Introduction: Navigating the Global Market for material adecuado

In an increasingly interconnected world, sourcing the right materials—known as “material adecuado”—is a critical challenge for international B2B buyers. Whether you’re constructing a new facility in Africa, renovating an office in South America, or sourcing components in the Middle East or Europe, the stakes are high. The materials you select can significantly impact not only the quality and durability of your project but also your overall budget and timeline. This guide aims to demystify the process of selecting suitable materials, providing you with actionable insights into the types of materials available, their applications, and best practices for supplier vetting.

Our comprehensive approach covers essential factors such as cost considerations, material properties, and maintenance requirements, ensuring that you make informed purchasing decisions. You’ll learn how to evaluate suppliers effectively and understand regional variances that may affect material availability and pricing. By the end of this guide, you will be equipped to navigate the global market confidently, optimizing your projects while minimizing risks. Whether you’re in Saudi Arabia or Vietnam, our expert insights will empower you to choose the right materials that align with your specific project needs and goals.

Understanding material adecuado Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Stone | Durable, unique aesthetics, natural variations | High-end construction, landscaping | Pros: Timeless appeal, longevity. Cons: Higher cost, requires skilled installation. |

| Concrete | Versatile, strong, customizable, and cost-effective | Infrastructure, commercial buildings | Pros: Low maintenance, high strength. Cons: Can be prone to cracking, aesthetic limitations. |

| Wood | Warm appearance, renewable resource, various finishes | Residential buildings, furniture manufacturing | Pros: Aesthetic appeal, insulation properties. Cons: Vulnerable to moisture, requires maintenance. |

| Metal | High strength-to-weight ratio, recyclable, modern look | Industrial applications, roofing, framing | Pros: Durability, fire resistance. Cons: Can be expensive, prone to corrosion without treatment. |

| Ceramic | Wide range of designs, moisture-resistant, easy to clean | Flooring, wall coverings, sanitary ware | Pros: Versatile aesthetics, low maintenance. Cons: Can be brittle, may require professional installation. |

What Are the Characteristics of Natural Stone and Its Suitability for B2B Buyers?

Natural stone is renowned for its durability and unique aesthetic appeal, making it a favored choice for high-end construction and landscaping projects. Comprising materials like granite, marble, and limestone, natural stone varies in color, texture, and finish. B2B buyers should consider the specific project requirements, as these materials often require skilled installation and can be more expensive than alternatives. Their longevity and timeless appeal, however, can justify the investment in many luxury applications.

How Does Concrete Serve Various B2B Applications?

Concrete is a highly versatile material that offers significant strength and cost-effectiveness, making it ideal for a broad range of applications, including infrastructure and commercial building projects. Its customizable nature allows for various finishes and forms, catering to aesthetic needs while maintaining structural integrity. Buyers should account for potential cracking issues and the need for professional installation, but the low maintenance requirements and durability often make concrete a preferred choice in large-scale B2B projects.

Why Is Wood a Popular Choice Among B2B Buyers?

Wood provides a warm aesthetic and is a renewable resource, making it suitable for various applications, from residential buildings to furniture manufacturing. Different types of wood offer various finishes, allowing businesses to tailor their choices to specific design needs. However, wood is vulnerable to moisture and requires regular maintenance to preserve its appearance and structural integrity. B2B buyers should weigh the aesthetic benefits against the long-term maintenance requirements when considering wood for their projects.

What Are the Advantages and Disadvantages of Using Metal in B2B Projects?

Metal materials, such as steel and aluminum, are known for their high strength-to-weight ratio and modern appearance, making them popular in industrial applications, roofing, and framing. The recyclability of metal also appeals to environmentally conscious businesses. However, buyers should be aware of the potential for corrosion if not properly treated and the higher initial costs compared to other materials. The durability and fire resistance of metal can provide long-term value, especially in demanding applications.

How Does Ceramic Material Fit into B2B Construction and Design?

Ceramic materials are widely utilized for flooring, wall coverings, and sanitary ware due to their moisture resistance and ease of cleaning. They come in a vast array of designs, making them suitable for both functional and aesthetic purposes in various commercial settings. While ceramic is durable, it can be brittle, necessitating careful handling and professional installation. Buyers should consider the specific needs of their projects, balancing the aesthetic versatility of ceramic with its installation requirements.

Key Industrial Applications of material adecuado

| Industry/Sector | Specific Application of material adecuado | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Exterior and Interior Finishing Materials | Enhances aesthetic appeal and durability of structures | Ensure compliance with local building codes and climate suitability |

| Manufacturing | Custom Molding and Components | Increases production efficiency and product quality | Verify material compatibility with manufacturing processes |

| Automotive | Lightweight Composite Materials | Improves fuel efficiency and performance of vehicles | Assess material properties for safety and regulatory compliance |

| Renewable Energy | Structural Components for Solar and Wind Installations | Supports sustainable energy solutions and reduces costs | Focus on material longevity and resistance to environmental factors |

| Consumer Electronics | Enclosures and Components | Enhances product durability and user experience | Consider sourcing from suppliers with a track record in innovation |

How is ‘material adecuado’ used in the construction industry?

In the construction sector, ‘material adecuado’ is vital for both exterior and interior finishing. Proper selection of materials such as tiles, laminates, and paints can significantly enhance the aesthetic appeal and longevity of structures. For international B2B buyers, understanding local climate conditions is essential; materials must be durable against environmental factors like humidity or extreme temperatures, especially in regions like Africa and the Middle East. Additionally, compliance with local building codes is critical to avoid legal issues and ensure safety.

