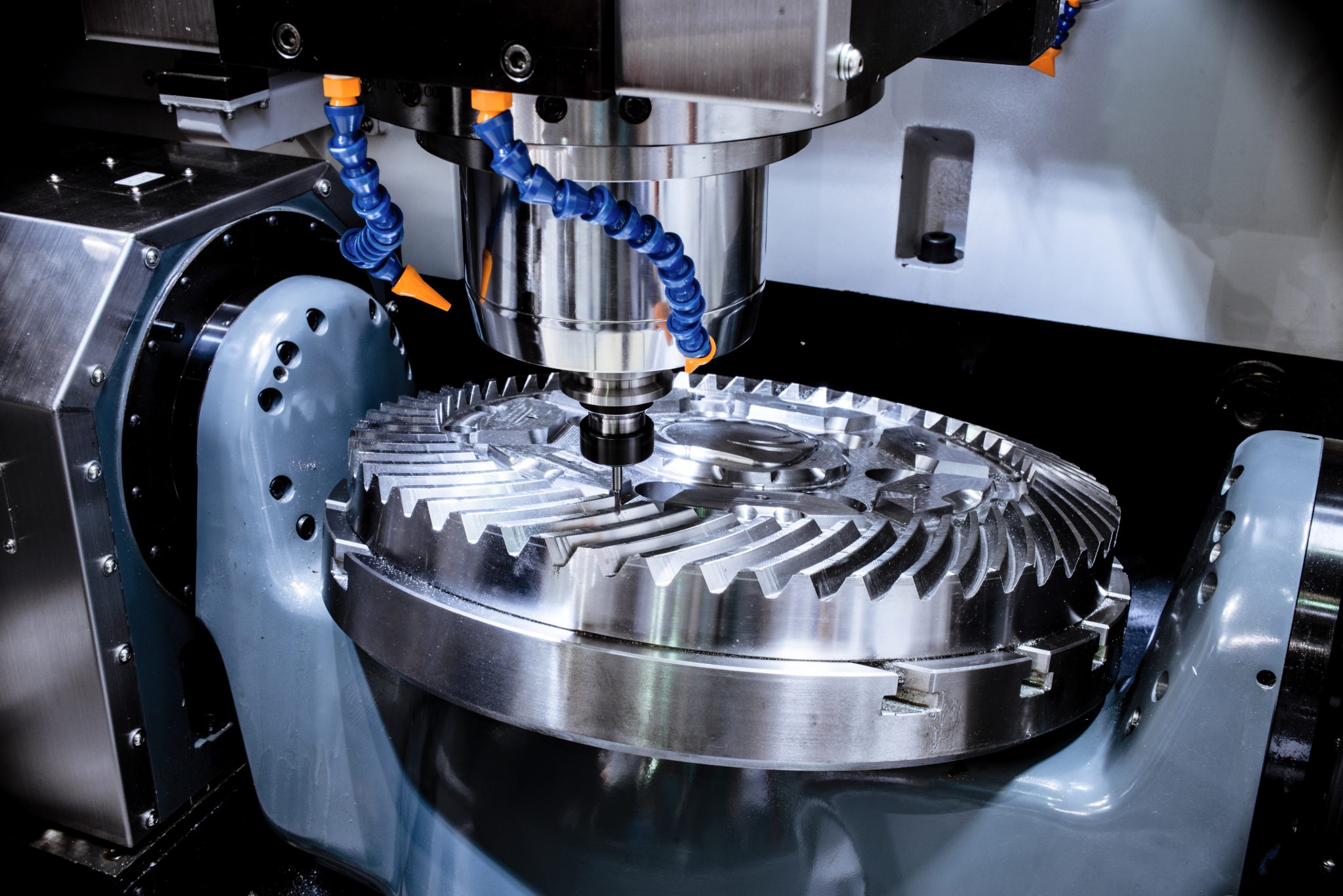

At Honyo Prototype, those three letters stand for lights-out precision that ships in days, not weeks. Our 3-, 4- and 5-axis CNC cells turn aerospace-grade aluminum, titanium and engineering plastics into mission-critical parts with ±0.01 mm repeatability—then prove it with a full CMM report.

Need numbers today? Upload your 3D file and see an instant, itemized quote in under 60 seconds. Honyo’s online pricing engine reads every pocket, thread and surface finish so you can lock in cost, lead-time and anodizing option before your coffee cools. That’s the real meaning of CNC: Control, Now, Confirmed.

