Introduction: Navigating the Global Market for maschinenbau cad programme

In today’s fast-paced manufacturing landscape, sourcing the right maschinenbau CAD programme has become a critical challenge for international B2B buyers. The quest for software that not only enhances design efficiency but also integrates seamlessly with existing workflows is paramount, especially in regions like Africa, South America, the Middle East, and Europe. This guide serves as an essential resource for businesses looking to navigate the complexities of CAD software selection, providing a thorough examination of various types of programmes, their applications, and the latest trends influencing the market.

Throughout this guide, we will delve into the intricacies of the maschinenbau CAD programme landscape, exploring key factors such as supplier vetting processes, cost considerations, and the unique needs of different industries. By equipping buyers with actionable insights and practical tools, we aim to empower them to make informed purchasing decisions that align with their operational goals and budget constraints.

Whether you are in Saudi Arabia seeking innovative design solutions or a German manufacturer aiming to streamline your production processes, this guide offers a comprehensive framework to elevate your CAD software sourcing strategy. Understanding the nuances of each option available will not only enhance your design capabilities but also position your business for sustainable growth in a competitive global market.

Understanding maschinenbau cad programme Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2D CAD Software | Focuses on 2D drafting and design; simpler interface | Architectural plans, schematics, layouts | Pros: Easy to learn, cost-effective. Cons: Limited to 2D designs, less versatile. |

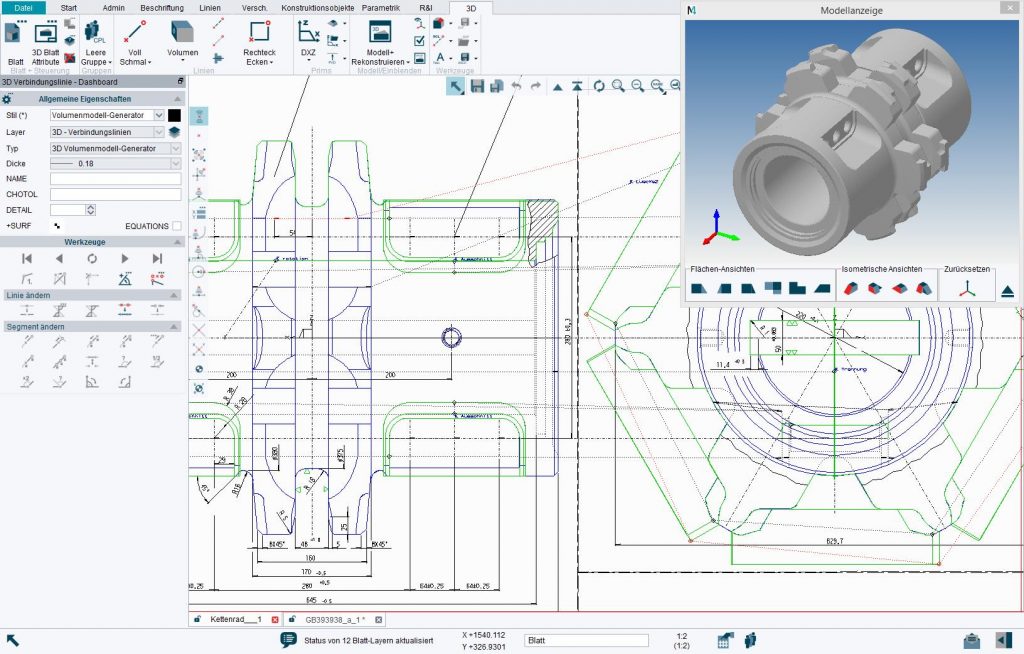

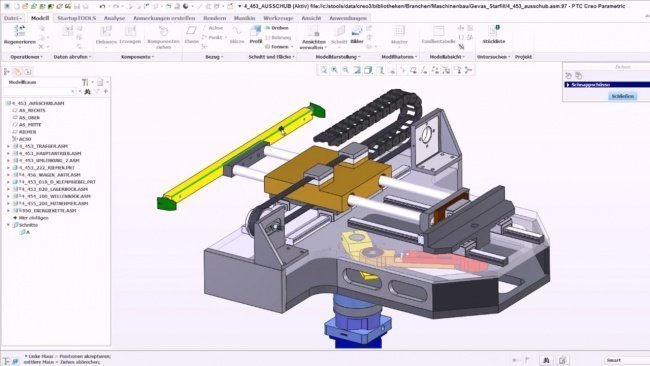

| 3D CAD Software | Enables 3D modeling and visualization; complex designs | Product design, mechanical engineering | Pros: Realistic visualizations, better design accuracy. Cons: Higher learning curve, more expensive. |

| BIM Software | Integrates building information modeling; collaborative | Construction, architecture, infrastructure | Pros: Enhances collaboration, comprehensive data management. Cons: Requires significant training and investment. |

| CAD/CAM Software | Combines design and manufacturing processes; automation | Manufacturing, CNC machining | Pros: Streamlines production, reduces errors. Cons: Initial setup can be complex and costly. |

| Cloud-Based CAD | Accessible from any device; real-time collaboration | Remote teams, project management | Pros: Flexibility, easy updates. Cons: Dependence on internet connectivity, potential data security concerns. |

What Are the Key Characteristics of 2D CAD Software?

2D CAD software is primarily designed for creating flat representations of objects, making it ideal for drafting and technical drawings. Its user-friendly interface allows for quick learning and application, especially beneficial for businesses that require straightforward design tasks, such as architectural plans or basic schematics. When purchasing, B2B buyers should consider the software’s compatibility with existing tools and the specific features that cater to their industry needs. While it is cost-effective, its limitations in 3D capabilities may hinder businesses looking for more complex design solutions.