What role does ‘material adecuado’ play in manufacturing?

In manufacturing, ‘material adecuado’ is crucial for producing custom molds and components, particularly in sectors like automotive and consumer goods. The right materials can improve production efficiency, reduce waste, and enhance the overall quality of the final product. For B2B buyers, it is imperative to verify that the selected materials are compatible with existing manufacturing processes. This may involve testing for durability, flexibility, and resistance to wear, which can vary significantly across different regions, including South America and Europe.

How does ‘material adecuado’ enhance automotive applications?

In the automotive industry, lightweight composite materials are increasingly utilized to improve vehicle performance and fuel efficiency. By choosing ‘material adecuado,’ manufacturers can reduce the overall weight of vehicles without compromising safety or structural integrity. For international buyers, it is essential to assess the material properties to ensure they meet stringent safety and regulatory standards in their respective markets, such as those found in Europe and the Middle East. This careful consideration can lead to significant cost savings over the vehicle’s lifecycle.

Why is ‘material adecuado’ important for renewable energy projects?

In renewable energy, ‘material adecuado’ is critical for constructing structural components used in solar and wind installations. The right materials not only support the efficiency of these systems but also contribute to sustainability goals by reducing long-term operational costs. B2B buyers should focus on sourcing materials that offer longevity and resistance to environmental factors, particularly in regions prone to extreme weather. Understanding the local supply chain and ensuring reliable sourcing can enhance project viability and performance.

How does ‘material adecuado’ improve consumer electronics?

In the consumer electronics sector, ‘material adecuado’ is essential for creating durable enclosures and components that enhance user experience. Selecting the right materials can lead to increased product longevity and better performance, which is crucial in a competitive market. For international B2B buyers, it’s important to consider sourcing from suppliers known for innovation and quality, as this can significantly impact the end product’s success. Additionally, understanding regional preferences and compliance standards can help in making informed sourcing decisions.

3 Common User Pain Points for ‘material adecuado’ & Their Solutions

Scenario 1: Misalignment Between Material Properties and Project Requirements

The Problem: B2B buyers often face significant challenges when the materials they select do not align with the specific requirements of their projects. For instance, a construction firm may choose a flooring material that is visually appealing but lacks the necessary durability for high-traffic areas. This misalignment can lead to premature wear, increased maintenance costs, and ultimately, client dissatisfaction. Buyers may feel overwhelmed by the variety of options available and unsure of how to assess the material properties effectively.

The Solution: To avoid this pitfall, B2B buyers should engage in a thorough needs assessment before selecting materials. This involves clearly defining the project requirements, including load-bearing capacities, environmental conditions, and aesthetic considerations. Collaborating closely with architects or engineers can provide invaluable insights into the necessary specifications. Additionally, creating a checklist of critical material properties—such as hardness, flexibility, resistance to moisture, and maintenance needs—can streamline the selection process. Buyers should also consider leveraging technology, such as material property databases, to compare options systematically. This proactive approach not only ensures the right material is chosen but also fosters stronger relationships with clients by demonstrating a commitment to quality and performance.

Scenario 2: Lack of Expert Guidance in Material Selection

The Problem: Many B2B buyers encounter difficulties when selecting materials due to insufficient technical knowledge or lack of access to expert advice. This is particularly prevalent in industries like construction or manufacturing, where the implications of poor material choices can be costly. Buyers may find themselves second-guessing their decisions, leading to delays and potential project failures. The absence of reliable sources for expert guidance can exacerbate this issue, leaving buyers feeling isolated and uncertain.

The Solution: To combat this challenge, B2B buyers should prioritize building relationships with trusted suppliers and manufacturers who can provide expert guidance throughout the material selection process. Engaging with suppliers who offer comprehensive support services, including consultation, technical specifications, and product demonstrations, can significantly enhance decision-making. Moreover, attending industry trade shows, webinars, and training sessions can equip buyers with the knowledge to make informed choices. Creating a network of peers in the industry can also facilitate knowledge sharing and provide insights into best practices. By leveraging these resources, buyers can confidently select materials that meet their project requirements and mitigate the risks associated with inadequate guidance.

Scenario 3: Budget Constraints Impacting Material Choices

The Problem: Budget constraints are a common pain point for B2B buyers, often forcing them to make compromises in material selection. This can lead to the adoption of lower-quality materials that do not meet the project’s demands, resulting in long-term costs that exceed initial savings. Buyers may struggle to balance quality and cost, feeling pressured to choose materials that fit their budget rather than those that are ideal for their projects.

The Solution: To address budget limitations while ensuring quality, B2B buyers should adopt a strategic approach to sourcing materials. This includes conducting a thorough market analysis to identify suppliers who offer competitive pricing without compromising on quality. Buyers can also explore alternative materials that provide similar functionality at a lower cost, such as engineered products instead of natural ones. Implementing bulk purchasing strategies or long-term contracts with suppliers can also yield significant savings. Additionally, buyers should factor in the total cost of ownership (TCO) when evaluating materials, considering not only the initial price but also maintenance, durability, and lifecycle costs. This holistic approach allows buyers to make informed decisions that align with their budgetary constraints while still meeting project requirements effectively.

Strategic Material Selection Guide for material adecuado

What Are the Key Properties of Common Materials for Material Adequado?

When selecting materials for various applications, understanding their key properties is crucial. Here, we analyze four common materials used in construction and manufacturing, focusing on their performance characteristics, advantages, disadvantages, and specific considerations for international B2B buyers.