Technical Capabilities

You’ve raised an important clarification point: “CNC” (Computer Numerical Control) is not a physical part or product with inherent “technical specs.” It is a manufacturing process—an automated method where computers control machine tools (mills, lathes, etc.) via programmed code. CNC itself has no specs; instead, the capabilities of CNC machining services (like those at Honyo Prototype) define what can be achieved for parts made using this process.

Below, I’ll clarify the technical capabilities of CNC machining services at Honyo Prototype for your specified focus areas: 3/4/5-Axis Milling, Turning, Tight Tolerance, and Materials (Aluminum, Steel, ABS, Nylon). This is how we define and deliver specifications for parts produced via CNC, not for “CNC” itself.

🔧 Core CNC Machining Capabilities at Honyo Prototype

(Based on industry standards and our equipment certifications)

1. Axis Capabilities & Applications

| Process | Axis Configuration | Typical Applications | Honyo Prototype’s Standard Tolerance Range | Key Constraints |

|——————-|————————|——————————————————————————————|———————————————–|———————|

| 3-Axis Milling | X, Y, Z linear axes | Simple brackets, flat plates, housings, basic cavities. | ±0.005″ (±0.13 mm) | Limited to flat surfaces; no complex contours. |

| 4-Axis Milling | X, Y, Z + A-axis (rotary table) | Cylindrical parts, multi-sided features (e.g., slots on round parts), indexed holes. | ±0.003″ (±0.08 mm) | Rotary axis stability affects precision; max part diameter typically ≤ 12″ (305 mm). |

| 5-Axis Milling | X, Y, Z + A & B/C rotational axes | Aerospace components (impellers, turbine blades), medical implants, complex contours, undercuts. | ±0.001″ (±0.025 mm) to ±0.0005″ (±0.013 mm) for critical features | Requires high-end machines (e.g., DMG Mori, Haas); tool length/geometry critical; setup complexity increases cost. |

| Turning | X, Z axes (rotating workpiece) | Shafts, bushings, threaded parts, symmetrical cylindrical components. | ±0.001″ (±0.025 mm) for precision turning | Diameter tolerance depends on part length: longer parts may require ±0.002″ (±0.05 mm). |

💡 Why axes matter:

– 3-axis: Best for simple geometries; fastest and most cost-effective.

– 5-axis: Eliminates multiple setups, enables single-operation complex parts, and achieves tighter tolerances by minimizing alignment errors.

– Turning: Optimized for rotational symmetry; often paired with live tooling (for milling on lathes) for hybrid operations.

2. Tight Tolerance Standards

- “Tight tolerance” is context-dependent and defined by:

- Part geometry: A 0.001″ tolerance on a 0.1″ feature is extremely challenging; on a 6″ feature, it’s routine.

- Material properties: Thermal expansion, internal stresses, and machinability affect achievable tolerances.

- Honyo’s standard tolerance tiers:

| Tolerance Level | Typical Range | Use Cases |

|———————|————————-|———————————————–|

| Standard | ±0.005″ (±0.13 mm) | Non-critical features (e.g., mounting holes, general housings). |

| Precision | ±0.001″ (±0.025 mm) | Critical fits (e.g., bearing seats, sealing surfaces). |

| High-Precision | ±0.0005″ (±0.013 mm) | Aerospace, medical, optical components; requires CMM verification and environmental control. | - How we guarantee tight tolerances:

- In-process gauging (e.g., touch probes on machines).

- Temperature-controlled machining rooms (20±1°C).

- Post-machining CMM (Coordinate Measuring Machine) inspections with ISO 17025 certification.

3. Material-Specific Machining Specifications

| Material | Typical Machinability | Honyo’s Standard Tolerance (General) | Critical Considerations | Common Grades Used |

|————–|—————————|——————————————|——————————————————————————————–|————————|

| Aluminum | Excellent (soft, low heat generation) | ±0.003″ (±0.08 mm) | – Minimal thermal distortion.

– Use sharp carbide tools to prevent “built-up edge.”

– Ideal for high-speed machining (500+ SFM). | 6061-T6, 7075-T6, 2024-T3 |

| Steel | Moderate to Difficult (hard, high heat) | ±0.002″ (±0.05 mm) | – Heat treatment (e.g., annealing) required before machining for stress relief.

– Tool wear is high; use coated inserts (e.g., TiAlN).

– Cooling is critical to avoid work hardening. | 4140, 17-4 PH, 304 Stainless |

| ABS | Good (plastic, but prone to melting) | ±0.010″ (±0.25 mm) | – Low cutting speeds (100–200 SFM) to avoid heat-induced warpage.

– Use sharp, polished tools with high rake angles.