How Does 3D CAD Software Enhance Design Processes?

3D CAD software provides the ability to create detailed three-dimensional models, which are essential for industries such as product design and mechanical engineering. This type of software allows users to visualize designs more realistically and assess functionality before physical production. B2B buyers should evaluate the software’s features, such as simulation capabilities and integration with other tools, to ensure it meets their design requirements. Although it offers significant advantages in accuracy and visualization, the higher complexity and cost can be a barrier for smaller businesses.

Why Is BIM Software Important for Construction Projects?

Building Information Modeling (BIM) software stands out for its capacity to integrate various aspects of building design, construction, and management. It allows multiple stakeholders to collaborate effectively, providing a centralized platform for data sharing and project updates. For B2B buyers in construction or architecture, investing in BIM software can lead to improved project outcomes and efficiency. However, it often requires a more significant investment in training and infrastructure, which should be factored into the purchasing decision.

What Advantages Does CAD/CAM Software Offer in Manufacturing?

CAD/CAM software merges design and manufacturing processes, enabling automated production workflows. This integration is crucial for industries that require precision, such as CNC machining and other manufacturing applications. B2B buyers should focus on the software’s ability to streamline production and reduce errors, which can lead to significant cost savings. While the initial setup may be complex and costly, the long-term benefits of increased efficiency often justify the investment.

How Can Cloud-Based CAD Solutions Benefit Remote Teams?

Cloud-based CAD solutions facilitate access to design tools from any location, promoting real-time collaboration among remote teams. This flexibility is increasingly valuable in today’s global market, where teams may be distributed across various regions. Buyers should consider the software’s security features and ease of use, as these factors are crucial for protecting sensitive designs and ensuring smooth collaboration. Although it offers significant advantages, reliance on internet connectivity and potential security risks are important considerations for businesses.

Key Industrial Applications of maschinenbau cad programme

| Industry/Sector | Specific Application of maschinenbau cad programme | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Design of complex machinery and equipment | Increases design efficiency and reduces time to market | Software compatibility with existing systems, training support for staff |

| Automotive | Vehicle component design and simulation | Enhances innovation and optimizes performance | Need for robust simulation features, compliance with industry standards |

| Aerospace | Aircraft structural design and analysis | Improves safety and compliance with regulations | Requirements for high precision and certification capabilities |

| Construction | Structural engineering and building design | Streamlines project workflows and enhances collaboration | Consideration of BIM integration and multi-discipline collaboration tools |

| Energy | Renewable energy systems design (e.g., wind turbines) | Supports sustainable design practices and efficiency | Need for energy-specific modeling tools and regulatory compliance features |

How is the ‘maschinenbau cad programme’ Applied in Manufacturing?

In the manufacturing sector, the maschinenbau CAD programme is pivotal for designing complex machinery and equipment. It enables engineers to create detailed 3D models, allowing for better visualization and analysis of mechanical components. This reduces errors and accelerates the prototyping process, ultimately shortening the time to market. Buyers should consider software compatibility with their existing systems and the availability of training resources to ensure smooth integration and effective use.

What Role Does the ‘maschinenbau cad programme’ Play in Automotive Design?

Within the automotive industry, the maschinenbau CAD programme is extensively used for designing vehicle components and conducting simulations to assess performance. This application not only fosters innovation but also helps manufacturers optimize designs for safety and efficiency. Buyers in this sector should prioritize CAD solutions that offer robust simulation capabilities and ensure compliance with stringent industry standards, which are critical for maintaining quality and safety.

How is the ‘maschinenbau cad programme’ Utilized in Aerospace Engineering?

In aerospace engineering, the maschinenbau CAD programme is essential for the structural design and analysis of aircraft. It supports the creation of intricate designs that meet rigorous safety and regulatory requirements. By using CAD software, aerospace engineers can simulate real-world conditions, enhancing safety and performance. Buyers must look for high-precision tools that align with certification requirements and offer advanced analysis features to facilitate compliance with aviation regulations.

What Benefits Does the ‘maschinenbau cad programme’ Offer in Construction?

For the construction industry, the maschinenbau CAD programme enhances structural engineering and building design processes. It streamlines project workflows by integrating Building Information Modeling (BIM) tools, facilitating collaboration among architects, engineers, and contractors. This leads to improved project timelines and reduced costs. When sourcing CAD solutions, businesses should consider the integration capabilities with BIM and the availability of collaborative tools to support multi-disciplinary teams.

How is the ‘maschinenbau cad programme’ Applied in Energy Sector Projects?

In the energy sector, particularly in renewable energy systems like wind turbines, the maschinenbau CAD programme is utilized to design efficient and sustainable solutions. This software aids in optimizing designs for energy production while adhering to environmental standards. Buyers should focus on CAD tools that offer specialized modeling features for energy applications and ensure compliance with local regulations to support sustainable practices in their projects.

3 Common User Pain Points for ‘maschinenbau cad programme’ & Their Solutions

Scenario 1: Inefficiencies in Design Collaboration Across Borders

The Problem: B2B buyers in the machinery manufacturing sector often face significant challenges when collaborating with international teams. Time zone differences, language barriers, and varying standards can lead to miscommunication, delays, and increased costs. For example, a design team in Germany may struggle to align their CAD designs with the requirements of a production team in South America, resulting in rework and wasted resources. This inefficiency can compromise project timelines and hinder innovation, especially when trying to launch products in competitive markets.