Steel: A Versatile Choice for Structural Applications

Steel is widely recognized for its strength and durability. It typically boasts a high tensile strength, making it suitable for load-bearing applications. Key properties include a temperature rating of up to 600°C and excellent corrosion resistance when treated or alloyed.

Pros: Steel’s primary advantages are its high strength-to-weight ratio and versatility in various applications, from structural beams to automotive components. It can be fabricated into complex shapes, making it suitable for diverse projects.

Cons: The main limitations of steel include susceptibility to corrosion if not properly treated and higher costs compared to other materials like concrete. Additionally, its manufacturing process can be energy-intensive, impacting overall sustainability.

Impact on Application: Steel is compatible with a wide range of media, including water and chemicals, depending on the alloy used. Its strength makes it ideal for high-stress environments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should consider compliance with local standards such as ASTM or DIN for construction projects. Additionally, understanding the availability of treated steel to prevent corrosion in humid environments is essential.

Concrete: The Foundation of Many Structures

Concrete is a composite material composed of aggregates, cement, and water, known for its compressive strength. It can withstand high pressure and is resistant to fire, making it a popular choice for foundations and structural elements.

Pros: Concrete’s advantages include low cost, excellent durability, and the ability to mold into various shapes. It is also readily available in most regions, making it a practical choice for large-scale projects.

Cons: However, concrete has limitations in tensile strength, requiring reinforcement with materials like steel. It can also be prone to cracking under certain conditions, which may necessitate additional maintenance.

Impact on Application: Concrete is compatible with various media, including water and soil, making it suitable for foundations, pavements, and retaining walls.

Considerations for International Buyers: Buyers should be aware of local standards for concrete mix design, especially in regions prone to earthquakes or extreme weather. Understanding the local climate’s impact on curing times is also crucial.

Polypropylene: A Lightweight Alternative for Various Applications

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It is often used in applications ranging from packaging to automotive parts.

Pros: The key advantages of polypropylene include its low density, excellent chemical resistance, and versatility. It can be easily molded into complex shapes, making it suitable for various applications.

Cons: However, polypropylene is less durable under high temperatures compared to metals and can degrade when exposed to UV light unless treated. Its mechanical strength is also lower than that of steel or concrete.

Impact on Application: Polypropylene is compatible with a wide range of chemicals, making it ideal for containers and piping systems in chemical processing.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as JIS for plastic materials. Additionally, understanding the local market’s preferences for recyclable materials can influence purchasing decisions.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is another widely used material known for its lightweight and corrosion-resistant properties. It is often employed in applications where weight savings are critical, such as in aerospace and automotive industries.

Pros: The primary advantages of aluminum include its excellent corrosion resistance, high strength-to-weight ratio, and ease of fabrication. It can be anodized for additional protection, enhancing its lifespan.

Cons: On the downside, aluminum is generally more expensive than steel and has lower tensile strength. It may also require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: Aluminum is suitable for various media, including water and air, and is often used in applications requiring lightweight and strong materials.

Considerations for International Buyers: Buyers should consider the availability of aluminum alloys that meet local standards and the implications of sourcing aluminum from sustainable suppliers, especially in regions with stringent environmental regulations.

Summary Table of Material Selection

| Material | Typical Use Case for material adecuado | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural beams, automotive parts | High strength-to-weight ratio | Susceptible to corrosion | High |

| Concrete | Foundations, pavements | Low cost and excellent durability | Prone to cracking | Low |

| Polypropylene | Packaging, automotive components | Lightweight and chemical resistance | Lower durability at high temps | Medium |

| Aluminum | Aerospace, automotive applications | Corrosion-resistant and lightweight | Higher cost than steel | High |

This guide serves as a foundation for B2B buyers to make informed decisions when selecting materials for their projects, ensuring compliance with local standards and meeting specific application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for material adecuado

What Are the Key Stages in the Manufacturing Process for Material Adecuado?

The manufacturing process for material adecuado involves several critical stages that ensure the final product meets the specific requirements of the project. The main stages are material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage includes sourcing and selecting high-quality raw materials based on the project’s specifications. For example, if the material is intended for construction, factors such as durability, weather resistance, and compliance with local building codes must be considered. Suppliers should conduct thorough inspections to ensure that materials are free from defects.

-

Forming: In this stage, the raw materials undergo various processes to achieve the desired shape and size. Techniques such as extrusion, molding, and machining may be employed, depending on the material type and end-use. For instance, metals may be forged or cast, while polymers might be injected into molds. B2B buyers should inquire about the specific forming techniques used, as they can significantly impact the material’s properties.

-

Assembly: Once the components are formed, they are assembled into the final product. This stage may involve welding, fastening, or adhesive bonding, depending on the material and application. Proper assembly techniques are crucial to ensuring the structural integrity and performance of the final product. Buyers should verify that manufacturers use industry-standard practices during assembly to avoid potential failures in the field.

-

Finishing: The final stage involves applying surface treatments or coatings to enhance the material’s appearance and performance. Finishing processes can include painting, polishing, or applying protective coatings. This stage is essential for materials exposed to harsh environments, as it can significantly extend their lifespan. Buyers should assess the finishing techniques employed by suppliers to ensure they align with their project requirements.

How Is Quality Assurance Implemented in Manufacturing Processes?

Quality assurance (QA) is critical in the manufacturing of material adecuado to ensure that products meet the necessary standards and specifications. This involves adhering to international standards and implementing rigorous quality control measures throughout the production process.