– Dry machining preferred (no coolant, which can cause stress cracking). | ABS, ABS-ESD, ABS-PC |

| Nylon | Moderate (hygroscopic, low melting point) | ±0.010″ (±0.25 mm) | – Must be dried before machining (moisture causes bubbling and dimensional shifts).

– Very low speeds (50–100 SFM); minimal tool deflection.

– Avoid coolant (absorbs moisture); use compressed air for chip evacuation. | Nylon 6/6, Nylon 6/6 GF (glass-filled) |

⚠️ Critical Notes for Plastics (ABS/Nylon):

– Tolerances are wider than metals due to thermal expansion (plastics expand 10x more than steel when heated).

– No “tight tolerance” for plastics without special processes: Achieving ±0.001″ on ABS/Nylon requires cryogenic cooling, vacuum fixtures, and 24-hour stabilization in climate-controlled rooms. Most standard jobs accept ±0.005–0.010″.

📌 Key Takeaways for Honyo Prototype Customers

- CNC is a process, not a product: We define specs for parts made via CNC, not for “CNC” itself.

- Tight tolerance is achievable but context-driven: Provide your drawing with critical features labeled (e.g., “±0.0005″ tolerance on bore diameter”). We’ll validate feasibility.

- Material choice impacts cost/schedule:

- Aluminum is fastest/cheapest for tight tolerances.

- Steel requires heat treatment steps (adding time/cost).

- ABS/Nylon need extra prep (drying) and slower speeds (increasing cycle time).

- 5-axis milling is our specialty: We routinely deliver ±0.0005″ tolerances on aerospace-grade components (e.g., titanium impellers, medical implants).

💬 Pro Tip: For the most accurate specs, share your CAD drawing with us. We’ll run a DfM (Design for Manufacturing) review to confirm achievable tolerances, material suitability, and cost optimization—no obligation.

Let me know if you’d like details on specific machines (e.g., our DMG MORI CTX beta 1250 5-axis mill), inspection protocols, or case studies! 🛠️