The Solution: To enhance collaboration, companies should invest in a centralized CAD platform that supports cloud-based collaboration. Solutions like Autodesk’s Fusion 360 allow teams from different regions to work on the same project in real-time, regardless of their location. This software not only facilitates seamless sharing of CAD files but also includes built-in communication tools to discuss design changes instantly. B2B buyers should prioritize selecting software that offers robust support for multiple languages and complies with international design standards. Additionally, establishing clear project management guidelines can help streamline communication and ensure that all teams are aligned on project goals and timelines.

Scenario 2: Difficulty in Integrating Legacy Systems with Modern CAD Tools

The Problem: Many companies in the machinery manufacturing sector are hindered by legacy systems that do not integrate well with modern CAD programs. This can be particularly problematic for firms that have invested heavily in older technologies but now find themselves needing to adopt newer software solutions for efficiency and competitiveness. The inability to transfer existing data into new CAD systems can lead to duplicated efforts, data loss, and frustration among staff who are already accustomed to their established workflows.

The Solution: To mitigate integration issues, companies should conduct a thorough analysis of their existing systems before transitioning to a new CAD program. It’s essential to look for CAD solutions that offer comprehensive data import/export functionalities and support for various file formats, ensuring compatibility with legacy systems. For instance, Autodesk products often include tools that facilitate easy migration of data from older platforms. In addition, B2B buyers should engage with vendors that provide robust customer support and training resources to assist in the integration process. This support can help teams navigate challenges and adapt more quickly to new technologies, ultimately leading to a smoother transition and improved productivity.

Scenario 3: High Training Costs for New CAD Software Implementation

The Problem: When adopting a new maschinenbau CAD program, companies often underestimate the training requirements for their teams. High training costs can become a significant barrier, especially for organizations operating on tight budgets or dealing with a skilled labor shortage. Employees may be hesitant to adopt new tools, fearing that they will not have the necessary skills to utilize the software effectively, which can lead to reduced morale and productivity.

The Solution: To address training costs and boost user confidence, companies should seek CAD solutions that offer comprehensive training programs and educational resources. Platforms like Autodesk provide a wealth of online tutorials, webinars, and community forums that can help users learn at their own pace. B2B buyers should consider investing in software that includes access to a dedicated support team or a learning management system that tracks employee progress. Additionally, creating a mentorship program within the organization can help more experienced employees guide newcomers through the learning process, fostering a supportive environment that encourages skill development. By prioritizing training and support, companies can ensure that their workforce is well-equipped to leverage new CAD tools, ultimately enhancing productivity and innovation.

Strategic Material Selection Guide for maschinenbau cad programme

When selecting materials for a maschinenbau CAD program, understanding the properties, advantages, and limitations of various materials is crucial. This guide analyzes four common materials—steel, aluminum, plastics, and composites—highlighting their relevance to product performance and considerations for international B2B buyers.

What Are the Key Properties of Steel in Maschinenbau Applications?

Steel is renowned for its strength and versatility, making it a staple in engineering and manufacturing. Key properties include high tensile strength, excellent durability, and good temperature resistance, typically rated up to 600°C. Steel also exhibits moderate corrosion resistance, which can be enhanced through coatings or alloying.

Pros & Cons: Steel’s durability and ability to withstand high loads make it ideal for structural applications. However, it is relatively heavy, which can be a disadvantage in applications where weight is critical. Additionally, the cost of high-quality steel can be significant, particularly for specialized alloys.

Impact on Application: Steel is compatible with various media, including gases and liquids, but its corrosion resistance may limit its use in highly corrosive environments unless treated.

Considerations for International Buyers: B2B buyers from regions like Europe and the Middle East should be aware of compliance with standards such as DIN and ASTM for steel grades. Understanding local regulations regarding material sourcing and environmental impact is also essential.

How Does Aluminum Compare as a Material Choice?

Aluminum is favored for its lightweight properties and excellent corrosion resistance. It typically performs well in temperatures up to 200°C and can be anodized for additional protection against wear and corrosion.

Pros & Cons: The primary advantage of aluminum is its weight, which allows for easier handling and reduced energy costs in transportation. However, aluminum is generally less strong than steel, which can limit its use in high-load applications. Additionally, the manufacturing complexity can increase costs, especially for intricate designs.

Impact on Application: Aluminum is suitable for applications involving exposure to moisture and chemicals, making it a popular choice in the automotive and aerospace industries.

Considerations for International Buyers: Buyers should consider the common standards for aluminum, such as JIS and ASTM, and ensure that their suppliers can meet these specifications. Understanding the availability of aluminum alloys in local markets is also crucial.

What Role Do Plastics Play in Maschinenbau CAD Programs?

Plastics, including thermoplastics and thermosets, offer versatility and lightweight characteristics. They can withstand temperatures ranging from -40°C to 100°C, depending on the type, and exhibit excellent chemical resistance.

Pros & Cons: Plastics are cost-effective and can be molded into complex shapes, which reduces manufacturing complexity. However, they generally lack the strength and durability of metals, making them unsuitable for high-stress applications.

Impact on Application: Plastics are ideal for applications involving low to moderate mechanical loads and are often used in consumer products and components that require insulation.

Considerations for International Buyers: Buyers should be aware of the specific plastic grades and their compliance with international standards, such as ISO. The availability of certain plastics may vary by region, impacting sourcing decisions.

Why Consider Composites in Maschinenbau Applications?

Composites, such as carbon fiber and fiberglass, combine the properties of different materials to achieve superior performance. They typically offer high strength-to-weight ratios and excellent fatigue resistance, with temperature ratings that can exceed 200°C.

Pros & Cons: The primary advantage of composites is their lightweight and high strength, making them ideal for aerospace and automotive applications. However, they can be expensive to manufacture and require specialized processes, which may increase overall project costs.