-

International Standards for Quality Assurance: Many manufacturers comply with international standards such as ISO 9001, which outlines the requirements for a quality management system. This certification indicates that a company consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific standards may apply, such as CE marking for products sold in Europe or API standards for oil and gas materials.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet the specified criteria before processing begins.

– In-Process Quality Control (IPQC): Ongoing checks are performed during manufacturing to monitor critical parameters and detect any deviations from quality standards.

– Final Quality Control (FQC): The finished product undergoes a thorough inspection and testing to ensure it meets all specifications before delivery to the client. -

Common Testing Methods for Quality Assurance: Various testing methods are employed to verify the quality of materials, including:

– Mechanical Testing: Assessing properties such as tensile strength, hardness, and impact resistance.

– Chemical Analysis: Ensuring material compositions meet required specifications.

– Non-Destructive Testing (NDT): Techniques like ultrasonic testing or radiography to identify defects without damaging the material.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers maintain high-quality standards. Here are several strategies to verify supplier QC practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their quality management systems, production facilities, and compliance with relevant standards.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help buyers understand the methodologies used in quality control and the results of various tests performed on the materials. These reports should include data on IQC, IPQC, and FQC activities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These inspections can help verify that the products meet international standards and specific project requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances that can impact their purchasing decisions:

-

Regulatory Compliance: Each region may have different regulatory requirements for materials. Buyers should ensure that suppliers are aware of and comply with local regulations and standards, such as CE marking in Europe or ASTM standards in the United States.

-

Cultural Considerations: Understanding cultural differences in business practices can influence quality control expectations. Buyers should communicate clearly and establish mutual expectations regarding quality standards and delivery timelines.

-

Logistics and Supply Chain Factors: The logistics of transporting materials across borders can affect quality. Buyers should consider the potential for material degradation during transit and verify that suppliers implement appropriate measures to mitigate these risks, such as protective packaging.

Conclusion

Understanding the manufacturing processes and quality assurance measures for material adecuado is essential for B2B buyers. By focusing on the stages of manufacturing, adhering to international standards, and verifying supplier practices, buyers can ensure that they select the right materials for their projects. This proactive approach not only helps in achieving project success but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘material adecuado’

Introduction

When sourcing the right materials for your project, it’s essential to follow a structured approach that ensures quality, suitability, and cost-effectiveness. This checklist is designed to guide B2B buyers through the critical steps of procuring ‘material adecuado’ for various applications, whether in construction, manufacturing, or other sectors. By adhering to these steps, you can make informed decisions that will enhance the success of your projects.

1. Define Your Project Requirements

Begin by clearly outlining the specific needs of your project. This includes understanding the functional requirements, environmental conditions, and aesthetic preferences. Knowing whether the materials will be used indoors or outdoors, for example, can significantly influence your choices.

- Consider factors such as durability, maintenance needs, and compliance with local regulations.

- Identify the volume of materials required to avoid over-ordering or under-ordering.

2. Research Material Options

Once you have a clear understanding of your requirements, research the various materials available. Different materials offer distinct advantages, and knowing your options is crucial for making an informed choice.

- Look into the properties of each material, including strength, flexibility, and thermal resistance.

- Assess how each material aligns with your project’s long-term goals, such as sustainability or cost efficiency.

3. Evaluate Supplier Credentials

Thoroughly vet potential suppliers to ensure they can meet your standards. This step is critical as the quality of materials often hinges on the reliability of the supplier.

- Request documentation such as certifications, quality assurance processes, and previous client references.

- Consider suppliers with a proven track record in your industry or region to mitigate risks.

4. Request Samples and Specifications

Before finalizing your purchase, obtain samples of the materials. This allows you to evaluate the quality and suitability firsthand, ensuring they meet your expectations.

- Examine the samples for consistency, finish, and performance against your project requirements.

- Review technical specifications and safety data sheets to understand handling and installation procedures.

5. Compare Pricing and Terms

Cost is a significant factor in procurement decisions. Compare pricing from different suppliers, but also consider the total cost of ownership, which includes shipping, handling, and potential waste.

- Look for bulk purchasing discounts or long-term contract pricing options.

- Ensure you understand payment terms, delivery schedules, and return policies to avoid future complications.

6. Plan for Logistics and Delivery

Effective logistics planning is vital for maintaining project timelines. Confirm that your supplier can meet your delivery requirements and that you have a plan for receiving and storing the materials.

- Discuss delivery timelines and the logistics of transporting materials to your site.

- Ensure you have adequate storage solutions to protect the materials from damage or deterioration upon arrival.

7. Establish a Communication Plan

Maintain open lines of communication with your supplier throughout the sourcing process. This fosters a collaborative relationship that can lead to better service and problem resolution.

- Set up regular check-ins to discuss progress and address any issues that arise.

- Keep detailed records of all communications for reference and accountability.

By following this checklist, you can navigate the complexities of sourcing ‘material adecuado’ with confidence, ensuring that you select the right materials for your specific needs while optimizing costs and timelines.

Comprehensive Cost and Pricing Analysis for material adecuado Sourcing

What are the Key Cost Components in Sourcing ‘material adecuado’?

When sourcing ‘material adecuado’, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality and type of raw materials significantly impact the overall cost. High-quality materials may have a higher upfront cost but can lead to reduced maintenance and longer lifecycle, ultimately providing better value.

