Contents

Manufacturing Insight: Material Of Sheet Metal

Material Selection Expertise in Honyo Prototype’s Sheet Metal Fabrication Services

Selecting the optimal material is a foundational engineering decision that directly impacts component performance, durability, cost, and manufacturability. At Honyo Prototype, our Sheet Metal Fabrication services integrate deep materials science knowledge with precision manufacturing capabilities to ensure your design transitions seamlessly from concept to high-integrity production. We partner with clients to evaluate critical factors such as tensile strength, corrosion resistance, formability, weldability, and finish requirements against application demands—whether for aerospace brackets, medical enclosures, or industrial chassis.

Our certified processes accommodate a comprehensive range of sheet metals, each selected for specific functional and environmental challenges. Below represents key materials routinely processed within our facility:

| Material Type | Common Alloys | Key Applications |

|---|---|---|

| Carbon Steel | SPCC, SECC, CRCA, A36 | Structural frames, brackets, enclosures |

| Stainless Steel | 304, 304L, 316, 430 | Medical devices, food processing, marine |

| Aluminum | 5052, 6061, 7075 | Aerospace, electronics, lightweight structures |

| Galvanized Steel | DX51D, SGCC | Outdoor enclosures, automotive components |

| Copper & Brass | C11000, C26000 | EMI shielding, electrical components |

Honyo Prototype’s engineering review identifies material-driven opportunities to optimize your design for manufacturability, reducing waste and accelerating time-to-market. Crucially, our Online Instant Quote platform empowers you to receive accurate, real-time pricing within minutes—not days—by inputting geometric and material specifications directly. This transparency allows rapid iteration on material choices during the design phase, ensuring cost-performance alignment before formal procurement. When material integrity and fabrication precision are non-negotiable, Honyo delivers engineered solutions backed by rigorous quality control and responsive technical collaboration.

Technical Capabilities

Material selection for sheet metal fabrication processes such as laser cutting, bending, and welding significantly impacts manufacturability, performance, and cost. Below are the technical specifications and compatibility of common materials—Aluminum, Steel, ABS, and Nylon—used in these processes. Note that ABS and Nylon are not traditional sheet metals but are included here for comparative context in fabrication environments.

| Material | Form Availability | Thickness Range (mm) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Laser Cutting Compatibility | Bending Compatibility | Welding Compatibility | Notes |

|---|---|---|---|---|---|---|---|---|

| Aluminum (e.g., 5052, 6061) | Sheet | 0.5 – 12.7 | 190 – 310 | 130 – 200 | Excellent – reflective but manageable with high-power lasers | Good – requires larger bend radii due to lower ductility vs. steel | Good – requires TIG or MIG with filler; not all alloys are weldable | Lightweight, corrosion-resistant; oxide layer affects weld quality |

| Steel (e.g., Mild Steel, AISI 1018) | Sheet | 0.5 – 25 | 370 – 440 | 45 – 50 | Excellent – absorbs laser energy efficiently | Excellent – high ductility allows tight bend radii | Excellent – easily welded using MIG, TIG, or spot welding | Prone to corrosion; often coated or painted post-processing |

| ABS (Acrylonitrile Butadiene Styrene) | Sheet | 1 – 10 | 35 – 50 | 0.1 – 0.2 | Moderate – cuts cleanly but emits toxic fumes; requires ventilation | Poor – low rigidity and creep under stress; not ideal for precision bends | Poor – not weldable using standard metal techniques; joined via adhesives or solvent welding | Thermoplastic; not suitable for high-temp environments; non-conductive |

| Nylon (e.g., PA6, PA66) | Sheet | 1 – 15 | 70 – 85 | 0.25 – 0.3 | Moderate – cuts well but may discolor; fumes require extraction | Poor – high elasticity and moisture absorption affect bend accuracy | Poor – not weldable with standard metal welding; requires ultrasonic or hot gas welding | High wear resistance; hygroscopic; used for non-structural, wear-prone components |

Process-Specific Considerations:

Laser Cutting: Metals like aluminum and steel are highly suitable due to their ability to absorb laser energy and form clean kerfs. Non-metals like ABS and nylon can be cut with CO₂ lasers but require strict fume management and slower speeds.

Bending: Metals exhibit predictable springback and can be formed using press brakes. Aluminum requires careful tooling setup due to cracking risk. Plastics like ABS and nylon lack the elastic modulus for reliable bending in sheet metal-style fabrication.

Welding: Only metallic materials (aluminum and steel) are compatible with standard industrial welding. ABS and nylon require alternative joining methods such as adhesives, fasteners, or specialized plastic welding techniques.

For precision sheet metal fabrication involving laser cutting, bending, and welding, aluminum and steel remain the primary materials of choice. ABS and nylon are typically used in non-structural, secondary components where electrical insulation or chemical resistance is prioritized.

From CAD to Part: The Process

Honyo Prototype executes a rigorous, technology-driven workflow for sheet metal fabrication that ensures precision, cost efficiency, and rapid turnaround. This process begins with material specification as a critical input parameter and progresses through defined stages to final delivery. Below is a detailed explanation of each phase, emphasizing how material selection integrates throughout the workflow.