Impact on Application: Composites are compatible with various media and environments, making them suitable for specialized applications where traditional materials may fail.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant standards and certifications specific to their industry. Understanding the market for composites in different regions, particularly in emerging markets, can also influence procurement strategies.

Summary Table of Material Selection

| Material | Typical Use Case for maschinenbau cad programme | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, machinery parts | High strength and durability | Heavy and can be expensive | High |

| Aluminum | Automotive and aerospace applications | Lightweight and corrosion resistant | Lower strength compared to steel | Medium |

| Plastics | Consumer products, insulation components | Cost-effective and versatile | Limited strength for high-stress use | Low |

| Composites | Aerospace and high-performance automotive parts | High strength-to-weight ratio | High manufacturing costs | High |

This analysis provides a comprehensive overview of material selection considerations for B2B buyers in the maschinenbau sector, ensuring informed decisions that align with project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for maschinenbau cad programme

What Are the Main Stages of Manufacturing Processes in the Maschinenbau CAD Programme?

The manufacturing process for components designed using a maschinenbau CAD programme typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages helps B2B buyers evaluate the efficiency and quality of potential suppliers.

How Is Material Prepared in Maschinenbau Manufacturing?

Material preparation is the first step in the manufacturing process. This stage involves selecting the appropriate materials based on the specifications generated in the CAD software. Common materials include metals, plastics, and composites. Once selected, materials undergo processes such as cutting, milling, or shearing to achieve the desired dimensions. This initial preparation is crucial, as the quality of the raw materials directly affects the final product’s integrity.

What Forming Techniques Are Commonly Used in CAD-Driven Manufacturing?

The forming stage involves shaping the prepared materials into the required forms. Techniques such as casting, forging, and machining are commonly employed. For instance, precision machining is often used to create intricate designs, ensuring that components meet stringent specifications. Advanced techniques like 3D printing have also gained traction, allowing for rapid prototyping and reduced lead times. Understanding these techniques helps B2B buyers assess which suppliers can deliver the most innovative solutions.

How Does the Assembly Process Function in Maschinenbau Manufacturing?

Following the forming stage, assembly is critical for bringing together various components into a complete product. This process can be manual, automated, or a combination of both, depending on the complexity and volume of production. In CAD-driven environments, assembly is often facilitated by digital models that allow for accurate alignment and fitting. B2B buyers should inquire about the assembly methods used by suppliers, as efficient assembly processes can lead to reduced costs and shorter delivery times.

What Finishing Techniques Are Employed in CAD Manufacturing?

Finishing processes enhance the aesthetic and functional qualities of the final product. Techniques such as painting, anodizing, or polishing are used to improve surface quality and protect against corrosion or wear. The finishing stage not only affects the appearance but also the performance and durability of the components. Buyers should consider suppliers that employ advanced finishing techniques, as these can significantly impact the lifecycle of the products.

How Is Quality Assurance Implemented in Maschinenbau Manufacturing?

Quality assurance (QA) is a crucial aspect of manufacturing that ensures products meet specified standards and customer expectations. Various international and industry-specific standards guide quality assurance processes, with ISO 9001 being one of the most widely recognized.

What International Standards Should B2B Buyers Look For?

ISO 9001 establishes a framework for quality management systems, focusing on continuous improvement and customer satisfaction. B2B buyers should prioritize suppliers who are ISO 9001 certified, as this indicates a commitment to quality. Additionally, industry-specific certifications such as CE marking for products sold in Europe or API standards for oil and gas components can further assure buyers of a supplier’s compliance with regulatory requirements.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential for maintaining product quality throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective action.

- Final Quality Control (FQC): This final inspection stage verifies that the completed product meets all design specifications and quality standards before shipping.

Implementing these checkpoints helps ensure that defects are minimized and customer satisfaction is maximized.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to assess product quality, including:

- Dimensional Inspection: Ensures that products meet specified measurements and tolerances.

- Material Testing: Evaluates the mechanical properties of materials, such as tensile strength and hardness.

- Functional Testing: Verifies that the product operates as intended under expected conditions.

B2B buyers should request information about the testing methods used by suppliers to ensure that robust quality assurance practices are in place.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for B2B buyers to ensure they receive high-quality products. Several methods can be employed:

- Audits: Conducting supplier audits allows buyers to assess the effectiveness of quality management systems firsthand. These audits can be scheduled or random, providing insights into the supplier’s operations.

- Quality Reports: Requesting regular quality reports can help buyers stay informed about any issues that arise during production and how they are addressed.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes and product quality.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Different regions may have specific regulatory requirements or standards, impacting how products are manufactured and certified. Buyers should be aware of these differences and ensure that their suppliers comply with both local and international standards.

Conclusion

Understanding the manufacturing processes and quality assurance practices associated with the maschinenbau CAD programme is crucial for B2B buyers. By familiarizing themselves with the stages of manufacturing, relevant quality standards, and verification methods, buyers can make informed decisions when selecting suppliers. Prioritizing suppliers with robust quality management systems and certifications will help ensure the delivery of high-quality products that meet their specifications and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘maschinenbau cad programme’

Introduction

Navigating the procurement of a maschinenbau CAD programme can be complex, particularly for international B2B buyers. This guide aims to streamline your sourcing process, ensuring you make informed decisions tailored to your specific needs and operational goals.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is the first step in the sourcing process. Consider factors such as the type of projects you’ll be working on (2D vs. 3D design), compatibility with existing systems, and the specific features you need, such as simulation capabilities or collaboration tools. A well-defined specification helps in filtering out unsuitable software options early in the process.

Step 2: Assess Vendor Reputation and Experience

Investigate potential vendors to gauge their market reputation and experience in the maschinenbau CAD sector. Look for companies with a proven track record in delivering CAD solutions for similar industries. Customer testimonials, case studies, and industry awards can provide insights into a vendor’s reliability and performance.