-

Labor: Labor costs encompass both direct and indirect labor associated with production and installation. This can vary greatly depending on the region and the complexity of the project.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Costs related to tools and equipment necessary for production. Custom tooling can increase initial costs but may lead to efficiencies in production.

-

Quality Control (QC): Implementing robust QC measures ensures that materials meet specified standards, which can prevent costly rework or replacements down the line.

-

Logistics: Transportation and handling costs, which can be influenced by the distance from the supplier, shipping methods, and import/export regulations.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the typical margins in your industry can provide leverage during negotiations.

How Do Price Influencers Affect the Cost of ‘material adecuado’?

Several factors can influence pricing when sourcing materials:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs due to economies of scale. Be mindful of MOQs, as ordering below these thresholds can lead to significantly higher prices.

-

Specifications and Customization: Custom specifications often lead to increased costs. Determine if customization is necessary for your project, as standard products may offer significant savings.

-

Materials: The type and quality of materials directly influence pricing. Higher quality materials may cost more upfront but can lead to savings in the long run due to lower maintenance costs.

-

Quality Certifications: Materials that meet specific quality standards or certifications may come at a premium. However, these certifications can be critical for compliance in certain industries.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: Understanding the Incoterms can help clarify responsibilities regarding shipping and delivery costs. This knowledge is crucial when negotiating terms with international suppliers.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

B2B buyers can adopt several strategies to maximize cost-efficiency:

-

Negotiate Effectively: Always negotiate prices, especially when dealing with high-volume orders. Leverage quotes from multiple suppliers to foster competitive pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, operation, and disposal of the materials. This holistic view can lead to more informed purchasing decisions.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and import duties that can affect overall costs. Establish relationships with local suppliers when possible to mitigate these issues.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of all costs involved. This transparency helps in comparing offers and understanding potential hidden costs.

-

Plan for Flexibility: Build flexibility into your purchasing strategy to adapt to changing market conditions. This could involve considering alternative materials or suppliers to avoid supply chain disruptions.

Disclaimer on Indicative Prices

Pricing for ‘material adecuado’ can vary widely based on market conditions, material specifications, and supplier capabilities. The insights provided here are intended to guide decision-making but should be validated with current market research and supplier consultations. Always seek multiple quotes and consider the total cost implications before finalizing any procurement decision.

Alternatives Analysis: Comparing material adecuado With Other Solutions

Understanding Alternatives to ‘Material Adecuado’

In the B2B landscape, selecting the right materials for construction or manufacturing projects is crucial for achieving desired outcomes. While ‘material adecuado’ serves as a reliable option, it’s essential to explore alternative solutions that may better suit specific project needs or budgets. This analysis will compare ‘material adecuado’ with two viable alternatives, providing insights that can guide international buyers in making informed decisions.

Comparison Table

| Comparison Aspect | ‘Material Adecuado’ | Alternative 1: Composite Materials | Alternative 2: Recycled Materials |

|---|---|---|---|

| Performance | High durability, tailored for specific applications | Excellent strength-to-weight ratio, versatile | Varies widely; quality depends on source |

| Cost | Moderate to high, depending on specifications | Generally cost-effective, but varies with type | Often lower cost, depending on availability |

| Ease of Implementation | Requires skilled labor for installation | Can be easy to install; pre-fabricated options available | May require additional processing for quality |

| Maintenance | Low maintenance with proper care | Minimal maintenance needed | Maintenance varies; some require more care |

| Best Use Case | Ideal for high-stress environments | Suitable for lightweight structures and automotive | Best for eco-friendly projects and cost-sensitive applications |

Detailed Breakdown of Alternatives

Composite Materials

Composite materials are engineered to combine the best properties of different substances, offering an excellent strength-to-weight ratio. These materials are particularly advantageous in industries such as aerospace and automotive, where minimizing weight while maximizing strength is essential. However, while composite materials can be cost-effective, the initial investment may be higher than traditional materials. Additionally, their installation often requires specialized labor, which can add to project timelines.

Recycled Materials

Recycled materials present an appealing alternative for environmentally-conscious projects. They are often less expensive than new materials, making them an attractive option for cost-sensitive buyers. However, the performance of recycled materials can vary significantly based on their source and processing. Some recycled options may require additional treatments to meet industry standards, which can complicate implementation. They are best suited for projects where sustainability is a primary goal, but buyers should assess the quality to ensure they meet project requirements.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between ‘material adecuado’ and its alternatives, B2B buyers should carefully evaluate their specific project requirements, including performance needs, budget constraints, and environmental considerations. Understanding the nuances of each option can help buyers select the material or method that best aligns with their strategic objectives. Engaging with industry experts and conducting thorough market research can further enhance decision-making, leading to successful project outcomes.

Essential Technical Properties and Trade Terminology for material adecuado

What Are the Key Technical Properties of ‘material adecuado’?

When selecting ‘material adecuado’ for any project, understanding its technical properties is crucial. Here are several essential specifications to consider:

1. Material Grade

Material grade refers to the classification of a material based on its physical and chemical properties. It impacts strength, durability, and suitability for various applications. For B2B buyers, selecting the right grade is vital to ensure that the material can withstand operational demands without premature failure, which can lead to costly repairs and downtime.

2. Tolerance

Tolerance defines the permissible limit of variation in a physical dimension. In construction and manufacturing, precise tolerances ensure that components fit together correctly, which is essential for the structural integrity of a project. For businesses, understanding tolerances can help avoid costly rework and ensure compliance with industry standards.