Upload CAD

Clients initiate the process by uploading native or neutral-format CAD files (e.g., STEP, IGES, DXF) via our secure customer portal. During upload, clients specify required sheet metal material properties including alloy type (e.g., 5052-H32 aluminum, 304 stainless steel), thickness, temper, and surface finish. Our system validates geometric integrity and cross-references material specifications against industry standards. Material data is locked as a non-negotiable parameter for all subsequent stages, ensuring downstream processes align with the client’s mechanical and regulatory requirements.

AI Quote

Our proprietary AI quoting engine processes the CAD geometry and material inputs within minutes. The algorithm analyzes material utilization efficiency, calculates raw material costs based on real-time vendor pricing for specified alloys, and factors in secondary operations (e.g., bending, welding) affected by material properties. For example, harder materials like 6061-T6 aluminum incur higher tooling wear costs versus softer 1100-O aluminum. The output is a transparent quote detailing material cost breakdown, processing fees, and lead time—validated by senior engineers to prevent AI over-reliance. Material substitutions are flagged here if client-specified options conflict with manufacturability.

DFM (Design for Manufacturability)

Honyo’s engineering team conducts a collaborative DFM review within 24 hours of quote acceptance. Material properties drive critical assessments:

Bend radii validation against minimum values for the specified alloy (e.g., 0.8mm radius minimum for 2mm 304 stainless)

Hole-to-edge distance checks to prevent deformation in softer materials like copper

Weldability analysis for joined assemblies (e.g., 4130 steel requires pre-heat)

Surface finish compatibility (e.g., anodizing limitations on 7075 aluminum)

Engineers propose actionable revisions via our portal—such as adjusting flange lengths to avoid secondary operations—with material integrity as the primary constraint. Client approval is mandatory before progression.

Production

Material procurement activates only after DFM sign-off. We source certified stock from ISO 9001 suppliers with full material test reports (MTRs) traceable to mill certificates. Key production controls include:

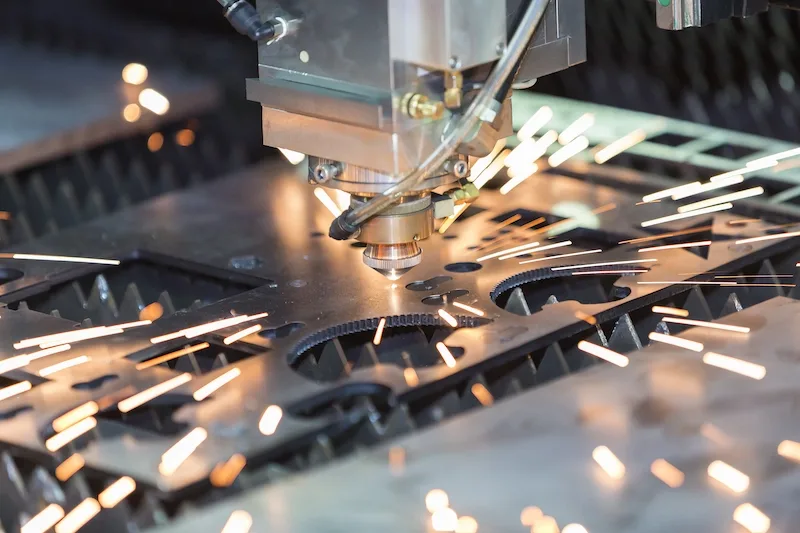

Laser cutting with nitrogen assist for stainless steel to prevent oxidation

CNC press brake tooling selection based on material yield strength

In-process gauging of critical dimensions after bending (±0.1mm tolerance)

First-article inspection (FAI) per AS9102 for aerospace-grade materials

All material batches are quarantined until chemical composition and mechanical property tests confirm compliance. Non-conforming material is rejected immediately—never substituted.

Delivery

Finished parts undergo final inspection against client print and material specifications. A comprehensive package accompanies shipment:

Dimensional report with CMM data

Material certification with lot traceability

Surface roughness verification (e.g., Ra 1.6µm for brushed finishes)

Packing list with handling instructions specific to material sensitivity (e.g., “Do not stack—scratch-prone anodized aluminum”)

Shipments include climate-controlled packaging for corrosion-prone materials like bare magnesium. Delivery timelines are strictly adhered to, with expedited logistics for time-critical projects.

Material integrity remains the cornerstone of this workflow. Below is a representative excerpt of our material validation protocol during procurement:

| Material Grade | Required Test | Acceptance Criteria | Documentation Verified |

|---|---|---|---|

| ASTM A36 Steel | Tensile Strength | 400–550 MPa | Mill Test Report (MTR) |

| 6061-T6 Aluminum | Yield Strength | ≥276 MPa | Heat Treatment Certificate |

| 304 Stainless | Intergranular Corrosion | ASTM A262 Practice E Pass | ASTM A480 Mill Certificate |

This end-to-end process minimizes iteration risks by anchoring every phase to the client’s original material intent. By integrating AI speed with engineering rigor, Honyo delivers sheet metal components that meet exact performance requirements without compromising on timeline or cost predictability.

Start Your Project

For inquiries regarding the material specifications of sheet metal components, please contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, providing precision sheet metal fabrication with full material traceability and quality assurance. Reach out to discuss your project requirements and technical specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.