Step 3: Evaluate Software Features and Usability

Once you have a shortlist of vendors, compare the features of their CAD programs. Focus on usability—ensure the software has an intuitive interface and provides adequate training resources. Important features to consider include:

– Customization options: Ensure the software can adapt to your specific workflows.

– Integration capabilities: Check if it works seamlessly with other tools in your design ecosystem.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications and comply with international standards. Certifications such as ISO 9001 for quality management can indicate a commitment to excellence. Compliance with regional regulations is also crucial, especially if you are operating in highly regulated markets.

Step 5: Request Demonstrations and Trials

Before making a final decision, request product demonstrations or trial versions of the software. This allows your team to assess the functionality and user experience firsthand. During this phase, pay attention to:

– Technical support: Evaluate the quality of customer support during the trial.

– Learning curve: Determine how quickly your team can become proficient with the software.

Step 6: Consider Pricing Structures and Total Cost of Ownership

Examine the pricing models offered by different suppliers. Look beyond the initial purchase price to consider the total cost of ownership, which includes maintenance fees, subscription costs, and potential upgrade expenses. Transparent pricing structures can help you avoid unexpected costs down the line.

Step 7: Finalize Your Decision with Legal Considerations

Before signing any contracts, ensure that all legal aspects are covered. Review licensing agreements and terms of service carefully to understand your rights and obligations. It may be beneficial to consult with a legal advisor to ensure that the contract aligns with your company’s interests and provides adequate protection.

By following this checklist, you will be well-equipped to select a maschinenbau CAD programme that meets your operational needs and supports your business objectives effectively.

Comprehensive Cost and Pricing Analysis for maschinenbau cad programme Sourcing

What Are the Key Cost Components in Sourcing Maschinenbau CAD Programs?

When sourcing maschinenbau CAD programs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The software itself is often the largest expense, with prices varying based on the complexity and capabilities of the CAD program. High-quality software that integrates advanced features like BIM (Building Information Modeling) or specific industry functionalities will generally command higher prices.

-

Labor: Skilled labor for installation, training, and maintenance is another significant cost. Depending on the geographical location, labor costs can vary considerably, impacting the total expenditure on CAD software implementation.

-

Manufacturing Overhead: This includes indirect costs related to the production of CAD tools, such as utilities and administrative expenses. For software solutions, overhead can be less pronounced but still relevant, especially when considering the overall operation of the software vendor.

-

Tooling: In the context of CAD, tooling refers to the specific licenses and additional tools that may be required for full functionality. This could mean purchasing add-ons or modules that cater to specific design needs.

-

Quality Control: Ensuring the software meets industry standards and certifications can incur additional costs. This is particularly important for buyers in regulated industries.

-

Logistics: Although CAD software is typically delivered digitally, logistics may include costs related to training, support, and cloud services, especially for international buyers who may require localized support.

-

Margin: Finally, suppliers include a profit margin in their pricing, which can vary based on market conditions and competitive dynamics.

How Do Price Influencers Affect the Cost of Maschinenbau CAD Programs?

Numerous factors can influence the pricing of maschinenbau CAD programs.

-

Volume/MOQ: Larger orders typically benefit from economies of scale, leading to lower per-unit costs. When negotiating, it’s beneficial to consider potential bulk purchasing agreements.

-

Specifications and Customization: Custom solutions tailored to specific project requirements can significantly increase costs. Buyers should clearly define their needs to avoid unnecessary expenditures.

-

Materials and Quality Certifications: The choice of software and its certifications can impact pricing. High-quality, certified programs may carry a premium but can offer long-term savings through efficiency and reliability.

-

Supplier Factors: The reputation and reliability of the software vendor can also play a crucial role. Established brands might charge more but often provide better support and resources.

-

Incoterms: Understanding the shipping terms and responsibilities outlined in Incoterms can help buyers anticipate additional costs related to delivery, customs, and taxes.

What Are the Best Buyer Tips for Cost-Efficiency in CAD Program Sourcing?

International B2B buyers can employ several strategies to ensure cost-efficiency when sourcing maschinenbau CAD programs:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you are considering multiple software solutions. Leverage potential long-term partnerships to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also ongoing costs, such as support, updates, and training. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances for International Markets: Be aware of regional pricing differences. Markets in Africa and South America may face additional costs due to import duties or local taxes. Ensure that you factor in these elements when budgeting.

-

Market Research: Conduct thorough research on available options and their pricing structures. Understanding the competitive landscape can provide leverage in negotiations.

-

Seek Local Suppliers: Whenever possible, sourcing from local vendors can reduce logistics costs and simplify support and training logistics.

Disclaimer on Pricing

Prices for maschinenbau CAD programs can vary widely based on numerous factors, including regional market conditions, specific software capabilities, and supplier agreements. Always consult with multiple vendors and consider obtaining quotes tailored to your specific requirements.

Alternatives Analysis: Comparing maschinenbau cad programme With Other Solutions

Exploring Alternatives to Maschinenbau CAD Programme for Design Solutions

In the competitive landscape of engineering and design, choosing the right CAD software is crucial for enhancing productivity and meeting project demands. While the Maschinenbau CAD programme offers robust features tailored for mechanical design, several alternative solutions may provide different strengths and benefits. This section compares the Maschinenbau CAD programme with two viable alternatives: Autodesk Inventor and SolidWorks, helping B2B buyers make informed decisions.

| Comparison Aspect | Maschinenbau CAD Programme | Autodesk Inventor | SolidWorks |

|---|---|---|---|

| Performance | High efficiency for mechanical design tasks | Excellent for 3D modeling with simulation capabilities | Strong in parametric design and assembly management |

| Cost | Moderate initial investment; licensing may vary | Subscription model can be costly over time | Competitive pricing with multiple licensing options |

| Ease of Implementation | Requires specific training; user-friendly interface | Moderate learning curve; extensive support resources available | User-friendly with a large community for support |

| Maintenance | Regular updates; responsive support | Frequent updates; comprehensive maintenance plans | Strong support network; regular updates included |

| Best Use Case | Ideal for specialized mechanical engineering projects | Best for complex assemblies and simulations | Suitable for product design and engineering across industries |

What Are the Pros and Cons of Autodesk Inventor Compared to Maschinenbau CAD Programme?