3. Flexibility

Flexibility measures a material’s ability to bend without breaking. This property is particularly important for materials used in environments subject to stress or movement. B2B buyers must assess flexibility to ensure that the material will perform effectively under expected conditions, minimizing the risk of damage or failure.

4. Resistance to Environmental Factors

This encompasses a material’s ability to withstand conditions such as heat, moisture, chemicals, and UV exposure. Materials with high resistance are crucial for projects exposed to harsh environments. Understanding this property helps buyers select materials that will last longer and require less maintenance, ultimately providing better value.

5. Lifecycle Cost

Lifecycle cost includes all expenses associated with a material from acquisition through disposal. This concept is essential for B2B buyers as it allows for a comprehensive evaluation of cost-effectiveness over time. Choosing materials with lower lifecycle costs can lead to significant savings in maintenance, energy consumption, and replacement.

6. Aesthetic Qualities

While technical properties are crucial, the aesthetic appeal of materials should not be overlooked. Factors such as color, texture, and finish can influence the overall perception of a project. For B2B buyers, selecting materials that align with brand identity and customer expectations can enhance marketability.

What Are Common Trade Terminology and Jargon Related to ‘material adecuado’?

Understanding industry-specific terms is essential for navigating the procurement process effectively. Here are some key terms frequently encountered in the context of ‘material adecuado’:

1. OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, collaborating with OEMs can ensure high-quality components that meet specific project requirements.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for B2B buyers to manage inventory costs and ensure that they are purchasing a sufficient amount to meet project demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for a specific quantity of materials or services. This process is essential for B2B buyers to compare pricing and terms across different suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international shipping to define the responsibilities of buyers and sellers. Understanding these terms helps B2B buyers clarify shipping responsibilities, costs, and risks associated with the transportation of materials.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the goods. For B2B buyers, understanding lead times is crucial for project planning and ensuring timely delivery of materials, which can prevent delays in project completion.

6. Certification

Certification denotes that a material has met specific industry standards or regulations. For B2B buyers, selecting certified materials ensures compliance with safety and quality benchmarks, which can enhance the overall credibility and reliability of their projects.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, optimize procurement processes, and ultimately enhance project outcomes.

Navigating Market Dynamics and Sourcing Trends in the material adecuado Sector

What Are the Current Market Dynamics and Key Trends in the Material Adequado Sector?

The global material adecuado sector is undergoing significant transformation driven by various factors, including technological advancements, changing consumer preferences, and regulatory pressures. Emerging technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) are reshaping how businesses source and utilize materials. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed purchasing decisions.

One notable trend is the shift towards digital sourcing platforms that facilitate real-time procurement and inventory management. These platforms allow buyers to compare materials based on quality, price, and supplier reliability, enhancing transparency in the supply chain. Furthermore, the demand for customization is on the rise, as buyers seek materials tailored to specific project requirements, whether for construction, manufacturing, or other applications.

Moreover, geopolitical factors are influencing sourcing strategies. For instance, buyers in Europe and the Middle East may be reassessing their supply chains to mitigate risks associated with political instability or trade tariffs. This has led to a diversification of suppliers, emphasizing the importance of building robust relationships with local and international manufacturers.

How Are Sustainability and Ethical Sourcing Shaping the Material Adequado Sector?

Sustainability has become a critical consideration for B2B buyers in the material adecuado sector. The environmental impact of material production and usage is under scrutiny, prompting buyers to prioritize sustainable options. Ethical sourcing practices not only enhance brand reputation but also align with the growing consumer demand for corporate responsibility.

Buyers are increasingly looking for materials certified by recognized sustainability standards, such as FSC (Forest Stewardship Council) for wood products or LEED (Leadership in Energy and Environmental Design) certification for construction materials. These certifications assure buyers that the materials have been sourced responsibly, minimizing environmental degradation and promoting social equity.

Additionally, companies are investing in circular economy practices, focusing on materials that can be recycled or repurposed at the end of their lifecycle. This trend is particularly relevant in regions like Europe, where regulations are tightening around waste management and resource recovery. By adopting sustainable sourcing strategies, B2B buyers not only contribute to environmental preservation but also enhance their competitive advantage in a market increasingly driven by ethical considerations.

What Is the Brief Evolution and History of Material Adequado in the B2B Context?

The concept of material adecuado has evolved significantly over the years, transitioning from a focus solely on functionality to a more nuanced understanding that incorporates sustainability, efficiency, and cost-effectiveness. Initially, materials were chosen primarily based on availability and cost; however, the modern B2B landscape demands a more holistic approach.

Historically, the materials sector has been influenced by industrial revolutions that prioritized mass production and resource extraction. However, as environmental awareness grew in the late 20th century, businesses began to recognize the importance of sustainable practices. This shift has led to the development of innovative materials and sourcing strategies that prioritize longevity, recyclability, and ethical production.

Today, buyers in the material adecuado sector are tasked with navigating a complex landscape that balances economic considerations with environmental and social responsibilities. This evolution underscores the importance of staying informed about industry trends and sourcing practices that not only meet immediate project needs but also contribute to a sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of material adecuado

-

How do I determine the right materials for my construction project?

To determine the right materials for your construction project, first assess the specific requirements of the space. Consider factors such as whether the materials will be used indoors or outdoors, as this significantly impacts durability and maintenance needs. Research the characteristics of various materials, including their resistance to weather, flexibility, and maintenance requirements. Consulting with a construction expert can also provide valuable insights, ensuring that your selections align with both aesthetic goals and functional durability. -

What is the best type of flooring material for high-traffic areas?