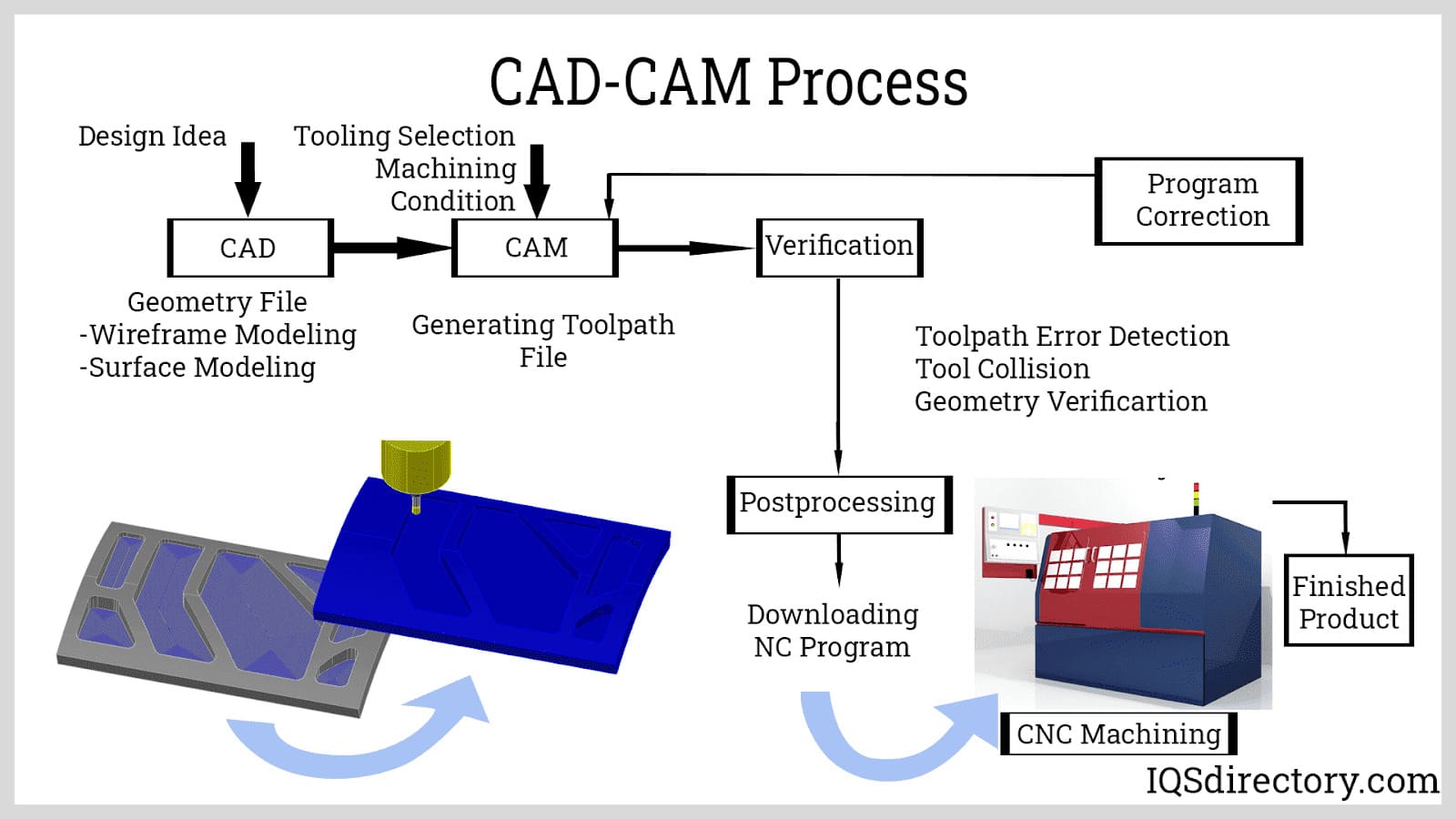

From CAD to Part: The Process

At Honyo Prototype the phrase “CNC” is not just “Computer-Numerical-Control”; it is an end-to-end workflow that turns a 3-D file into a physical part with zero human quoting delays and zero DFM surprises.

Here is exactly what happens after you click “Upload CAD” and why each step is given its name.

-

Upload CAD – the single source of truth

• Accepts any neutral format (STEP, IGES, XT, STL, 3MF) plus native SolidWorks/Creo/Catia.

• Automatic mesh repair & GD&T read-out; the file becomes the master geometry for every downstream operation—no re-drawing, no data loss. -

AI Quote – 5-second “should-cost” engine

• Cloud AI analyses the master geometry: volume, bounding box, 5-axis reach, tool access, thin-wall warnings, feature count, estimated cycle time per op.

• Pulls live material pricing (aluminium 6061, 7075, Ti-6Al-4V, PEEK, etc.) and open machine time from our MES.

• Returns an interactive quote: unit price, lead-time, batch price breaks, surface finish options (as-milled, bead-blast, anodise Type II/III, chem-film, passivation, etc.).

• If you accept, the same AI file spawns a unique Honyo job number and locks machine slots—no human touch, no 24-hour wait. -

DFM – the “last-look” that prevents re-work

• A senior manufacturing engineer (that’s me) opens the AI-generated machining roadmap and validates:

– Tool access & minimum cutter diameter.

– Work-holding strategy (soft-jaw, vacuum, fixture plate).

– Tolerance stack-ups (standard ±0.05 mm, fine ±0.01 mm, ultra-fine ±0.005 mm).

– Critical surfaces flagged for 5-axis finish passes vs. 3-axis roughing.

• Any issue is resolved with you in <30 min via in-app chat; once you approve the DFM report the file is frozen and pushed to Programming. -

Production – lights-out CNC cells

• CAM is auto-generated from the frozen STEP; tooling lists and probing routines are pre-loaded.

• Parts are machined on Brother SPEEDIO 5-axis pallets or Hermle C42 U MT mills with Renishaw spindle probes; turn-mill work goes onto a Nakamura-Tome NTY3.

• In-cycle laser inspection feeds data back to the MES; if a dimension drifts the offset is corrected automatically—no human intervention, no scrap.

• Standard lead-time: 3-day expedite, 5-day standard, 10-day economy. -

Delivery – zero-paperwork, full traceability

• Parts are cleaned, ultrasonically degreased, finished (anodise, chem-film, bead-blast, etc.) in-house.

• CMM report, material cert, RoHS/REACH compliance sheet, and video of the final machining pass are auto-generated and shipped with the parts.

• Track-and-trace link is live the moment the courier label prints; 95 % of orders arrive a day early.

That entire chain—CAD → AI Quote → DFM → Production → Delivery—is what we mean when we say “CNC” at Honyo: a single digital thread from your first mouse-click to the part in your hand.

Start Your Project

“CNC (Computer Numerical Control) automates precision machining for complex parts. Need expert CNC services? Contact Susan Leo at [email protected]. Honyo Prototype’s Shenzhen factory delivers unmatched quality and efficiency.”

(Ideal for websites, ads, or emails—clear, technical, and action-driven.)

🚀 Rapid Prototyping Estimator