Autodesk Inventor excels in 3D mechanical design and simulation, making it a strong contender for users needing intricate modeling capabilities. The software supports advanced simulation tools that enable users to predict performance and validate designs early in the process. However, the subscription model may lead to higher long-term costs, and while its learning curve is manageable, it requires dedicated training for optimal use.

How Does SolidWorks Compare to Maschinenbau CAD Programme?

SolidWorks is renowned for its intuitive interface and robust parametric design capabilities, which allow for rapid iteration and easy modifications. It is particularly favored in industries where product design and assembly are critical, offering extensive libraries and tools to streamline the design process. However, while it is competitively priced, some users may find its performance less efficient in highly specialized mechanical applications compared to the Maschinenbau CAD programme.

Conclusion: How Can B2B Buyers Choose the Right CAD Solution?

Selecting the appropriate CAD solution hinges on specific project requirements and organizational needs. B2B buyers should evaluate the performance of each software in relation to their design complexity, budget constraints, and ease of implementation. A thorough assessment of maintenance requirements and support options is also essential. By aligning software capabilities with business objectives, organizations can enhance their design processes, optimize costs, and improve overall productivity.

Essential Technical Properties and Trade Terminology for maschinenbau cad programme

What Are the Essential Technical Properties in Maschinenbau CAD Programs?

When selecting a CAD program for maschinenbau (machine construction), understanding the key technical specifications is crucial for ensuring optimal performance and compatibility with your projects. Here are some critical properties to consider:

-

Material Grade

– Definition: Material grade refers to the specific classification of materials used in the design and manufacturing process, indicating their strength, durability, and suitability for various applications.

– B2B Importance: Selecting the appropriate material grade is vital for ensuring product safety, performance, and compliance with industry standards. Businesses must consider the material’s properties to avoid costly design modifications and ensure product reliability. -

Tolerance

– Definition: Tolerance is the allowable limit of variation in a physical dimension or measured value, determining how much a part can deviate from specified measurements.

– B2B Importance: Accurate tolerances are essential for ensuring that parts fit together correctly, reducing the risk of failure in assembled products. For manufacturers, maintaining tight tolerances can significantly impact production efficiency and cost-effectiveness. -

Surface Finish

– Definition: Surface finish refers to the texture and smoothness of a product’s surface, which can affect aesthetic appeal, functionality, and performance.

– B2B Importance: A proper surface finish can improve wear resistance, reduce friction, and enhance the product’s overall lifespan. Businesses need to specify surface finish requirements to meet customer expectations and industry standards. -

Load Capacity

– Definition: Load capacity indicates the maximum weight or force that a component can withstand without failure.

– B2B Importance: Understanding load capacity is critical for ensuring that designs can support operational demands. This knowledge helps prevent failures that could lead to downtime and loss of revenue. -

Dimensional Stability

– Definition: Dimensional stability refers to a material’s ability to maintain its dimensions and shape under varying environmental conditions.

– B2B Importance: In industries where precision is paramount, dimensional stability ensures that products perform consistently over time, even when exposed to temperature changes or humidity. This reduces the risk of rework and increases customer satisfaction.

What Are the Common Trade Terms in Maschinenbau CAD Programs?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B environment. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: In the maschinenbau sector, partnering with an OEM can provide access to high-quality components and enhance product offerings without the need for extensive in-house manufacturing. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest number of units that a supplier is willing to sell.

– Importance: Understanding MOQs helps businesses manage inventory and production costs effectively. It can also impact purchasing decisions, especially for smaller companies that may not have large capital outlays. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers to request pricing and terms for specific goods or services.

– Importance: Issuing an RFQ allows companies to compare prices and terms from multiple suppliers, helping them to make informed purchasing decisions and negotiate better deals. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importance: Understanding Incoterms is crucial for managing logistics and shipping costs, ensuring clarity in contractual obligations, and minimizing disputes in international trade. -

CAD (Computer-Aided Design)

– Definition: CAD refers to software used for creating precision drawings or technical illustrations.

– Importance: CAD is integral to the maschinenbau industry, facilitating design efficiency, improving accuracy, and enabling complex simulations that enhance product development processes.

By understanding these technical properties and industry terms, B2B buyers can navigate the complexities of maschinenbau CAD programs more effectively, leading to better decision-making and improved project outcomes.

Navigating Market Dynamics and Sourcing Trends in the maschinenbau cad programme Sector

What Are the Key Market Dynamics and Trends in the Maschinenbau CAD Programme Sector?

The global landscape for the Maschinenbau CAD programme sector is rapidly evolving due to several significant drivers. First, the increasing demand for precision engineering and automation across industries is pushing manufacturers to adopt advanced CAD solutions. This shift is especially pronounced in emerging markets in Africa and South America, where infrastructure development is gaining momentum. The Middle East, particularly in nations like Saudi Arabia, is also investing heavily in technology to support its Vision 2030 initiative, which aims to diversify its economy away from oil dependence.