For high-traffic areas, materials like porcelain tiles, luxury vinyl, and commercial-grade laminate are ideal due to their durability and ease of maintenance. Porcelain tiles are highly resistant to scratches and stains, making them a top choice for busy environments. Luxury vinyl offers a balance of comfort and toughness, while commercial-grade laminate provides an attractive appearance with excellent wear resistance. Always consider factors such as slip resistance and ease of cleaning when making your selection. -

How can I assess the quality of materials before purchasing?

To assess the quality of materials, start by examining certifications and compliance with industry standards. Request samples to evaluate the material’s physical properties, such as texture, weight, and finish. Engage with suppliers to understand the sourcing and manufacturing processes, as reputable suppliers often provide transparency regarding their materials. Additionally, customer reviews and case studies can give insights into the performance and longevity of the materials in similar applications. -

What are the minimum order quantities (MOQs) for international suppliers?

Minimum order quantities (MOQs) can vary significantly between suppliers and types of materials. Typically, international suppliers may set MOQs based on production costs and shipping efficiencies. It’s advisable to discuss MOQs upfront during negotiations, as some suppliers may offer flexibility based on your needs or potential for future orders. Understanding MOQs will help you manage your budget and inventory effectively while ensuring you have adequate materials for your projects. -

What payment terms should I expect when sourcing materials internationally?

Payment terms when sourcing materials internationally can range from upfront payments to net 30, 60, or even 90 days. Common practices include a deposit upon order confirmation and the balance before shipment. It’s crucial to negotiate terms that suit your cash flow while ensuring the supplier is comfortable. Additionally, consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks associated with international transactions. -

How do I ensure compliance with international trade regulations when sourcing materials?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws of your country and those of your supplier. This includes understanding tariffs, taxes, and documentation required for customs clearance. Engaging with a freight forwarder or customs broker can streamline this process, as they have expertise in navigating the complexities of international trade. Regularly review updates on trade agreements and regulations that may affect your sourcing strategy. -

What logistics considerations should I keep in mind when importing materials?

When importing materials, consider logistics factors such as shipping methods, lead times, and costs. Determine the best mode of transport (air, sea, or land) based on urgency and budget. Account for potential delays due to customs clearance or transport issues. Establish a reliable logistics partner who can provide real-time tracking and support to ensure timely delivery. Additionally, evaluate warehousing needs upon arrival to manage inventory effectively. -

How can I customize materials to meet specific project requirements?

Customizing materials typically involves discussing your project specifications with the supplier. Many manufacturers offer options for size, color, texture, and finish to meet unique needs. Be prepared to share detailed design concepts and performance requirements. It may also be beneficial to request prototypes or mock-ups to evaluate the customizations before committing to a larger order. Engaging in early discussions with suppliers can facilitate a smoother customization process and ensure you achieve the desired results.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Material Adecuado Manufacturers & Suppliers List

1. PISOS – Marcas y Tipologías

Domain: pisosiberia.com

Registered: 2013 (12 years)

Introduction: PISOS: Marcas – Porcelanosa, Cesantoni, Vitromex, Tecnopiso, Firenze; Tipologías – Cemento, Madera, Mármol, Metalizado, Piedra; Formatos – 80x160cm, 60x120cm, 20x120cm, 45x91cm, 80x80cm, 60x60cm, 30x60cm, 20x60cm, 20x20cm, 30×7.5cm; INTERIORISMO: Líneas – Papel Tapiz, Wall Panel, SPC Prime, Duela Vinílica; BAÑOS: Marcas – American Standard, Grohe, Helvex, Urrea; Líneas – Accesorios, Grifería, Refa…