Current B2B technology trends include the integration of Artificial Intelligence (AI) and Machine Learning (ML) within CAD software, enhancing design capabilities and operational efficiency. Companies are increasingly looking for cloud-based solutions that allow for real-time collaboration among teams dispersed globally. Furthermore, the rise of Industry 4.0 is compelling organizations to implement integrated solutions that combine CAD with other systems like Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP). This interconnectedness is essential for companies aiming to enhance their design agility and innovation capacity.

For international B2B buyers, understanding these dynamics is crucial. The ability to adapt to local market conditions while leveraging global technological advancements will define competitive advantage. Buyers should focus on sourcing CAD programmes that not only meet their immediate design needs but also align with broader industry trends such as digital transformation and integrated workflows.

How Is Sustainability Shaping Sourcing in the Maschinenbau CAD Programme Sector?

Sustainability is becoming a non-negotiable consideration in the Maschinenbau CAD programme sector, influencing sourcing strategies and product development. As environmental concerns rise globally, companies are under increasing pressure to reduce their carbon footprints. This shift is prompting manufacturers to seek out CAD solutions that support sustainable design practices, enabling them to evaluate the environmental impact of their projects from the outset.

Ethical sourcing is equally important, as stakeholders demand greater transparency in supply chains. Companies are now prioritizing suppliers who adhere to sustainable practices, such as using recycled materials and minimizing waste. Certifications like ISO 14001 for environmental management and LEED for sustainable building practices are gaining traction, making them essential for B2B buyers looking to ensure that their sourcing aligns with green standards.

Moreover, the integration of sustainability into CAD software itself is becoming a key trend. Advanced tools now allow designers to simulate the environmental impact of materials and processes, facilitating the selection of greener alternatives. Buyers in the Maschinenbau sector should prioritize CAD solutions that offer such capabilities, ensuring that their projects are not only efficient but also environmentally responsible.

What Is the Historical Context Behind the Evolution of CAD in Maschinenbau?

The history of CAD in the Maschinenbau sector dates back to the 1960s, when early computer-aided design systems began to replace manual drafting methods. Initially, these systems were limited in functionality and primarily used for 2D designs. However, as computational power increased, so did the capabilities of CAD software, paving the way for 3D modeling and simulation.

By the 1980s, CAD had become integral to engineering and manufacturing processes, enabling faster and more accurate designs. The introduction of parametric modeling in the 1990s revolutionized the industry, allowing engineers to create complex geometries and easily modify designs based on changing specifications. Today, CAD tools are not just design software; they are comprehensive platforms that integrate with various technologies, offering functionalities that support the entire product lifecycle.

This evolution reflects a broader trend toward digitalization in manufacturing, making it essential for B2B buyers to understand how historical advancements in CAD have shaped current capabilities and future potential in the Maschinenbau sector.

Frequently Asked Questions (FAQs) for B2B Buyers of maschinenbau cad programme

-

How do I select the right CAD software for machine design?

Choosing the right CAD software for machine design involves assessing your specific project requirements and the capabilities of available software. Start by defining your design goals, such as whether you need 2D drafting, 3D modeling, or simulation features. Evaluate compatibility with existing tools in your workflow and consider user support and training resources. Additionally, look for software that offers flexibility in licensing, such as subscription models, to adapt to your organization’s changing needs. -

What are the key features to look for in a CAD program for manufacturing?

When evaluating CAD programs for manufacturing, prioritize features like 3D modeling capabilities, simulation tools, and collaboration functionalities. Look for software that integrates well with product lifecycle management (PLM) systems and offers libraries of standard components to streamline design processes. Advanced visualization and rendering tools can also enhance presentations and facilitate stakeholder communication. Lastly, ensure the program supports international standards and file formats, which is crucial for global collaboration. -

What are the common payment terms for CAD software licenses in B2B transactions?

Payment terms for CAD software licenses can vary significantly among suppliers. Many companies offer flexible payment options, including upfront payments, annual subscriptions, or monthly payment plans. It’s essential to clarify terms such as any initial deposits, installment schedules, and conditions for renewal or cancellation. Additionally, inquire about discounts for bulk purchases or long-term commitments, which can provide significant savings. -

How can I ensure the quality of CAD software before purchasing?

To ensure the quality of CAD software, consider requesting a trial or demo version to evaluate its features and usability firsthand. Investigate customer reviews and case studies from other businesses in your industry to gain insights into their experiences. Additionally, check for certifications or partnerships with industry standards organizations, which can indicate reliability and performance. Engaging with the vendor’s support team during the trial can also provide a sense of their customer service quality. -

What customization options are typically available for CAD software?

Most CAD software solutions offer various customization options to cater to specific industry needs. Users can often create custom toolsets, macros, and templates to streamline repetitive tasks. Additionally, some software allows for API integrations, enabling further customization and connection with other systems like ERP or PLM solutions. Discussing your specific requirements with the vendor can help identify the best customization features available. -

What logistics considerations should I keep in mind when sourcing CAD software internationally?

When sourcing CAD software internationally, consider factors such as software localization, including language support and compliance with local regulations. Additionally, assess the vendor’s ability to provide timely software updates and technical support across different time zones. Be aware of potential import duties or taxes that may apply to software purchases in your country. Finally, ensure that the licensing terms are valid in your region to avoid legal issues. -

How do I vet suppliers for CAD software effectively?

Vetting suppliers for CAD software involves a thorough evaluation of their reputation, experience, and customer service capabilities. Start by checking their track record in the industry, including years of operation and client testimonials. Investigate their support offerings, such as training programs and technical assistance, which are crucial for successful implementation. Additionally, request references from current clients to gain insights into their satisfaction and the supplier’s reliability. -

What are the minimum order quantities (MOQs) for CAD software licenses in B2B transactions?

Minimum order quantities (MOQs) for CAD software licenses can vary widely by supplier and specific software package. Some vendors may offer individual licenses with no MOQ, while others may require bulk purchases for discounts. It’s advisable to inquire directly with potential suppliers about their MOQ policies and any associated benefits, such as pricing reductions or enhanced support services for larger orders. Understanding these terms can help you make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Maschinenbau Cad Programme Manufacturers & Suppliers List

1. Autodesk – Key Products

Domain: autodesk.com

Registered: 1989 (36 years)

Introduction: Top products include AutoCAD, Revit, Civil 3D, AutoCAD LT, BIM Collaborate Pro, Inventor, Fusion, Fusion extensions, Navisworks, 3ds Max, Maya, Arnold, Flow Capture, and Flow Production Tracking. CAD software offers integrated BIM tools for architecture, engineering, and construction, as well as professional CAD/CAM tools for product design and manufacturing. Key features include 2D drafting, 3D m…

2. Hexagon – CAD CAM Software

Domain: hexagon.com

Registered: 1993 (32 years)

Introduction: Computer-Aided Manufacturing (CAD CAM software) enables manufacturers to generate, manage, and optimise CNC machining toolpaths for efficient production. It includes features for automated measurement systems, quality assurance software, and portable measuring systems for accurate measurement directly in the manufacturing environment. The software supports local service and support to help overcom…

3. OnShape – Mechanical Action Simulation

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. OnShape – Cost: over $1000; Features: mechanical action simulation, parts databases. 2. Fusion 360 – Cost: Free hobbyist version; Features: mechanical design, part importing. 3. Solidworks – Cost: $10/month for hobbyists; Features: part importing, toolbox with screws, nuts, etc. 4. FreeCAD – Cost: Free; Features: open-source mechanical design software.

4. Siemens – NX CAD

Domain: plm.sw.siemens.com

Registered: 1986 (39 years)

Introduction: NX CAD is an advanced industrial machinery design software by Siemens that enhances machine engineering capabilities, allowing for innovative, connected smart machines. It supports a multidisciplinary design approach, enabling rapid iteration of complex components and assemblies through parametric and direct modeling. Key features include advanced simulation capabilities (motion analysis, stress a…

5. BobCAD-CAM – CAD Design Software

Domain: bobcad.com

Registered: 1996 (29 years)

Introduction: CAD Design Software – BobCAD-CAM

Key Features:

– New wire frame geometry feature (Silhouette Boundary) for calculating 2D profiles from 3D models.

– Hundreds of easy-to-use geometry creating and editing tools for developing sophisticated part models.

– Powerful wireframe, surface, and solid model design tools for simple flat patterns to complex 3D models.

– New features include:

– Closest Snap:…

6. Tebis – CAD/CAM and MES Software

Domain: tebis.com

Registered: 1998 (27 years)

Introduction: Tebis offers specialized CAD/CAM and MES software for manufacturing, designed to enhance efficiency in processing manufacturing projects and ensuring high-quality, on-time deliveries. Key features include:

1. **CAD Software**: Automated design tasks for manufacturers, utilizing parametric/associative surface and solid technology for creating, modifying, and improving CAD models.

2. **CAM Softwa…

7. CNC-Step – ConstruCAM-3D Software

Domain: cnc-step.com

Registered: 2005 (20 years)

Introduction: ConstruCAM-3D is a CAD-CAM software designed for CNC milling and engraving in 2D and 3D. It is user-friendly, requiring no programming skills, and allows immediate productivity. The software automatically calculates control commands from graphical drafts for machining various materials including plastic, wood, metal, and stone. Key features include:

– Price-performance ratio as a new CAD CAM stand…

8. Dassault Systèmes – CATIA CAD Software

Domain: 3ds.com

Registered: 1995 (30 years)

Introduction: Powerful Mechanical Design Software by Dassault Systèmes, including CATIA, which has been a leader in CAD design since 1982. The software enables engineers and designers to create intricate technical drawings and 3D models, streamlining the product development process. Key features include: 2D CAD for technical drawings, 3D CAD for modeling, FEA for structural analysis, FEM for design element anal…

9. Lantek – Flex3d Steelwork

Domain: lantek.com

Registered: 2001 (24 years)

Introduction: Lantek Flex3d Steelwork is a flexible CNC plasma CAD software designed for manufacturing with beam cutting machines using plasma technology. It supports all types of plasma heads and can produce parts with various finishes. The software manages inner operations in beam parts, side cut operations, and irregular operations on part sides. It also simulates in 3D the cutting sequence of any plasma bea…

Strategic Sourcing Conclusion and Outlook for maschinenbau cad programme

As the global landscape of manufacturing and design continues to evolve, the importance of strategic sourcing for maschinenbau CAD programs cannot be overstated. By leveraging top-tier CAD solutions such as Autodesk’s Inventor and Fusion, companies can enhance their design efficiency, reduce errors, and improve collaboration across teams. This not only accelerates the product development cycle but also positions organizations to better respond to market demands and fluctuations.

International buyers from regions like Africa, South America, the Middle East, and Europe must prioritize partnerships with software providers that offer comprehensive training, support, and integration capabilities. Such strategic sourcing not only ensures that teams are equipped with the necessary tools but also fosters innovation and adaptability within the workforce.

Looking ahead, the focus should be on adopting cloud-based solutions that facilitate real-time collaboration and data management. By embracing these advanced technologies, businesses can unlock new avenues for growth and remain competitive in an increasingly dynamic market. Now is the time for decision-makers to invest in robust CAD programs that promise to transform their design processes and drive sustainable success.