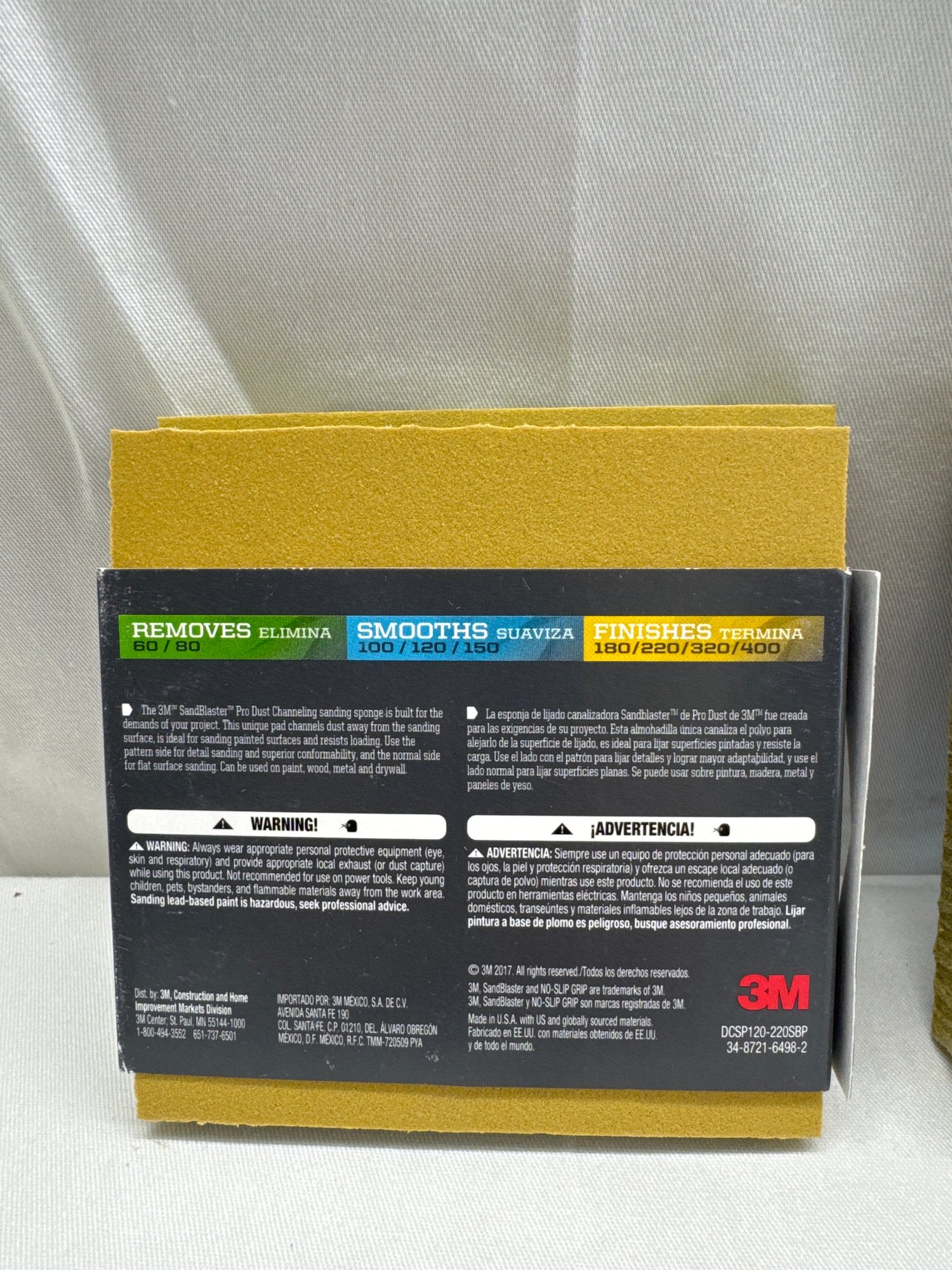

2. Class Labels – Materiales para Etiquetas

Domain: class-labels.com

Registered: 2015 (10 years)

Introduction: Materiales para etiquetas: 1. Papel: – Papel mate: Común para productos de consumo. – Papel brillo (couché): Ofrece impresión definida, usado en medicamentos y cosméticos. – Papel térmico: Imprime a base de calor, económico, para etiquetas de corta duración. 2. Materiales sintéticos: – Polipropileno: Durabilidad y resistencia a la humedad, ideal para ambientes duros. – Polietileno: Gran elasticida…

3. Metalmecanica – Mecanizado CNC de Alta Precisión

Domain: metalmecanica.com

Registered: 2000 (25 years)

Introduction: El mecanizado CNC utiliza una máquina controlada numéricamente para fabricar piezas a partir de materiales como metales puros, aleaciones y plásticos. Los materiales comunes incluyen:

– Aluminio: Ideal para la industria aeroespacial y automovilística, buena relación resistencia-peso, más caro y difícil de soldar que el acero.

– Latón: Usado en la industria marina, resistente a la corrosión.

– B…

4. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

5. Verbok – Tipos de Papel para Impresión

Domain: verbok.com

Registered: 2012 (13 years)

Introduction: Tipos de papel para impresión: 1. Papel satinado: acabado suave y brillante, ideal para impresiones de alta calidad. 2. Papel mate: acabado discreto y elegante, adecuado para documentos de texto y fotografías en blanco y negro. 3. Papel fotográfico: alta calidad de imagen y acabado brillante, imprescindible para fotografías. Técnicas de impresión: 1. Impresión digital: rápida producción y alta cal…

6. Block Victoria – Materiales de Construcción

Domain: blockvictoria.com.mx

Registered: 2011 (14 years)

Introduction: This company, Block Victoria – Materiales de Construcción, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. SignLabs – Materiales para Rótulos

Domain: signlabs.es

Introduction: Materiales para rótulos: Plástico, Aluminio, Madera. 1. Plástico: Ligero, flexible, bajo coste, fabricado en acrílico o PVC, adecuado para interiores y exteriores. Ventajas: Económico, fácil de trabajar, versátil, ligero. Desventajas: Durabilidad limitada en condiciones extremas, impacto ambiental, apariencia menos exclusiva. 2. Aluminio: Duradero, resistente a la corrosión, ligero, ideal para ext…

Strategic Sourcing Conclusion and Outlook for material adecuado

How Can Strategic Sourcing Optimize Your Material Selection?

In conclusion, choosing the right material adecuando is not just about meeting project specifications; it’s a strategic decision that can significantly impact your project’s success. Understanding the specific requirements of your project, such as the environment where materials will be used, is crucial. Furthermore, knowing the properties of materials—including durability, flexibility, and maintenance needs—ensures that you select products that align with your project goals.

Strategic sourcing enhances your purchasing process by enabling you to compare quality and prices effectively. Engaging with suppliers who offer high-quality materials can prevent costly mistakes in the long run. This is particularly pertinent for international buyers in regions like Africa, South America, the Middle East, and Europe, where diverse environmental factors may influence material performance.

As you move forward, consider establishing partnerships with reliable suppliers who can provide the necessary expertise and support. Invest time in research and consultation to ensure that your material choices not only fit your immediate needs but also contribute to sustainable and cost-effective outcomes. By prioritizing strategic sourcing, you position your projects for success and longevity in an increasingly competitive market.